The Latest York Chiller Parts for HVAC Upgrades

In the fast-evolving realm of commercial and industrial HVAC systems, staying at the forefront of technological advancements is crucial for maintaining optimal performance. One key player in this landscape is York, renowned for its commitment to innovation. In this comprehensive exploration, we delve into the latest advancements in York chiller parts, uncovering how these components are revolutionizing HVAC upgrades. For inquiries and to explore the cutting-edge capabilities of York chiller parts, contact Midwest Parts Center at +1 800 368 8385.

The Dynamics of HVAC Upgrades:

Upgrading HVAC systems is not merely a response to wear and tear; it is a strategic move to enhance efficiency, reduce operational costs, and embrace the latest in technology. Within this context, the selection of high-performance components becomes paramount, and York chiller parts emerge as a beacon of innovation in the world of HVAC upgrades.

- Variable Speed Drives:

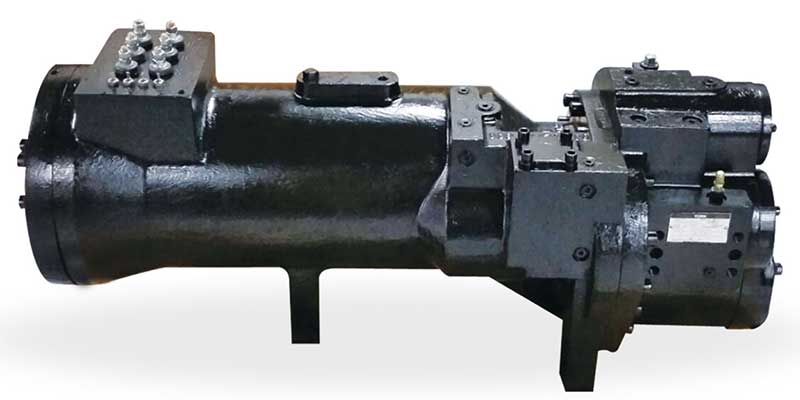

At the forefront of the latest York chiller parts innovations are variable speed drives. These components offer a dynamic solution to the energy demands of HVAC systems. By adjusting the speed of the chiller compressor motor, variable speed drives optimize energy consumption based on real-time cooling demands. This not only results in significant energy savings but also extends the lifespan of the chiller by reducing wear and tear associated with frequent starts and stops.

- Smart Sensors for Predictive Maintenance:

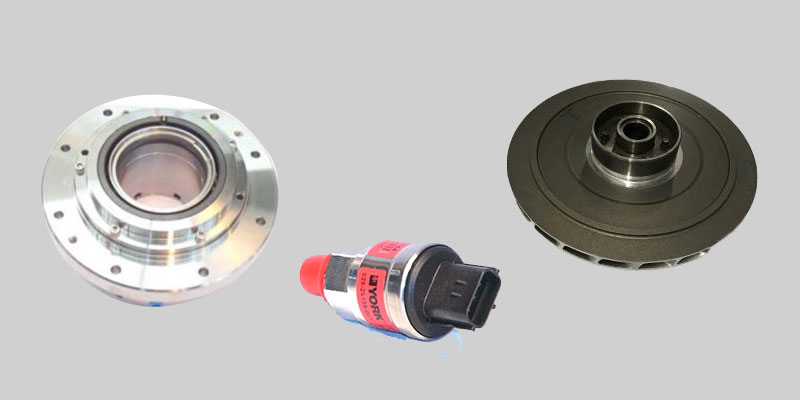

York chiller parts now integrate smart sensors designed to usher in a new era of predictive maintenance. These sensors continuously monitor the performance of critical components, collecting and analyzing data in real-time. By identifying trends and patterns indicative of potential issues, smart sensors enable predictive maintenance strategies, allowing for timely interventions before major problems arise. This proactive approach minimizes downtime, increases system reliability, and maximizes the operational lifespan of the chiller.

- Advanced Control Systems:

The latest York chiller parts feature advanced control systems that provide unparalleled precision and adaptability. These controls allow for fine-tuning the operation of the chiller to match specific load conditions, optimizing efficiency at varying capacities. Additionally, advanced controls facilitate seamless integration with building automation systems, offering a centralized and responsive approach to managing HVAC systems.

- Eco-Friendly Refrigerants:

In response to the growing emphasis on environmental sustainability, York chiller parts now incorporate eco-friendly refrigerants. These refrigerants have lower global warming potential (GWP) and ozone depletion potential (ODP), aligning with regulatory standards and reducing the overall environmental impact of HVAC systems. Upgrading to York chiller parts with eco-friendly refrigerants positions businesses as stewards of green practices in their industries.

