NeedlePoint Bipolar Ionization air purification: Facilities have traditionally placed a high value on maintaining the best available indoor air quality in their industrial and commercial settings. It has an effect on the equipment and operations as well as the health of those working in the facility.

Because of the coronavirus epidemic, business owners and facility managers are now more worried than ever about Indoor Air Quality.

Because of the coronavirus epidemic, business owners and facility managers are now more worried than ever about Indoor Air Quality.

An arrowhead’s point In the fight against bacteria, viruses, and dangerous microorganisms, bipolar ionization technology is one of the most effective methods now available. The coronavirus is rendered inert in less than 30 minutes, according to independent testing. In terms of stopping the transmission of SARS-CoV-2 across an area, this may not be the greatest product on the market.

Why Use Bipolar Ionization in HVAC Systems?

Business owners have been looking for methods to keep their staff and customers safe since the outbreak of the COVID-19 worldwide pandemic began. There has been an increase in demand for items that enhance indoor air quality since the coronavirus is transmitted mostly by airborne droplets.

Business owners have been looking for methods to keep their staff and customers safe since the outbreak of the COVID-19 worldwide pandemic began. There has been an increase in demand for items that enhance indoor air quality since the coronavirus is transmitted mostly by airborne droplets.

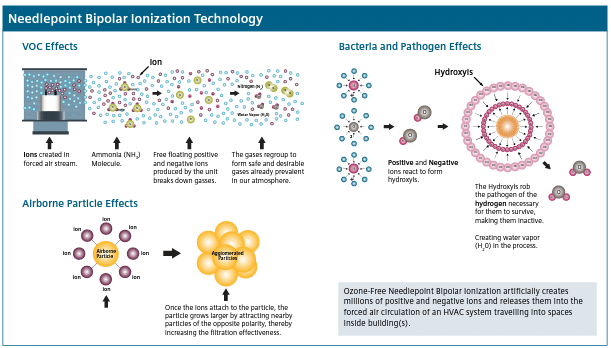

Volatile organic molecules can be effectively destroyed using bipolar ionization technology. After 30 minutes of operating a bipolar ion generator through an HVAC system, 99 percent of the coronavirus in the air has been eliminated.

Cleaner, healthier air is only one of the many advantages that come with bipolar ionization technology. Virens are killed and particles are reduced when using a bipolar ion generator. It will save you time and money by making your facility more sanitary and requiring less dusting. Using a bipolar ion generator also means less time and money spent on HVAC maintenance. Filters and collectors in your HVAC system are no longer necessary thanks to NPBI technology’s impressive dust reduction capabilities.

The positive and negative ion effects of NPBI technology also aid to minimize bad odors by eliminating the causes of these odors. As a company owner, it means you won’t have to spend money on artificial perfumes, deodorizers, or cleaners in order to maintain a clean and fresh-smelling environment.

Is Bipolar Ionization Safe?

The procedure of bipolar ionization is completely risk-free. A bipolar ion generator is safe enough to be used in a medical facility, a school campus, a government building, and an airport since it is so effective at destroying dangerous airborne particles.

The procedure of bipolar ionization is completely risk-free. A bipolar ion generator is safe enough to be used in a medical facility, a school campus, a government building, and an airport since it is so effective at destroying dangerous airborne particles.

Bipolar ionization technology developed in the 1960s and 1970s, which relied on glass tubes, may have produced hazardous byproducts like ozone. Ozone and ultraviolet radiation are no longer hazardous with contemporary NPBI technology. Bipolar ion generators, on the other hand, are more ecologically friendly. Heavy metals, corrosive compounds, or potentially dangerous substances like mercury are not used here.

It’s critical to know how airborne viruses migrate if you want to keep them under control. Coughing, sneezing, and talking can all transmit the coronavirus, for example. Invisible to the human eye, sneezes create up to 30,000 droplets. These tiny droplets can move at rates of up to 60 mph.

It’s critical to know how airborne viruses migrate if you want to keep them under control. Coughing, sneezing, and talking can all transmit the coronavirus, for example. Invisible to the human eye, sneezes create up to 30,000 droplets. These tiny droplets can move at rates of up to 60 mph. Airborne viruses are rendered inactive by these ionizers’ proactive purifying methods. Millions of positive and negative oxygen ions are generated by these bipolar ionization devices. They inactivate viral cells by removing hydrogen molecules from them when discharged into the air transportation system.

