Upgrading Cooling Systems with York Chiller Parts in Louisville

In the vibrant city of Louisville, where scorching summers are the norm, the need for efficient and reliable cooling systems cannot be overstated. For commercial and industrial establishments in this bustling Kentucky metropolis, ensuring that cooling systems are up to the task is essential. One of the most effective ways to achieve this is by upgrading cooling systems with York Chiller Parts in Louisville. York, a trusted name in the HVAC industry, offers a range of high-quality Chiller Parts that are engineered to enhance the performance and efficiency of HVAC systems.

This article explores the benefits and strategies of upgrading cooling systems with York Chiller Parts in Louisville. If you’re ready to take your HVAC systems to the next level, you can reach out to York at their toll-free number: 1-800-368-8385, a service dedicated exclusively to the needs of commercial and industrial clients.

The Louisville Cooling Challenge

Louisville experiences hot and humid summers, making efficient cooling systems a necessity. Commercial and industrial facilities in the city rely heavily on HVAC systems to maintain comfortable indoor environments for employees, customers, and equipment. However, as these systems age, they may become less efficient, leading to higher energy consumption, increased operational costs, and reduced comfort levels.

The Solution: Upgrading with York Chiller Parts in Louisville

York Chiller Parts in Louisville offer a viable solution to the cooling challenge. These parts are designed to enhance the efficiency and reliability of HVAC systems, ultimately leading to improved comfort, reduced energy costs, and longer system lifespans. Let’s explore how upgrading cooling systems with York Chiller Parts can benefit your Louisville-based business:

1. Improved Energy Efficiency

Older HVAC systems can be energy hogs, especially during peak summer months. Upgrading with York Chiller Parts, which include energy-efficient compressors, motors, and control systems, can lead to significant energy savings. These parts are designed to maximize cooling efficiency while minimizing energy consumption, resulting in lower utility bills and a reduced carbon footprint.

2. Enhanced Performance

York Chiller Parts are engineered to deliver consistent and reliable cooling performance. By replacing outdated or worn-out components with York’s precision-engineered parts, you can maintain optimal temperature control, humidity levels, and air quality, ensuring a comfortable and productive indoor environment.

3. Reduced Maintenance Costs

Aging HVAC systems often require frequent maintenance and repairs, which can be costly and disruptive. Upgrading with York Chiller Parts in Louisville can reduce maintenance expenses. These parts are known for their durability and longevity, resulting in fewer breakdowns and lower ongoing maintenance costs.

4. Extended System Lifespan

By enhancing the performance and reliability of your cooling system with York Chiller Parts, you can significantly extend the lifespan of your HVAC equipment. This means a longer return on investment and reduced capital expenditures for system replacements.

5. Environmental Benefits

Efficiency improvements achieved through the use of York Chiller Parts contribute to environmental sustainability. Reduced energy consumption leads to lower greenhouse gas emissions, aligning your business with green initiatives and regulatory requirements.

Strategies for Upgrading with York Chiller Parts in Louisville

When considering an upgrade to your cooling system with York Chiller Parts in Louisville, it’s essential to follow a strategic approach:

1. System Assessment: Begin by assessing your existing HVAC system’s performance and identifying areas that require improvement. Consider factors such as energy consumption, maintenance history, and comfort levels.

2. Component Selection: Work with HVAC professionals to select the right York Chiller Parts for your specific needs. This may include upgrading compressors, condensers, evaporators, control systems, or other critical components.

3. Professional Installation: Ensure that the selected Chiller Parts are installed by experienced technicians who are familiar with York’s equipment. Proper installation is crucial to achieving the desired performance improvements.

4. Regular Maintenance: Once the upgrade is complete, continue to invest in regular maintenance to keep the system operating at its best. York Chiller Parts are designed for longevity, but ongoing care is essential.

5. Energy Monitoring: Implement energy monitoring and management tools to track the system’s performance and energy consumption. This data can help you optimize HVAC operations further.

6. Consider Renewable Energy: In alignment with Louisville’s commitment to sustainability, explore opportunities to integrate renewable energy sources, such as solar panels, with your upgraded HVAC system to further reduce energy costs.

In the dynamic city of Louisville, where summers can be unforgiving, having efficient and reliable cooling systems is paramount. Upgrading your HVAC systems with York Chiller Parts in Louisville is a strategic move that pays off in numerous ways—lower energy bills, improved comfort, reduced maintenance costs, and a longer system lifespan. To embark on this journey of enhanced cooling efficiency, contact York at 1-800-368-8385.

