Louisville KY YORK Chiller of Essential Components: Any cooling system that wants to keep running at peak efficiency needs regular maintenance. Thus, it is highly recommended that you rely on York components and services for effective maintenance and repair. Those dependent on York components should blend a variety of York components, their applications, and their unique qualities.

For optimal performance, however, it must be compatible with your setup. YORK is an established brand that has helped pave the way for future businesses.

Louisville KY YORK Chiller 8 most valuable items sold in York and their function(s)

YORK Controls has the widest selection of water and air-cooled industrial and commercial chillers. Our smaller, more energy-efficient chillers, including heating, can be adapted for nearly any comfort or process chilling application to reduce your facility’s carbon footprint, provide a healthier indoor environment, and save energy costs.

YORK Controls has the widest selection of water and air-cooled industrial and commercial chillers. Our smaller, more energy-efficient chillers, including heating, can be adapted for nearly any comfort or process chilling application to reduce your facility’s carbon footprint, provide a healthier indoor environment, and save energy costs.

The following are a few examples of York wares that you might find yourself in:

York YK/ YVAA chiller parts

It is crucial to have easy access to high-quality supplies that meet the needs of the facility manager if the chiller equipment malfunctions or breaks down.

So, consider YVAA chiller parts, as YK chillers, or the York YLAA chiller parts if you need reliable components for your chiller. Moreover, customers receive a sufficient supply, and consumers receive nothing but the highest quality, making this the ideal location for a quick pit stop.

York YT chiller parts

One of the best ways to ensure your workplace or residence is always pleasant and comfortable is to keep the temperature low.

You can’t run a successful business without using modern cooling equipment, and York YT Chillers are a crucial part of that. Temperature control is necessary for commercial and industrial buildings throughout the four seasons. Maintaining the peak performance of your chiller is possible when you use genuine York YT parts.

York YVAA chiller parts

The YVAA chiller is controlled by Variable Speed Drive (VSD) technology, a highly recommended product family component. This air-cooled chiller has a stellar reputation in the commercial air conditioning industry for its reliability and effectiveness. The YVAA chiller efficiently cools the building while reducing operational expenses.

The YVAA chiller is controlled by Variable Speed Drive (VSD) technology, a highly recommended product family component. This air-cooled chiller has a stellar reputation in the commercial air conditioning industry for its reliability and effectiveness. The YVAA chiller efficiently cools the building while reducing operational expenses.

Always use York-applied parts for the longest possible lifespan of your chiller unit in commercial and industrial settings.

Louisville KY York Chiller Part

Use only trusted York components in your HVAC system. All of the listed devices can use all Louisville KY york chiller components. The most practical solution for effective cooling would be incorporating these devices into York machines.

York Genuine parts (Louisville KY YORK Chiller)

Use only genuine York products to ensure the longevity of your HVAC system. When you use factory-authorized replacement components, your chiller and other critical machinery will serve you well for years.

York preventative maintenance kits

The air conditioning systems those York replacement components are designed to service. Over the years, thousands of people have relied on York’s preventative maintenance kits. A Preventive Maintenance Kit contains all the parts and tools necessary to perform annual service and is standard equipment for most modern chiller models.

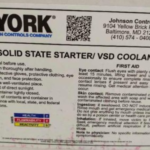

York VSD coolant

When it comes to the components of your chiller, nothing but the best will do. When only YORK VSD coolant is used in YORK machinery, the equipment stays in peak condition and maintains the YORK name and reputation.

Commercial Importance OF Louisville KY York Chiller Parts

People living and working in substandard conditions are more likely to experience irritation and agitation. In turn, the structure itself will suffer. Consequently, if your AC or furnace has started acting funny, you should look into getting some replacement York components. The York name is synonymous with quality and excellence in every aspect.

People living and working in substandard conditions are more likely to experience irritation and agitation. In turn, the structure itself will suffer. Consequently, if your AC or furnace has started acting funny, you should look into getting some replacement York components. The York name is synonymous with quality and excellence in every aspect.

We carry various Louisville KY YORK chiller parts and products to assist you in equipment acquisition, maintenance, and repair. They offer cooling and cooling systems, packaged systems, and other equipment components. When you need to find HVAC Parts, we can assist you in locating the appropriate York products for your air conditioner.

There are two ways that

There are two ways that  Midwest Needlepoint Bipolar Ionization can split water molecules into constituent positively charged Hydrogen Ions and negatively charged hydroxyl ions. NPBI also splits oxygen into bipolar oxygen ions. The bipolar ions adhere to the surfaces of pathogens and damage them by combining with Hydrogen and Nitrogen atoms from the surface of the pathogens.