Airborne viruses are rendered inactive by these ionizers’ proactive purifying methods. Millions of positive and negative oxygen ions are generated by these bipolar ionization devices. They inactivate viral cells by removing hydrogen molecules from them when discharged into the air transportation system. It is theoretically possible that bipolar ionization can remove viruses from the air and reduce the amount of virus-infected droplets and particles in the air.

It is theoretically possible that bipolar ionization can remove viruses from the air and reduce the amount of virus-infected droplets and particles in the air.

The significance of indoor air quality has been highlighted over the last two years, and GPS is pleased to be partnering with outstanding groups like Roof Above in our hometown of Charlotte to address this vital problem and need.

The significance of indoor air quality has been highlighted over the last two years, and GPS is pleased to be partnering with outstanding groups like Roof Above in our hometown of Charlotte to address this vital problem and need. In order to produce better indoor air, GPS has developed patented needlepoint bipolar ionization technology (NPBI TM), which does so without emitting dangerous amounts of ozone or other byproducts. Gps needlepoint bipolar ionization products meet or exceed all applicable UL and CE requirements. GPS products enhance air quality by eliminating airborne particles, such as some smells, viruses, and germs, via the use of NPBI technology. Today,

In order to produce better indoor air, GPS has developed patented needlepoint bipolar ionization technology (NPBI TM), which does so without emitting dangerous amounts of ozone or other byproducts. Gps needlepoint bipolar ionization products meet or exceed all applicable UL and CE requirements. GPS products enhance air quality by eliminating airborne particles, such as some smells, viruses, and germs, via the use of NPBI technology. Today,  Its NEEDLEPOINT BIPOLAR IONIZATION (NPBI) technology, commonly known as NPBI, has been the subject of more than 30 patents and more than 150,000 installations globally, making Global

Its NEEDLEPOINT BIPOLAR IONIZATION (NPBI) technology, commonly known as NPBI, has been the subject of more than 30 patents and more than 150,000 installations globally, making Global

Because HVAC equipment is so durable, parts may not be the first thing to mind. If you could avoid taking anything for granted, you would be better off. HVAC system maintenance should be performed regularly. Some parts may need replacing due to normal wear and tear.

Because HVAC equipment is so durable, parts may not be the first thing to mind. If you could avoid taking anything for granted, you would be better off. HVAC system maintenance should be performed regularly. Some parts may need replacing due to normal wear and tear. Throughout its lifetime, the HVAC system is bound to malfunction. Many parts of the equipment can be replaced to restore the system to its original state. It’s not surprising that the HVAC unit needs to be replaced because it’s designed to withstand the harsh conditions found in commercial and industrial buildings.

Throughout its lifetime, the HVAC system is bound to malfunction. Many parts of the equipment can be replaced to restore the system to its original state. It’s not surprising that the HVAC unit needs to be replaced because it’s designed to withstand the harsh conditions found in commercial and industrial buildings.

This

This  Needlepoint bipolar ionization is a technique that generates positively and negatively charged particles in HVAC systems and portable air cleaners. Manufacturers of these sorts of devices may sell this technology to assist in eliminating viruses from the air, such as SARS-2-CoV, the virus that causes COVID-19, or allow surface disinfection of surfaces within a treated area, provided they have evidence to indicate efficacy. This is a new technique, and a minimal study examines it outside of the lab.

Needlepoint bipolar ionization is a technique that generates positively and negatively charged particles in HVAC systems and portable air cleaners. Manufacturers of these sorts of devices may sell this technology to assist in eliminating viruses from the air, such as SARS-2-CoV, the virus that causes COVID-19, or allow surface disinfection of surfaces within a treated area, provided they have evidence to indicate efficacy. This is a new technique, and a minimal study examines it outside of the lab. The most popular method for capturing airborne SARS-CoV-2 is filtration, which scientists and regulatory organizations usually approve. Cleaning indoor air should be at the forefront of all mitigation methods to prevent the virus from spreading because COVID-19 is a respiratory illness – but it isn’t. So when the CDC recently announced instructions on keeping facilities open safely, which included social distance, wearing masks, hand washing, surface cleaning, and contact tracing, it took it off the priority list.

The most popular method for capturing airborne SARS-CoV-2 is filtration, which scientists and regulatory organizations usually approve. Cleaning indoor air should be at the forefront of all mitigation methods to prevent the virus from spreading because COVID-19 is a respiratory illness – but it isn’t. So when the CDC recently announced instructions on keeping facilities open safely, which included social distance, wearing masks, hand washing, surface cleaning, and contact tracing, it took it off the priority list.

Choose from a wide range of energy, acoustic, and mechanical combinations to meet your specific application requirements and preferences.

