York Chiller Parts in Louisville Enhancing Cooling Solutions

In the heart of the Bluegrass State, Louisville stands as a vibrant and dynamic city with a rich history, bustling industries, and a diverse range of businesses. Amidst the city’s varied landscape lies a critical need for efficient cooling solutions to combat the sweltering heat of summer and maintain optimal indoor environments year-round. One name that has consistently risen to meet these challenges is York, a reputable brand known for its top-tier chiller systems and components. This article delves into the world of York chiller parts in Louisville, exploring how these components contribute to the city’s cooling infrastructure, efficiency, and comfort.

The Importance of Cooling Solutions in Louisville

Louisville’s climate is characterized by humid summers and varying temperature extremes. From the towering corporate offices to the bustling commercial centers and sprawling industrial facilities, the need for effective cooling solutions is paramount. Efficient cooling is not merely a matter of comfort; it directly impacts productivity, energy consumption, and overall well-being. With the city’s growth and development, the demand for reliable cooling solutions has never been greater.

York Chiller Parts in Louisville Enhancing Cooling Solutions

York: A Legacy of Excellence

For decades, York has been a trusted name in the HVAC industry, delivering innovative and reliable chiller systems and parts. Founded on a commitment to engineering excellence and continuous innovation, York has earned a reputation for providing cutting-edge solutions that address the diverse cooling needs of cities like Louisville.

A Closer Look at york chiller parts in louisville

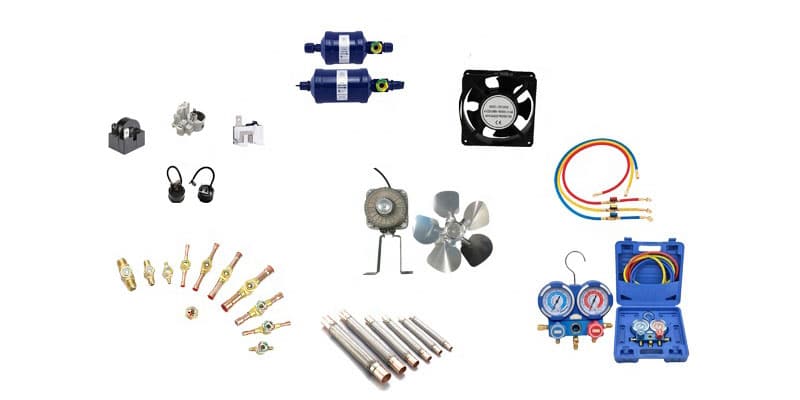

York chiller parts in louisville form the backbone of cooling systems that cater to Louisville’s varied requirements. From industrial facilities requiring precise temperature control to commercial spaces demanding consistent comfort, these parts play a pivotal role in achieving optimal cooling performance. Let’s delve into some of the key york chiller parts in louisville that power Louisville’s cooling infrastructure:

- Compressors: Compressors lie at the heart of any chiller system. York’s compressors are engineered for efficiency, ensuring the conversion of refrigerant into high-pressure gas for effective heat exchange.

- Condenser Coils: Louisville’s humid climate requires efficient heat dissipation. York’s condenser coils excel at releasing heat, allowing the refrigerant to condense and ready itself for another cooling cycle.

- Evaporator Coils: As central components in the cooling process, York’s evaporator coils absorb heat, causing the refrigerant to evaporate and cool the chilled water that circulates through Louisville’s buildings.

- Expansion Valves: York’s expansion valves regulate the flow of refrigerant into the evaporator coils, a crucial step in the refrigeration cycle that controls pressure and temperature.

- Variable Frequency Drives (VFDs): Recognizing the need for energy efficiency, York incorporates VFDs that adjust motor speed based on demand, conserving energy and reducing operational costs.

- Fans and Blowers: Louisville’s diverse spaces demand effective airflow management. York’s fans and blowers ensure optimal heat exchange by circulating air across coils and enhancing cooling efficiency.

- Pumps: Whether for chilled water or condenser water circulation, York’s pumps maintain efficient fluid flow, ensuring consistent heat transfer throughout Louisville’s cooling systems.

