Key Considerations for HVAC Professionals

As an HVAC professional, ensuring the efficient and smooth operation of heating, ventilation, and air conditioning systems is of utmost importance. When it comes to repairs and maintenance, having access to high-quality replacement parts is crucial. York, a renowned name in the HVAC industry, offers a wide range of replacement parts to support HVAC professionals in their service endeavors. In this article, we explore the key considerations for HVAC professionals when seeking a reliable York replacement parts supplier.

1. Genuine and Authentic Parts

The first and foremost consideration for HVAC professionals is to source genuine and authentic York replacement parts. Authentic parts not only ensure compatibility with the specific HVAC system but also guarantee optimal performance and longevity. A reliable York replacement parts supplier should be an authorized dealer of genuine York components, offering peace of mind to HVAC professionals and their clients.

2. Comprehensive Inventory

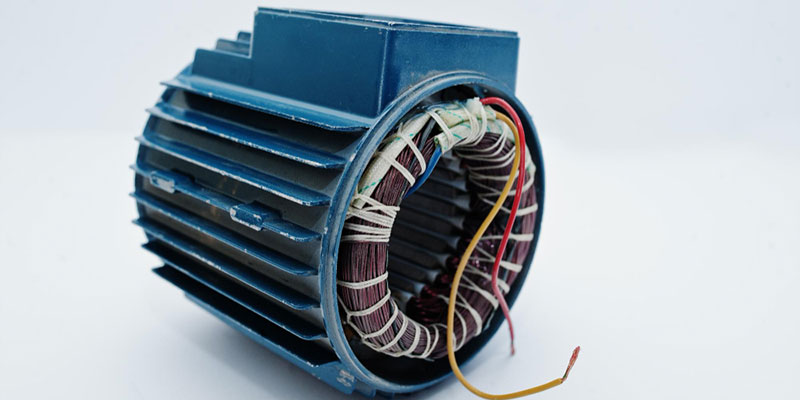

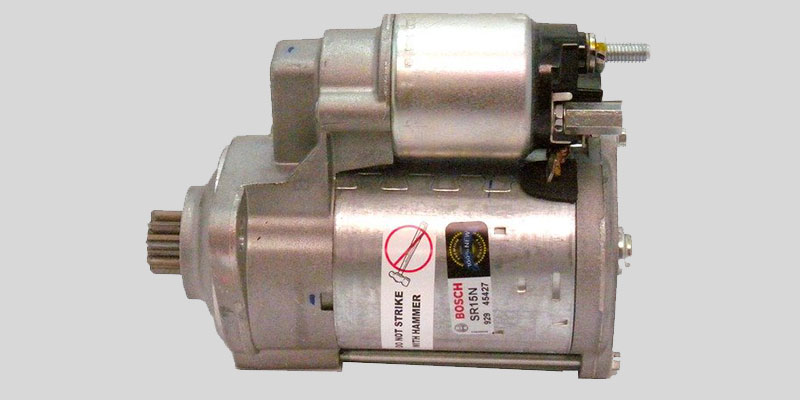

A reputable York replacement parts supplier should have a comprehensive inventory of various components to cater to the diverse needs of HVAC professionals. Whether it’s filters, compressors, motors, belts, or electronic control boards, having access to a wide range of parts under one roof simplifies the procurement process and saves valuable time.

3. Availability and Timely Delivery

HVAC systems may encounter unexpected breakdowns, and prompt access to replacement parts is crucial to minimize downtime for clients. A reliable York replacement parts supplier should have a well-established distribution network to ensure timely delivery of parts when needed. Timely availability of parts allows HVAC professionals to execute repairs efficiently and meet client expectations.

4. Technical Expertise and Support

HVAC professionals may require technical guidance or support when selecting the right replacement parts for specific systems. A dependable York replacement parts supplier should have a knowledgeable and experienced team capable of providing technical assistance. Having access to expert advice can help HVAC professionals make informed decisions and carry out repairs accurately.

5. Quality Assurance and Warranty

Quality assurance is paramount when it comes to replacement parts. A reputable York supplier should guarantee the quality and performance of their components. Furthermore, offering warranty coverage on replacement parts adds an extra layer of assurance for HVAC professionals and their clients.

