Importance of Regular Maintenance with VSD Coolant

In industrial and commercial environments, energy efficiency and equipment longevity are critical to maintaining operational productivity and cost control. One of the vital components contributing to these factors in HVAC systems, particularly those with Variable Speed Drives (VSDs), is the VSD coolant. Proper maintenance and timely replacement of VSD coolant ensure that systems continue to operate at peak performance. Midwest Parts Center, a trusted supplier for industrial parts, emphasizes the importance of regular VSD coolant maintenance to help facilities keep their systems running smoothly and efficiently. For expert guidance or service inquiries, Midwest Parts Center can be reached at +1 800 368 8385.

Understanding VSD Coolant in Industrial HVAC Systems

VSD Coolant plays a vital role in cooling and protecting the variable speed drives that control the operation of HVAC compressors and other motors. VSD technology allows HVAC systems to adjust motor speeds based on demand, which conserves energy and reduces wear on components. However, the operation of VSDs generates significant heat, and without efficient cooling, this heat can lead to component wear and potential system failures. VSD coolant is specifically formulated to absorb and dissipate this heat, keeping the drives operating within safe temperature ranges.

Regular maintenance with VSD coolant is essential to ensure that cooling remains effective, as coolant can degrade over time, lose its effectiveness, or become contaminated. Midwest Parts Center provides high-quality VSD coolant and guidance on maintaining HVAC systems for industrial clients, ensuring their equipment remains reliable and efficient.

The Role of VSD Coolant in Enhancing HVAC System Performance

- Temperature RegulationVSD coolant helps regulate the temperature of variable speed drives, allowing the system to perform efficiently without overheating. By preventing excessive heat buildup, VSD coolant minimizes the risk of drive failures and helps HVAC systems run smoothly.

- Improving System EfficiencyEfficient temperature management through proper VSD coolant maintenance ensures that the HVAC system doesn’t have to work harder than necessary. This efficiency translates into lower energy costs and optimized performance, making it easier for facilities to manage utility expenses.

- Extending Equipment LifespanOverheating can cause significant wear on system components, but with regular VSD coolant maintenance, facilities can protect their equipment from heat-related damage. Midwest Parts Center offers VSD coolant solutions that promote long-term system health, extending the lifespan of valuable HVAC assets.

- Ensuring Reliable OperationConsistent HVAC performance is crucial for industrial facilities, where system failures can lead to costly downtime. VSD coolant maintenance ensures that systems remain dependable, reducing the likelihood of unexpected shutdowns and the associated productivity losses.

The Importance of Regular Maintenance with VSD Coolant

While many industrial operators may recognize the benefits of VSD technology, the role of coolant in maintaining system efficiency is sometimes overlooked. Regular maintenance with VSD coolant is crucial for ensuring the consistent performance of HVAC systems in demanding industrial settings. Here are some reasons why regular maintenance is essential:

1. Preventing System Downtime

In industrial facilities, HVAC system downtime can lead to significant disruptions and financial losses. Overheated VSDs are a common cause of such downtime, but regular coolant maintenance can prevent this. By replacing and monitoring VSD coolant as recommended, facilities can avoid overheating issues and ensure continuous operation.

2. Improving Energy Efficiency

An efficiently operating VSD reduces energy consumption by adjusting motor speeds to match the actual cooling or heating demand. However, without effective cooling, VSDs cannot perform optimally, leading to higher energy consumption. Proper VSD coolant maintenance allows the drives to operate at optimal temperatures, supporting the energy-efficient benefits of variable speed technology.

3. Reducing Maintenance Costs

Reactive maintenance is often more costly than preventive maintenance. By scheduling regular maintenance for VSD coolant, facilities can catch minor issues before they become major repairs. Midwest Parts Center offers the expertise needed to create a proactive maintenance schedule, helping facilities manage maintenance costs effectively.

4. Protecting System Components

VSDs are only one part of the overall HVAC system, and issues within the drives can impact other components. For instance, excessive heat from malfunctioning VSDs can place additional strain on compressors, fans, and coils. Regular coolant maintenance helps ensure that each part of the system operates within safe temperature ranges, reducing the strain on other components.

How Midwest Parts Center Supports Effective VSD Coolant Maintenance

Midwest Parts Center provides comprehensive support for industrial and commercial clients seeking to optimize their HVAC systems. As a leading supplier of VSD coolant in the Midwest, Midwest Parts Center offers a range of products and services designed to help facilities maintain their systems efficiently. Here’s how Midwest Parts Center assists clients in maintaining effective VSD coolant management:

- High-Quality VSD Coolant SupplyMidwest Parts Center stocks high-quality VSD coolant that meets the stringent demands of industrial applications. Their selection includes coolants specifically formulated for HVAC systems, providing reliable performance and longevity.

