York HVAC Parts Supplier Commitment to High Quality parts. In the realm of indoor climate control, the quest for comfort is paramount. Behind the scenes of every efficient heating, ventilation, and air conditioning (HVAC) system lies a symphony of essential components working in harmony. York HVAC Parts Supplier, a trusted name in the industry, stands as a cornerstone of this symphony, delivering a wide range of vital components that ensure comfort, reliability, and optimal performance. Join us on a journey through the realm of HVAC components, where comfort is elevated to an art form.

Precision Engineered for Performance

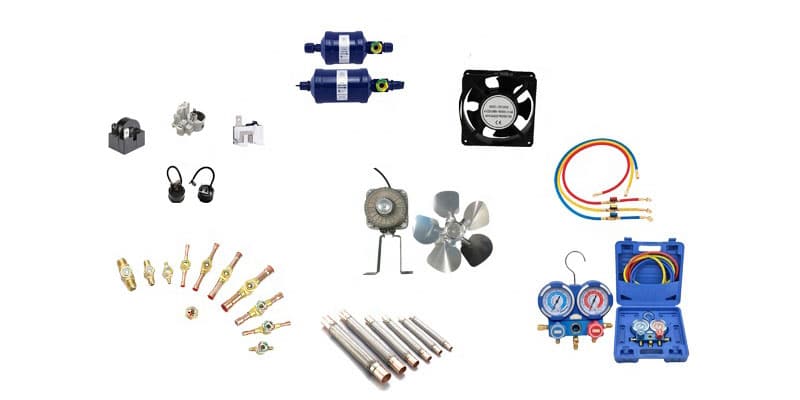

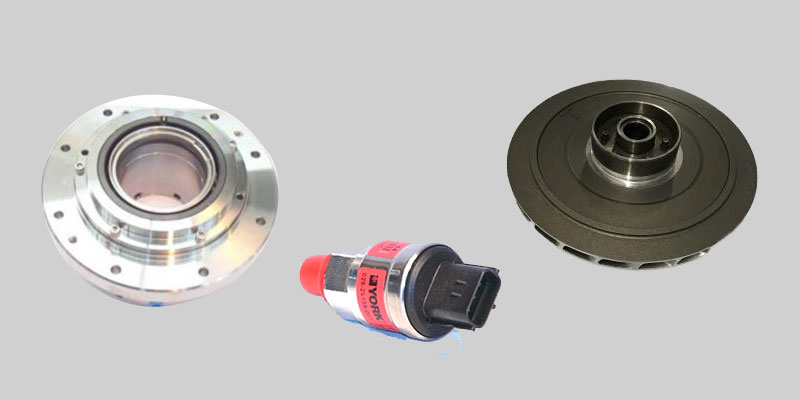

York HVAC Parts Supplier’s commitment to comfort begins with precision engineering. Each component is meticulously designed and manufactured to exacting standards. From compressors and fans to coils and valves, every piece of the puzzle plays a vital role in creating the perfect indoor environment. This focus on precision guarantees that the components seamlessly integrate into systems, contributing to their overall efficiency.

The Comprehensive Range: Building Blocks of Comfort

Diving into York HVAC Parts Supplier’s catalog reveals a treasure trove of essential components. Air handlers that regulate airflow, condenser units that manage heat exchange, thermostats that offer precise control – each component serves as a building block of comfort. The supplier’s range ensures that HVAC professionals have access to the parts they need to create reliable and comfortable systems.

Efficiency at the Core: Energy-Saving Solutions

In a world increasingly concerned with energy conservation, York HVAC Parts Supplier takes the lead by offering energy-efficient solutions. Variable-speed motors, smart thermostats, and high-efficiency compressors are just a few examples of components that not only enhance comfort but also reduce energy consumption. The supplier’s commitment to efficiency aligns with the industry’s drive towards sustainability.

