Unveiling the Advantages of Partnering with a York Parts Distributor

In the dynamic world of commercial and industrial operations, the seamless functioning of equipment is vital for maintaining productivity, efficiency, and ultimately, success. However, wear and tear, as well as unexpected malfunctions, are inevitable occurrences that necessitate prompt action to rectify issues and prevent costly downtime. This underscores the critical importance of having a trusted York parts distributor – one that offers authenticity, reliability, and efficiency. Midwest Parts Center proudly serves as your premier York parts distributor, providing an extensive inventory of genuine parts and unparalleled support tailored to the unique requirements of commercial and industrial sectors.

As a trusted York parts distributor, Midwest Parts Center understands the paramount significance of authenticity in ensuring the seamless integration and optimal performance of replacement parts with your equipment. Each York part available through our inventory is meticulously engineered and manufactured to meet the exacting standards and specifications set forth by York, guaranteeing compatibility and reliability. By entrusting Midwest Parts Center as your distributor, you can rest assured that you are receiving genuine York parts of the highest quality.

One of the primary advantages of partnering with Midwest Parts Center as your York parts distributor is our steadfast commitment to providing prompt and efficient service. We recognize the urgency associated with addressing equipment issues and minimizing downtime in commercial and industrial settings. Therefore, we maintain an extensive inventory of York parts and offer expedited shipping options to ensure timely delivery of the parts you need, precisely when you need them. Moreover, our dedicated team of professionals stands ready to provide technical assistance and support to help you identify the right parts for your specific applications.

In addition to authenticity and reliability, Midwest Parts Center offers unparalleled expertise and knowledge in the realm of York parts distribution. Our team of seasoned professionals possesses a deep understanding of York equipment and replacement parts, enabling us to offer expert guidance and recommendations to assist you in making informed decisions. Whether you’re in need of a compressor, a motor, or a control board, you can rely on Midwest Parts Center to provide the ideal part for your requirements.

Another significant advantage of partnering with Midwest Parts Center is our steadfast commitment to customer satisfaction. We recognize that every business is unique, with its own distinct set of challenges and requirements. Consequently, we take a personalized approach to every interaction, taking the time to comprehensively understand your specific needs and priorities. Whether you operate a small business or a large-scale industrial facility, you can count on Midwest Parts Center to deliver tailored solutions that precisely align with your specifications.

Accessibility and convenience are paramount considerations at Midwest Parts Center. To this end, we offer multiple channels for accessing support and assistance, including our toll-free number, +1 800 368 8385, through which our knowledgeable customer service representatives are readily available to address any inquiries or orders. Additionally, our user-friendly online platform provides a seamless means of browsing our extensive catalog, placing orders, and tracking shipments – all from the comfort and convenience of your workspace.

As a company entrenched in commercial and industrial areas, Midwest Parts Center possesses a profound understanding of the unique challenges and requirements inherent to businesses operating within these sectors. Consequently, we are steadfastly committed to providing comprehensive support and service to our customers, aiding them in overcoming obstacles and achieving success. Whether you require a single replacement part or an entire suite of parts for your equipment, you can rely on Midwest Parts Center to serve as your steadfast partner every step of the way.

In conclusion, Midwest Parts Center stands as your premier York parts distributor, offering authenticity, reliability, expertise, and unparalleled customer service to businesses within commercial and industrial sectors. By partnering with us, you gain access to a comprehensive inventory of genuine York parts, expedited shipping options, and personalized support tailored to your specific needs. Contact us today at +1 800 368 8385 to discover how we can assist you in fulfilling your York parts requirements and fostering success within your business.