- Enhanced Heat Exchangers:

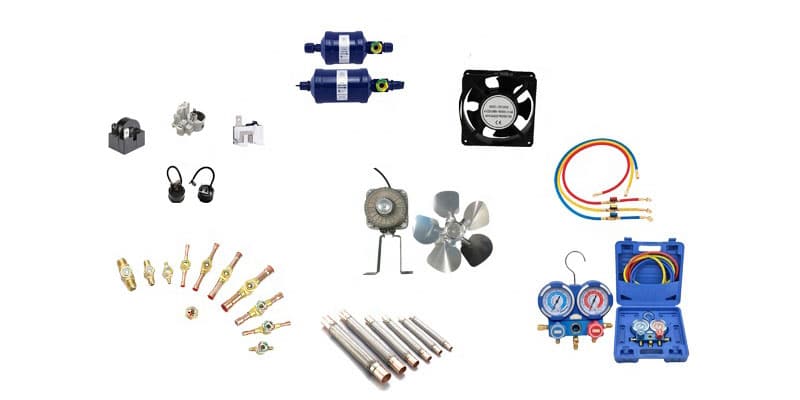

The heart of any chiller is its heat exchanger, and York chiller parts have seen significant advancements in this critical component. Enhanced heat exchangers optimize heat transfer efficiency, improving the overall performance of the chiller. This innovation translates to faster and more effective cooling, contributing to energy savings and increased operational efficiency.

- Adaptive Capacity Control:

To meet the demands of variable cooling loads, York chiller parts now feature adaptive capacity control mechanisms. These systems adjust the capacity of the chiller to match the actual cooling needs of the space, preventing energy wastage during periods of low demand. This adaptive capacity control ensures that the chiller operates at peak efficiency across a wide range of operating conditions.

- Intelligent Diagnostics and Connectivity:

Connectivity is a hallmark of modern HVAC systems, and York chiller parts are no exception. These components feature intelligent diagnostics and connectivity options that enable remote monitoring and control. Facility managers can access real-time data, receive alerts, and make adjustments to the chiller system from anywhere, streamlining maintenance and ensuring optimal performance.

- Energy Recovery Systems:

York chiller parts now integrate energy recovery systems designed to capture and repurpose waste heat. By recovering heat from the chiller’s operation, these systems contribute to overall energy efficiency. The repurposed heat can be used for heating applications or redirected to other processes within the facility, further reducing the environmental impact of HVAC operations.

The Impact on HVAC Upgrades:

Now, let’s delve into how the latest York chiller parts are transforming the landscape of HVAC upgrades for commercial and industrial applications.

- Energy Savings and Operational Efficiency:

The variable speed drives, adaptive capacity control, and enhanced heat exchangers in the latest York chiller parts collectively contribute to significant energy savings and operational efficiency. Businesses upgrading to these components can experience a noticeable reduction in energy consumption, leading to lower operational costs and a more sustainable HVAC operation.

- Proactive Maintenance for Increased Reliability:

Smart sensors and predictive maintenance capabilities are game-changers in ensuring the reliability of chiller systems. The ability to identify and address potential issues before they escalate minimizes unplanned downtime, reduces the risk of major failures, and extends the overall lifespan of the chiller. This proactive approach to maintenance enhances system reliability and supports uninterrupted HVAC operations.

- Environmental Stewardship:

The incorporation of eco-friendly refrigerants and energy recovery systems aligns HVAC operations with environmental sustainability goals. Upgrading to York chiller parts with these features not only ensures compliance with environmental regulations but also positions businesses as responsible stewards of the environment. The reduced carbon footprint and efficient use of resources contribute to a greener and more sustainable operation.

- Precision Control and Adaptability:

Advanced control systems and adaptive capacity control mechanisms provide unparalleled precision in managing chiller operations. These features allow for fine-tuning the chiller’s performance to match the specific needs of the space, ensuring optimal comfort and temperature control. The adaptability of York chiller parts makes them well-suited for applications with varying cooling loads, providing consistent performance across changing conditions.

- Remote Monitoring and Connectivity:

Intelligent diagnostics and connectivity options empower facility managers with real-time insights into chiller performance. The ability to monitor and control the chiller remotely enhances operational efficiency and simplifies maintenance tasks. Remote access to diagnostic data allows for timely decision-making, reducing the need for on-site interventions and improving overall system management.

- Long-Term Cost Savings:

While the upfront investment in the latest York chiller parts may be significant, the long-term cost savings are substantial. Energy-efficient components, proactive maintenance strategies, and extended equipment lifespan contribute to a reduced total cost of ownership. Businesses that prioritize these high-performance components can enjoy long-term financial benefits, making the initial investment a strategic and cost-effective choice.