- Control Panels and Modules: York’s advanced control panels and modules provide precise temperature regulation, system monitoring, and safety features essential for efficient cooling.

- Sensors: The accuracy of cooling systems depends on real-time data. York’s sensors monitor parameters like temperature, pressure, and flow, allowing for effective control and diagnostics.

- Safety Controls: In a city where temperature extremes can stress cooling systems, York’s safety controls provide safeguards that prevent system failures and maintain consistent cooling.

Driving Efficiency and Sustainability

The fusion of York chiller parts in Louisville cooling solutions results in not only enhanced performance but also increased energy efficiency and sustainability. With rising environmental concerns and a global push for greener technologies, York’s commitment to designing energy-efficient components aligns seamlessly with Louisville’s goal of reducing its carbon footprint.

Collaboration with Local Experts

York’s presence in Louisville goes beyond providing york chiller parts in louisville it involves collaboration with local HVAC experts, engineers, and technicians. This synergy ensures that York’s solutions are tailored to meet the city’s unique cooling demands, whether it’s ensuring comfortable temperatures in hospitality establishments or maintaining critical operations in healthcare facilities.

In the heart of Kentucky, Louisville’s dynamic landscape demands equally dynamic cooling solutions. york chiller parts in louisville have risen to the occasion, powering the city’s cooling infrastructure, enhancing efficiency, and ensuring comfort in the face of extreme weather. With a legacy of excellence, a commitment to innovation, and a focus on sustainability, York continues to play a vital role in shaping the cooling landscape of Louisville, a city that thrives on its ability to adapt and excel.

Exploring York Chiller Parts in Louisville

Nestled on the banks of the Ohio River, Louisville, Kentucky, boasts a blend of history, culture, and industry. As a city with diverse needs and a range of applications, effective cooling solutions are a necessity to combat the heat and humidity that characterize its climate. Among the names synonymous with superior cooling technology is York, a brand renowned for its exceptional chiller systems and components. In this article, we embark on a journey to explore the world of York chiller parts in Louisville, uncovering the vital role they play in shaping the city’s comfort, efficiency, and innovation.

The Cooling Imperative in Louisville

Louisville experiences a climate that oscillates between sweltering summers and cooler winters. From expansive commercial spaces to critical industrial facilities, maintaining optimal indoor environments is paramount. The significance of efficient cooling solutions extends beyond mere comfort—it directly influences productivity, energy consumption, and overall quality of life. As the city evolves, the demand for reliable and effective cooling solutions continues to grow.

Exploring York Chiller Parts in Louisville

York: Pioneering Cooling Excellence

For decades, York has been a beacon of excellence in the HVAC industry, offering cutting-edge chiller systems and components. Built on a foundation of engineering prowess and unwavering innovation, York has earned a reputation for delivering solutions that cater to the diverse cooling needs of cities like Louisville.

An Insight into york chiller parts in louisville

The backbone of Louisville’s cooling infrastructure lies in york chiller parts in louisville. From industrial complexes requiring precise temperature control to commercial establishments demanding consistent comfort, these parts form the bedrock of efficient cooling performance. Let’s delve into some of the key york chiller parts in louisville that power Louisville’s cooling systems:

- Compressors: Serving as the heart of chiller systems, York’s compressors excel in converting low-pressure refrigerant vapor into high-pressure gas, facilitating the heat exchange process.

- Condenser Coils: In a city where heat dissipation is vital, York’s condenser coils shine. They efficiently release absorbed heat, allowing the refrigerant to condense and prepare for another cooling cycle.

- Evaporator Coils: Crucial in the cooling cycle, York’s evaporator coils absorb heat, enabling the refrigerant to evaporate and cool the water coursing through Louisville’s buildings.

- Expansion Valves: York’s expansion valves hold the reins of refrigerant flow into the evaporator coils, a pivotal step in the refrigeration cycle regulating pressure and temperature.

- Variable Frequency Drives (VFDs): A nod to energy efficiency, York employs VFDs that adapt motor speed based on demand, conserving energy and slashing operational costs.

