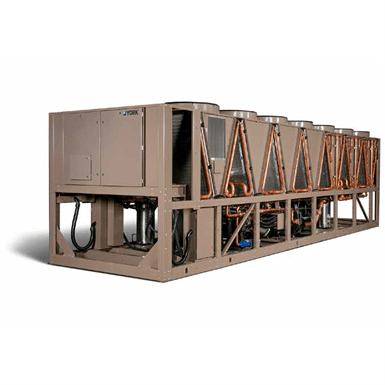

Chilling systems from York YLAA are typically installed in commercial buildings to maintain airflow and adapt cooling systems to meet the requirements of individual retail centers. As a result, commercial air systems provide York YLAA Commercial chiller components for service that receive replacement performance throughout the entire year.

The fact is that no brand can take York’s place due to the excellent reputation that York YLAA Commercial chiller components have earned; there is typically a strong demand for them. We can offer commercial and industrial application features, regardless of how popular York HVAC parts are.

Components for Commercial Chillers York YLAA

You may get York YLAA Commercial Chiller Parts with a lifetime guarantee. As a result of our extensive experience in the HVAC  industry, we have a thorough understanding of the requirements for heating and cooling in the industrial and commercial sectors.

industry, we have a thorough understanding of the requirements for heating and cooling in the industrial and commercial sectors.

The fact is that the prerequisites for climate regulation are only applicable to specific installations. Replacement cooling units for York YLAA acquired from us can fulfill various needs.

A few of the factories make use of industrial chillers to generate pleasant air. Additionally, the chillers supply cool air for other tasks, such as production and other activities. In addition, the systems have to be adequate to compensate for the size and energy requirements of the cooling systems.

YLAA and Air Conditioning

Air-conditioning systems are another factor that may contribute to increased running costs. As a direct result, decision-makers pay attention to the energy consumed. When put to use, York YLAA Commercial chiller parts for service can assist in the upkeep and preservation of the effectiveness of air-conditioning systems.

In plants, cooling systems contribute to increased comfort, efficiency, and productivity levels. Plants can achieve optimum temperature control with the assistance of HVAC systems provided by York without wasting precious resources. Additionally, clients have access to various resources and leadership in our delivery process. We provide services as well as parts and plants for HVAC systems.

Elements Designed as Replacements for York Chillers

When operating HVAC systems, parts delivery is most effective for York YLAA Commercial Chiller Parts. These parts are available in good quality. It can be challenging to perform maintenance on ventilation systems in industrial facilities or commercial buildings.

When operating HVAC systems, parts delivery is most effective for York YLAA Commercial Chiller Parts. These parts are available in good quality. It can be challenging to perform maintenance on ventilation systems in industrial facilities or commercial buildings.

Continuous monitoring, routine maintenance, and continuing condition checks are all necessities for these systems. Components must contribute to cost reduction to accommodate the significant role that cooling systems play in large buildings.

York YLAA Customer Assistance

We can assist consumers in locating parts for pre-existing York models like the YLAA by working with them. In addition, our specialists can collaborate with clients to track down inaccessible parts or products not currently sold in the open market. End users may be sure of acquiring high-quality equipment if they do business with authentic York dealers, which is why it is advisable to negotiate with them.

Customers of York can expect the best fit and performance from their chillers because genuine parts are manufactured in York and only supplied by authorized dealers. Although there are online sellers who try to sell York YLAA Commercial chiller parts, these parts are not authentic. Authorized dealers only supply genuine parts.

Summary

No alternative can adequately take their place regarding high-quality HVAC elements. c can fit all York equipment with York parts without any problems. An exhaustive look through Midwest Parts Center’s inventory for York YLAA Commercial chiller replacement parts.

No alternative can adequately take their place regarding high-quality HVAC elements. c can fit all York equipment with York parts without any problems. An exhaustive look through Midwest Parts Center’s inventory for York YLAA Commercial chiller replacement parts.

Using original YLAA components for your HVAC system will guarantee the highest possible level of efficiency during its entire lifespan. We provide a comprehensive selection of parts, an extensive network of distribution channels, and a variety of preventative maintenance solutions, one of which is a yearly inspection and service. Find everything you need in a flash to ensure your business will continue running well for years to come.

When precise temperature control is needed, industrial chillers are typically employed. YLAA chillers, for example, are used by wineries to maintain the fermentation and storage temperatures of the beverage.

When precise temperature control is needed, industrial chillers are typically employed. YLAA chillers, for example, are used by wineries to maintain the fermentation and storage temperatures of the beverage. When deciding on the right chiller size for your cooling needs, there are numerous things to keep in mind. York YLAA Chillers’ sizing tool can help you quickly establish your chiller’s capacity and freight weight.

When deciding on the right chiller size for your cooling needs, there are numerous things to keep in mind. York YLAA Chillers’ sizing tool can help you quickly establish your chiller’s capacity and freight weight.

Choose from a wide range of energy, acoustic, and mechanical combinations to meet your specific application requirements and preferences.

Choose from a wide range of energy, acoustic, and mechanical combinations to meet your specific application requirements and preferences. The York YLAA chiller parts have been tested and proven reliable in reducing the frequency of service calls. Scroll compressors have been in operation for tens of thousands of hours in a wide range of industries.

The York YLAA chiller parts have been tested and proven reliable in reducing the frequency of service calls. Scroll compressors have been in operation for tens of thousands of hours in a wide range of industries.