How Midwest Parts Center Leads the Way:

As a company specializing in HVAC solutions for commercial and industrial applications, Midwest Parts Center is at the forefront of incorporating the latest York chiller parts into their offerings. Recognizing the transformative impact of these innovations on HVAC upgrades, Midwest Parts Center is committed to providing businesses with cutting-edge components that deliver unparalleled performance.

Contact Midwest Parts Center:

For businesses eager to explore the capabilities of the latest York chiller parts and elevate their HVAC systems to new heights, Midwest Parts Center is ready to assist. Contact Midwest Parts Center at +1 800 368 8385 for inquiries, consultations, and to explore how these innovative components can be seamlessly integrated into your HVAC upgrades.

In conclusion, the latest York chiller parts represent a pinnacle of innovation in the world of HVAC upgrades. From variable speed drives to smart sensors, advanced controls, and eco-friendly features, these components are designed to meet the evolving needs of commercial and industrial applications. As businesses strive for energy efficiency, reliability, and environmental sustainability in their HVAC operations, the latest York chiller parts, championed by Midwest Parts Center, stand as a testament to the transformative power of cutting-edge technology in the pursuit of optimal heating and cooling solutions.

The Latest Innovations in York chiller parts for HVAC Systems

In the dynamic landscape of commercial and industrial HVAC systems, staying ahead of the curve is essential for achieving optimal performance, energy efficiency, and sustainability. York, a stalwart in the HVAC industry, continues to push the boundaries of innovation with its latest advancements in chiller parts. In this in-depth exploration, we unravel the cutting-edge innovations in York chiller parts and how these components are redefining the benchmarks for HVAC systems. For inquiries and to embrace the forefront of HVAC technology, contact Midwest Parts Center at +1 800 368 8385.

The Evolution of York Chiller Parts:

As HVAC technology evolves to meet the increasing demands of efficiency, environmental considerations, and precision control, York chiller parts have emerged as pioneers in driving these advancements. The latest innovations in York chiller parts are not just incremental improvements; they represent a paradigm shift in how HVAC systems are designed, operated, and maintained.

1. Variable Speed Drives – Revolutionizing Efficiency:

At the heart of the latest York chiller parts innovation is the integration of variable speed drives (VSD). This transformative technology allows the chiller’s compressor motor to dynamically adjust its speed based on real-time cooling demands. The result is a significant reduction in energy consumption, as the chiller operates more efficiently and adapts to the varying loads of the HVAC system. Businesses adopting York chiller parts with VSD experience not only cost savings but also contribute to a greener and more sustainable operation.

2. Smart Sensors for Predictive Intelligence:

York chiller parts now incorporate smart sensors that provide a wealth of real-time data to enhance system performance. These sensors continuously monitor critical parameters such as temperature, pressure, and performance metrics. The data collected is then analyzed to predict potential issues before they escalate, enabling a proactive approach to maintenance. Predictive intelligence powered by smart sensors minimizes downtime, extends the lifespan of chiller components, and ensures uninterrupted HVAC operations.

3. Advanced Control Systems – Precision and Adaptability:

The latest York chiller parts feature advanced control systems that redefine precision and adaptability in HVAC operations. These systems allow for fine-tuning the chiller’s performance to match specific load conditions, optimizing efficiency at varying capacities. Furthermore, these controls seamlessly integrate with building automation systems, providing a centralized approach to managing HVAC operations. The result is unparalleled precision in temperature control and adaptability to diverse operating conditions.

4. Eco-Friendly Refrigerants – Sustainable Cooling Solutions:

As environmental sustainability takes center stage, York chiller parts have embraced the use of eco-friendly refrigerants. These refrigerants have lower global warming potential (GWP) and ozone depletion potential (ODP), aligning with regulatory standards and reducing the overall environmental impact of HVAC systems. Businesses choosing York chiller parts with eco-friendly refrigerants not only meet compliance requirements but also contribute to a more sustainable and environmentally responsible approach to cooling.

5. Enhanced Heat Exchangers – Optimizing Heat Transfer:

Critical to the efficiency of any chiller system, the heat exchanger has undergone significant advancements in York chiller parts. Enhanced heat exchangers optimize heat transfer efficiency, resulting in faster and more effective cooling. This innovation not only contributes to energy savings but also enhances the overall performance of the chiller, making it a key component in the latest York chiller parts lineup.

6. Adaptive Capacity Control – Meeting Variable Demands:

One of the challenges in HVAC operations is adapting to variable cooling loads. York chiller parts address this challenge with adaptive capacity control mechanisms. These systems adjust the capacity of the chiller to match the actual cooling needs of the space, preventing energy wastage during periods of low demand. The adaptive capacity control ensures that the chiller operates at peak efficiency across a wide range of operating conditions.