- Fans and Blowers: With diverse spaces come varying airflow requirements. York’s fans and blowers ensure optimal heat exchange by circulating air across coils, enhancing cooling efficiency.

- Pumps: Be it for chilled water or condenser water circulation, York’s pumps maintain steady fluid flow, guaranteeing uniform heat transfer throughout Louisville’s cooling systems.

- Control Panels and Modules: York’s sophisticated control panels and modules provide precise temperature regulation, system monitoring, and indispensable safety features for effective cooling.

- Sensors: Real-time data is pivotal for accurate cooling systems. York’s sensors monitor temperature, pressure, and flow, enabling precise control and efficient diagnostics.

- Safety Controls: In a city susceptible to extreme temperatures, York’s safety controls provide fail-safes that avert system breakdowns, ensuring sustained cooling reliability.

Elevating Efficiency and Sustainability

The fusion of york chiller parts in louisville cooling solutions yields not just enhanced performance, but also heightened energy efficiency and sustainability. With global concerns driving the shift towards greener technologies, York’s dedication to crafting energy-efficient components aligns seamlessly with Louisville’s goal of curbing its environmental impact.

Collaborative Ties with Local Experts

York’s presence in Louisville goes beyond the provision of york chiller parts in louisville; it involves active collaboration with local HVAC experts, engineers, and technicians. This synergy ensures that York’s solutions are meticulously tailored to address the city’s unique cooling demands—be it achieving optimal comfort levels in hospitality establishments or sustaining critical operations in healthcare facilities.

Louisville’s dynamic landscape mandates equally dynamic cooling solutions. york chiller parts in louisville rise to this challenge, fueling the city’s cooling infrastructure, enhancing efficiency, and fortifying comfort against climatic adversities. With a legacy steeped in excellence, a penchant for innovation, and an unwavering commitment to sustainability, York continues to wield a pivotal role in shaping Louisville’s cooling narrative—a city that thrives on its ability to adapt, excel, and remain cool in every sense of the word.

Empowering Louisville with york chiller parts in louisville

Louisville, Kentucky, a city of innovation and history, experiences a climate characterized by fluctuating temperatures and high humidity. The challenge of maintaining comfortable indoor environments across its diverse sectors is met head-on by efficient heating, ventilation, and air conditioning (HVAC) systems. In this pursuit, york chiller parts in louisville emerged as a beacon of excellence. This article delves into the dynamic synergy between york chiller parts in louisville HVAC needs, exploring how these components enhance efficiency, energy conservation, and overall comfort.

Unveiling the HVAC Imperative in Louisville

Louisville’s climatic variability, from sweltering summers to brisk winters, underscores the critical role of effective HVAC systems. From bustling commercial establishments to sensitive healthcare facilities, precise temperature control is not just desirable—it’s a necessity. Optimal indoor conditions influence productivity, customer experiences, and employee well-being. Louisville’s growth demands HVAC solutions that are responsive, sustainable, and tailored to its diverse sectors.

York: Pioneering HVAC Excellence

York’s legacy in the HVAC realm is one of unwavering commitment to innovation and performance. With decades of experience, York has solidified its position as a trusted provider of cutting-edge HVAC solutions. From chiller systems to individual components, York is synonymous with engineering excellence and reliability.

Empowering Louisville with york chiller parts in louisville

Unlocking the Potential of york chiller parts in louisville

At the core of Louisville’s HVAC optimization lies york chiller parts in louisville. These components seamlessly integrate with chiller systems, yielding benefits that extend beyond mere temperature control. Let’s delve into some of the key york chiller parts in louisville that empower Louisville’s HVAC landscape:

- Compressors: The heart of chiller systems, York’s compressors efficiently elevate refrigerant vapor pressure, a pivotal step in the cooling process.

- Condenser Coils: In a city prone to heat and humidity, York’s condenser coils are adept at dissipating heat, allowing refrigerant to condense and prepare for the next cycle.

- Evaporator Coils: As central components, York’s evaporator coils absorb heat, enabling refrigerant to evaporate and cool the water that circulates within buildings.

