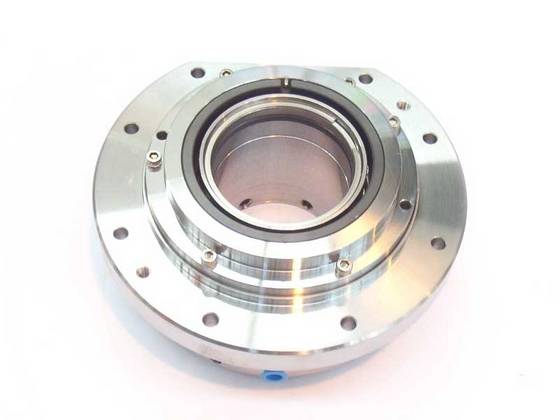

York YT Midwest Chiller Parts for Maintenance Projects

Cooling systems are complex temperature control systems. Service engineers use York YT Midwest chiller parts to ensure the maintenance of the cooling systems. In reality, cooling systems in harsh environments are subject to stringent requirements. Also, commercial facilities and industrial centers rely on cooling systems year-round.

Cooling systems are complex temperature control systems. Service engineers use York YT Midwest chiller parts to ensure the maintenance of the cooling systems. In reality, cooling systems in harsh environments are subject to stringent requirements. Also, commercial facilities and industrial centers rely on cooling systems year-round.

York YT Midwest chiller parts for maintenance are ideal for cooling jobs. Midwest Parts Center is a leading supplier of HVAC parts and equipment for the York brand. Industrial plants and commercial buildings also rely on the Midwest Parts Center as an authorized heating and cooling equipment source. Finally, customers discover that sourcing components from trusted suppliers help improve the management of air-conditioning systems.

York YT Midwest chiller parts are excellent for service and maintenance needs. Also, service technicians can be responsible for the care and parts of a cooling system. These components actually decrease the time it takes to perform a repair. Furthermore, spare components reduce offline time for HVAC systems. Short-term problems associated with repairs require a critical response. Commercial establishments cannot afford to delay the repair. Also, for commercial enterprises, temperature control systems are far too important.

York YT Midwest chiller parts are excellent for service and maintenance needs. Also, service technicians can be responsible for the care and parts of a cooling system. These components actually decrease the time it takes to perform a repair. Furthermore, spare components reduce offline time for HVAC systems. Short-term problems associated with repairs require a critical response. Commercial establishments cannot afford to delay the repair. Also, for commercial enterprises, temperature control systems are far too important.

Midwest Parts Center is a competent provider of HVAC services and equipment. We work with commercial companies to find YT cooling units for various applications. Parts procurement is a practical way to manage cooling units. Spare parts are beneficial for small and large repairs. HVAC units require qualified care from a service professional. Cooling units are most dependable with proper care.

York YT Midwest Chiller Parts for Maintenance Tasks

Contact Midwest Parts Center to find out how we can help you find high-quality parts for York refrigerators. We help end-users find parts that meet the needs of cooling units. Spare parts allow facilities to restart a crashed unit more quickly. Also, spare parts limit the cost of ownership by extending the use of the unit. Finally, using HVAC parts for repairs or replacement is simply an economic decision.

Effective Cool Air Solutions

The YT chillers are another efficient model from York. The system incorporates advanced technology developed exclusively for the brand. Since efficiency is a major concern of plants, the technology of the YT chillers is ideal. Also, facilities hoping to make the most of a cooling system in the long term should consider working with the Midwest Parts Center to meet ongoing needs.

The YT chillers are another efficient model from York. The system incorporates advanced technology developed exclusively for the brand. Since efficiency is a major concern of plants, the technology of the YT chillers is ideal. Also, facilities hoping to make the most of a cooling system in the long term should consider working with the Midwest Parts Center to meet ongoing needs.

The YT model is streamlined, and the York YT Midwest chiller parts facilitate maintenance. Midwest Parts Center is a respected supplier of parts and equipment for York. Customers should contact the Midwest Parts Center for equipment catalogs of spare parts. Are you interested in exploring our wide range of components for the YT chillers?