York is your trusted partner in Louisville, providing premium HVAC solutions, Chiller Parts, rental services, and repair solutions that cater specifically to the needs of commercial and industrial clients. Elevate your cooling systems with York Chiller Parts and ensure your Louisville-based business thrives in comfort and efficiency.

Exploring York Chiller Parts in Louisville for your HVAC Solution

Louisville, Kentucky, a city known for its rich history and vibrant culture, also experiences its fair share of hot and humid summers. In this thriving metropolis, commercial and industrial facilities rely on efficient HVAC systems to provide comfort and maintain productivity. Ensuring that these systems operate at peak performance is vital. Enter York Chiller Parts in Louisville – the solution to your HVAC needs.

York, a trusted name in the HVAC industry, offers a range of top-quality Chiller Parts designed to enhance the efficiency and reliability of your HVAC systems. This article delves into the world of York Chiller Parts in Louisville, highlighting their benefits and how they can serve as the ultimate HVAC solution for your commercial or industrial needs. For expert guidance and access to York’s premium HVAC services, including Chiller Parts, rental solutions, and repair services, simply dial their toll-free number: 1-800-368-8385.

The Louisville HVAC Challenge

Louisville’s climate presents a unique HVAC challenge. With hot and humid summers, commercial and industrial establishments must contend with increased cooling demands. A well-functioning HVAC system isn’t just about comfort; it’s essential for maintaining productivity, preserving equipment, and creating a conducive indoor environment.

The Power of York Chiller Parts in Louisville

York Chiller Parts in Louisville offer a compelling solution to these HVAC challenges. These parts are designed to optimize your cooling systems, ensuring efficient operation, lower energy costs, and extended equipment lifespans. Here’s why York Chiller Parts should be your choice for HVAC solutions in Louisville:

1. Energy Efficiency: One of the primary benefits of York Chiller Parts is their ability to improve energy efficiency. Outdated HVAC systems can be energy hogs, especially during the hot Louisville summers. York’s Chiller Parts, including energy-efficient compressors, motors, and control systems, are designed to maximize cooling efficiency while minimizing energy consumption. This results in lower utility bills and a reduced environmental impact.

2. Enhanced Performance: York Chiller Parts are engineered to provide consistent and reliable cooling performance. By replacing old or worn-out components with York’s precision-engineered parts, you can maintain optimal temperature control, humidity levels, and air quality. This ensures a comfortable and productive indoor environment for employees, customers, and equipment.

3. Cost Savings: Outdated HVAC systems often require frequent maintenance and repairs, which can be expensive and disruptive. Upgrading with York Chiller Parts can reduce maintenance expenses. These parts are known for their durability and longevity, resulting in fewer breakdowns and lower ongoing maintenance costs.

4. Longer Lifespan: By enhancing the performance and reliability of your cooling system with York Chiller Parts, you can significantly extend the lifespan of your HVAC equipment. This means a longer return on investment and reduced capital expenditures for system replacements.

5. Environmental Benefits: Efficiency improvements achieved through the use of York Chiller Parts contribute to environmental sustainability. Reduced energy consumption leads to lower greenhouse gas emissions, aligning your business with green initiatives and regulatory requirements.

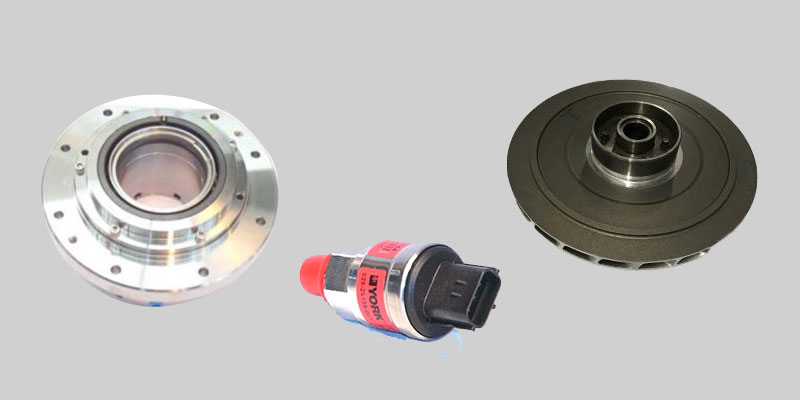

6. Tailored Solutions: York offers a wide range of Chiller Parts to suit your specific HVAC needs. Whether you need compressors, condensers, evaporators, or control systems, York has you covered. Their tailored solutions ensure that you get the right parts for your particular system.