- Expansion Valves: York’s expansion valves regulate refrigerant flow into the evaporator coils, maintaining precise pressure and temperature control.

- Variable Frequency Drives (VFDs): Committed to energy efficiency, York incorporates VFDs that adapt motor speed, conserving energy and minimizing operational costs.

- Fans and Blowers: With diverse spaces demanding tailored airflow, York’s fans and blowers ensure optimal heat exchange by circulating air across coils, boosting cooling efficiency.

- Pumps: Be it for chilled water or condenser water, York’s pumps maintain consistent fluid flow, guaranteeing uniform heat transfer throughout HVAC systems.

- Control Panels and Modules: York’s sophisticated control panels provide meticulous temperature regulation, system monitoring, and safety features crucial for efficient cooling.

- Sensors: Real-time data is pivotal for precise HVAC operation. York’s sensors monitor temperature, pressure, and flow, enabling accurate control and effective diagnostics.

- Safety Controls: York’s safety controls act as fail-safes in extreme temperature conditions, preventing system breakdowns and ensuring reliable cooling.

Elevating Efficiency and Sustainability

The integration of york chiller parts in louisville HVAC systems yields not just enhanced performance but also heightened energy efficiency and sustainability. In an era of heightened environmental awareness, York’s dedication to crafting energy-efficient components aligns seamlessly with Louisville’s drive towards a greener future.

Collaborative Partnership with Local Experts

York’s involvement transcends supplying york chiller parts in louisville; it extends to collaboration with local HVAC experts, engineers, and technicians. This collaboration ensures that York’s solutions are finely tuned to address Louisville’s unique HVAC requirements, whether it’s achieving optimal comfort in hospitality venues or maintaining critical operations in data centers.

As Louisville continues to evolve, its HVAC needs become more intricate and pressing. york chiller parts in louisville stand as a testament to innovation and reliability, catering to the city’s dynamic cooling requirements. With a legacy built on excellence, a penchant for innovation, and a steadfast commitment to sustainability, York chiller components play a pivotal role in shaping Louisville’s HVAC landscape—a landscape defined by efficiency, comfort, and an unwavering commitment to optimizing the indoor environment.

The Best York chiller parts in Louisville

The “best” York chiller parts in Louisville can vary depending on specific HVAC needs, applications, and the level of performance required. However, certain york chiller parts in louisville consistently stand out for their quality, efficiency, and impact on HVAC systems in Louisville. Here are some of the top york chiller parts in louisville that are often considered among the best for optimizing cooling solutions in Louisville:

- York YVFA Variable-Speed Screw Chiller: This chiller is known for its exceptional energy efficiency and flexibility, making it suitable for a wide range of applications in Louisville’s diverse climate.

- York YD Dual Centrifugal Chiller: These chillers offer high efficiency and capacity, making them ideal for larger commercial and industrial facilities in Louisville.

- York OptiView Control Center: An advanced control system that provides real-time monitoring, diagnostics, and optimization for York chiller systems, enhancing performance and energy efficiency.

- York YMC² Magnetic Centrifugal Chiller: These chillers utilize magnetic-bearing technology for enhanced efficiency, quieter operation, and improved reliability.

- York YLAA Air-Cooled Scroll Chiller: Designed for efficient cooling in smaller spaces, this chiller is known for its compact size, energy efficiency, and ease of installation.

- York YVWA Variable-Speed Water-Cooled Screw Chiller: Featuring variable-speed drive technology, this chiller delivers excellent energy efficiency and precise temperature control.

- York YK-EP Millennium Centrifugal Chiller: Known for its durability and efficiency, this chiller is suitable for industrial applications that demand reliable performance.

- York OptiRun Control System: A user-friendly control system that optimizes chiller operation, helping to achieve energy savings and maximize efficiency.

- York YLRA Air-Cooled Scroll Chiller: This chiller offers a balance of efficiency and reliability, making it a popular choice for various commercial applications in Louisville.

- York VSD Screw Compressors: These variable-speed screw compressors provide efficient and precise control over cooling capacity, contributing to energy savings.