York parts distributor help you for Factories to Warehouses, Catering to Your Commercial Needs

In the vast and bustling landscape of commercial and industrial operations, the smooth operation of machinery and equipment is pivotal for maintaining productivity, minimizing downtime, and ensuring business success. However, the wear and tear of components and the occasional need for replacements are inevitable realities that businesses must contend with. This is where a trusted York parts distributor comes into play, offering a lifeline of authenticity, reliability, and efficiency to factories, warehouses, and various commercial establishments. Midwest Parts Center proudly serves as your go-to York parts distributor, catering to the diverse needs of businesses across commercial and industrial sectors.

As a trusted York parts distributor, Midwest Parts Center understands the critical importance of authenticity in ensuring the seamless integration and optimal performance of replacement parts with your equipment. Each York part available through our inventory is meticulously engineered and manufactured to meet the exacting standards and specifications set forth by York, guaranteeing compatibility and reliability. By entrusting Midwest Parts Center as your distributor, you can rest assured that you are receiving genuine York parts of the highest quality.

One of the primary advantages of partnering with Midwest Parts Center as your York parts distributor is our steadfast commitment to providing prompt and efficient service. We recognize the urgency associated with addressing equipment issues and minimizing downtime in commercial and industrial settings. Therefore, we maintain an extensive inventory of York parts and offer expedited shipping options to ensure timely delivery of the parts you need, precisely when you need them. Moreover, our dedicated team of professionals stands ready to provide technical assistance and support to help you identify the right parts for your specific applications.

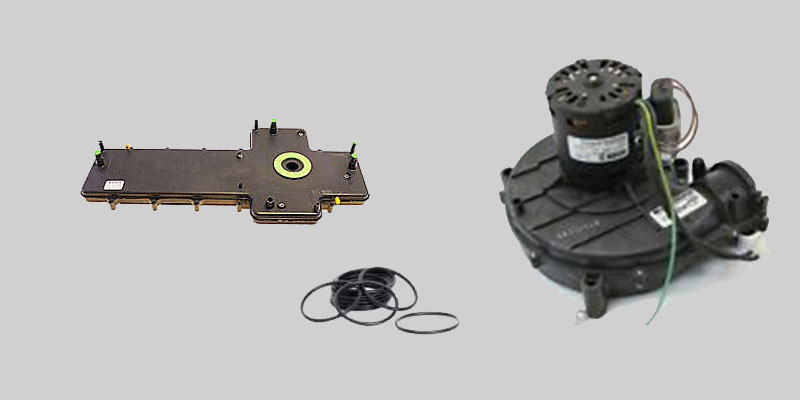

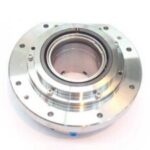

From factories to warehouses, Midwest Parts Center caters to a diverse range of commercial needs, offering comprehensive solutions tailored to the unique requirements of each establishment. Whether you’re operating a manufacturing facility, a distribution center, or a commercial kitchen, our extensive inventory of genuine York parts ensures that you have access to the components you need to keep your operations running smoothly. From compressors and motors to control boards and sensors, we have the parts you need to maintain and repair your equipment, ensuring uninterrupted productivity and efficiency.

In addition to authenticity and reliability, Midwest Parts Center offers unparalleled expertise and knowledge in the realm of York parts distribution. Our team of seasoned professionals possesses a deep understanding of York equipment and replacement parts, enabling us to offer expert guidance and recommendations to assist you in making informed decisions. Whether you’re in need of routine maintenance parts or emergency replacements, you can rely on Midwest Parts Center to provide the ideal solution for your requirements.

Another significant advantage of partnering with Midwest Parts Center is our steadfast commitment to customer satisfaction. We recognize that every business is unique, with its own distinct set of challenges and requirements. Consequently, we take a personalized approach to every interaction, taking the time to comprehensively understand your specific needs and priorities. Whether you operate a small business or a large-scale industrial facility, you can count on Midwest Parts Center to deliver tailored solutions that precisely align with your specifications.