- Maintenance Scheduling and SupportUnderstanding that each facility’s HVAC needs are unique, Midwest Parts Center offers tailored support for scheduling VSD coolant maintenance. Their team works with clients to develop schedules that fit their operational requirements, ensuring that coolant is replaced and maintained at optimal intervals.

- Expert Guidance on Coolant ManagementThe professionals at Midwest Parts Center possess extensive knowledge of HVAC systems and VSD maintenance. They provide clients with expert advice on coolant usage, storage, and replacement, helping facilities make informed decisions about their HVAC care.

- Responsive Customer ServiceRecognizing the importance of quick response times in industrial maintenance, Midwest Parts Center offers responsive customer service to address client inquiries and service requests. Facilities in need of VSD coolant or maintenance guidance can rely on Midwest Parts Center for timely support and delivery.

The Benefits of Preventive Maintenance with VSD Coolant for Industrial Facilities

For industrial facilities, preventive maintenance is a strategy that maximizes the value of HVAC systems while minimizing the risk of costly repairs. Regular maintenance with VSD coolant plays an essential role in this approach, providing benefits that support efficient and reliable operations. Here’s a closer look at how preventive maintenance with VSD coolant benefits industrial facilities:

1. Cost Savings Through Energy Efficiency

Regular VSD coolant maintenance allows HVAC systems to maintain energy efficiency, which translates to lower energy bills for facilities. Over time, these savings can be substantial, making preventive maintenance an investment that pays for itself.

2. Enhanced Operational Reliability

Predictable and reliable HVAC operation is critical in industrial settings, where temperature control impacts both processes and personnel. By prioritizing VSD coolant maintenance, facilities can achieve consistent system performance, reducing the risk of unexpected breakdowns.

3. Prolonged Equipment Life

Routine maintenance prevents overheating and minimizes wear on VSDs and other HVAC components. This proactive care extends the lifespan of HVAC systems, allowing facilities to maximize the value of their investment in this equipment.

4. Environmental Benefits

Efficient HVAC systems consume less energy, reducing the facility’s carbon footprint. By maintaining VSD coolant and supporting optimal system performance, facilities can achieve their sustainability goals while also benefiting from cost savings.

Regular maintenance with VSD coolant is critical for any facility that depends on efficient and reliable HVAC systems. Midwest Parts Center, a leading supplier of VSD coolant and other industrial HVAC components, provides the products and support necessary for effective coolant maintenance. By choosing Midwest Parts Center, facilities in the Midwest gain access to high-quality coolant, expert guidance, and dedicated customer service, empowering them to maintain optimal system performance.

For facilities that prioritize efficiency, reliability, and cost-effective operations, regular maintenance with VSD coolant is an essential practice. Midwest Parts Center can be reached at +1 800 368 8385 to discuss VSD coolant solutions and other services that support the efficiency of industrial HVAC systems.

This draft includes key elements for a comprehensive article on the importance of VSD coolant and regular maintenance, with Midwest Parts Center positioned as the go-to resource for industrial HVAC needs. Let me know if there are specific details you’d like to expand upon.

What are the good sign of perfect VSD Coolant service

Industrial and commercial facilities rely on their HVAC systems to perform consistently, and Variable Speed Drives (VSDs) play a crucial role in this process. For VSDs to work efficiently, high-quality VSD Coolant is essential, but it’s equally important to know when your VSD Coolant service is meeting the highest standards. Properly serviced VSD Coolant can extend the life of your equipment, reduce operational costs, and enhance the overall performance of your HVAC systems. Midwest Parts Center is dedicated to helping industrial clients achieve optimal efficiency by providing reliable VSD Coolant service. To inquire about service and products, contact Midwest Parts Center at +1 800 368 8385.

Understanding the Role of VSD Coolant in HVAC Systems

VSD Coolant is integral to HVAC systems, especially in industrial and commercial settings. VSDs allow the system’s motor to adjust speeds according to demand, conserving energy and reducing wear on the system. This process generates substantial heat, and VSD Coolant helps to dissipate it, ensuring the system runs smoothly. Without effective coolant, VSDs can overheat, leading to increased energy consumption, premature component wear, and costly repairs.

Regular service of VSD Coolant is essential for maintaining the efficacy of HVAC systems. The quality of this service impacts the coolant’s longevity, effectiveness, and the overall performance of the system. Midwest Parts Center is committed to helping clients maintain these systems through perfect VSD Coolant service.

