The Pivotal Role of York VSD Coolant in the Industrial Sector

In the dynamic and competitive landscape of the industrial sector, maintaining efficient and reliable equipment is essential for productivity and operational success. HVAC (Heating, Ventilation, and Air Conditioning) systems play a crucial role in creating optimal working conditions. To ensure the performance and longevity of these systems, it’s imperative to use the right components. York VSD Coolant, provided by trusted suppliers like Midwest Parts Center, based in Louisville, Kentucky, is a cornerstone of industrial operations.

With a strong presence in commercial and industrial areas, Midwest Parts Center ensures that businesses can easily access genuine York VSD Coolant through their toll-free number, 1-800-368-8385. This accessibility empowers industries to thrive by relying on York VSD Coolant for the performance and reliability they need in their HVAC systems.

The Fundamental Role of York VSD Coolant in the Industrial Sector

- Optimizing Energy Efficiency: Energy efficiency is a top priority in the industrial sector. Cooling systems, including HVAC, often account for a significant portion of energy consumption. York VSD Coolant is designed to optimize the energy efficiency of HVAC systems, reducing energy consumption and operational costs. This is crucial for industries looking to maintain a competitive edge.

- Environmental Responsibility: As environmental concerns grow, businesses are under increasing pressure to reduce their carbon footprint. York VSD Coolant is engineered to operate efficiently, minimizing energy usage and contributing to a company’s sustainability goals and environmental responsibility.

- Equipment Longevity: In the industrial sector, equipment downtime can be costly and disruptive. York VSD Coolant helps extend the life of HVAC systems by ensuring they run efficiently and reduce wear and tear. This translates to fewer breakdowns, lower maintenance costs, and increased equipment longevity.

- Process Consistency: Many industrial processes rely on controlled environmental conditions to maintain product quality and adhere to strict regulations. Consistent cooling provided by York VSD Coolant ensures that these environmental conditions are met, ensuring product quality and regulatory compliance.

Why Industries Trust York VSD Coolant for Operational Excellence

- Proven Performance: York is a respected name in the HVAC industry, known for its quality and reliability. York VSD Coolant maintains the same high standards, ensuring it performs exceptionally well in industrial applications. The York name is synonymous with excellence and a reputation for consistent performance.

- Precision Formulation: York VSD Coolant is specifically formulated for use in VSD (Variable Speed Drive) HVAC systems. Its precise formulation ensures that it meets the unique requirements of these systems, optimizing their performance and energy efficiency.

- Quality Assurance: York VSD Coolant undergoes rigorous quality control processes and testing to guarantee it meets the specifications required for VSD HVAC systems. Industries place their trust in this coolant because it offers unwavering quality, reliability, and precision, essential for maintaining operational efficiency.

- Expert Knowledge: York VSD Coolant is a specialized product, and its proper use requires expert knowledge. Trusted suppliers like Midwest Parts Center have a team of experts with comprehensive knowledge of York HVAC equipment and the coolant itself. This expertise ensures industries make informed decisions about their HVAC systems, enhancing their competitive edge.

- Accessibility and Convenience: Quick access to York VSD Coolant is vital in the fast-paced world of industrial operations. Midwest Parts Center offers a toll-free number (1-800-368-8385) for businesses in need of this critical coolant. This accessibility underscores the company’s commitment to delivering seamless service, ensuring industries maintain their operations without interruption.

- Reliable Supply Chain: Timely access to York VSD Coolant is indispensable in industries where downtime can result in substantial losses. A reputable supplier maintains a dependable supply chain, ensuring businesses can source the coolant they need promptly. This minimizes disruptions and helps industries remain competitive by avoiding unnecessary downtime.

- Local Presence: Midwest Parts Center’s local presence in Louisville offers industries a significant advantage. The company understands the unique HVAC equipment requirements of the region and can provide tailored solutions, which are invaluable for maintaining competitive operations.