Accessibility and convenience are paramount considerations at Midwest Parts Center. To this end, we offer multiple channels for accessing support and assistance, including our toll-free number, +1 800 368 8385, through which our knowledgeable customer service representatives are readily available to address any inquiries or orders. Additionally, our user-friendly online platform provides a seamless means of browsing our extensive catalog, placing orders, and tracking shipments – all from the comfort and convenience of your workspace.

As a company entrenched in commercial and industrial areas, Midwest Parts Center possesses a profound understanding of the unique challenges and requirements inherent to businesses operating within these sectors. Consequently, we are steadfastly committed to providing comprehensive support and service to our customers, aiding them in overcoming obstacles and achieving success. Whether you require a single replacement part or an entire suite of parts for your equipment, you can rely on Midwest Parts Center to serve as your steadfast partner every step of the way.

In conclusion, Midwest Parts Center stands as your premier York parts distributor, offering authenticity, reliability, expertise, and unparalleled customer service to businesses within commercial and industrial sectors. By partnering with us, you gain access to a comprehensive inventory of genuine York parts, expedited shipping options, and personalized support tailored to your specific needs. Contact us today at +1 800 368 8385 to discover how we can assist you in fulfilling your York parts requirements and fostering success within your business.

The Strategic Role of Our York parts distributor in Industrial Operations

In the dynamic landscape of industrial operations, the seamless functioning of machinery and equipment is paramount for maintaining productivity, minimizing downtime, and ensuring operational efficiency. However, the wear and tear of components, as well as unexpected malfunctions, are inevitable occurrences that can disrupt production and incur significant costs if not addressed promptly and effectively.

This underscores the critical role of a trusted York parts distributor – one that offers authenticity, reliability, and efficiency to industrial facilities. Midwest Parts Center proudly serves as your strategic partner in York parts distribution, providing comprehensive solutions tailored to the unique requirements of industrial operations.

As a trusted York parts distributor, Midwest Parts Center understands the paramount importance of authenticity in ensuring the seamless integration and optimal performance of replacement parts with industrial equipment. Each York part available through our inventory is meticulously engineered and manufactured to meet the exacting standards and specifications set forth by York, guaranteeing compatibility and reliability. By entrusting Midwest Parts Center as your distributor, you can rest assured that you are receiving genuine York parts of the highest quality.

One of the primary advantages of partnering with Midwest Parts Center as your York parts distributor is our steadfast commitment to providing prompt and efficient service. We recognize the urgency associated with addressing equipment issues and minimizing downtime in industrial settings. Therefore, we maintain an extensive inventory of York parts and offer expedited shipping options to ensure timely delivery of the parts you need, precisely when you need them. Moreover, our dedicated team of professionals stands ready to provide technical assistance and support to help you identify the right parts for your specific applications.

Industrial operations encompass a wide range of activities, each with its own unique set of challenges and requirements. From manufacturing plants to distribution centers, Midwest Parts Center caters to the diverse needs of industrial facilities, offering comprehensive solutions tailored to the specific demands of each operation. Whether you’re in need of replacement parts for HVAC systems, conveyor belts, or processing equipment, our extensive inventory of genuine York parts ensures that you have access to the components you need to keep your operations running smoothly.

In addition to authenticity and reliability, Midwest Parts Center offers unparalleled expertise and knowledge in the realm of York parts distribution. Our team of seasoned professionals possesses a deep understanding of York equipment and replacement parts, enabling us to offer expert guidance and recommendations to assist you in making informed decisions. Whether you’re in need of routine maintenance parts or emergency replacements, you can rely on Midwest Parts Center to provide the ideal solution for your requirements.

Another significant advantage of partnering with Midwest Parts Center is our steadfast commitment to customer satisfaction. We recognize that industrial operations are complex endeavors that require personalized attention and support. Consequently, we take a tailored approach to every interaction, taking the time to comprehensively understand your specific needs and priorities. Whether you operate a small-scale manufacturing facility or a large-scale industrial complex, you can count on Midwest Parts Center to deliver solutions that precisely align with your operational requirements.