Enquire about spare parts for the York YT chiller unit.

York YLAA Commercial chiller systems are used in commercial buildings to maintain airflow and adapt cooling systems to commercial centers’ specific needs. Therefore,

York YLAA Commercial chiller systems are used in commercial buildings to maintain airflow and adapt cooling systems to commercial centers’ specific needs. Therefore,  We have acquired a comprehensive knowledge of industrial and commercial heating and cooling needs through our HVAC industry expertise. The reality is that the requirements for climate regulation only apply to individual installations. York YLAA replacement cooling units purchased through the Midwest Parts Center can meet many requirements.

We have acquired a comprehensive knowledge of industrial and commercial heating and cooling needs through our HVAC industry expertise. The reality is that the requirements for climate regulation only apply to individual installations. York YLAA replacement cooling units purchased through the Midwest Parts Center can meet many requirements. Parts delivery is most effective when controlling HVAC systems. Maintenance of ventilation systems in industrial plants or commercial buildings is complicated. The systems require continuous monitoring, regular maintenance, and ongoing condition checks. Due to the enormous role of cooling systems in large buildings, components must contribute to cost control.

Parts delivery is most effective when controlling HVAC systems. Maintenance of ventilation systems in industrial plants or commercial buildings is complicated. The systems require continuous monitoring, regular maintenance, and ongoing condition checks. Due to the enormous role of cooling systems in large buildings, components must contribute to cost control.

The building managers hope to improve the air quality in the facilities. Viruses easily spread where people congregate daily, and

The building managers hope to improve the air quality in the facilities. Viruses easily spread where people congregate daily, and

Air conditioners play a major role in providing comfortable air. Also, air-conditioning systems provide germ-free breathing air. Because people often work in proximity, infection control is a must. The reality is germs spread rapidly. Ventilation is a unique tool in the fight against infection control. Indeed, every employee and customer needs a room with clean air. Clean air can provide long-term benefits. Healthy air also promotes a healthier lifestyle.

Air conditioners play a major role in providing comfortable air. Also, air-conditioning systems provide germ-free breathing air. Because people often work in proximity, infection control is a must. The reality is germs spread rapidly. Ventilation is a unique tool in the fight against infection control. Indeed, every employee and customer needs a room with clean air. Clean air can provide long-term benefits. Healthy air also promotes a healthier lifestyle.

Facility managers hope to improve air quality in the facilities. Viruses easily spread where people gather daily, and

Facility managers hope to improve air quality in the facilities. Viruses easily spread where people gather daily, and  In addition to the CDC’s preventive measures, commercial facilities can implement tools to stop the spread of viruses. Bipolar ionization is also a possible treatment. Needlepoint bipolar ionization is the key force in Midwest Global Plasma Solutions for industrial buildings. The ionization inactivates viruses and kills germs on contact. Furthermore, the treatment provides purification for the air in facilities. Midwest Global Plasma Solutions offers a high kill rate and many other perks.

In addition to the CDC’s preventive measures, commercial facilities can implement tools to stop the spread of viruses. Bipolar ionization is also a possible treatment. Needlepoint bipolar ionization is the key force in Midwest Global Plasma Solutions for industrial buildings. The ionization inactivates viruses and kills germs on contact. Furthermore, the treatment provides purification for the air in facilities. Midwest Global Plasma Solutions offers a high kill rate and many other perks. HVAC systems play a key role in providing comfortable air. Air conditioners also ensure germ-free breathing air. Because people often work in proximity, infection control is a must. The fact is that germs are spreading rapidly. Ventilation is a unique instrument in the fight against infection control. In fact, every employee and customer needs a space with clean air. Clean air can provide long-term benefits. Healthy air also encourages a healthier lifestyle.