In conclusion, York VSD Coolant is a vital component of industrial success, offering energy efficiency, environmental responsibility, equipment longevity, and process consistency for HVAC systems. Its proven performance, precision formulation, quality assurance, and the accessibility and expertise it provides empower industries to maintain consistent operations, reduce energy costs, minimize downtime, and meet environmental and sustainability goals.

In an environment where energy efficiency, environmental responsibility, and operational reliability are paramount, a reputable York VSD Coolant supplier has consistently proven its value and continues to be a trusted partner for industries seeking excellence in commercial and industrial areas. Companies can rely on their York VSD Coolant supplier to provide the reliability and performance they need to outperform competitors and secure their market position.

Trusting York VSD Coolant for Unwavering Reliability

In the ever-evolving landscape of the commercial and industrial sectors, the reliable operation of HVAC (Heating, Ventilation, and Air Conditioning) systems is pivotal to productivity, cost-efficiency, and environmental responsibility. To ensure these systems perform optimally, businesses must rely on high-quality components. York VSD Coolant, supplied by reputable vendors like Midwest Parts Center, based in Louisville, Kentucky, stands as the epitome of reliability in industrial operations.

With a strong presence in commercial and industrial areas, Midwest Parts Center ensures that businesses can easily access genuine York VSD Coolant through their toll-free number, 1-800-368-8385. This accessibility empowers industries to excel by trusting York VSD Coolant for the performance and reliability they need in their HVAC systems.

The Essence of Reliability in York VSD Coolant

- Energy Efficiency: Energy efficiency is a paramount concern in the industrial sector. HVAC systems often constitute a significant portion of a facility’s energy consumption. York VSD Coolant is specifically engineered to optimize the energy efficiency of these systems, significantly reducing energy consumption and operational costs.

- Environmental Responsibility: With an increased emphasis on environmental sustainability, businesses are increasingly expected to reduce their carbon footprint. York VSD Coolant contributes to this goal by operating efficiently, reducing energy usage, and aligning with environmental responsibility standards.

- Equipment Longevity: In an environment where equipment downtime can be costly and disruptive, York VSD Coolant extends the life of HVAC systems. It ensures the systems run efficiently, minimizing wear and tear, reducing maintenance costs, and increasing equipment longevity.

- Process Consistency: Many industrial processes require precise environmental conditions to maintain product quality and meet regulatory standards. York VSD Coolant delivers consistent cooling to HVAC systems, ensuring these critical environmental conditions are maintained, upholding product quality and compliance.

Why Industries Trust York VSD Coolant for Reliability

- Proven Performance: The York brand is synonymous with quality and reliability in the HVAC industry. York VSD Coolant continues this tradition, maintaining the same high standards. Its proven performance is well-regarded and trusted by industries seeking reliable HVAC solutions.

- Precision Formulation: York VSD Coolant is specially formulated for use in Variable Speed Drive (VSD) HVAC systems. Its precise formulation aligns perfectly with the unique requirements of these systems, optimizing their performance and energy efficiency.

- Quality Assurance: York VSD Coolant undergoes rigorous quality control processes and testing to ensure it meets the exact specifications required for VSD HVAC systems. Industries trust this coolant because it offers unwavering quality, reliability, and precision – essential for operational efficiency.

- Expert Knowledge: York VSD Coolant is a specialized product, and its proper use demands expertise. Trusted suppliers like Midwest Parts Center offer a team of experts with comprehensive knowledge of York HVAC equipment and the coolant itself. This expertise assures industries make informed decisions about their HVAC systems, enhancing their competitive edge.

- Accessibility and Convenience: Quick access to York VSD Coolant is essential in the fast-paced world of industrial operations. Midwest Parts Center offers a toll-free number (1-800-368-8385) for businesses in need of this critical coolant, reaffirming the company’s commitment to delivering seamless service. This ensures industries maintain their operations without interruption.

- Reliable Supply Chain: Timely access to York VSD Coolant is indispensable in industries where downtime can result in substantial losses. Reputable suppliers maintain a dependable supply chain, ensuring businesses can source the coolant they need promptly. This minimizes disruptions and helps industries remain competitive by avoiding unnecessary downtime.