6. Competitive Pricing

While quality is essential, competitive pricing also matters to HVAC professionals looking to maintain profitability. A reliable York replacement parts supplier should offer competitive pricing without compromising on the authenticity and quality of their components.

7. Customer Reviews and Reputation

Before partnering with a York replacement parts supplier, HVAC professionals should research customer reviews and assess the supplier’s reputation in the industry. Positive reviews and a solid reputation indicate reliability and customer satisfaction.

Conclusion

For HVAC professionals, finding a reliable York replacement parts supplier is crucial to ensure the efficiency and reliability of their services. Genuine and authentic parts, a comprehensive inventory, timely delivery, technical expertise, quality assurance, competitive pricing, and a reputable reputation are key considerations when selecting the right supplier. By partnering with a trusted York replacement parts supplier, HVAC professionals can enhance their capabilities, offer top-notch services to clients, and maintain the optimal performance of HVAC systems for years to come.

Ensuring Timely and Quality Solutions for Your HVAC Needs

In the HVAC industry, ensuring the smooth operation of heating, ventilation, and air conditioning systems is essential for the comfort and productivity of occupants. Regular maintenance and occasional repairs are inevitable, and having access to high-quality replacement parts is critical for HVAC professionals. York, a trusted name in the HVAC industry, offers a wide range of replacement parts through authorized suppliers. In this article, we explore the importance of partnering with a York replacement parts supplier to ensure timely and quality solutions for your HVAC needs.

1. Genuine York Replacement Parts

One of the primary advantages of choosing a York replacement parts supplier is the assurance of receiving genuine components. Authentic York replacement parts are specifically designed and manufactured to meet the highest quality standards set by the brand. These parts are engineered to fit seamlessly with York HVAC systems, ensuring optimal performance and reliability.

2. Compatibility and Performance

York replacement parts are developed to be compatible with the brand’s HVAC systems, eliminating the risk of using subpar or ill-fitting components. By sourcing replacement parts from an authorized York supplier, HVAC professionals can have confidence in the performance and longevity of the repaired systems.

3. Comprehensive Inventory

York replacement parts suppliers typically maintain a comprehensive inventory of components, ranging from filters, compressors, motors, valves, thermostats, and more. Having a diverse selection of replacement parts readily available ensures that HVAC professionals can quickly find the components they need, minimizing downtime for their clients.

Ensuring Timely and Quality Solutions for Your HVAC Needs

4. Timely Delivery

HVAC systems may encounter unexpected breakdowns, and prompt access to replacement parts is crucial for efficient repairs. A reliable York replacement parts supplier has a well-established distribution network, enabling them to offer timely delivery to HVAC professionals. Quick access to replacement parts allows HVAC professionals to complete repairs promptly, minimizing inconvenience to building occupants.

5. Expert Technical Support

Navigating the vast array of replacement parts can be challenging, especially when dealing with complex HVAC systems. A trusted York supplier should offer expert technical support to assist HVAC professionals in selecting the right components for specific repair tasks. This guidance ensures accurate replacements and prevents costly mistakes.

6. Quality Assurance and Warranty

Quality assurance is a fundamental aspect of York replacement parts. A reputable supplier will stand by the quality and performance of their components, providing assurance to HVAC professionals and their clients. Additionally, offering warranty coverage on replacement parts further instills confidence in the reliability of the components.

7. Long-Term Partnerships

Establishing a partnership with a York replacement parts supplier fosters a long-term relationship built on trust and reliability. Consistently receiving high-quality replacement parts in a timely manner contributes to the seamless operation of HVAC businesses, allowing them to focus on providing exceptional services to their clients.

Conclusion

Partnering with a York replacement parts supplier is a wise decision for HVAC professionals seeking timely and quality solutions for their repair and maintenance needs. Genuine York replacement parts, compatibility, comprehensive inventory, timely delivery, expert technical support, quality assurance, and long-term partnerships are the key benefits of working with a trusted York supplier. By ensuring timely access to authentic replacement parts, HVAC professionals can offer efficient and reliable services, ultimately enhancing the performance and longevity of HVAC systems for the satisfaction of their clients.