Durability and Reliability: The Foundation of Comfort

Comfort is more than just temperature control; it’s also about peace of mind. York HVAC Parts Supplier understands this and places a premium on durability and reliability. Every component undergoes rigorous testing to ensure that it can withstand the demands of continuous operation. This commitment to longevity enhances the overall comfort experience for end-users.

York HVAC Parts Supplier Commitment to High Quality parts

Customization for Every Need: Tailored Comfort Solutions

HVAC systems vary based on building size, climate, and usage patterns. York HVAC Parts Supplier acknowledges this diversity by offering customizable solutions. Whether it’s selecting the right size of a component or choosing a technology that aligns with specific requirements, the supplier’s range caters to the diverse needs of the HVAC industry.

Supporting Professionals: Expertise and Assistance

Delivering comfort goes beyond components; it extends to knowledge and support. York HVAC Parts Supplier provides HVAC professionals with expert guidance, technical resources, and responsive customer support. This comprehensive approach ensures that professionals have the tools they need to deliver comfort to their clients effectively.

Conclusion: Elevating the Comfort Experience

In the intricate world of HVAC systems, York HVAC Parts Supplier emerges as a reliable partner in delivering comfort. With precision-engineered components, a comprehensive range, energy-efficient solutions, durability, customization, and expert support, the supplier enriches the comfort experience for both professionals and end-users. Each component isn’t just a part; it’s a contributor to an artful symphony of indoor comfort that York HVAC Parts Supplier orchestrates with unwavering dedication.

York HVAC Parts Supplier Commitment to Quality

In the world of HVAC systems, quality isn’t just a desirable trait; it’s a fundamental necessity. When it comes to heating, ventilation, and air conditioning (HVAC), the components that make up these systems must meet stringent standards of reliability and performance. York HVAC Parts Supplier stands as a beacon of excellence, upholding an unwavering commitment to quality. This article delves into the core principles and practices that drive York HVAC Parts Supplier’s dedication to providing reliable solutions that define industry standards.

Quality as a Cornerstone: Setting the Standard

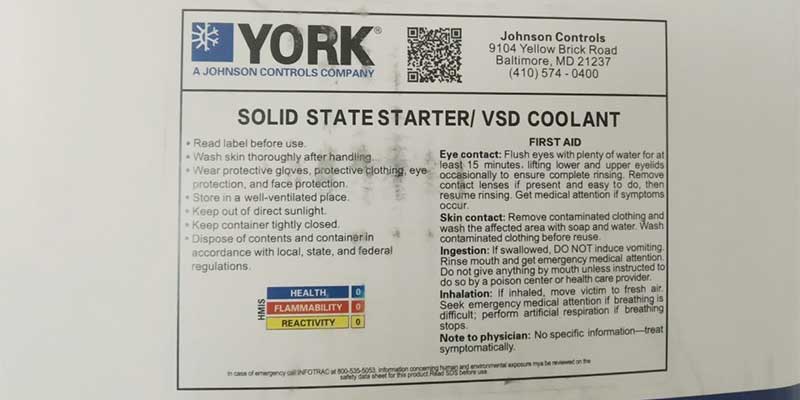

York HVAC Parts Supplier’s journey towards becoming a trusted source of reliable solutions starts with a foundation built on quality. Every component that bears the supplier’s name undergoes a meticulous selection process, where materials, design, and manufacturing are scrutinized to ensure they meet or exceed industry standards. This focus on quality is the bedrock upon which all other commitments are built.

Rigorous Testing: Beyond the Surface

Ensuring quality goes beyond appearance; it extends to the performance and durability of each component. York HVAC Parts Supplier employs rigorous testing protocols that simulate real-world conditions. From stress tests to performance assessments, these tests expose components to extreme scenarios, guaranteeing that they can withstand the challenges of daily operation.

Certifications and Compliance: Seals of Excellence

York HVAC Parts Supplier’s commitment to quality is further affirmed by certifications and compliance with industry standards. Each component is tested and certified by recognized authorities, assuring customers that they are investing in products that have been thoroughly vetted for safety and performance. These certifications are more than just seals; they are symbols of the supplier’s dedication to excellence.

