Commercial Needlepoint Bipolar Ionization Service for HVAC

Commercial Needlepoint bipolar ionization service through Midwest Parts Center can address the challenge of infection control in facilities. The technology is capable of removing airborne microorganisms as well as germs on the surface of objects. Certainly, one of the best advantages of commercial needlepoint bipolar ionization is its ability to purify the air. Air purification is a necessity in commercial buildings. In fact, clean air contributes to a better lifestyle in summary.

Commercial Needlepoint bipolar ionization service through Midwest Parts Center can address the challenge of infection control in facilities. The technology is capable of removing airborne microorganisms as well as germs on the surface of objects. Certainly, one of the best advantages of commercial needlepoint bipolar ionization is its ability to purify the air. Air purification is a necessity in commercial buildings. In fact, clean air contributes to a better lifestyle in summary.

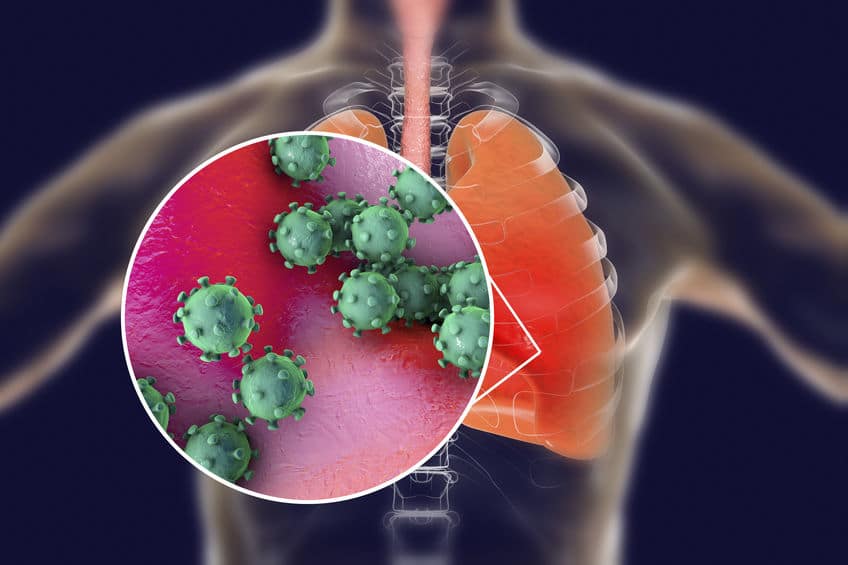

Because of the recent news surrounding the coronavirus and COVID-19, companies search for viable air purification alternatives. The CDC recommended that facilities review air-conditioning systems to ensure that buildings have proper ventilation. The coronavirus is airborne, which means that it can travel through conduits inside of a facility. Air handlers, vents, and filters are all susceptible to infection due to viral outbreaks.

Combat Infection with HVAC

HVAC units are not just used for temperature control. Air-Conditioning units provide breathable air. Breathable air is free from viruses, contaminants, and pollution. In some facilities, however, germs can enter a building through a ventilation system. For this reason, facility managers can retrofit systems with antiviral devices such as Global Plasma Solutions.

HVAC units are not just used for temperature control. Air-Conditioning units provide breathable air. Breathable air is free from viruses, contaminants, and pollution. In some facilities, however, germs can enter a building through a ventilation system. For this reason, facility managers can retrofit systems with antiviral devices such as Global Plasma Solutions.

Commercial needlepoint bipolar ionization is the cornerstone of Global Plasma Solutions. End-users can expect clean air that is void of foul odors and VOCs. VOCs are harmful and can certainly lead to major illnesses if not addressed.

Every year people fall ill due to germ exposure. Illness resulting from infectious disease can cause individuals to lose valuable time from work as they focus on recovery. For businesses, having large sums of staff out due to sickness will cause productivity to decline. Building sickness is also a major culprit that is responsible for making people ill. Infections such as the common cold, flu, and other illnesses can spread rapidly due to poor ventilation and hygiene among building occupants.

Commercial needlepoint bipolar ionization is a simple and cost-effective way to address the need for clean air. In fact, the method offers numerous benefits including cost savings on energy. The process saves resources by controlling outdoor air. Outdoor air can cause irregular temperatures, which can be detrimental to a facility.

Summary of Clean Air Technology

Clean air is a necessity for commercial facilities. The recent pandemic due to coronavirus and COVID-19 has moved companies to alter their approach to clean air. Air purification happens to be a worthwhile investment as it contributes to productivity and profitability.