Partnering with a Trusted York Replacement Parts Supplier

In the world of HVAC (heating, ventilation, and air conditioning) systems, the efficient operation and longevity of equipment are crucial factors for the comfort and productivity of building occupants. Regular maintenance and occasional repairs are inevitable to keep HVAC systems in top condition. For HVAC professionals and businesses, partnering with a trusted York replacement parts supplier can significantly enhance the efficiency and longevity of HVAC systems. In this article, we explore the advantages of collaborating with a reputable York replacement parts supplier.

1. Access to Genuine York Replacement Parts

The foundation of a successful partnership with a trusted York replacement parts supplier lies in the assurance of receiving genuine components. Authentic York replacement parts are specifically engineered to meet the brand’s high-quality standards. These components are designed to fit seamlessly with York HVAC systems, ensuring optimal performance and reliability.

2. Compatibility and Performance

Utilizing genuine York replacement parts enhances compatibility with existing HVAC systems. Substituting non-original components can compromise the performance and efficiency of the system. By sourcing replacement parts from a trusted York supplier, HVAC professionals can have confidence in the compatibility and performance of the repaired systems.

3. Extensive Inventory for Quick Solutions

Reputable York replacement parts suppliers maintain an extensive inventory of components, encompassing a wide range of HVAC parts. From filters and compressors to motors and valves, a diverse selection of replacement parts is readily available. Quick access to a comprehensive inventory allows HVAC professionals to swiftly find the components they need, minimizing downtime for their clients.

Partnering with a Trusted York Replacement Parts Supplier

4. Timely Delivery and Prompt Solutions

HVAC systems may experience sudden breakdowns, and swift access to replacement parts is essential for efficient repairs. A trusted York replacement parts supplier boasts a well-organized distribution network, enabling them to offer timely delivery to HVAC professionals. This promptness ensures that HVAC professionals can complete repairs swiftly, minimizing inconvenience to building occupants.

5. Expert Technical Support

Navigating the array of replacement parts can be daunting, especially when dealing with complex HVAC systems. A reliable York supplier should offer expert technical support to assist HVAC professionals in selecting the right components for specific repair tasks. This guidance ensures accurate replacements and avoids costly mistakes.

6. Quality Assurance and Warranty

Reliable York replacement parts suppliers prioritize quality assurance. They stand by the quality and performance of their components, providing assurance to HVAC professionals and their clients. Additionally, offering warranty coverage on replacement parts further instills confidence in the reliability of the components.

7. Long-Term Relationship and Trust

Establishing a partnership with a trusted York replacement parts supplier fosters a long-term relationship built on trust and reliability. Consistently receiving high-quality replacement parts in a timely manner contributes to the seamless operation of HVAC businesses, allowing them to focus on providing exceptional services to their clients.

Conclusion

Partnering with a trusted York replacement parts supplier is a strategic decision for HVAC professionals and businesses seeking to enhance the efficiency and longevity of HVAC systems. Access to genuine York replacement parts, compatibility, extensive inventory, timely delivery, expert technical support, quality assurance, and a long-term relationship based on trust are the key advantages of collaborating with a reputable York supplier. By ensuring timely access to authentic replacement parts, HVAC professionals can deliver efficient and reliable services, ultimately contributing to the optimized performance and extended lifespan of HVAC systems, much to the satisfaction of their clients.

The Role of a York Replacement Parts Supplier in Quick Turnaround

Efficient HVAC (heating, ventilation, and air conditioning) systems are essential for maintaining comfortable and productive environments in various settings. However, like any mechanical system, HVAC units can experience occasional breakdowns or require routine maintenance. When faced with repair needs, time is of the essence to minimize downtime and restore optimal functioning. A reliable York replacement parts supplier plays a crucial role in streamlining HVAC repairs and ensuring a quick turnaround. In this article, we explore how partnering with a trusted York replacement parts supplier expedites the repair process.

1. Comprehensive Inventory at Your Fingertips

A reputable York replacement parts supplier maintains a comprehensive inventory of various HVAC components. This includes filters, compressors, motors, thermostats, valves, and more. Having access to a wide range of replacement parts under one roof allows HVAC professionals to quickly locate the required components for repairs. A comprehensive inventory ensures that the required parts are readily available, saving valuable time and minimizing equipment downtime.