It is common to employ industrial chillers in food-processing processes that demand precise temperature control. Winery YLAA chillers, for example, are used to maintain a consistent temperature during the fermentation and storage of the beverage. Cooling mixers, potable water, and jacketed tanks of yeast are all key bakery components that benefit from bakery chillers. The process of molding plastic via injection

It is common to employ industrial chillers in food-processing processes that demand precise temperature control. Winery YLAA chillers, for example, are used to maintain a consistent temperature during the fermentation and storage of the beverage. Cooling mixers, potable water, and jacketed tanks of yeast are all key bakery components that benefit from bakery chillers. The process of molding plastic via injection h the investment. Building managers and business owners can acquire the necessary solutions to avoid chiller difficulties to lessen the significant impact of unexpected outages.

h the investment. Building managers and business owners can acquire the necessary solutions to avoid chiller difficulties to lessen the significant impact of unexpected outages.

High capacities and environmentally friendly characteristics distinguish York as a pioneer in air-cooled chiller technology. Compact, energy-efficient

High capacities and environmentally friendly characteristics distinguish York as a pioneer in air-cooled chiller technology. Compact, energy-efficient

With accessibility to a large selection of quality components, like

With accessibility to a large selection of quality components, like

The heater performs numerous functions as part of the chiller, including cutting off the heat exchanger valve while the heater is activated and submerged in a reservoir and keeping the valve open when no heat spikes are visible. Small heaters are attached to the powerhead on the YLAA chiller parts and are used to combat low ambient difficulties. The chillers are also built to the highest possible standards to maximize their effectiveness, reliability, and flexibility.

The heater performs numerous functions as part of the chiller, including cutting off the heat exchanger valve while the heater is activated and submerged in a reservoir and keeping the valve open when no heat spikes are visible. Small heaters are attached to the powerhead on the YLAA chiller parts and are used to combat low ambient difficulties. The chillers are also built to the highest possible standards to maximize their effectiveness, reliability, and flexibility.

Furthermore, climate control demands are different for every chiller system purchased. It is the reason why we are here to make life easier; whether you need a chiller as a part of a unit to lower the energy consumption or perhaps offer that cool air, we got you covered. When you get a supplier that offers you reliable and high-quality York YLAA chiller parts, it is such a relief. Midwest Parts Center Is here to ensure you access these parts and take you through all you need to know about air conditioning equipment.

Furthermore, climate control demands are different for every chiller system purchased. It is the reason why we are here to make life easier; whether you need a chiller as a part of a unit to lower the energy consumption or perhaps offer that cool air, we got you covered. When you get a supplier that offers you reliable and high-quality York YLAA chiller parts, it is such a relief. Midwest Parts Center Is here to ensure you access these parts and take you through all you need to know about air conditioning equipment.

At the mention of York YLAA commercial chiller parts, the protection of budgets and the environment is a priority. The

At the mention of York YLAA commercial chiller parts, the protection of budgets and the environment is a priority. The  Midwest Parts Centre offers you the best chiller parts; thanks to York YLAA’s stability, chiller units can now be adapted to the cooling requirements up to a rated output of about 100KW. The main purpose of the

Midwest Parts Centre offers you the best chiller parts; thanks to York YLAA’s stability, chiller units can now be adapted to the cooling requirements up to a rated output of about 100KW. The main purpose of the  We ensure that we stick to all the procedures detailed in the parts manuscript, including the installation process, commissioning, and maintenance duties, and must only be performed perfectly by trained professionals and a qualified team. Midwest Parts Centre also gives you a warranty for the parts you purchase from us. However, it is important to note that our warranty is restricted to services and maintenances for the parts only. Among these will be replacements, shipping of parts, and failure of certain parts which have failed due to maintenance. Our chiller parts warranty specifies the chiller unit model, and manufacturer’s details such as serial number, among many things, paramount to YLAA parts.

We ensure that we stick to all the procedures detailed in the parts manuscript, including the installation process, commissioning, and maintenance duties, and must only be performed perfectly by trained professionals and a qualified team. Midwest Parts Centre also gives you a warranty for the parts you purchase from us. However, it is important to note that our warranty is restricted to services and maintenances for the parts only. Among these will be replacements, shipping of parts, and failure of certain parts which have failed due to maintenance. Our chiller parts warranty specifies the chiller unit model, and manufacturer’s details such as serial number, among many things, paramount to YLAA parts.

Midwest Parts Center is the best place to stop when looking for chiller parts, from the YK chiller parts to the YLAA chiller parts and now

Midwest Parts Center is the best place to stop when looking for chiller parts, from the YK chiller parts to the YLAA chiller parts and now  Commercial establishments are unique and at times, finding the right fit of equipment that is not problematic for the establishment structure is hard work. However, Midwest Parts Center has had years of experience that have proven useful. In the end, we have a deep understanding of how commercial establishments are and can work to ensure that whatever these parts you need can be installed and facilitated to your liking.

Commercial establishments are unique and at times, finding the right fit of equipment that is not problematic for the establishment structure is hard work. However, Midwest Parts Center has had years of experience that have proven useful. In the end, we have a deep understanding of how commercial establishments are and can work to ensure that whatever these parts you need can be installed and facilitated to your liking. Midwest Parts Center helps you identify and pick the correct York YLAA industrial chiller parts that meet your needs and can be integrated into your equipment without further interfering with your existing air system equipment. There is an extensive list of models you can choose from. We help you make the right selection because it saves you the time and expenses of replacing the parts shortly after reinstalling them. If you install a faulty chiller part, you risk having costly repairs, and that is not our aim. Midwest Parts Center is your go-to supplier for sound advice and

Midwest Parts Center helps you identify and pick the correct York YLAA industrial chiller parts that meet your needs and can be integrated into your equipment without further interfering with your existing air system equipment. There is an extensive list of models you can choose from. We help you make the right selection because it saves you the time and expenses of replacing the parts shortly after reinstalling them. If you install a faulty chiller part, you risk having costly repairs, and that is not our aim. Midwest Parts Center is your go-to supplier for sound advice and