Clean air is a necessity for commercial facilities. The recent pandemic due to coronavirus and COVID-19 has moved companies to alter their approach to clean air. Air purification happens to be a worthwhile investment as it contributes to productivity and profitability.

A commercial HVAC technician can take the time to inspect current air-conditioning units and ventilation systems for great circulation. Furthermore, your service technician can install Global Plasma Solutions onto current forced-air units for a fraction of the cost of lost time at work. In truth, facilities must have long-term goals for meeting and exceeding clean air standards as times change and threats persist.

Interested in learning how we can help achieve the cleanest air possible? Contact us to ask about our commercial pure air services.

The infectious spread is not uncommon in large facilities. In truth, people become infected with viruses at work every year.

The infectious spread is not uncommon in large facilities. In truth, people become infected with viruses at work every year.  applied to existing forced-air units by a commercial service technician. Moreover, the recent threat of coronavirus affecting facilities has re-engaged discussions on ionization in commercial buildings. As a result, facility managers and business owners have jumped into action to prevent the spread of COVID-19.

applied to existing forced-air units by a commercial service technician. Moreover, the recent threat of coronavirus affecting facilities has re-engaged discussions on ionization in commercial buildings. As a result, facility managers and business owners have jumped into action to prevent the spread of COVID-19. Businesses are hoping to decrease exposure to coronavirus and other germs by enlisting a device known as ionization. Industrial Bipolar ionization renders germs inactive by removing an important hydrogen bond to generate free radicals. The free radicals that form as the result of ionization attack viruses and render them inactive.

Businesses are hoping to decrease exposure to coronavirus and other germs by enlisting a device known as ionization. Industrial Bipolar ionization renders germs inactive by removing an important hydrogen bond to generate free radicals. The free radicals that form as the result of ionization attack viruses and render them inactive.

Building managers are hoping to boost the overall quality of air in facilities. Viruses spread easily where folks gather daily, and

Building managers are hoping to boost the overall quality of air in facilities. Viruses spread easily where folks gather daily, and  Together with preventative measures urged by the CDC, commercial facilities can implement tools to stop the spread of viruses. Also, a potential treatment is bipolar ionization. Needlepoint bipolar ionization is the central force in Midwest Global Plasma Solutions. In fact, ionization inactivates viruses and kills germs on contact. Furthermore, the treatment provides purification for the air in facilities. Midwest Global Plasma Solutions offers a high kill rate plus many other benefits.

Together with preventative measures urged by the CDC, commercial facilities can implement tools to stop the spread of viruses. Also, a potential treatment is bipolar ionization. Needlepoint bipolar ionization is the central force in Midwest Global Plasma Solutions. In fact, ionization inactivates viruses and kills germs on contact. Furthermore, the treatment provides purification for the air in facilities. Midwest Global Plasma Solutions offers a high kill rate plus many other benefits. Air-Conditioning units play a major part in providing comfortable air. Furthermore, A/C units offer breathable air that is void of germs. Because individuals work in close quarters often, infection control is a must. The reality is that germs propagate quickly. Ventilation is a unique tool in the fight to manage infection control. Indeed, every employee and customer needs a space with clean air. Cleaner air can provide long-lasting benefits. Additionally, healthy air promotes healthier lifestyles.

Air-Conditioning units play a major part in providing comfortable air. Furthermore, A/C units offer breathable air that is void of germs. Because individuals work in close quarters often, infection control is a must. The reality is that germs propagate quickly. Ventilation is a unique tool in the fight to manage infection control. Indeed, every employee and customer needs a space with clean air. Cleaner air can provide long-lasting benefits. Additionally, healthy air promotes healthier lifestyles.

Both clientele and employees need a well-ventilated atmosphere to run an enterprise.

Both clientele and employees need a well-ventilated atmosphere to run an enterprise.  The CDC has provided guidelines to the public on how to stop the spread of viruses potentially. Moreover, the authority on diseases has also advised that facilities consider the effects of ventilation and air-conditioning units on infection control. As a Commercial coronavirus sanitizer, HVAC units can purify the air by removing harmful viruses and germs.

The CDC has provided guidelines to the public on how to stop the spread of viruses potentially. Moreover, the authority on diseases has also advised that facilities consider the effects of ventilation and air-conditioning units on infection control. As a Commercial coronavirus sanitizer, HVAC units can purify the air by removing harmful viruses and germs. Since not everyone adheres to the guidelines set forth on infection control, other methods must be used. Our Commercial coronavirus sanitizer method combats surface and airborne germs with precision. Furthermore, using Global Plasma Solutions as a sanitizer device improves air quality, temperature, and outdoor airflow.