2. Timely Delivery for Urgent Needs

Unexpected breakdowns can disrupt operations and inconvenience occupants. A reliable York replacement parts supplier understands the urgency of repairs and offers timely delivery options. Their efficient distribution network ensures that replacement parts reach HVAC professionals promptly. Timely delivery is critical in expediting the repair process, enabling HVAC professionals to swiftly restore the functionality of HVAC systems.

3. Genuine Parts for Optimal Performance

Utilizing genuine York replacement parts is crucial for the efficient operation of HVAC systems. Authentic components are designed and tested to meet the highest quality standards set by the brand. When HVAC professionals source genuine parts from an authorized supplier, they ensure compatibility and optimal performance. By avoiding subpar or non-original components, HVAC professionals can guarantee that repaired systems will operate efficiently.

The Role of a York Replacement Parts Supplier in Quick Turnaround

4. Technical Support for Informed Decisions

Navigating the complexities of HVAC systems and replacement parts can be challenging. A trusted York replacement parts supplier offers expert technical support to assist HVAC professionals in making informed decisions. Whether it’s selecting the right replacement part or determining the most suitable repair approach, technical guidance enhances the efficiency of repairs.

5. Quality Assurance for Long-Lasting Solutions

A reputable York replacement parts supplier prioritizes quality assurance. They stand by the quality and performance of their components, instilling confidence in HVAC professionals and their clients. Quality assurance ensures that the repaired HVAC systems will operate reliably and have an extended lifespan. It also minimizes the risk of recurrent breakdowns, saving time and resources in the long run.

6. Building Long-Term Partnerships

Establishing a long-term partnership with a trusted York replacement parts supplier is mutually beneficial. Regular collaboration fosters trust and reliability. HVAC professionals can rely on their supplier to deliver genuine components promptly, while the supplier gains loyal customers. A strong partnership streamlines the procurement process, expedites repairs, and contributes to the seamless operation of HVAC businesses.

Conclusion

A trusted York replacement parts supplier plays a pivotal role in streamlining HVAC repairs and ensuring a quick turnaround. With a comprehensive inventory, timely delivery options, genuine parts, expert technical support, and quality assurance, HVAC professionals can expedite the repair process and promptly restore optimal functioning of HVAC systems. By partnering with a reliable York supplier, HVAC professionals can deliver efficient and reliable repair services, minimizing downtime for their clients and contributing to the smooth operation of buildings and facilities.

Maximizing HVAC Performance & Benefits of Choosing the Right York Replacement Parts Supplier

In the HVAC (heating, ventilation, and air conditioning) industry, optimal performance and reliability of systems are paramount to maintaining comfortable and productive environments. Regular maintenance and occasional repairs are essential to ensure HVAC systems operate at their best. Choosing the right York replacement parts supplier is a crucial factor in maximizing the performance of HVAC systems. In this article, we explore the benefits of partnering with the right York replacement parts supplier to achieve superior HVAC performance.

1. Genuine York Replacement Parts

The foundation of selecting the right York replacement parts supplier lies in the assurance of receiving genuine components. Genuine York replacement parts are specifically designed and manufactured to meet the brand’s high-quality standards. These parts are engineered to fit seamlessly with York HVAC systems, ensuring optimal performance and reliability.

2. Enhanced Compatibility and Performance

Using genuine York replacement parts enhances compatibility with existing HVAC systems. Non-original components may not meet the required specifications, leading to compromised performance and efficiency. By sourcing replacement parts from an authorized York supplier, HVAC professionals can have confidence in the compatibility and performance of the repaired systems.

3. Comprehensive Inventory for Convenience

A reputable York replacement parts supplier maintains a comprehensive inventory of components, ranging from filters and compressors to motors and valves. Having access to a diverse selection of replacement parts under one roof simplifies the procurement process for HVAC professionals. Quick access to necessary components saves time and effort, allowing for efficient repairs and maintenance.

4. Timely Delivery and Swift Solutions

HVAC systems may encounter unexpected breakdowns that demand prompt attention. A trusted York replacement parts supplier understands the urgency of repairs and offers timely delivery options. With an efficient distribution network, replacement parts reach HVAC professionals swiftly, minimizing downtime for clients and restoring optimal functioning.