- Local Presence: Midwest Parts Center’s local presence in Louisville offers industries a significant advantage. The company understands the unique HVAC equipment requirements of the region and can provide tailored solutions, which are invaluable for maintaining competitive operations.

In conclusion, York VSD Coolant is a trusted asset for industries seeking reliability and performance in their HVAC systems. With a focus on energy efficiency, environmental responsibility, equipment longevity, and process consistency, York VSD Coolant has established itself as an invaluable resource for industrial operations. Its proven performance, precise formulation, quality assurance, and the accessibility and expertise it offers empower industries to maintain consistent operations, reduce energy costs, minimize downtime, and meet environmental and sustainability goals.

In a realm where energy efficiency, environmental responsibility, and operational reliability are non-negotiable, a reputable supplier of York VSD Coolant has consistently demonstrated its value, cementing its role as a trusted partner for industries looking to excel in commercial and industrial areas. Companies can rely on York VSD Coolant to provide the reliability and performance they need to outperform competitors and secure their market position.

York VSD Coolant: The Backbone of Industry

In the competitive and ever-evolving landscape of the industrial sector, the reliable operation of HVAC (Heating, Ventilation, and Air Conditioning) systems is pivotal to success. These systems ensure the comfort of employees, product quality, and the overall efficiency of a facility. At the core of these systems is a critical component – York VSD Coolant. Companies across commercial and industrial areas trust the expertise of Midwest Parts Center, headquartered in Louisville, Kentucky, for their reliable supply of genuine York VSD Coolant.

With a robust presence in the commercial and industrial sectors, Midwest Parts Center ensures that businesses can conveniently access this essential coolant through their toll-free number, 1-800-368-8385. This accessibility empowers industries to excel, relying on York VSD Coolant as the backbone of their HVAC systems.

The Critical Role of York VSD Coolant in Industry

- Energy Efficiency: In an era where energy efficiency is paramount, HVAC systems play a significant role in a facility’s energy consumption. York VSD Coolant is designed to optimize the energy efficiency of these systems, reducing energy consumption and operational costs.

- Environmental Responsibility: Companies today face increasing pressure to reduce their carbon footprint. York VSD Coolant operates efficiently, minimizing energy usage and aligning with sustainability goals, making it an essential component for environmentally responsible operations.

- Equipment Longevity: Downtime due to equipment failure is costly and disruptive. York VSD Coolant extends the life of HVAC systems by ensuring they run efficiently, reducing wear and tear. This translates to fewer breakdowns, lower maintenance costs, and increased equipment longevity.

- Process Consistency: Many industrial processes require precise environmental conditions to maintain product quality and adhere to regulatory standards. Consistent cooling provided by York VSD Coolant ensures that these critical environmental conditions are maintained, upholding product quality and compliance.

Why Industries Rely on York VSD Coolant as the Backbone

- Proven Performance: The York brand is synonymous with quality and reliability in the HVAC industry. York VSD Coolant continues this tradition, maintaining the same high standards. Its proven performance is well-regarded and trusted by industries seeking reliable HVAC solutions.

- Precision Formulation: York VSD Coolant is formulated specifically for use in Variable Speed Drive (VSD) HVAC systems. Its precise formulation ensures it meets the unique requirements of these systems, optimizing their performance and energy efficiency.

- Quality Assurance: York VSD Coolant undergoes rigorous quality control processes and testing to ensure it meets the specifications required for VSD HVAC systems. Industries trust this coolant because it offers unwavering quality, reliability, and precision – essential for operational efficiency.

- Expert Knowledge: York VSD Coolant is a specialized product, and its proper use demands expertise. Trusted suppliers like Midwest Parts Center offer a team of experts with comprehensive knowledge of York HVAC equipment and the coolant itself. This expertise assures industries make informed decisions about their HVAC systems, enhancing their competitive edge.

