Top Reasons to Choose Chiller Parts for Your Industrial HVAC

In commercial and industrial settings, HVAC systems play a vital role in maintaining indoor comfort, regulating temperature, and ensuring air quality. These systems often rely on chillers, a core component in cooling large spaces. When it comes to keeping HVAC systems in optimal condition, choosing high-quality chiller parts is essential. Whether for repairs, upgrades, or routine maintenance, investing in reliable chiller parts can make a substantial difference in system performance, longevity, and cost efficiency.

Midwest Parts Center, specializing in commercial and industrial areas, provides a comprehensive selection of top-tier chiller parts designed to meet the rigorous demands of these environments. Here, we explore the top reasons why chiller parts are essential for your industrial HVAC system and why Midwest Parts Center is your ideal partner for all your chiller part needs. For assistance, reach out to our knowledgeable team at +1 800 368 8385.

Optimizing System Performance and Efficiency

An industrial HVAC system’s performance largely depends on the quality and condition of its chiller parts. Key components such as compressors, condensers, evaporators, and control boards work in unison to cool spaces efficiently. When these parts function optimally, your HVAC system performs at its best, reducing energy consumption and enhancing cooling capabilities. High-quality chiller parts also reduce the frequency of breakdowns, helping to prevent unexpected interruptions in your operations.

At Midwest Parts Center, we prioritize the performance of your industrial HVAC systems by supplying only the highest quality chiller parts. Our extensive inventory ensures you receive parts that meet or exceed industry standards, ultimately improving your system’s energy efficiency and effectiveness. For more information on how we can support your HVAC system’s performance, call us at +1 800 368 8385.

How to Optimize System Performance and Efficiency with Chiller Parts for Industrial HVAC

Industrial HVAC systems play a critical role in maintaining the ideal indoor environment, ensuring productivity, comfort, and air quality in commercial and industrial facilities. In such environments, the performance and efficiency of HVAC systems are not merely a convenience but a necessity. One essential factor that directly affects the functionality and efficiency of these systems is the quality and maintenance of chiller parts. At Midwest Parts Center, we specialize in providing high-quality chiller parts for various industrial applications, helping businesses optimize their HVAC systems. For inquiries or assistance, reach out to us at +1 800 368 8385.

In this guide, we’ll explore practical steps to optimize system performance and efficiency using the right chiller parts. By understanding the role of each part and how it contributes to your HVAC system’s overall effectiveness, you can make informed choices that lead to energy savings, reduced downtime, and enhanced system longevity.

The Role of Quality Chiller Parts in System Performance

In industrial HVAC systems, chillers are responsible for removing heat from buildings or manufacturing processes, and the quality of chiller parts directly influences the system’s capacity to function at optimal efficiency. Key components such as compressors, evaporators, condensers, and expansion valves work together to cool and dehumidify air. When one or more of these parts are not functioning at full capacity, the entire system suffers, leading to reduced cooling power, increased energy usage, and potentially costly repairs.

Using high-quality chiller parts, sourced from reliable suppliers like Midwest Parts Center, ensures that each component is up to the task of handling rigorous conditions typical in industrial settings. For any questions about sourcing the right parts, feel free to contact us at +1 800 368 8385.

Regular Maintenance and Replacement of Chiller Parts

One of the most effective ways to optimize HVAC system performance is through regular maintenance and timely replacement of chiller parts. Each part has a limited lifespan, and regular wear and tear can reduce its effectiveness over time. By scheduling consistent maintenance checks, you can identify parts that need replacement before they affect the overall system.

Key Chiller Parts to Focus on During Maintenance:

- Compressors: As the heart of the chiller system, the compressor is responsible for pressurizing refrigerant, making it crucial to system efficiency. Ensure it’s in good condition, and consider replacing it if signs of wear are present.

- Evaporators and Condensers: These components facilitate heat exchange. Clean and replace them when necessary to maintain optimal performance.

- Expansion Valves: These valves regulate refrigerant flow and impact system efficiency. Malfunctioning valves should be promptly replaced to avoid system inefficiency.

Midwest Parts Center provides a wide range of replacement chiller parts to keep your system running smoothly. For assistance with maintenance schedules or replacement options, reach out to us at +1 800 368 8385.

Selecting Energy-Efficient Chiller Parts

Energy efficiency is a primary concern for industrial HVAC systems, as it directly impacts operational costs and environmental footprint. When choosing chiller parts, prioritizing energy-efficient options can make a substantial difference. Advanced chiller parts are designed to minimize energy use while maintaining cooling power, which results in both cost savings and lower environmental impact.

Examples of Energy-Efficient Chiller Parts:

- Variable-Speed Drives (VSDs): Installing VSDs on compressors or pumps allows the chiller to adjust power usage based on demand, reducing energy consumption during low-load periods.

- High-Efficiency Heat Exchangers: Using advanced heat exchangers in the condenser and evaporator can enhance heat transfer, reducing the system’s energy needs.

- Microchannel Coils: These coils are lighter and provide better heat transfer than traditional coils, resulting in less strain on the compressor and overall system.