5. Expert Technical Support

HVAC systems can be complex, and selecting the right replacement parts can be challenging. A reliable York supplier should offer expert technical support to assist HVAC professionals in making informed decisions. Technical guidance ensures accurate replacements and helps avoid costly errors during repairs, ultimately contributing to enhanced system performance.

6. Quality Assurance for Longevity

A reputable York replacement parts supplier prioritizes quality assurance. They stand by the quality and performance of their components, providing peace of mind to HVAC professionals and their clients. Utilizing high-quality replacement parts ensures that HVAC systems operate reliably, have an extended lifespan, and experience fewer breakdowns.

7. Building Lasting Partnerships

Partnering with the right York replacement parts supplier fosters a long-term relationship built on trust and reliability. Consistently receiving genuine components in a timely manner contributes to the seamless operation of HVAC businesses. Long-lasting partnerships streamline the procurement process, facilitate efficient repairs, and contribute to the success of HVAC professionals.

Conclusion

Choosing the right York replacement parts supplier is vital for maximizing HVAC performance and ensuring the reliable operation of systems. Genuine components, enhanced compatibility, a comprehensive inventory, timely delivery options, expert technical support, quality assurance, and lasting partnerships are the key benefits of collaborating with the right York supplier.

By sourcing genuine York replacement parts from a trusted supplier, HVAC professionals can deliver top-notch services, optimize system performance, and provide superior comfort and efficiency for their clients. The right York replacement parts supplier becomes an invaluable partner in the success of HVAC businesses, ensuring that buildings and facilities remain comfortable and productive throughout their lifespan.

Without air systems, it is impossible for any organization, regardless of its size, to function correctly. The purchase of this chiller represents a significant financial investment for expanding businesses that are required to safeguard the health and safety of their workforce.

Without air systems, it is impossible for any organization, regardless of its size, to function correctly. The purchase of this chiller represents a significant financial investment for expanding businesses that are required to safeguard the health and safety of their workforce. The brand York is linked with high-quality items that perform that competitors cannot top. The majority of businesses make use of products manufactured by York. It may be as easy as controlling a piece of the cooling system by searching extensively through many companies if a part of the cooling unit needs to be fixed or changed.

The brand York is linked with high-quality items that perform that competitors cannot top. The majority of businesses make use of products manufactured by York. It may be as easy as controlling a piece of the cooling system by searching extensively through many companies if a part of the cooling unit needs to be fixed or changed. Given the substantial impact that air conditioning has on the surrounding environment, one of our primary objectives is to make the system as eco-friendly as possible.

Given the substantial impact that air conditioning has on the surrounding environment, one of our primary objectives is to make the system as eco-friendly as possible.

function at peak efficiency. Thus, it is highly recommended that you rely on York components and services for effective maintenance and repair. Those dependent on York components should educate themselves about the many types of York components and their purposes, functions, and distinguishing features.

function at peak efficiency. Thus, it is highly recommended that you rely on York components and services for effective maintenance and repair. Those dependent on York components should educate themselves about the many types of York components and their purposes, functions, and distinguishing features. For a dependable HVAC system, you need York components. All of the above devices are compatible with

For a dependable HVAC system, you need York components. All of the above devices are compatible with  It is crucial to have ready access to high-quality supplies that meet the facility management’s demands in the event chiller equipment malfunctions or breaks down.

It is crucial to have ready access to high-quality supplies that meet the facility management’s demands in the event chiller equipment malfunctions or breaks down.

Clean air conditioning is a significant consideration, and units need cost savings, but the energy bill is a major obstacle for companies trying to work efficiently within a budget.

Clean air conditioning is a significant consideration, and units need cost savings, but the energy bill is a major obstacle for companies trying to work efficiently within a budget. The HVAC system performs as designed with little effort, thanks to using York Industrial VSD Coolant for chillers. The heating, ventilation, and air conditioning (HVAC) system in a building is crucial for maintaining a comfortable indoor temperature and meeting regulations.

The HVAC system performs as designed with little effort, thanks to using York Industrial VSD Coolant for chillers. The heating, ventilation, and air conditioning (HVAC) system in a building is crucial for maintaining a comfortable indoor temperature and meeting regulations.