HVAC systems play a key role in providing comfortable air. Air conditioners also ensure germ-free breathing air. Because people often work in proximity, infection control is a must. The fact is that germs are spreading rapidly. Ventilation is a unique instrument in the fight against infection control. In fact, every employee and customer needs a space with clean air. Clean air can provide long-term benefits. Healthy air also encourages a healthier lifestyle.

An infectious spread is not uncommon in large facilities. In truth, people become infected with viruses at work yearly. However, the

An infectious spread is not uncommon in large facilities. In truth, people become infected with viruses at work yearly. However, the Companies hope to reduce exposure to coronavirus and other germs by using a device known as ionization. Midwest

Companies hope to reduce exposure to coronavirus and other germs by using a device known as ionization. Midwest  It has been found that Global Plasma Solutions produces viruses that are not viable. An important step is taken during the final state of Midwest bipolar ionization, in which ions bind with a pathogen to remove a hydrogen bond. Hydrogen bonding is vital. According to a study carried out on Global Plasma Solutions, the killing rate for the main pathogens, including E., is up to 99%. Coli, Legionella, and Mold. Also, pathogens such as norovirus and MRSA had high death rates, at just over 93%.

It has been found that Global Plasma Solutions produces viruses that are not viable. An important step is taken during the final state of Midwest bipolar ionization, in which ions bind with a pathogen to remove a hydrogen bond. Hydrogen bonding is vital. According to a study carried out on Global Plasma Solutions, the killing rate for the main pathogens, including E., is up to 99%. Coli, Legionella, and Mold. Also, pathogens such as norovirus and MRSA had high death rates, at just over 93%.

Midwest Part Center’s

Midwest Part Center’s  HVAC systems are not only used for temperature control. Air-Conditioning provides breathable air. The air is free of viruses, pollutants, and contamination. In some facilities, however, germs can enter a building via a ventilation system. For this reason, facility managers can retrofit systems with antiviral devices like Global Plasma Solutions. Industrial n

HVAC systems are not only used for temperature control. Air-Conditioning provides breathable air. The air is free of viruses, pollutants, and contamination. In some facilities, however, germs can enter a building via a ventilation system. For this reason, facility managers can retrofit systems with antiviral devices like Global Plasma Solutions. Industrial n Clean air is a must for industrial facilities. The recent pandemic caused by coronavirus and COVID-19 has encouraged companies to change their pure air approach with Industrial needlepoint bipolar ionization. Air purification is a beneficial expenditure as it gives to productivity and profitability.

Clean air is a must for industrial facilities. The recent pandemic caused by coronavirus and COVID-19 has encouraged companies to change their pure air approach with Industrial needlepoint bipolar ionization. Air purification is a beneficial expenditure as it gives to productivity and profitability.

HVAC units are not just used for temperature control. Air-Conditioning units provide breathable air. Breathable air is free from viruses, contaminants, and pollution. In some facilities, however, germs can enter a building through a ventilation system. For this reason, facility managers can retrofit systems with antiviral devices such as Global Plasma Solutions.

HVAC units are not just used for temperature control. Air-Conditioning units provide breathable air. Breathable air is free from viruses, contaminants, and pollution. In some facilities, however, germs can enter a building through a ventilation system. For this reason, facility managers can retrofit systems with antiviral devices such as Global Plasma Solutions. Clean air is a necessity for commercial facilities. The recent pandemic due to coronavirus and COVID-19 has moved companies to alter their approach to clean air. Air purification happens to be a worthwhile investment as it contributes to productivity and profitability.

Clean air is a necessity for commercial facilities. The recent pandemic due to coronavirus and COVID-19 has moved companies to alter their approach to clean air. Air purification happens to be a worthwhile investment as it contributes to productivity and profitability.

The infectious spread is not uncommon in large facilities. In truth, people become infected with viruses at work every year.