7. Expert Support: York is not just a provider of Chiller Parts; they are a trusted partner in HVAC solutions. Their team of experts can guide you through the process of selecting and installing the right Chiller Parts for your Louisville-based business.

Exploring Upgrade Strategies with York Chiller Parts in Louisville

When considering an upgrade to your HVAC system with York Chiller Parts in Louisville, it’s essential to follow a strategic approach:

1. System Assessment: Begin by conducting a thorough assessment of your existing HVAC system’s performance. Identify areas that require improvement, such as energy consumption, maintenance history, and comfort levels.

2. Component Selection: Work closely with HVAC professionals to select the appropriate York Chiller Parts for your specific needs. This may involve upgrading compressors, condensers, evaporators, control systems, or other vital components.

3. Professional Installation: Ensure that the selected Chiller Parts are installed by experienced technicians familiar with York’s equipment. Proper installation is crucial to achieving the desired performance improvements.

4. Regular Maintenance: After the upgrade is complete, continue to invest in regular maintenance to keep the system operating at its best. York Chiller Parts are designed for longevity, but ongoing care is essential to maximizing their benefits.

5. Energy Monitoring: Implement energy monitoring and management tools to track the system’s performance and energy consumption continually. This data can help you optimize HVAC operations further.

In Louisville, where summers can be sweltering, having efficient and reliable HVAC systems is not a luxury—it’s a necessity. Upgrading your HVAC systems with York Chiller Parts in Louisville is a strategic move that pays off in numerous ways—lower energy bills, improved comfort, reduced maintenance costs, and a longer system lifespan.

To embark on this journey of enhanced cooling efficiency, contact York at 1-800-368-8385. York is your trusted partner in Louisville, providing premium HVAC solutions, Chiller Parts, rental services, and repair solutions tailored to the needs of commercial and industrial clients. Elevate your HVAC systems with York Chiller Parts and ensure that your Louisville-based business thrives in comfort and efficiency.

Maximizing Efficiency with York Chiller Parts in Louisville

Louisville, Kentucky, known for its lively culture and humid summers, relies heavily on efficient HVAC systems to combat the heat. For commercial and industrial facilities in Louisville, ensuring that cooling systems operate efficiently is not just a luxury; it’s a necessity. York Chiller Parts in Louisville offer a powerful solution to enhance HVAC efficiency and maintain comfortable indoor environments.

York, a trusted name in the HVAC industry, provides a range of high-quality Chiller Parts engineered to optimize performance and reduce energy consumption. This article delves into the world of York Chiller Parts in Louisville, emphasizing their role in maximizing HVAC efficiency. If you’re ready to elevate your cooling systems, contact York at their toll-free number: 1-800-368-8385. This service is dedicated exclusively to the needs of commercial and industrial clients.

The Louisville Challenge: Efficient Cooling

Louisville’s hot and humid climate presents a unique challenge for commercial and industrial HVAC systems. Cooling systems must not only maintain comfort but also operate efficiently to avoid soaring energy bills and reduce their environmental footprint. This challenge underscores the importance of optimizing HVAC efficiency.

The Power of York Chiller Parts in Louisville

York Chiller Parts in Louisville offer a compelling solution to the efficiency challenge. These parts are engineered to enhance the performance and reliability of HVAC systems, resulting in numerous benefits, including lower energy consumption and operational costs. Here’s how upgrading with York Chiller Parts can help you maximize HVAC efficiency in Louisville:

1. Energy Efficiency: One of the primary benefits of York Chiller Parts is their ability to improve energy efficiency. Older HVAC systems can be energy-intensive, particularly during hot summer months. York’s Chiller Parts, including energy-efficient compressors, motors, and control systems, are designed to maximize cooling efficiency while minimizing energy consumption. This results in lower utility bills and a reduced environmental impact.

2. Consistent Cooling Performance: York Chiller Parts are engineered to provide consistent and reliable cooling performance. By replacing outdated or worn-out components with York’s precision-engineered parts, you can maintain optimal temperature control, humidity levels, and air quality. This ensures a comfortable and productive indoor environment, irrespective of external weather conditions.