- York Water-Cooled Condensers: These condensers are designed for high-efficiency heat rejection, crucial for maintaining efficient chiller operation in Louisville’s warm climate.

- York Expansion Valves: Precise and reliable expansion valves play a critical role in maintaining optimal refrigerant flow and temperature control within chiller systems.

- York Evaporator Coils: High-quality evaporator coils ensure efficient heat exchange and cooling performance in various HVAC applications.

- York Variable Frequency Drives (VFDs): VFDs optimize motor speed and power consumption, contributing to energy savings and enhanced system performance.

- York Sensors and Controls: Accurate sensors and intuitive controls are essential for maintaining precise temperature regulation and system diagnostics.

It’s important to note that the best york chiller parts in louisville for a specific application in Louisville will depend on factors such as the size of the space, cooling requirements, energy efficiency goals, and more. Consulting with HVAC experts and considering the unique needs of the facility will help determine the optimal combination of york chiller parts in louisville to achieve the desired cooling outcomes.

The primary mover in the chiller system is the compressor, which generates a pressure differential to transport the refrigerant. Centrifugal, screw, scroll, and reciprocating compressors are the most popular types of refrigerant compressors. The advantages and disadvantages of each variety are different. The condenser is always situated between the evaporator and condenser.

The primary mover in the chiller system is the compressor, which generates a pressure differential to transport the refrigerant. Centrifugal, screw, scroll, and reciprocating compressors are the most popular types of refrigerant compressors. The advantages and disadvantages of each variety are different. The condenser is always situated between the evaporator and condenser. After the compressor and before the expansion valve comes the condenser. The condenser’s job is to extract the refrigerant’s heat from the evaporator, where it was captured. Air-cooled and water-cooled condensers are the two most common types of condensers.

After the compressor and before the expansion valve comes the condenser. The condenser’s job is to extract the refrigerant’s heat from the evaporator, where it was captured. Air-cooled and water-cooled condensers are the two most common types of condensers. The evaporator is responsible for capturing the unwanted heat from the building and transferring it to the refrigerant. It is located between the expansion valve and compressor and can be transferred to the cooling tower and rejected.

The evaporator is responsible for capturing the unwanted heat from the building and transferring it to the refrigerant. It is located between the expansion valve and compressor and can be transferred to the cooling tower and rejected.

Commercial York Chiller Parts: Midwest Parts Centre provides you with a wide range of innovative products, expert installation and service, and systems integration to enhance operation energy outcomes for your chiller. The Commercial York chiller contains various parts, including variable speed drives (VSD). This part is essential to your chiller because it is used in your chiller unit and the condensers to control the fan speed. When the VSD is put into a condenser or your chiller, it increases the efficiency of the glycol chiller by modulating fan speed and making sure that pressure stays consistent all the time within the machine.

Commercial York Chiller Parts: Midwest Parts Centre provides you with a wide range of innovative products, expert installation and service, and systems integration to enhance operation energy outcomes for your chiller. The Commercial York chiller contains various parts, including variable speed drives (VSD). This part is essential to your chiller because it is used in your chiller unit and the condensers to control the fan speed. When the VSD is put into a condenser or your chiller, it increases the efficiency of the glycol chiller by modulating fan speed and making sure that pressure stays consistent all the time within the machine. It doesn’t matter if it’s a refrigeration chiller, an industrial chiller, or a heat exchanger; having the right parts for your York chiller plays a huge role in its functioning. Some of the most crucial chiller parts include:

It doesn’t matter if it’s a refrigeration chiller, an industrial chiller, or a heat exchanger; having the right parts for your York chiller plays a huge role in its functioning. Some of the most crucial chiller parts include: The Power panel is used to accrue to the unit directly, and it can be separated from the plant room’s wall together with control cables running between them. The main role played by the power panel is to manage the electrical power flow to the refrigerator.

The Power panel is used to accrue to the unit directly, and it can be separated from the plant room’s wall together with control cables running between them. The main role played by the power panel is to manage the electrical power flow to the refrigerator.