The infectious spread is not uncommon in large facilities. In truth, people become infected with viruses at work every year.  applied to existing forced-air units by a commercial service technician. Moreover, the recent threat of coronavirus affecting facilities has re-engaged discussions on ionization in commercial buildings. As a result, facility managers and business owners have jumped into action to prevent the spread of COVID-19.

applied to existing forced-air units by a commercial service technician. Moreover, the recent threat of coronavirus affecting facilities has re-engaged discussions on ionization in commercial buildings. As a result, facility managers and business owners have jumped into action to prevent the spread of COVID-19. Businesses are hoping to decrease exposure to coronavirus and other germs by enlisting a device known as ionization. Industrial Bipolar ionization renders germs inactive by removing an important hydrogen bond to generate free radicals. The free radicals that form as the result of ionization attack viruses and render them inactive.

Businesses are hoping to decrease exposure to coronavirus and other germs by enlisting a device known as ionization. Industrial Bipolar ionization renders germs inactive by removing an important hydrogen bond to generate free radicals. The free radicals that form as the result of ionization attack viruses and render them inactive.

Building managers are hoping to boost the overall quality of air in facilities. Viruses spread easily where folks gather daily, and

Building managers are hoping to boost the overall quality of air in facilities. Viruses spread easily where folks gather daily, and  Together with preventative measures urged by the CDC, commercial facilities can implement tools to stop the spread of viruses. Also, a potential treatment is bipolar ionization. Needlepoint bipolar ionization is the central force in Midwest Global Plasma Solutions. In fact, ionization inactivates viruses and kills germs on contact. Furthermore, the treatment provides purification for the air in facilities. Midwest Global Plasma Solutions offers a high kill rate plus many other benefits.

Together with preventative measures urged by the CDC, commercial facilities can implement tools to stop the spread of viruses. Also, a potential treatment is bipolar ionization. Needlepoint bipolar ionization is the central force in Midwest Global Plasma Solutions. In fact, ionization inactivates viruses and kills germs on contact. Furthermore, the treatment provides purification for the air in facilities. Midwest Global Plasma Solutions offers a high kill rate plus many other benefits. Air-Conditioning units play a major part in providing comfortable air. Furthermore, A/C units offer breathable air that is void of germs. Because individuals work in close quarters often, infection control is a must. The reality is that germs propagate quickly. Ventilation is a unique tool in the fight to manage infection control. Indeed, every employee and customer needs a space with clean air. Cleaner air can provide long-lasting benefits. Additionally, healthy air promotes healthier lifestyles.

Air-Conditioning units play a major part in providing comfortable air. Furthermore, A/C units offer breathable air that is void of germs. Because individuals work in close quarters often, infection control is a must. The reality is that germs propagate quickly. Ventilation is a unique tool in the fight to manage infection control. Indeed, every employee and customer needs a space with clean air. Cleaner air can provide long-lasting benefits. Additionally, healthy air promotes healthier lifestyles.

Both clientele and employees need a well-ventilated atmosphere to run an enterprise.

Both clientele and employees need a well-ventilated atmosphere to run an enterprise.  The CDC has provided guidelines to the public on how to stop the spread of viruses potentially. Moreover, the authority on diseases has also advised that facilities consider the effects of ventilation and air-conditioning units on infection control. As a Commercial coronavirus sanitizer, HVAC units can purify the air by removing harmful viruses and germs.

The CDC has provided guidelines to the public on how to stop the spread of viruses potentially. Moreover, the authority on diseases has also advised that facilities consider the effects of ventilation and air-conditioning units on infection control. As a Commercial coronavirus sanitizer, HVAC units can purify the air by removing harmful viruses and germs. Since not everyone adheres to the guidelines set forth on infection control, other methods must be used. Our Commercial coronavirus sanitizer method combats surface and airborne germs with precision. Furthermore, using Global Plasma Solutions as a sanitizer device improves air quality, temperature, and outdoor airflow.

Since not everyone adheres to the guidelines set forth on infection control, other methods must be used. Our Commercial coronavirus sanitizer method combats surface and airborne germs with precision. Furthermore, using Global Plasma Solutions as a sanitizer device improves air quality, temperature, and outdoor airflow.