- Accessibility and Convenience: Quick access to York VSD Coolant is vital in the fast-paced world of industrial operations. Midwest Parts Center offers a toll-free number (1-800-368-8385) for businesses in need of this critical coolant, reaffirming the company’s commitment to delivering seamless service. This ensures industries maintain their operations without interruption.

- Reliable Supply Chain: Timely access to York VSD Coolant is indispensable in industries where downtime can result in substantial losses. Reputable suppliers maintain a dependable supply chain, ensuring businesses can source the coolant they need promptly. This minimizes disruptions and helps industries remain competitive by avoiding unnecessary downtime.

- Local Presence: Midwest Parts Center’s local presence in Louisville offers industries a significant advantage. The company understands the unique HVAC equipment requirements of the region and can provide tailored solutions, which are invaluable for maintaining competitive operations.

In conclusion, York VSD Coolant serves as the backbone of the industrial sector, offering energy efficiency, environmental responsibility, equipment longevity, and process consistency for HVAC systems. Its proven performance, precise formulation, quality assurance, and the accessibility and expertise it offers empower industries to maintain consistent operations, reduce energy costs, minimize downtime, and meet environmental and sustainability goals.

In an environment where energy efficiency, environmental responsibility, and operational reliability are non-negotiable, a reputable supplier of York VSD Coolant has consistently demonstrated its value, cementing its role as a trusted partner for industries seeking excellence in commercial and industrial areas. Companies can rely on York VSD Coolant to provide the reliability and performance they need to outperform competitors and secure their market position.

The Role of York VSD coolant in a Competitive Market

In today’s highly competitive and rapidly evolving industrial landscape, the efficiency and reliability of HVAC (Heating, Ventilation, and Air Conditioning) systems are essential for operational success. These systems not only regulate climate but also impact energy consumption, sustainability, and product quality. At the heart of these HVAC systems lies a critical component – York VSD Coolant. Trusted providers like Midwest Parts Center, located in Louisville, Kentucky, understand the importance of this coolant and offer businesses easy access to genuine York VSD Coolant through their toll-free number, 1-800-368-8385. With a strong presence in commercial and industrial areas, Midwest Parts Center empowers businesses to thrive by relying on York VSD Coolant for the performance and reliability required in their HVAC systems.

The Crucial Role of York VSD Coolant in a Competitive Market

- Enhancing Energy Efficiency: Energy efficiency is a top priority in the modern industrial sector. HVAC systems are significant contributors to energy consumption in commercial and industrial spaces. York Coolant is specifically designed to optimize energy efficiency, reducing energy consumption and operating costs, making it an indispensable component in maintaining a competitive edge.

- Environmental Responsibility: Today, businesses are under increasing pressure to reduce their carbon footprint and adopt sustainable practices. York VSD Coolant plays a vital role in environmental responsibility by operating efficiently, reducing energy usage, and aligning with sustainability goals.

- Prolonging Equipment Lifespan: Equipment downtime can be costly and disruptive. York Coolant helps extend the life of HVAC systems by ensuring they run efficiently, reducing wear and tear, and minimizing breakdowns. This translates to lower maintenance costs and increased equipment longevity.

- Ensuring Process Consistency: Many industrial processes depend on precise environmental conditions to maintain product quality and regulatory compliance. York VSD Coolant provides consistent cooling, ensuring these critical environmental conditions are upheld, and product quality is maintained.

Why Industries Depend on York Coolant in a Competitive Market

- Proven Performance: The York brand is synonymous with quality and reliability in the HVAC industry. York VSD Coolant continues this tradition, maintaining the same high standards. Its proven performance is well-regarded and trusted by industries seeking reliable HVAC solutions.

- Precision Formulation: York VSD Coolant is specifically formulated for use in Variable Speed Drive (VSD) HVAC systems. Its precise formulation ensures it meets the unique requirements of these systems, optimizing their performance and energy efficiency.