Since not everyone adheres to the guidelines set forth on infection control, other methods must be used. Our Commercial coronavirus sanitizer method combats surface and airborne germs with precision. Furthermore, using Global Plasma Solutions as a sanitizer device improves air quality, temperature, and outdoor airflow.

Now businesses face a certain dilemma in handling problems such as the coronavirus and the subsequent COVID-19 infection. While facilities are implementing new techniques to manage infection control, using HVAC units is reasonably cost-effective. Because air circulates throughout buildings, it is merely logical that an antiviral treatment would be applied to ventilation systems and their components.

Now businesses face a certain dilemma in handling problems such as the coronavirus and the subsequent COVID-19 infection. While facilities are implementing new techniques to manage infection control, using HVAC units is reasonably cost-effective. Because air circulates throughout buildings, it is merely logical that an antiviral treatment would be applied to ventilation systems and their components.  Commercial HVAC units can receive Global Plasma Solutions as an enhancement with the help of a service technician. Commercial heating and cooling technicians can install the device onto existing forced-air units. Choosing to invest in an Industrial COVID19 sanitizer treatment for facilities is worth the money because of coronavirus issues. Exposure to the virus has transformed how companies operate and serve customers.

Commercial HVAC units can receive Global Plasma Solutions as an enhancement with the help of a service technician. Commercial heating and cooling technicians can install the device onto existing forced-air units. Choosing to invest in an Industrial COVID19 sanitizer treatment for facilities is worth the money because of coronavirus issues. Exposure to the virus has transformed how companies operate and serve customers.

Our industry experts can install Global Plasma Solutions

Our industry experts can install Global Plasma Solutions  Exposure to outdoor air leaves facilities vulnerable to the effects of mold and mildew. Mildew is responsible for poor air quality as well as foul odors. Working around foul odors is not ideal. Global Plasma Solutions, as an industrial sanitizer, is centered on providing breathable air. Healthy breathing air is necessary because people spend over 8 hours in various facilities throughout the year. In fact, the CDC has suggested that facilities examine their heating and cooling settings and ventilation systems. Proper ventilation helps to slow the spread of coronavirus, according to research. In truth, most facilities should consider updating infection control protocols to protect building occupants better.

Exposure to outdoor air leaves facilities vulnerable to the effects of mold and mildew. Mildew is responsible for poor air quality as well as foul odors. Working around foul odors is not ideal. Global Plasma Solutions, as an industrial sanitizer, is centered on providing breathable air. Healthy breathing air is necessary because people spend over 8 hours in various facilities throughout the year. In fact, the CDC has suggested that facilities examine their heating and cooling settings and ventilation systems. Proper ventilation helps to slow the spread of coronavirus, according to research. In truth, most facilities should consider updating infection control protocols to protect building occupants better. Exposure to contamination in buildings leads to lost productivity as people must call out due to illness. The attractive point about Global Plasma Solutions is that it reduces building sickness syndrome in facilities. As a result, companies may gain increased work output from employees. Because the technology also provides better control of inside air temperatures, Global Plasma Solutions provides greater thermal comfort and increases productivity.

Exposure to contamination in buildings leads to lost productivity as people must call out due to illness. The attractive point about Global Plasma Solutions is that it reduces building sickness syndrome in facilities. As a result, companies may gain increased work output from employees. Because the technology also provides better control of inside air temperatures, Global Plasma Solutions provides greater thermal comfort and increases productivity.

Once utilize in HVAC units, needlepoint bi-polar ionization provides many positive aspects within a commercial center. Our

Once utilize in HVAC units, needlepoint bi-polar ionization provides many positive aspects within a commercial center. Our  The issue with developing the illness is that people are not able to work. Furthermore, the loss of employees results in a loss of productivity. Declined productivity will lead companies and staff to lose profits and income. What’s more, there are economic consequences for widespread outbreaks. Clean air contributes at least to a healthy environment. Additionally, breathable air is totally free of toxins, pollutants, and also viruses. Addressing air quality with HVAC Midwest antiviral sanitizer is an excellent method.