Midwest Needlepoint Bipolar Ionization can split water molecules into constituent positively charged Hydrogen Ions and negatively charged hydroxyl ions. NPBI also splits oxygen into bipolar oxygen ions. The bipolar ions adhere to the surfaces of pathogens and damage them by combining with Hydrogen and Nitrogen atoms from the surface of the pathogens. The NPBI system acts the same against dust and mold in the air. The bipolar ions bind with particles in the air in an attempt to lose their charge. As this happens, the particles become charged and attract more molecules and solid particles within the airspace, causing them to merge and form larger particles. The larger particles are easily filtrated by existing air conditioning and filtration systems resulting in cleaner air with fewer solid particles.

The NPBI system acts the same against dust and mold in the air. The bipolar ions bind with particles in the air in an attempt to lose their charge. As this happens, the particles become charged and attract more molecules and solid particles within the airspace, causing them to merge and form larger particles. The larger particles are easily filtrated by existing air conditioning and filtration systems resulting in cleaner air with fewer solid particles.

You can’t take a chance with anything less than custom-made components for your chiller. As a well-known firm and brand, YORK has a stellar track record. Regular maintenance and system updates are required to extend the life of heavy equipment. Your company’s prosperity depends on the efficiency of your chiller, which is a significant financial investment.

You can’t take a chance with anything less than custom-made components for your chiller. As a well-known firm and brand, YORK has a stellar track record. Regular maintenance and system updates are required to extend the life of heavy equipment. Your company’s prosperity depends on the efficiency of your chiller, which is a significant financial investment. A part of the heating and cooling system is the

A part of the heating and cooling system is the  The VSD coolant system keeps the HVAC and Chiller at a comfortable temperature. Removing moisture from the air through cooling systems improves indoor air quality. York VSD chiller coolant ensures a trouble-free and efficient operation of your HVAC equipment.

The VSD coolant system keeps the HVAC and Chiller at a comfortable temperature. Removing moisture from the air through cooling systems improves indoor air quality. York VSD chiller coolant ensures a trouble-free and efficient operation of your HVAC equipment.

Finding brand names like

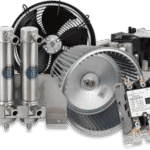

Finding brand names like  Our air handler and air system replacement parts provide the exact form, fit, and functionality required and maintenance services to ensure they function correctly in your system.

Our air handler and air system replacement parts provide the exact form, fit, and functionality required and maintenance services to ensure they function correctly in your system. With YORK original parts, you are guaranteed optimum controls and services to ensure that your Industrial HVAC systems run smoothly. This unrivaled collection of HVAC products and solutions will assist you in creating buildings that are more pleasant, safer, and efficient.

With YORK original parts, you are guaranteed optimum controls and services to ensure that your Industrial HVAC systems run smoothly. This unrivaled collection of HVAC products and solutions will assist you in creating buildings that are more pleasant, safer, and efficient.

Industrial YORK YT Chiller Parts are of the highest quality. The parts of the YORK YT chiller for industrial and commercial use are comparable to those found in other chillers. It makes choosing elements that match the unit appropriate for seamless part integration.

Industrial YORK YT Chiller Parts are of the highest quality. The parts of the YORK YT chiller for industrial and commercial use are comparable to those found in other chillers. It makes choosing elements that match the unit appropriate for seamless part integration. It’s best to buy genuine York YT parts rather than knockoffs while shopping for York YT parts. You can always count on high-quality equipment and meticulous attention to detail. You may rely on features for air systems, chillers, condensers, and maintenance kits for commercial and industrial systems.

It’s best to buy genuine York YT parts rather than knockoffs while shopping for York YT parts. You can always count on high-quality equipment and meticulous attention to detail. You may rely on features for air systems, chillers, condensers, and maintenance kits for commercial and industrial systems.

Every construction decision presents an opportunity to create a more efficient, intelligent, and connected space – an environment tailored to our daily lives and work.

Every construction decision presents an opportunity to create a more efficient, intelligent, and connected space – an environment tailored to our daily lives and work. Every system we offer comes with world-class YORK service and support to help keep it running at optimal performance. Every YORK system is built for efficient, long-lasting performance that uses less energy and runs more efficiently in real-world settings, from simple retrofits to the most sophisticated, custom installations worldwide.

Every system we offer comes with world-class YORK service and support to help keep it running at optimal performance. Every YORK system is built for efficient, long-lasting performance that uses less energy and runs more efficiently in real-world settings, from simple retrofits to the most sophisticated, custom installations worldwide. To buy YORK Spare Parts, we created this selection, in which you can find our offer for sale. Our main goal is for you to check online the price for a wide range of products that make up the YORK Spare Parts family and buy at the best price while also knowing the shipping price to any destination.