- Quality Assurance: York Coolant undergoes rigorous quality control processes and testing to ensure it meets the specifications required for VSD HVAC systems. Industries trust this coolant because it offers unwavering quality, reliability, and precision – essential for operational efficiency.

- Expert Knowledge: York VSD Coolant is a specialized product, and its proper use demands expertise. Trusted suppliers like Midwest Parts Center offer a team of experts with comprehensive knowledge of York HVAC equipment and the coolant itself. This expertise ensures industries make informed decisions about their HVAC systems, enhancing their competitive edge.

- Accessibility and Convenience: Quick access to York VSD Coolant is vital in the fast-paced world of industrial operations. Midwest Parts Center offers a toll-free number (1-800-368-8385) for businesses in need of this critical coolant, reaffirming the company’s commitment to delivering seamless service. This ensures industries maintain their operations without interruption.

- Reliable Supply Chain: Timely access to York Coolant is indispensable in industries where downtime can result in substantial losses. Reputable suppliers maintain a dependable supply chain, ensuring businesses can source the coolant they need promptly. This minimizes disruptions and helps industries remain competitive by avoiding unnecessary downtime.

- Local Presence: Midwest Parts Center’s local presence in Louisville offers industries a significant advantage. The company understands the unique HVAC equipment requirements of the region and can provide tailored solutions, which are invaluable for maintaining competitive operations.

In summary, York VSD Coolant serves as a linchpin in the competitive market, offering energy efficiency, environmental responsibility, equipment longevity, and process consistency for HVAC systems. Its proven performance, precise formulation, quality assurance, and the accessibility and expertise it offers empower industries to maintain consistent operations, reduce energy costs, minimize downtime, and meet environmental and sustainability goals.

In an environment where energy efficiency, environmental responsibility, and operational reliability are essential, a reputable supplier of York VSD Coolant has consistently demonstrated its value, cementing its role as a trusted partner for industries looking to excel in commercial and industrial areas. Companies can rely on York VSD Coolant to provide the reliability and performance they need to outperform competitors and secure their market position.

Clean air conditioning is a significant consideration, and units need cost savings, but the energy bill is a major obstacle for companies trying to work efficiently within a budget.