The issue with developing the illness is that people are not able to work. Furthermore, the loss of employees results in a loss of productivity. Declined productivity will lead companies and staff to lose profits and income. What’s more, there are economic consequences for widespread outbreaks. Clean air contributes at least to a healthy environment. Additionally, breathable air is totally free of toxins, pollutants, and also viruses. Addressing air quality with HVAC Midwest antiviral sanitizer is an excellent method. During the deployment of bipolar ionization, Global Plasma Solutions reduces contaminants and kills the spores that infect heating and cooling systems. What’s more, the technology removes volatile organic compounds, which are also harmful. In fact, Global Plasma Solutions kills germs, and microorganisms, and decimates viruses. Quite put, needlepoint bi-polar ionization is an innovative method that delivers numerous benefits for buildings.

During the deployment of bipolar ionization, Global Plasma Solutions reduces contaminants and kills the spores that infect heating and cooling systems. What’s more, the technology removes volatile organic compounds, which are also harmful. In fact, Global Plasma Solutions kills germs, and microorganisms, and decimates viruses. Quite put, needlepoint bi-polar ionization is an innovative method that delivers numerous benefits for buildings.

Midwest Parts Center is the premier source for Industrial York preventative maintenance kits. In truth, even the smallest parts can have an impact on chiller performance. Keeping up with a chiller’s service is a continuous project. In fact, chillers need constant monitoring, seasonal service, and status checks. Minor parts should also be checked and replaced if needed consistently. Moreover, parts that become worn down due to frequent use should also be replaced to avoid major damage.

Midwest Parts Center is the premier source for Industrial York preventative maintenance kits. In truth, even the smallest parts can have an impact on chiller performance. Keeping up with a chiller’s service is a continuous project. In fact, chillers need constant monitoring, seasonal service, and status checks. Minor parts should also be checked and replaced if needed consistently. Moreover, parts that become worn down due to frequent use should also be replaced to avoid major damage. Through our experience, we understand that commercial and industrial clients have unique requirements for HVAC. As a result, we can offer an assortment of components that are suitable for your configuration. Consider working with an HVAC parts specialist from Midwest Part Center. Discover an extensive selection of parts and equipment from York’s catalog.

Through our experience, we understand that commercial and industrial clients have unique requirements for HVAC. As a result, we can offer an assortment of components that are suitable for your configuration. Consider working with an HVAC parts specialist from Midwest Part Center. Discover an extensive selection of parts and equipment from York’s catalog.

Chillers are complicated temperature control systems. HVAC service technicians use

Chillers are complicated temperature control systems. HVAC service technicians use  Reach out to Midwest Parts Center to discover how we can help discover quality parts for York chillers. We support end-users in finding parts that match the needs of chiller units. Spare parts enable facilities to return a downed unit to service faster. Additionally, spare parts limit operation costs by extending equipment usage. Finally, employing HVAC parts for repair or replacement is simply an economical choice.

Reach out to Midwest Parts Center to discover how we can help discover quality parts for York chillers. We support end-users in finding parts that match the needs of chiller units. Spare parts enable facilities to return a downed unit to service faster. Additionally, spare parts limit operation costs by extending equipment usage. Finally, employing HVAC parts for repair or replacement is simply an economical choice. The YT chiller is another efficient model by York. The system includes advanced technology that is exclusive to the brand. Because efficiency is a prime concern for facilities, the technology found in the YT chiller is ideal. Furthermore, facilities that hope to get the most out of a cooling system over the long haul should consider working with Midwest Parts Center for ongoing needs.

The YT chiller is another efficient model by York. The system includes advanced technology that is exclusive to the brand. Because efficiency is a prime concern for facilities, the technology found in the YT chiller is ideal. Furthermore, facilities that hope to get the most out of a cooling system over the long haul should consider working with Midwest Parts Center for ongoing needs.

There is no doubt that chillers are complex machines. HVAC technicians use

There is no doubt that chillers are complex machines. HVAC technicians use

Contact Midwest Parts Center to discover how we can help with quality York parts for your chiller. We work with our end users to satisfy HVAC needs. Commercial facilities can return units to service without delay due to better access to parts. The reality is that parts can get a unit up and running quickly. Moreover, spare components reduce operation costs by prolonging the HVAC equipment. Deploying components for repair and replacement is an economical option for facilities.

Contact Midwest Parts Center to discover how we can help with quality York parts for your chiller. We work with our end users to satisfy HVAC needs. Commercial facilities can return units to service without delay due to better access to parts. The reality is that parts can get a unit up and running quickly. Moreover, spare components reduce operation costs by prolonging the HVAC equipment. Deploying components for repair and replacement is an economical option for facilities.