Good Signs of Perfect VSD Coolant Service

Knowing what defines high-quality VSD Coolant service is essential. Here are the signs to look out for that indicate a perfect service:

1. Consistent Temperature Regulation

A clear sign of effective VSD Coolant service is stable temperature control in the VSDs. When the coolant is properly maintained, it should dissipate heat effectively, allowing the drives to operate within safe temperature ranges. This consistency is a positive indicator that your coolant is in good condition and functioning as it should.

- Indicator: The system operates without overheating, and temperature fluctuations are minimal, even during heavy use.

2. Improved System Efficiency

Properly serviced VSD Coolant contributes directly to system efficiency. When VSDs run at ideal temperatures, the HVAC system can maintain energy-efficient operations. Perfect VSD Coolant service enables the drive to operate with lower energy consumption, leading to overall cost savings.

- Indicator: Noticeable reduction in energy bills, and the HVAC system operates efficiently without drawing excess power.

3. Reduced Frequency of Repairs

Frequent repairs can indicate that the VSD Coolant is not effectively protecting your HVAC system. Proper VSD Coolant service should reduce the strain on system components, minimizing the likelihood of breakdowns.

- Indicator: Fewer unexpected repairs and lower maintenance costs, signaling that the coolant is providing adequate protection to the system.

4. Extended Equipment Lifespan

One of the main goals of maintaining VSD Coolant is to prolong the lifespan of the HVAC system. High-quality VSD Coolant service should keep the equipment in optimal condition, preventing premature wear and extending the system’s operational life.

- Indicator: Equipment continues to perform reliably over an extended period, beyond expected lifespan projections.

5. Consistent Coolant Quality and Levels

During regular VSD Coolant service, technicians should check for coolant quality and ensure levels are maintained. Perfect service will mean that the coolant is free from contaminants and at the appropriate level, ensuring optimal performance.

- Indicator: Visual inspection shows clean, contaminant-free coolant at the correct level, with no signs of degradation.

Why Midwest Parts Center Is the Go-To for Perfect VSD Coolant Service

Midwest Parts Center is renowned for its commitment to quality and customer satisfaction, particularly in commercial and industrial sectors. Their VSD Coolant services are designed to provide clients with peace of mind, knowing that their systems are operating at peak efficiency. Here’s why Midwest Parts Center is the ideal partner for VSD Coolant needs:

1. Expertise in Industrial HVAC Systems

Midwest Parts Center specializes in industrial HVAC systems and understands the unique requirements of these environments. With a team of experts, they provide tailored VSD Coolant solutions that meet the rigorous demands of industrial facilities.

2. High-Quality VSD Coolant Products

The quality of coolant used plays a significant role in the effectiveness of the service. Midwest Parts Center offers only the highest quality VSD Coolant products, ensuring that clients receive a reliable and long-lasting solution.

3. Comprehensive Maintenance Programs

Midwest Parts Center offers full-service maintenance programs that include regular inspections, coolant replacement, and system assessments to ensure the VSD Coolant is always performing at its best.

4. Commitment to Customer Service

With a commitment to responsive and reliable service, Midwest Parts Center is available to address client concerns, answer questions, and provide support as needed. They can be reached at +1 800 368 8385 for inquiries related to VSD Coolant service.

5. Customized Solutions for Each Client

Recognizing that every industrial setup is unique, Midwest Parts Center offers customized VSD Coolant service solutions tailored to the specific needs of each client, ensuring that they receive optimal results.

How to Ensure Continued Benefits from VSD Coolant Service

Perfect VSD Coolant service is not a one-time task but a continuous commitment. Here’s how facilities can maximize the benefits of their VSD Coolant service:

- Regular Maintenance Check-Ups Schedule regular check-ups with Midwest Parts Center to inspect coolant levels, quality, and effectiveness. Routine inspections can catch early signs of wear or contamination.

- Monitor Energy Consumption Facilities should monitor their energy consumption patterns. A sudden increase in energy use may indicate that the VSD Coolant requires attention or replacement.

- Document Service Records Keep records of each service, noting the coolant’s condition and any recommendations from the technicians. This documentation helps track the coolant’s performance over time.

- Invest in Quality Coolant Investing in high-quality VSD Coolant from Midwest Parts Center ensures that your system receives the best protection and cooling available, maximizing the effectiveness of the service.

For industrial and commercial HVAC systems, perfect VSD Coolant service is crucial to ensuring efficiency, reliability, and longevity. The good signs of effective coolant service include consistent temperature regulation, improved system efficiency, reduced repair needs, extended equipment lifespan, and well-maintained coolant quality. Midwest Parts Center offers the expertise, high-quality products, and dedicated support needed to provide clients with exceptional VSD Coolant service.

