The Advantage of York chiller parts in Louisville for Industrial HVAC Solutions

In the dynamic landscape of industrial HVAC solutions, the choice of components is pivotal for ensuring optimal performance, efficiency, and longevity. Among the leading contenders in the realm of chiller parts, York Chiller Parts stand out as a benchmark for excellence. In this comprehensive exploration, we unveil the distinct advantage of York Chiller Parts in Louisville for industrial HVAC solutions. For inquiries and to leverage the unparalleled performance of York Chiller Parts in your industrial setting, contact Midwest Parts Center at +1 800 368 8385.

The Significance of York Chiller Parts in Louisville:

Louisville, a hub of industrial activity, demands HVAC solutions that can withstand the rigors of intense operations. York Chiller Parts, specifically tailored for industrial applications, offer a unique set of advantages that contribute to the efficiency, reliability, and sustainability of HVAC systems in Louisville.

1. Precision Engineering for Louisville’s Unique Needs:

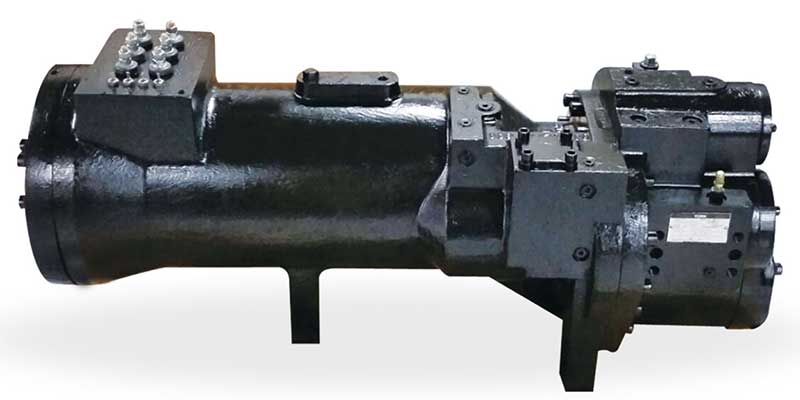

Louisville’s industrial landscape presents unique challenges in terms of temperature control, environmental conditions, and varying loads. York Chiller Parts are engineered with precision to meet these specific needs. The components are designed to operate seamlessly in industrial settings, providing precise temperature control and adaptability to fluctuating conditions. This precision engineering ensures that HVAC systems equipped with York Chiller Parts can deliver consistent performance in the diverse industrial environments of Louisville.

2. Robust Construction for Durability:

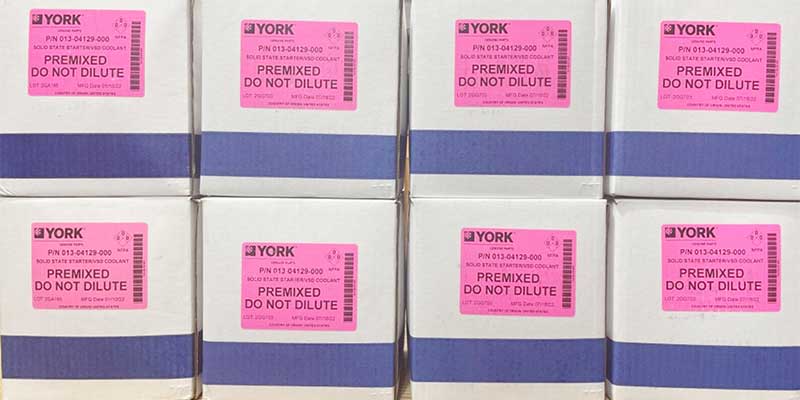

Industrial facilities in Louisville often operate round the clock, subjecting HVAC systems to continuous stress. York Chiller Parts, known for their robust construction, are built to withstand the demanding conditions of industrial operations. Whether it’s the compressors, heat exchangers, or other critical components, the durability of York Chiller Parts ensures a longer lifespan and reduced maintenance requirements, contributing to the uninterrupted operation of industrial HVAC systems.

3. Localized Solutions with York Chiller Parts in Louisville:

The advantage of choosing York Chiller Parts in Louisville extends beyond their global reputation. By opting for York Chiller Parts in Louisville, businesses benefit from localized solutions that are tailored to the specific industrial needs of the region. York Chiller Parts, when sourced through Midwest Parts Center, provide not just quality components but also expertise in addressing the unique challenges posed by Louisville’s industrial landscape.

4. Eco-Friendly Refrigerants for Environmental Compliance:

Louisville, like many industrial centers, places a growing emphasis on environmental sustainability. York Chiller Parts integrate eco-friendly refrigerants with lower global warming potential (GWP) and ozone depletion potential (ODP).

This aligns industrial HVAC systems with environmental regulations, contributing to a reduced carbon footprint and positioning businesses in Louisville as environmentally responsible stewards.

5. Adaptive Capacity Control for Variable Loads:

Industrial processes in Louisville often result in variable cooling demands. York Chiller Parts feature adaptive capacity control mechanisms, allowing the HVAC system to adjust its capacity based on real-time cooling needs. This adaptability ensures that the system operates at peak efficiency, even in the face of fluctuating industrial loads. The advantage of adaptive capacity control enhances energy efficiency and reduces operational costs for industrial facilities in Louisville.