7. Intelligent Diagnostics and Connectivity – Remote Monitoring and Management:

Connectivity is a hallmark of modern HVAC systems, and York chiller parts have embraced intelligent diagnostics and connectivity options. Facility managers can now remotely monitor and control the chiller system, accessing real-time data and making adjustments from anywhere. This connectivity streamlines maintenance tasks, facilitates quick decision-making, and ensures optimal system management, contributing to the overall efficiency of HVAC operations.

8. Energy Recovery Systems – Harnessing Waste Heat:

In the pursuit of energy efficiency, York chiller parts now incorporate energy recovery systems. These systems capture and repurpose waste heat generated during the chiller’s operation. The repurposed heat can be used for heating applications within the facility or redirected to other processes, further reducing energy consumption and enhancing the sustainability of HVAC operations.

The Impact on HVAC Systems:

Now, let’s delve into how the latest innovations in York chiller parts are transforming the landscape of HVAC systems for commercial and industrial applications.

1. Unprecedented Energy Efficiency:

The integration of variable speed drives, eco-friendly refrigerants, and energy recovery systems collectively contributes to unprecedented energy efficiency in HVAC systems. Businesses adopting the latest York chiller parts experience significant reductions in energy consumption, leading to lower operational costs and a smaller environmental footprint. The commitment to energy efficiency aligns with sustainability goals and regulatory standards.

2. Predictive Maintenance for Enhanced Reliability:

Smart sensors and predictive maintenance capabilities redefine the reliability of HVAC systems. The ability to predict and address potential issues before they cause system failures minimizes downtime and enhances the overall reliability of the chiller. This proactive maintenance approach extends the operational lifespan of components, providing businesses with the assurance of uninterrupted HVAC operations.

3. Sustainable Cooling Practices:

The use of eco-friendly refrigerants and energy recovery systems positions HVAC systems as contributors to sustainable cooling practices. Businesses adopting York chiller parts with these features are not only meeting environmental regulations but also actively participating in reducing their carbon footprint. This commitment to sustainability resonates with environmentally conscious consumers and stakeholders.

4. Precision Control for Optimal Performance:

Advanced control systems and adaptive capacity control mechanisms provide unparalleled precision in managing HVAC operations. The ability to fine-tune the chiller’s performance based on specific load conditions ensures optimal comfort and temperature control. Precision control is especially crucial in commercial and industrial spaces where varying conditions demand adaptability for consistent performance.

5. Remote Monitoring for Streamlined Management:

Intelligent diagnostics and connectivity options empower facility managers with real-time insights into chiller performance. Remote monitoring and management streamline maintenance tasks, facilitate quick decision-making, and ensure optimal system performance. The ability to access diagnostic data from anywhere enhances the overall efficiency of HVAC operations, reducing the need for on-site interventions.

6. Long-Term Cost Savings:

While the upfront investment in the latest York chiller parts may be significant, the long-term cost savings are substantial. Energy-efficient components, predictive maintenance strategies, and extended equipment lifespan contribute to a reduced total cost of ownership.

Businesses that prioritize these high-performance components can enjoy long-term financial benefits, making the initial investment a strategic and cost-effective choice.

Businesses that prioritize these high-performance components can enjoy long-term financial benefits, making the initial investment a strategic and cost-effective choice.

How Midwest Parts Center Leads the Way:

As a company dedicated to providing HVAC solutions for commercial and industrial areas, Midwest Parts Center stands at the forefront of incorporating the latest innovations in York chiller parts. Recognizing the transformative impact of these advancements, Midwest Parts Center is committed to providing businesses with cutting-edge components that deliver unparalleled performance.

Contact Midwest Parts Center:

For businesses eager to explore the capabilities of the latest York chiller parts and embrace the forefront of HVAC technology, Midwest Parts Center is ready to assist. Contact Midwest Parts Center at +1 800 368 8385 for inquiries, consultations, and to discover how these innovative components can be seamlessly integrated into your HVAC systems.

In conclusion, the latest innovations in York chiller parts represent a pinnacle of excellence in the HVAC industry. From variable speed drives to smart sensors, advanced controls, and eco-friendly features, these components are designed to meet the evolving needs of commercial and industrial applications. As businesses seek optimal performance, energy efficiency, and sustainability in their HVAC operations, the latest York chiller parts, championed by Midwest Parts Center, stand as a testament to the transformative power of cutting-edge technology in the pursuit of excellence in heating and cooling solutions.