3. Lower Maintenance Costs: Older HVAC systems often require frequent maintenance and repairs, which can be costly and disruptive. Upgrading with York Chiller Parts can reduce maintenance expenses. These parts are known for their durability and longevity, resulting in fewer breakdowns and lower ongoing maintenance costs.

4. Extended System Lifespan: By enhancing the performance and reliability of your cooling system with York Chiller Parts, you can significantly extend the lifespan of your HVAC equipment. This means a longer return on investment and reduced capital expenditures for system replacements.

5. Environmental Benefits: Efficiency improvements achieved through the use of York Chiller Parts contribute to environmental sustainability. Reduced energy consumption leads to lower greenhouse gas emissions, aligning your business with green initiatives and regulatory requirements.

Exploring Efficiency Upgrade Strategies with York Chiller Parts in Louisville

When considering an upgrade to your HVAC system with York Chiller Parts in Louisville, it’s essential to follow a strategic approach:

1. System Assessment: Begin by conducting a comprehensive assessment of your existing HVAC system’s performance. Identify areas that require improvement, such as energy consumption, maintenance history, and comfort levels.

2. Component Selection: Collaborate with HVAC professionals to select the appropriate York Chiller Parts for your specific needs. This may involve upgrading compressors, condensers, evaporators, control systems, or other critical components.

3. Professional Installation: Ensure that the selected Chiller Parts are installed by experienced technicians who are familiar with York’s equipment. Proper installation is crucial to achieving the desired performance improvements.

4. Regular Maintenance: After the upgrade is complete, continue to invest in regular maintenance to keep the system operating at its best. York Chiller Parts are designed for longevity, but ongoing care is essential to maximizing their benefits.

5. Energy Monitoring: Implement energy monitoring and management tools to continually track the system’s performance and energy consumption. This data can help you optimize HVAC operations further.

In Louisville, where the summers can be relentless, having efficient and reliable HVAC systems is crucial. Upgrading your HVAC systems with York Chiller Parts in Louisville is a strategic move that pays off in numerous ways—lower energy bills, improved comfort, reduced maintenance costs, and a longer system lifespan. To embark on this journey of enhanced cooling efficiency, contact York at 1-800-368-8385. York is your trusted partner in Louisville, providing premium HVAC solutions, Chiller Parts, rental services, and repair solutions tailored to the needs of commercial and industrial clients. Elevate your HVAC efficiency with York Chiller Parts and ensure that your Louisville-based business thrives in comfort and cost savings.

Enhancing HVAC Performance with York Chiller Parts in Louisville

Louisville, Kentucky, a city known for its warm hospitality and vibrant culture, also faces sweltering summers that put a premium on effective cooling systems. For the commercial and industrial sectors in Louisville, ensuring peak HVAC system performance is not just a matter of comfort—it’s vital for productivity and cost-efficiency. York Chiller Parts in Louisville offer a powerful solution to elevate your HVAC performance.

As a trusted name in the HVAC industry, York provides a range of high-quality Chiller Parts designed to optimize performance and reliability. This article delves into the world of York Chiller Parts in Louisville, emphasizing their role in enhancing HVAC performance. If you’re ready to take your HVAC systems to the next level, contact York at their toll-free number: 1-800-368-8385, exclusively serving commercial and industrial clients.

The HVAC Challenge in Louisville

Louisville’s climate poses a unique challenge for HVAC systems. The hot and humid summers require cooling systems that not only maintain comfort but also operate efficiently to keep energy costs in check. The reliability and performance of HVAC systems are critical for businesses, ensuring that employees, customers, and equipment remain comfortable and productive.

The Power of York Chiller Parts in Louisville

York Chiller Parts in Louisville offer a compelling solution to the HVAC performance challenge. These parts are designed to optimize the efficiency and reliability of HVAC systems, resulting in numerous benefits, including lower energy consumption and operational costs. Here’s how York Chiller Parts can enhance HVAC performance in Louisville:

1. Energy Efficiency: One of the primary advantages of York Chiller Parts is their ability to improve energy efficiency. Older HVAC systems can be energy hogs, especially during the hot Louisville summers. York’s Chiller Parts, which include energy-efficient compressors, motors, and control systems, are engineered to maximize cooling efficiency while minimizing energy consumption. This results in lower utility bills and a reduced environmental footprint.