To buy YORK Spare Parts, we created this selection, in which you can find our offer for sale. Our main goal is for you to check online the price for a wide range of products that make up the YORK Spare Parts family and buy at the best price while also knowing the shipping price to any destination.

8 TipsTo Prevent Downtime With York Applied Precision Air Compressor Parts

8 TipsTo Prevent Downtime With York Applied Precision Air Compressor Parts Pressure-washing your cooler is critical, mainly if you work in dirtier environments. Cleaning your cooler before you need it will save you time.

Pressure-washing your cooler is critical, mainly if you work in dirtier environments. Cleaning your cooler before you need it will save you time. The belts and couplings on your air compressor don’t always get the attention they deserve. People frequently forget to monitor them, and issues can arise quickly. Belts and couplings wear down quickly, especially when the weather is hot. When they become worn out, they can reduce the effectiveness of an air compressor or perhaps prevent it from working at all. Checking your compressor’s belts and couplings regularly can help keep it in good working order.

The belts and couplings on your air compressor don’t always get the attention they deserve. People frequently forget to monitor them, and issues can arise quickly. Belts and couplings wear down quickly, especially when the weather is hot. When they become worn out, they can reduce the effectiveness of an air compressor or perhaps prevent it from working at all. Checking your compressor’s belts and couplings regularly can help keep it in good working order.

Various energy, acoustic, and mechanical combinations are available to suit your needs and preferences. Choose a lighter, more efficient chiller that requires less maintenance in the long term to save money.

Various energy, acoustic, and mechanical combinations are available to suit your needs and preferences. Choose a lighter, more efficient chiller that requires less maintenance in the long term to save money. The York YLAA doesn’t have to spend more money to be a leader in sustainability. An innovative heat exchanger and R-410A refrigerant make the YLAA chiller ideal for use in sensitive environments. Consequently, this cooler is green.

The York YLAA doesn’t have to spend more money to be a leader in sustainability. An innovative heat exchanger and R-410A refrigerant make the YLAA chiller ideal for use in sensitive environments. Consequently, this cooler is green.

The YK Commercial York has three distinct advantages. As a result, York Parts is the first thing that springs to mind when discussing HVAC equipment. Some parts of your HVAC system may need to be changed even if you are just required to repair it regularly.

The YK Commercial York has three distinct advantages. As a result, York Parts is the first thing that springs to mind when discussing HVAC equipment. Some parts of your HVAC system may need to be changed even if you are just required to repair it regularly. Having reliable brands and service providers for service and repairs would be helpful. Every user of York YK parts can count on it without appearing complacent about the functionality of their HVAC system. Avoid consulting other generic parts providers should you need to repair, service, or replace some part in your HVAC system.

Having reliable brands and service providers for service and repairs would be helpful. Every user of York YK parts can count on it without appearing complacent about the functionality of their HVAC system. Avoid consulting other generic parts providers should you need to repair, service, or replace some part in your HVAC system. Air conditioning is used in every industry to promote productivity and comfort. Air quality concerns many establishments, from factories and schools to malls and warehouses. Workplaces should be pleasant, clean, and relaxing. Using the York components during routine repairs and maintenance of the chiller system can improve the system’s efficiency.

Air conditioning is used in every industry to promote productivity and comfort. Air quality concerns many establishments, from factories and schools to malls and warehouses. Workplaces should be pleasant, clean, and relaxing. Using the York components during routine repairs and maintenance of the chiller system can improve the system’s efficiency.

Rather than relying on brute force dilution of contaminants by adding more fresh air to indoor spaces, required outside airflow rates can be lowered by tackling the contaminants of emerging concern (CECs) directly.

Rather than relying on brute force dilution of contaminants by adding more fresh air to indoor spaces, required outside airflow rates can be lowered by tackling the contaminants of emerging concern (CECs) directly.  ASHRAE does not recommend a specific CO2 level — just that very high CO2 concentrations (e.g., higher than 5000 parts per million or ppm) might represent a health risk. Additionally, ASHRAE notes that CO2 concentration is not a good marker of the concentration and occupant acceptance of other indoor air pollutants, such as VOCs released by building materials and furnishings. Therefore, CO2 concentration is not a reliable indicator of the overall IAQ in your commercial facility.

ASHRAE does not recommend a specific CO2 level — just that very high CO2 concentrations (e.g., higher than 5000 parts per million or ppm) might represent a health risk. Additionally, ASHRAE notes that CO2 concentration is not a good marker of the concentration and occupant acceptance of other indoor air pollutants, such as VOCs released by building materials and furnishings. Therefore, CO2 concentration is not a reliable indicator of the overall IAQ in your commercial facility.