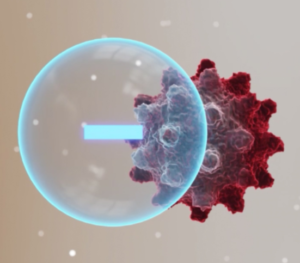

better be effectively-prepared to prevent coronavirus infections at the workplace. The World Health Organization has a significant role in advising facility owners on the measures they should take to enhance the safety and cleanliness of the air workers’ or customers’ breath.

better be effectively-prepared to prevent coronavirus infections at the workplace. The World Health Organization has a significant role in advising facility owners on the measures they should take to enhance the safety and cleanliness of the air workers’ or customers’ breath.  energy is developed to neutralize and absorb pollutants. Research shows that the process of ionization, whereby molecules and atoms are charged by adding bonds, is effective in killing mold. Thus, ionization is crucial in managing the spread of diseases, and viruses, especially the coronavirus.

energy is developed to neutralize and absorb pollutants. Research shows that the process of ionization, whereby molecules and atoms are charged by adding bonds, is effective in killing mold. Thus, ionization is crucial in managing the spread of diseases, and viruses, especially the coronavirus. ventilation systems of facilities, thus affecting the health of employees or occupants. It has become a significant technology during the pandemic and ensures the coronavirus is controlled effectively. Most industrial and commercial facilities are alarmed since the coronavirus is still spread through sneezing and coughing.

ventilation systems of facilities, thus affecting the health of employees or occupants. It has become a significant technology during the pandemic and ensures the coronavirus is controlled effectively. Most industrial and commercial facilities are alarmed since the coronavirus is still spread through sneezing and coughing.

Therefore, for immediate access to York’s comprehensive Commercial York Parts inventory, which includes its offerings in the heating and cooling categories? Purchasing advice for Commercial York Replacement Parts components, which can be challenging to locate on other websites dedicated to HVAC systems.

Therefore, for immediate access to York’s comprehensive Commercial York Parts inventory, which includes its offerings in the heating and cooling categories? Purchasing advice for Commercial York Replacement Parts components, which can be challenging to locate on other websites dedicated to HVAC systems. York’s replacement items for heating, ventilation, and air conditioning HVAC. To get these authentic components designed specifically for replacement purposes.

York’s replacement items for heating, ventilation, and air conditioning HVAC. To get these authentic components designed specifically for replacement purposes. York International is an industry pioneer in designing and manufacturing heating, ventilation, and air conditioning (HVAC) systems. With us, you will get everything you require to fix your system.

York International is an industry pioneer in designing and manufacturing heating, ventilation, and air conditioning (HVAC) systems. With us, you will get everything you require to fix your system.

High-efficiency chillers from YLAA put energy efficiency at the forefront of its industry thanks to their cutting-edge control algorithms. YLAA chillers have some of the best IPLV (off-design) performance in their category.

High-efficiency chillers from YLAA put energy efficiency at the forefront of its industry thanks to their cutting-edge control algorithms. YLAA chillers have some of the best IPLV (off-design) performance in their category. The YLAA chiller offers a diverse selection of options, each designed to perform dependably in a specific setting. It is possible to achieve a capture rate of 85% while maintaining a temperature of no more than 140 degrees Fahrenheit and 60 degrees Celsius.

The YLAA chiller offers a diverse selection of options, each designed to perform dependably in a specific setting. It is possible to achieve a capture rate of 85% while maintaining a temperature of no more than 140 degrees Fahrenheit and 60 degrees Celsius. The York YLAA chiller parts components have been tried and tested, and they are reliable in reducing the frequency of service calls. Since its introduction, scroll compressors have logged hundreds of thousands of hours of service in various industries.

The York YLAA chiller parts components have been tried and tested, and they are reliable in reducing the frequency of service calls. Since its introduction, scroll compressors have logged hundreds of thousands of hours of service in various industries.

The annual cost of unexpected downtime to the industry is estimated to be billions of dollars, making downtime a formidable foe for many organizations, especially those involved in producing or selling industrial machinery. Planned and unexpected downtime of machines during setup and switching must be minimized as much as possible.

The annual cost of unexpected downtime to the industry is estimated to be billions of dollars, making downtime a formidable foe for many organizations, especially those involved in producing or selling industrial machinery. Planned and unexpected downtime of machines during setup and switching must be minimized as much as possible. affect a cooling system’s efficiency.

affect a cooling system’s efficiency.