Accessibility and convenience are paramount considerations at Midwest Parts Center. To this end, we offer multiple channels for accessing support and assistance, including our toll-free number, +1 800 368 8385, through which our knowledgeable customer service representatives are readily available to address any inquiries or orders. Additionally, our user-friendly online platform provides a seamless means of browsing our extensive catalog, placing orders, and tracking shipments – all from the comfort and convenience of your workspace.

As a company entrenched in industrial areas, Midwest Parts Center possesses a profound understanding of the unique challenges and requirements inherent to industrial operations. Consequently, we are steadfastly committed to providing comprehensive support and service to our customers, aiding them in overcoming obstacles and achieving success. Whether you require a single replacement part or an entire suite of parts for your equipment, you can rely on Midwest Parts Center to serve as your strategic partner every step of the way.

In conclusion, Midwest Parts Center stands as your strategic York parts distributor, offering authenticity, reliability, expertise, and unparalleled customer service to industrial operations. By partnering with us, you gain access to a comprehensive inventory of genuine York parts, expedited shipping options, and personalized support tailored to your specific needs. Contact us today at +1 800 368 8385 to discover how we can assist you in fulfilling your York parts requirements and maximizing efficiency within your industrial operations.

How Our York parts distributor Supports Your Industrial Growth and Innovation Efforts

In the dynamic landscape of industrial operations, growth and innovation are essential drivers of success, enabling businesses to adapt to changing market dynamics, enhance efficiency, and maintain a competitive edge. Central to these endeavors is the seamless functioning of machinery and equipment, which relies heavily on the availability of genuine replacement parts to ensure optimal performance and reliability. As a trusted York parts distributor, Midwest Parts Center plays a pivotal role in supporting industrial growth and innovation by providing authentic, reliable, and efficient solutions tailored to the evolving needs of businesses in commercial and industrial sectors.

At the heart of our commitment as a York parts distributor lies a steadfast dedication to authenticity and quality. We understand the critical importance of genuine parts in ensuring the seamless integration and optimal performance of industrial equipment. Each York part available through our inventory undergoes rigorous testing and quality assurance measures to meet the exacting standards set forth by York, guaranteeing compatibility, reliability, and longevity. By entrusting Midwest Parts Center as your distributor, you gain access to a comprehensive selection of genuine York parts of the highest quality.

One of the primary advantages of partnering with Midwest Parts Center as your York parts distributor is our unwavering commitment to providing prompt and efficient service. We recognize the urgency associated with equipment breakdowns and the need for timely replacements in industrial settings. Therefore, we maintain an extensive inventory of York parts and offer expedited shipping options to ensure the swift delivery of the parts you need, precisely when you need them. Moreover, our team of knowledgeable professionals stands ready to provide technical assistance and support to help you identify the right parts for your specific applications.

Industrial growth and innovation encompass a wide range of activities, each with its own unique set of challenges and requirements. From manufacturing advancements to process improvements, Midwest Parts Center caters to the diverse needs of businesses in commercial and industrial sectors, offering comprehensive solutions tailored to drive growth and innovation. Whether you’re in need of replacement parts for HVAC systems, machinery, or automation equipment, our extensive inventory of genuine York parts ensures that you have access to the components you need to support your growth and innovation efforts.

In addition to authenticity and reliability, Midwest Parts Center offers unparalleled expertise and knowledge in the realm of York parts distribution. Our team of seasoned professionals possesses a deep understanding of York equipment and replacement parts, enabling us to offer expert guidance and recommendations to assist you in making informed decisions. Whether you’re in need of routine maintenance parts or specialized components for innovative projects, you can rely on Midwest Parts Center to provide the ideal solution for your requirements.