As the go-to supplier for VSD Coolant in the Midwest, Midwest Parts Center stands out for its commitment to excellence and customer satisfaction. Facilities seeking to improve their HVAC system’s performance can rely on Midwest Parts Center for all their VSD Coolant needs. For more information or to schedule service, contact Midwest Parts Center at +1 800 368 8385.

This outline captures the major points for your article, incorporating key information about the signs of effective VSD Coolant service and the role of Midwest Parts Center in supporting HVAC efficiency. Let me know if you’d like to expand on any particular sections.

needs coolant, you should probably avoid attempting to fix it on your own. Instead, it would help if you hire trained professionals to resolve the issue.

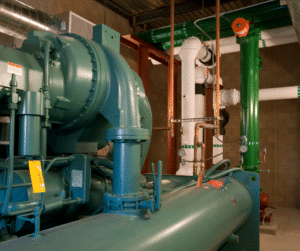

needs coolant, you should probably avoid attempting to fix it on your own. Instead, it would help if you hire trained professionals to resolve the issue. atmosphere. York VSD coolant, used in chillers, ensures that the machines continue functioning normally and effectively. HVAC equipment manage the expected airflow level within a building’s interior, regardless of the changing temperatures outside; ventilation and air conditioning systems are necessary for meeting the needs for filtered air.

atmosphere. York VSD coolant, used in chillers, ensures that the machines continue functioning normally and effectively. HVAC equipment manage the expected airflow level within a building’s interior, regardless of the changing temperatures outside; ventilation and air conditioning systems are necessary for meeting the needs for filtered air. The coolant is a crucial component for the transfer of heat during the process of converting liquids and vapors. Consequently, some companies have been forced to endure exorbitantly high energy expenses due to their efforts to manage York VSD coolant for their chillers and the VSD coolant.

The coolant is a crucial component for the transfer of heat during the process of converting liquids and vapors. Consequently, some companies have been forced to endure exorbitantly high energy expenses due to their efforts to manage York VSD coolant for their chillers and the VSD coolant.

Your chiller’s

Your chiller’s  Commercial and industrial settings are important markets for the chillers made by the York company in the US. The component used to boost the chiller’s performance is the York VSD coolant. Clean and purified air is in high demand.

Commercial and industrial settings are important markets for the chillers made by the York company in the US. The component used to boost the chiller’s performance is the York VSD coolant. Clean and purified air is in high demand. Coolers are also used in a wide range of locations, including hospitals and restaurants and hotels and schools, and manufacturing plants; they are used to maintain clean and comfortable air standards. Aside from that, coolers impact operating costs while also being extremely eco-friendly.

Coolers are also used in a wide range of locations, including hospitals and restaurants and hotels and schools, and manufacturing plants; they are used to maintain clean and comfortable air standards. Aside from that, coolers impact operating costs while also being extremely eco-friendly.

The

The  Chillers are installed in many facilities; restaurants, hospitals, manufacturing firms, and hotels utilize chillers to offer a comfortable air level. Although the problem is that they use an immense amount of energy because they are so colossal. During the successful seasons, a chiller may use at least fifty percent of electricity. Escalating energy expenses imply that operational cost will also increase. Not only do chillers affect operating expenditure, but they also have environmental changes.

Chillers are installed in many facilities; restaurants, hospitals, manufacturing firms, and hotels utilize chillers to offer a comfortable air level. Although the problem is that they use an immense amount of energy because they are so colossal. During the successful seasons, a chiller may use at least fifty percent of electricity. Escalating energy expenses imply that operational cost will also increase. Not only do chillers affect operating expenditure, but they also have environmental changes. Facilities are aware of the effect high consumption of energy can bring; they manage Midwest York VSD coolant for chillers; the VSD coolant is an incentive for chillers. The material helps a chiller process air effectively. Besides, the coolant aids in facilitating the flow of air in air conditioner systems. The York VSD model uses vapor compression; the system produces heat from the compressor’s water and heat. Commercial premises choose the chiller model because they need minimal maintenance compared to other models, are energy conservative, and provide high-quality cooling.

Facilities are aware of the effect high consumption of energy can bring; they manage Midwest York VSD coolant for chillers; the VSD coolant is an incentive for chillers. The material helps a chiller process air effectively. Besides, the coolant aids in facilitating the flow of air in air conditioner systems. The York VSD model uses vapor compression; the system produces heat from the compressor’s water and heat. Commercial premises choose the chiller model because they need minimal maintenance compared to other models, are energy conservative, and provide high-quality cooling.