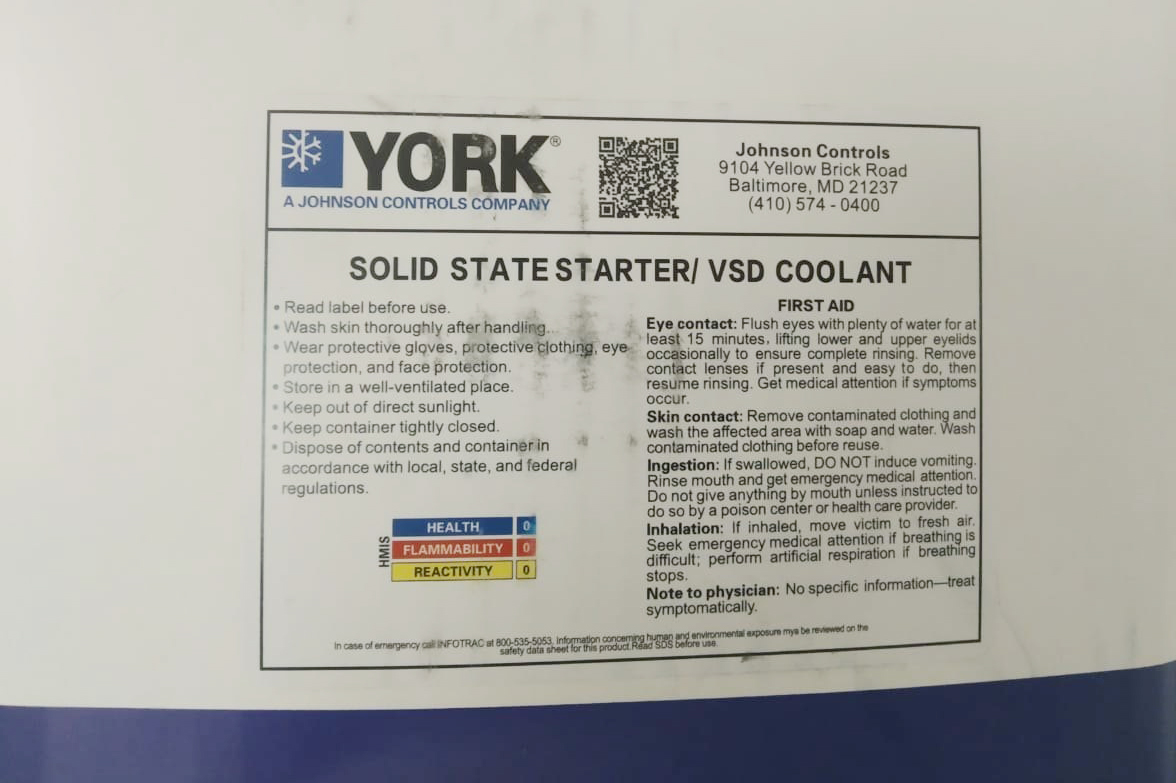

Clean air conditioning is a significant consideration, and units need cost savings, but the energy bill is a major obstacle for companies trying to work efficiently within a budget. The HVAC system performs as designed with little effort, thanks to using York Industrial VSD Coolant for chillers. The heating, ventilation, and air conditioning (HVAC) system in a building is crucial for maintaining a comfortable indoor temperature and meeting regulations.

The HVAC system performs as designed with little effort, thanks to using York Industrial VSD Coolant for chillers. The heating, ventilation, and air conditioning (HVAC) system in a building is crucial for maintaining a comfortable indoor temperature and meeting regulations.

needs coolant, you should probably avoid attempting to fix it on your own. Instead, it would help if you hire trained professionals to resolve the issue.

needs coolant, you should probably avoid attempting to fix it on your own. Instead, it would help if you hire trained professionals to resolve the issue. atmosphere. York VSD coolant, used in chillers, ensures that the machines continue functioning normally and effectively. HVAC equipment manage the expected airflow level within a building’s interior, regardless of the changing temperatures outside; ventilation and air conditioning systems are necessary for meeting the needs for filtered air.

atmosphere. York VSD coolant, used in chillers, ensures that the machines continue functioning normally and effectively. HVAC equipment manage the expected airflow level within a building’s interior, regardless of the changing temperatures outside; ventilation and air conditioning systems are necessary for meeting the needs for filtered air. The coolant is a crucial component for the transfer of heat during the process of converting liquids and vapors. Consequently, some companies have been forced to endure exorbitantly high energy expenses due to their efforts to manage York VSD coolant for their chillers and the VSD coolant.

The coolant is a crucial component for the transfer of heat during the process of converting liquids and vapors. Consequently, some companies have been forced to endure exorbitantly high energy expenses due to their efforts to manage York VSD coolant for their chillers and the VSD coolant.

You can’t take a chance with anything less than custom-made components for your chiller. As a well-known firm and brand, YORK has a stellar track record. Regular maintenance and system updates are required to extend the life of heavy equipment. Your company’s prosperity depends on the efficiency of your chiller, which is a significant financial investment.

You can’t take a chance with anything less than custom-made components for your chiller. As a well-known firm and brand, YORK has a stellar track record. Regular maintenance and system updates are required to extend the life of heavy equipment. Your company’s prosperity depends on the efficiency of your chiller, which is a significant financial investment. A part of the heating and cooling system is the

A part of the heating and cooling system is the  The VSD coolant system keeps the HVAC and Chiller at a comfortable temperature. Removing moisture from the air through cooling systems improves indoor air quality. York VSD chiller coolant ensures a trouble-free and efficient operation of your HVAC equipment.

The VSD coolant system keeps the HVAC and Chiller at a comfortable temperature. Removing moisture from the air through cooling systems improves indoor air quality. York VSD chiller coolant ensures a trouble-free and efficient operation of your HVAC equipment.