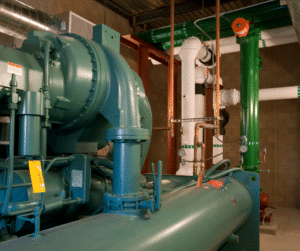

Choose from a wide range of energy, acoustic, and mechanical combinations to meet your specific application requirements and preferences. The York YLAA chiller parts have been tested and proven reliable in reducing the frequency of service calls. Scroll compressors have been in operation for tens of thousands of hours in a wide range of industries.

The York YLAA chiller parts have been tested and proven reliable in reducing the frequency of service calls. Scroll compressors have been in operation for tens of thousands of hours in a wide range of industries.

equipment by using replacement components for maintenance, repairs, and other servicing requirements.

equipment by using replacement components for maintenance, repairs, and other servicing requirements. Yes! Elements matching the unit make sense for seamless integration of parts. If you buy generic components, you’ll never know for sure whether or not they’ll fit your vehicle. As a result, you’ve lost both time and money if the parts don’t work together correctly.

Yes! Elements matching the unit make sense for seamless integration of parts. If you buy generic components, you’ll never know for sure whether or not they’ll fit your vehicle. As a result, you’ve lost both time and money if the parts don’t work together correctly. Managing temperature control systems necessitates regular replacing parts, making it challenging. Access to spare details is essential when working with machinery in a commercial or industrial structure that will see a lot of use. When it comes to York parts, we are an excellent decision to offer the most acceptable value, service, and selection; you can rest assured that you’ll get the best.

Managing temperature control systems necessitates regular replacing parts, making it challenging. Access to spare details is essential when working with machinery in a commercial or industrial structure that will see a lot of use. When it comes to York parts, we are an excellent decision to offer the most acceptable value, service, and selection; you can rest assured that you’ll get the best.

Your chiller’s

Your chiller’s  Commercial and industrial settings are important markets for the chillers made by the York company in the US. The component used to boost the chiller’s performance is the York VSD coolant. Clean and purified air is in high demand.

Commercial and industrial settings are important markets for the chillers made by the York company in the US. The component used to boost the chiller’s performance is the York VSD coolant. Clean and purified air is in high demand. Coolers are also used in a wide range of locations, including hospitals and restaurants and hotels and schools, and manufacturing plants; they are used to maintain clean and comfortable air standards. Aside from that, coolers impact operating costs while also being extremely eco-friendly.

Coolers are also used in a wide range of locations, including hospitals and restaurants and hotels and schools, and manufacturing plants; they are used to maintain clean and comfortable air standards. Aside from that, coolers impact operating costs while also being extremely eco-friendly.

Even if you’re using a different model of the York HVAC system, we have access to the most current stock. Since we have access to many facilities, we may acquire parts. There is a high need for details for chillers, air conditioners, and VRF systems.

Even if you’re using a different model of the York HVAC system, we have access to the most current stock. Since we have access to many facilities, we may acquire parts. There is a high need for details for chillers, air conditioners, and VRF systems. We offer only the highest-quality parts to keep your air conditioning system in top working order and help it last as long as possible with minimal maintenance.

We offer only the highest-quality parts to keep your air conditioning system in top working order and help it last as long as possible with minimal maintenance. To ensure that commercial and industrial chillers run as efficiently as possible, we use only high-quality, original equipment manufacturer (OEM) parts.

To ensure that commercial and industrial chillers run as efficiently as possible, we use only high-quality, original equipment manufacturer (OEM) parts.

Existing York chilling machines can use York replacement parts are no substitutes for the parts that York uses in its chillers because of the company’s standards. When a component is replaced with a similar item, it may result in a decrease in performance.

Existing York chilling machines can use York replacement parts are no substitutes for the parts that York uses in its chillers because of the company’s standards. When a component is replaced with a similar item, it may result in a decrease in performance. It is critical to select the appropriate components. Every replacement part must meet its standards. Filling some spare details with identical items may appear possible, but this could lead to subpar performance. York’s catalog contains many products, from significant components to small accessories.

It is critical to select the appropriate components. Every replacement part must meet its standards. Filling some spare details with identical items may appear possible, but this could lead to subpar performance. York’s catalog contains many products, from significant components to small accessories. Whether it’s a school, hospital, skyscraper, or data center, each facility faces its own set of problems. Facilities must be able to deal with various weather conditions, including seasonal and even hourly fluctuations.

Whether it’s a school, hospital, skyscraper, or data center, each facility faces its own set of problems. Facilities must be able to deal with various weather conditions, including seasonal and even hourly fluctuations.