2. Consistent Cooling Performance: York Chiller Parts are designed to provide consistent and reliable cooling performance. By replacing outdated or worn-out components with York’s precision-engineered parts, you can maintain optimal temperature control, humidity levels, and air quality. This ensures a comfortable and productive indoor environment, regardless of external weather conditions.

3. Reduced Maintenance Costs: Older HVAC systems often require frequent maintenance and repairs, which can be costly and disruptive. Upgrading with York Chiller Parts can reduce maintenance expenses. These parts are known for their durability and longevity, resulting in fewer breakdowns and lower ongoing maintenance costs.

4. Extended System Lifespan: By enhancing the performance and reliability of your cooling system with York Chiller Parts, you can significantly extend the lifespan of your HVAC equipment. This means a longer return on investment and reduced capital expenditures for system replacements.

5. Environmental Benefits: Efficiency improvements achieved through the use of York Chiller Parts contribute to environmental sustainability. Reduced energy consumption leads to lower greenhouse gas emissions, aligning your business with green initiatives and regulatory requirements.

Exploring Performance Enhancement Strategies with York Chiller Parts in Louisville

When considering an upgrade to your HVAC system with York Chiller Parts in Louisville, it’s essential to follow a strategic approach:

1. System Assessment: Begin by conducting a comprehensive assessment of your existing HVAC system’s performance. Identify areas that require improvement, such as energy consumption, maintenance history, and comfort levels.

2. Component Selection: Collaborate with HVAC professionals to select the appropriate York Chiller Parts for your specific needs. This may involve upgrading compressors, condensers, evaporators, control systems, or other vital components.

3. Professional Installation: Ensure that the selected Chiller Parts are installed by experienced technicians who are familiar with York’s equipment. Proper installation is crucial to achieving the desired performance improvements.

4. Regular Maintenance: After the upgrade is complete, continue to invest in regular maintenance to keep the system operating at its best. York Chiller Parts are designed for longevity, but ongoing care is essential to maximizing their benefits.

5. Energy Monitoring: Implement energy monitoring and management tools to continually track the system’s performance and energy consumption. This data can help you optimize HVAC operations further.

In Louisville, where the summers can be sweltering, having efficient and reliable HVAC systems is not just a luxury; it’s a necessity. Upgrading your HVAC systems with York Chiller Parts in Louisville is a strategic move that pays off in numerous ways—lower energy bills, improved comfort, reduced maintenance costs, and a longer system lifespan. To embark on this journey of enhanced cooling efficiency, contact York at 1-800-368-8385. York is your trusted partner in Louisville, providing premium HVAC solutions, Chiller Parts, rental services, and repair solutions tailored to the needs of commercial and industrial clients. Elevate your HVAC performance with York Chiller Parts and ensure that your Louisville-based business thrives in comfort and cost savings.

function at peak efficiency. Thus, it is highly recommended that you rely on York components and services for effective maintenance and repair. Those dependent on York components should educate themselves about the many types of York components and their purposes, functions, and distinguishing features.

function at peak efficiency. Thus, it is highly recommended that you rely on York components and services for effective maintenance and repair. Those dependent on York components should educate themselves about the many types of York components and their purposes, functions, and distinguishing features. For a dependable HVAC system, you need York components. All of the above devices are compatible with

For a dependable HVAC system, you need York components. All of the above devices are compatible with  It is crucial to have ready access to high-quality supplies that meet the facility management’s demands in the event chiller equipment malfunctions or breaks down.

It is crucial to have ready access to high-quality supplies that meet the facility management’s demands in the event chiller equipment malfunctions or breaks down.

YORK Controls has the widest selection of water and air-cooled industrial and commercial chillers. Our smaller, more energy-efficient chillers, including heating, can be adapted for nearly any comfort or process chilling application to reduce your facility’s carbon footprint, provide a healthier indoor environment, and save energy costs.

YORK Controls has the widest selection of water and air-cooled industrial and commercial chillers. Our smaller, more energy-efficient chillers, including heating, can be adapted for nearly any comfort or process chilling application to reduce your facility’s carbon footprint, provide a healthier indoor environment, and save energy costs. The YVAA chiller is controlled by Variable Speed Drive (VSD) technology, a highly recommended product family component. This air-cooled chiller has a stellar reputation in the commercial air conditioning industry for its reliability and effectiveness. The YVAA chiller efficiently cools the building while reducing operational expenses.