Customer-Centric Approach: Solutions that Inspire Trust

York HVAC Parts Supplier understands that quality isn’t just about the components; it’s about instilling trust. The supplier’s customer-centric approach involves not only delivering reliable solutions but also providing exceptional customer support. Whether it’s technical assistance, product information, or prompt responses, the supplier’s commitment to customers reinforces the notion that they are partners in a journey towards dependable comfort.

York HVAC Parts Supplier Commitment to Quality

Continuous Improvement: Nurturing Excellence

The pursuit of quality is an ongoing journey, and York HVAC Parts Supplier embraces this notion wholeheartedly. The supplier fosters a culture of continuous improvement, where feedback, innovation, and industry insights are integrated into its operations. This approach ensures that the quality of solutions evolves alongside advancements in technology and industry best practices.

Sustainability and Responsibility: Quality in Every Aspect

For York HVAC Parts Supplier, quality isn’t isolated to the components themselves; it extends to the supplier’s operations as a whole. The supplier embraces sustainability, responsible sourcing, and ethical practices as integral components of its commitment to quality. This holistic approach ensures that every aspect of the business resonates with the same level of excellence.

Conclusion: Setting the Gold Standard

In a landscape where reliability and performance define success, York HVAC Parts Supplier shines as a gold standard in quality. Through rigorous testing, certifications, customer-centricity, continuous improvement, and a holistic commitment to sustainability, the supplier redefines what it means to provide reliable solutions. Every component isn’t just a product; it’s a testament to the supplier’s dedication to delivering excellence that transcends expectations and sets a new benchmark for the HVAC industry.

The Role of York HVAC Parts Supplier in Maintenance

In the intricate world of heating, ventilation, and air conditioning (HVAC) systems, reliability isn’t just a luxury; it’s an absolute necessity. These systems play a pivotal role in maintaining comfortable and functional indoor environments, making their uninterrupted operation a top priority. Enter York HVAC Parts Supplier, a key player in the maintenance landscape. This article delves into the integral role that the supplier plays in keeping HVAC systems running smoothly through its comprehensive range of parts and dedicated support.

The Backbone of Maintenance: Reliable Parts

Maintenance is only as effective as the parts that go into the system. York HVAC Parts Supplier understands this truth and offers a comprehensive range of high-quality components that are essential for maintaining HVAC systems. From belts and filters to motors and sensors, each part plays a critical role in ensuring the optimal performance of the system.

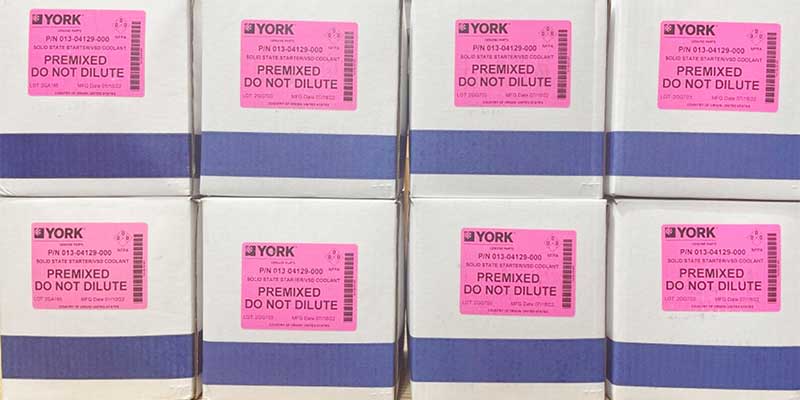

Minimizing Downtime: Swift Availability

When HVAC systems encounter issues, downtime can be costly and uncomfortable. York HVAC Parts Supplier acknowledges the urgency of the situation and maintains an efficient supply chain to ensure that the required parts are readily available. This swift availability minimizes downtime and helps HVAC professionals restore systems to their full functionality promptly.