Another significant advantage of partnering with Midwest Parts Center is our steadfast commitment to customer satisfaction. We recognize that industrial growth and innovation are complex endeavors that require personalized attention and support. Consequently, we take a tailored approach to every interaction, taking the time to comprehensively understand your specific needs and priorities. Whether you’re embarking on a new project or expanding existing operations, you can count on Midwest Parts Center to deliver solutions that precisely align with your growth and innovation objectives.

Accessibility and convenience are paramount considerations at Midwest Parts Center. To this end, we offer multiple channels for accessing support and assistance, including our toll-free number, +1 800 368 8385, through which our knowledgeable customer service representatives are readily available to address any inquiries or orders. Additionally, our user-friendly online platform provides a seamless means of browsing our extensive catalog, placing orders, and tracking shipments – all from the comfort and convenience of your workspace.

As a company entrenched in commercial and industrial areas, Midwest Parts Center possesses a profound understanding of the unique challenges and requirements inherent to industrial growth and innovation. Consequently, we are steadfastly committed to providing comprehensive support and service to our customers, aiding them in overcoming obstacles and achieving success. Whether you require a single replacement part or an entire suite of components for your innovative projects, you can rely on Midwest Parts Center to serve as your strategic partner every step of the way.

In conclusion, Midwest Parts Center stands as your trusted York parts distributor, offering authenticity, reliability, expertise, and unparalleled customer service to support industrial growth and innovation. By partnering with us, you gain access to a comprehensive inventory of genuine York parts, expedited shipping options, and personalized support tailored to your specific needs. Contact us today at +1 800 368 8385 to discover how we can assist you in fulfilling your York parts requirements and driving growth and innovation within your industrial operations.

You can use york parts to manufacture commercial chiller components. Air conditioning is crucial in commercial settings because it maintains a pleasant atmosphere and increases productivity.

You can use york parts to manufacture commercial chiller components. Air conditioning is crucial in commercial settings because it maintains a pleasant atmosphere and increases productivity. Cooling huge buildings consume a lot of energy, which can be prohibitively expensive for businesses utilizing them. Products that are both environmentally friendly and cost-effective, such as those made by York, are available. Midwest Part Center stores and delivers York application parts for clients worldwide.

Cooling huge buildings consume a lot of energy, which can be prohibitively expensive for businesses utilizing them. Products that are both environmentally friendly and cost-effective, such as those made by York, are available. Midwest Part Center stores and delivers York application parts for clients worldwide. There is a risk of building damage in an area with insufficient cold air supply, and the temperature conditions are unfavorable for the residents. Inefficient heating and cooling systems may be fixed appropriately using York components, which come with a lifetime warranty.

There is a risk of building damage in an area with insufficient cold air supply, and the temperature conditions are unfavorable for the residents. Inefficient heating and cooling systems may be fixed appropriately using York components, which come with a lifetime warranty.

Every construction decision presents an opportunity to create a more efficient, intelligent, and connected space – an environment tailored to our daily lives and work.

Every construction decision presents an opportunity to create a more efficient, intelligent, and connected space – an environment tailored to our daily lives and work. Every system we offer comes with world-class YORK service and support to help keep it running at optimal performance. Every YORK system is built for efficient, long-lasting performance that uses less energy and runs more efficiently in real-world settings, from simple retrofits to the most sophisticated, custom installations worldwide.

Every system we offer comes with world-class YORK service and support to help keep it running at optimal performance. Every YORK system is built for efficient, long-lasting performance that uses less energy and runs more efficiently in real-world settings, from simple retrofits to the most sophisticated, custom installations worldwide. To buy YORK Spare Parts, we created this selection, in which you can find our offer for sale. Our main goal is for you to check online the price for a wide range of products that make up the YORK Spare Parts family and buy at the best price while also knowing the shipping price to any destination.

To buy YORK Spare Parts, we created this selection, in which you can find our offer for sale. Our main goal is for you to check online the price for a wide range of products that make up the YORK Spare Parts family and buy at the best price while also knowing the shipping price to any destination.