The YVAA chiller is controlled by Variable Speed Drive (VSD) technology, a highly recommended product family component. This air-cooled chiller has a stellar reputation in the commercial air conditioning industry for its reliability and effectiveness. The YVAA chiller efficiently cools the building while reducing operational expenses. People living and working in substandard conditions are more likely to experience irritation and agitation. In turn, the structure itself will suffer. Consequently, if your AC or furnace has started acting funny, you should look into getting some replacement York components. The York name is synonymous with quality and excellence in every aspect.

People living and working in substandard conditions are more likely to experience irritation and agitation. In turn, the structure itself will suffer. Consequently, if your AC or furnace has started acting funny, you should look into getting some replacement York components. The York name is synonymous with quality and excellence in every aspect.

equipment by using replacement components for maintenance, repairs, and other servicing requirements.

equipment by using replacement components for maintenance, repairs, and other servicing requirements. Yes! Elements matching the unit make sense for seamless integration of parts. If you buy generic components, you’ll never know for sure whether or not they’ll fit your vehicle. As a result, you’ve lost both time and money if the parts don’t work together correctly.

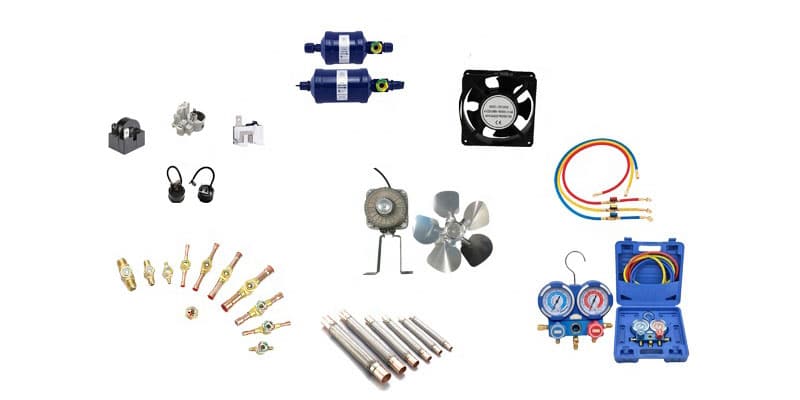

Yes! Elements matching the unit make sense for seamless integration of parts. If you buy generic components, you’ll never know for sure whether or not they’ll fit your vehicle. As a result, you’ve lost both time and money if the parts don’t work together correctly. Managing temperature control systems necessitates regular replacing parts, making it challenging. Access to spare details is essential when working with machinery in a commercial or industrial structure that will see a lot of use. When it comes to York parts, we are an excellent decision to offer the most acceptable value, service, and selection; you can rest assured that you’ll get the best.

Managing temperature control systems necessitates regular replacing parts, making it challenging. Access to spare details is essential when working with machinery in a commercial or industrial structure that will see a lot of use. When it comes to York parts, we are an excellent decision to offer the most acceptable value, service, and selection; you can rest assured that you’ll get the best.

Commercial chillers require

Commercial chillers require  A chiller works by removing heat from the exchange to create cool air. The process is long and complicated. Furthermore, many moving parts play an active role in pushing the exchange process. When a component is faulty or broken, standard techniques stress out air-conditioning units. As a result, chiller systems demand more energy to operate.

A chiller works by removing heat from the exchange to create cool air. The process is long and complicated. Furthermore, many moving parts play an active role in pushing the exchange process. When a component is faulty or broken, standard techniques stress out air-conditioning units. As a result, chiller systems demand more energy to operate. Parts also fill repair requirements when replacement is not required. Small repairs make a big difference to air-conditioning systems with various components. Technicians use equipment from repair kits to perform minor fixes. Of course, when a repair is not an option, replacement is the only other alternative. Replacing parts, however, costs less than replacing an entire system. Facilities plan to get years of usage out of air-conditioning systems.

Parts also fill repair requirements when replacement is not required. Small repairs make a big difference to air-conditioning systems with various components. Technicians use equipment from repair kits to perform minor fixes. Of course, when a repair is not an option, replacement is the only other alternative. Replacing parts, however, costs less than replacing an entire system. Facilities plan to get years of usage out of air-conditioning systems.