Quality Assurance: Confidence in Replacement

Replacing a component isn’t just about swapping one part for another; it’s about maintaining the same level of performance and reliability. York HVAC Parts Supplier’s commitment to quality assurance ensures that every replacement part upholds the same high standards as the original. This consistency guarantees that the system’s reliability is preserved.

Expert Support: Navigating Complexities

Maintenance often involves complex troubleshooting and decision-making. York HVAC Parts Supplier recognizes the challenges that HVAC professionals face and provides expert support to guide them through the process. From offering technical advice to sharing insights on part compatibility, the supplier’s support helps professionals make informed decisions.

Preventive Maintenance: A Proactive Approach

In the world of HVAC, prevention is often more cost-effective than reaction. York HVAC Parts Supplier’s role extends beyond providing replacement parts; it also encompasses preventive maintenance. The supplier offers solutions that aid in preventive care, such as advanced filters, corrosion-resistant components, and system monitoring tools that help identify potential issues before they escalate.

The Role of York HVAC Parts Supplier in Maintenance

Training and Resources: Empowering Professionals

The maintenance landscape evolves with technological advancements. York HVAC Parts Supplier empowers HVAC professionals by providing training and resources that keep them up-to-date with the latest developments. These resources enhance professionals’ skill sets, enabling them to tackle maintenance challenges effectively.

Conclusion: Beyond Components, Ensuring Continuity

In a world where seamless operation is paramount, York HVAC Parts Supplier emerges as a guardian of continuity. Through a comprehensive range of quality components, expert support, preventive solutions, and continuous training, the supplier plays an indispensable role in keeping HVAC systems running smoothly. Beyond being a parts provider, York HVAC Parts Supplier is a partner in maintaining indoor comfort, operational efficiency, and peace of mind for both professionals and end-users.

York HVAC Parts Supplier’s Worldwide Reach

In the modern landscape of commerce, borders are no longer barriers. The ability to seamlessly reach customers across the globe has become a defining factor for success. York HVAC Parts Supplier stands as a testament to this paradigm shift, exemplifying the power of global distribution. This article delves into the intricate web of logistics, strategies, and dedication that underpin York HVAC Parts Supplier’s expansive worldwide reach.

Strategic Locations: Bridging Continents

Global distribution isn’t a matter of chance; it’s a product of strategic foresight. York HVAC Parts Supplier strategically establishes distribution centers across continents, positioning itself to bridge geographical gaps efficiently. These strategically located centers ensure that HVAC professionals and businesses around the world have access to the supplier’s products without unnecessary delays.

Efficiency in Motion: Timely Deliveries

In a world where time is a prized commodity, timely deliveries are non-negotiable. York HVAC Parts Supplier understands this urgency and orchestrates its distribution network with clockwork precision. From order processing to transportation and delivery, every step is optimized to minimize lead times and ensure that customers receive their required parts when they need them the most.

Custom Solutions: Catering to Diverse Needs

The world is a tapestry of diverse climates, regulations, and demands. York HVAC Parts Supplier’s global distribution isn’t a one-size-fits-all approach; it’s a tailored solution for every corner of the globe. Whether it’s adapting to regional regulations or ensuring components are compatible with local systems, the supplier’s distribution network is designed to cater to the unique needs of different markets.

Technology as the Enabler: Real-Time Tracking

In the digital age, technology is the linchpin that transforms global distribution into a reality. York HVAC Parts Supplier leverages advanced tracking systems to provide real-time visibility into the status of shipments. This transparency empowers customers to monitor their orders, anticipate deliveries, and make informed decisions based on accurate information.

Sustainability in Transit: Eco-Conscious Practices

Global distribution isn’t just about reaching destinations; it’s also about doing so responsibly. York HVAC Parts Supplier integrates sustainability into its distribution network by employing eco-conscious practices. From using energy-efficient transportation methods to minimizing packaging waste, the supplier’s commitment to the environment echoes through its global operations.