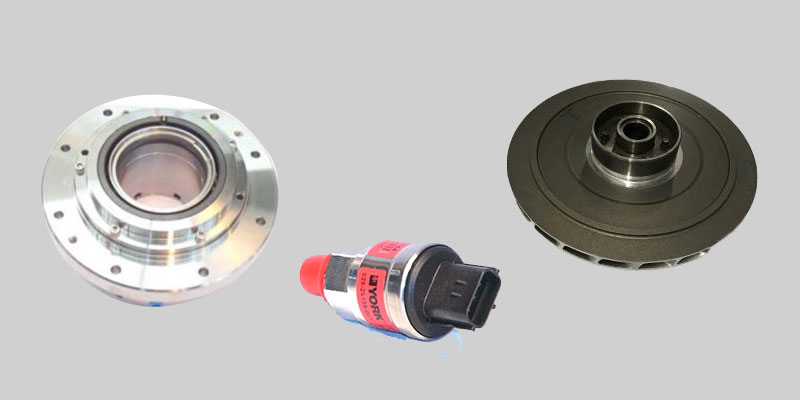

6. Smart Sensors for Predictive Maintenance:

The advantage of York Chiller Parts extends to the realm of predictive maintenance with the integration of smart sensors. These sensors continuously monitor critical components, collecting real-time data on temperature, pressure, and system performance. By leveraging predictive analytics, York Chiller Parts enable industrial facilities in Louisville to implement proactive maintenance strategies, preventing unexpected breakdowns and minimizing downtime.

7. Connectivity for Remote Monitoring and Management:

In the era of smart technology, the advantage of connectivity cannot be overstated. York Chiller Parts incorporate intelligent diagnostics and connectivity options that facilitate remote monitoring and management. Industrial facilities in Louisville can access real-time data, receive alerts, and make adjustments to the HVAC system from anywhere. This connectivity ensures swift responses to changing conditions, reducing the need for on-site interventions and enhancing overall system efficiency.

8. Comprehensive Support from Midwest Parts Center:

The advantage of choosing York Chiller Parts in Louisville is complemented by the support and expertise offered by Midwest Parts Center. As a leading provider of HVAC solutions for commercial and industrial applications, Midwest Parts Center is dedicated to ensuring that businesses in Louisville receive not just quality components but also unparalleled support. The comprehensive services include consultations, expert guidance, and a commitment to addressing the specific needs of industrial HVAC systems in the region.

The Impact on Industrial HVAC Solutions in Louisville:

Now, let’s delve into how the unique advantages of York Chiller Parts translate into tangible benefits for industrial HVAC solutions in Louisville.

1. Enhanced Operational Efficiency:

The precision engineering, adaptive capacity control, and connectivity features of York Chiller Parts collectively contribute to enhanced operational efficiency for industrial HVAC systems in Louisville. The components operate seamlessly, adjusting to varying industrial loads and optimizing energy consumption. This enhanced efficiency translates into lower operational costs and a more sustainable approach to industrial processes.

2. Increased System Reliability:

Industrial facilities in Louisville cannot afford downtime due to HVAC system failures. The robust construction, smart sensors, and predictive maintenance capabilities of York Chiller Parts significantly increase the reliability of industrial HVAC systems. By proactively addressing potential issues and minimizing unexpected breakdowns, businesses in Louisville can ensure uninterrupted operations and maintain productivity.

3. Long-Term Cost Savings:

While the initial investment in quality components like York Chiller Parts may be perceived as significant, the long-term cost savings are substantial. The durability, reduced maintenance requirements, and energy-efficient operation of York Chiller Parts contribute to a lower total cost of ownership. Businesses in Louisville can enjoy long-term financial benefits, making the choice of York Chiller Parts a strategic and cost-effective investment.

4. Environmental Stewardship:

The integration of eco-friendly refrigerants aligns industrial HVAC systems in Louisville with the city’s environmental goals. Choosing York Chiller Parts demonstrates a commitment to sustainability, contributing to a reduced carbon footprint and meeting regulatory standards. This environmental stewardship not only enhances the reputation of businesses but also resonates with environmentally conscious consumers and stakeholders.

5. Expert Guidance for Optimal Solutions:

The advantage of choosing York Chiller Parts in Louisville is amplified by the comprehensive support provided by Midwest Parts Center. Businesses can leverage expert guidance, consultations, and tailored solutions to address the specific challenges of industrial HVAC systems in the region. This level of support ensures that businesses in Louisville receive not just components but a holistic approach to optimizing their HVAC systems.

Contact Midwest Parts Center for York Chiller Parts in Louisville:

For businesses in Louisville eager to harness the advantage of York Chiller Parts and elevate their industrial HVAC solutions, Midwest Parts Center is the trusted partner. Contact Midwest Parts Center at +1 800 368 8385 for inquiries, consultations, and to explore how the unique advantages of York Chiller Parts can be seamlessly integrated into your industrial HVAC systems.

In conclusion, the advantage of York Chiller Parts in Louisville for industrial HVAC solutions is evident in the precision engineering, robust construction, and eco-friendly features that cater to the specific needs of the region. Businesses that choose York Chiller Parts, especially when sourced through Midwest Parts Center, gain a competitive edge with enhanced efficiency, increased reliability, and long-term cost savings. The strategic investment in York Chiller Parts not only positions industrial facilities in Louisville for operational success but also reflects a commitment to sustainability and environmental stewardship.