Responsive Support: Across Time Zones

Global distribution transcends time zones, and so does York HVAC Parts Supplier’s customer support. The supplier ensures that regardless of where customers are located, they have access to responsive assistance. Whether it’s addressing inquiries, providing technical support, or resolving issues, the supplier’s commitment to exceptional customer service remains unwavering.

Conclusion: Boundless Reach, Singular Commitment

In a world characterized by interconnectivity, York HVAC Parts Supplier redefines the scope of reach through its global distribution network. With strategic locations, efficiency, customization, technology integration, sustainability, and unwavering customer support, the supplier’s reach knows no bounds. As HVAC professionals and businesses around the world seek reliable solutions, York HVAC Parts Supplier stands as a beacon of assurance, offering not just products, but a seamless experience that transcends borders and exemplifies the true power of global distribution.

York HVAC Parts Supplier’s Technological Edge

In the ever-evolving landscape of heating, ventilation, and air conditioning (HVAC), efficiency and innovation are the driving forces that push the boundaries of what’s possible. York HVAC Parts Supplier stands at the forefront of this evolution, leveraging a technological edge to redefine industry standards. This article delves into the advanced technologies and innovative practices that empower York HVAC Parts Supplier to deliver unparalleled efficiency and cutting-edge solutions.

Smart Manufacturing: Precision Redefined

Efficiency starts at the manufacturing level, and York HVAC Parts Supplier employs smart manufacturing techniques to achieve precision and accuracy. From computer-aided design (CAD) to computer numerical control (CNC) machining, the supplier’s approach ensures that each component is crafted with meticulous detail, contributing to the overall efficiency of HVAC systems.

IoT Integration: Connecting Components

In the era of the Internet of Things (IoT), connectivity transforms HVAC systems into intelligent networks. York HVAC Parts Supplier integrates IoT technology into its components, enabling them to communicate and collaborate seamlessly. This interconnectivity not only enhances performance but also allows for data-driven insights that can optimize system efficiency and diagnose issues proactively.

Energy Efficiency Solutions: Sustainability in Action

Efficiency isn’t just about performance; it’s also about sustainability. York HVAC Parts Supplier pioneers energy-efficient solutions that reduce environmental impact while maximizing system performance. Components like variable-speed motors, smart thermostats, and energy-efficient compressors exemplify the supplier’s commitment to balancing efficiency and ecological responsibility.

Advanced Materials: Lightweight Strength

Materials are the building blocks of efficiency, and York HVAC Parts Supplier embraces advanced materials that enhance performance without adding unnecessary weight. Lightweight yet durable materials contribute to the overall efficiency of HVAC systems by reducing energy consumption while maintaining structural integrity.

Data Analytics for Optimization: Informed Decision-Making

The power of data analytics is harnessed by York HVAC Parts Supplier to optimize performance. By analyzing real-time and historical data, the supplier gains insights into usage patterns, wear and tear, and potential inefficiencies. This information empowers HVAC professionals to make informed decisions about maintenance and upgrades, ultimately boosting system efficiency.

Remote Monitoring and Control: Operational Agility

Efficiency doesn’t end with installation; it continues throughout the system’s lifecycle. York HVAC Parts Supplier offers remote monitoring and control capabilities that allow HVAC professionals and end-users to manage systems from a distance. This agility enhances efficiency by enabling timely adjustments, troubleshooting, and fine-tuning without the need for physical presence.

Conclusion: Defining Tomorrow’s HVAC Landscape

In a world driven by efficiency and innovation, York HVAC Parts Supplier emerges as a trailblazer. Through smart manufacturing, IoT integration, energy-efficient solutions, advanced materials, data analytics, and remote capabilities, the supplier sets a new standard for HVAC efficiency. Each component isn’t just a piece of the puzzle; it’s a testament to the supplier’s commitment to pushing the boundaries of what’s possible. With a technological edge that shapes tomorrow’s HVAC landscape, York HVAC Parts Supplier ensures that efficiency and innovation go hand in hand, redefining comfort and sustainability for the future.