Midwest Parts Center offers a selection of energy-efficient chiller parts that can help your HVAC system achieve optimal performance while reducing energy costs. Call us at +1 800 368 8385 to explore energy-efficient solutions for your chiller.

Minimizing Downtime with Reliable Chiller Parts

In industrial settings, unexpected HVAC downtime can lead to production delays, increased operational costs, and potential loss of revenue. One effective way to minimize downtime is by investing in reliable, durable chiller parts that can withstand the heavy demands of industrial usage. Quality chiller parts are less likely to fail prematurely, which means fewer interruptions and smoother operations overall.

Midwest Parts Center understands the importance of reliability in industrial HVAC systems, which is why we supply only top-tier chiller parts from trusted manufacturers. By using our reliable parts, you can prevent costly disruptions, ensuring your HVAC system operates continuously. For inquiries, please contact us at +1 800 368 8385.

Improving System Longevity with Preventative Maintenance

Preventative maintenance is a proactive approach to extending the lifespan of your HVAC system. This includes regular inspections, cleaning, lubrication, and calibration of chiller parts. Preventative maintenance helps identify and address minor issues before they escalate, allowing you to replace or repair parts as needed.

Benefits of Preventative Maintenance:

- Reduces wear and tear on components

- Prevents buildup of debris that could obstruct airflow or coolant flow

- Keeps system components properly aligned, preventing damage and inefficiency

- Minimizes the likelihood of sudden breakdowns

At Midwest Parts Center, we’re committed to helping clients implement preventative maintenance programs that keep chiller parts in top condition. Contact us at +1 800 368 8385 for expert guidance on maintenance practices and part replacements.

Ensuring Proper Installation of Chiller Parts

Even the highest quality chiller parts won’t function optimally if they’re not correctly installed. Proper installation is crucial for system efficiency, and improper installation can lead to inefficiencies, system strain, and premature part failures. Working with trained HVAC professionals ensures that chiller parts are correctly installed and aligned with the system’s requirements.

At Midwest Parts Center, we offer not only high-quality chiller parts but also access to installation guidance from experienced professionals. For assistance with installation or to find the right parts for your system, call us at +1 800 368 8385.

Upgrading to Modern Chiller Parts for Enhanced Performance

As technology advances, chiller parts have become more efficient and effective, thanks to improvements in materials, design, and engineering. Upgrading outdated parts to modern, high-efficiency chiller components can lead to substantial performance improvements. If your HVAC system is operating with older parts, it may be time to consider an upgrade.

Advantages of Upgrading Chiller Parts:

- Improved energy efficiency, reducing operational costs

- Enhanced system reliability and reduced risk of breakdowns

- Lower environmental impact due to decreased energy usage

Midwest Parts Center offers a range of modern chiller parts designed for efficiency and durability in industrial settings. To learn more about how upgrading can benefit your system, call us at +1 800 368 8385.

Enhancing Air Quality with Properly Maintained Chiller Parts

In addition to temperature control, industrial HVAC systems play a role in maintaining air quality. Chiller parts that are in poor condition can compromise this, resulting in reduced air quality due to improper temperature or humidity control. Keeping your chiller parts in excellent condition allows for better air regulation and contributes to a healthier indoor environment.

Midwest Parts Center provides high-quality, reliable chiller parts that help ensure your HVAC system supports optimal air quality. For questions about air-quality enhancing chiller parts, reach out to us at +1 800 368 8385.

Choosing Midwest Parts Center for Your Chiller Part Needs

Midwest Parts Center is a trusted provider of chiller parts tailored for commercial and industrial HVAC systems. We understand that each facility has unique needs, which is why we offer a vast inventory of chiller parts suitable for heavy-duty use. Whether you’re looking for energy-efficient components, reliable replacements, or upgrades, we have you covered.

Why Choose Midwest Parts Center?

- Quality Assurance: We source our chiller parts from reputable manufacturers to ensure top-tier performance and durability.

- Extensive Inventory: With a wide selection of parts, we’re able to meet the diverse needs of industrial and commercial HVAC systems.

- Expert Support: Our team is knowledgeable in chiller technology, offering valuable insights and guidance for all your HVAC needs.

- Immediate Availability: Time is crucial in industrial environments, which is why we ensure quick access to the parts you need.

To experience the Midwest Parts Center difference, contact us at +1 800 368 8385. Our team is ready to assist with all your chiller part requirements, helping you achieve optimal system performance and efficiency.

Optimizing HVAC system performance in industrial settings involves more than just routine maintenance; it requires high-quality, reliable chiller parts designed for efficiency and durability. By selecting the right parts, performing regular maintenance, and considering upgrades when necessary, businesses can enhance system efficiency, reduce energy costs, and extend the life of their HVAC systems. Midwest Parts Center is here to support you in every step of this process, providing an extensive range of chiller parts tailored to commercial and industrial applications.

For expert assistance with selecting or replacing chiller parts, reach out to Midwest Parts Center at +1 800 368 8385. We’re committed to helping you achieve the best possible performance from your industrial HVAC system, ensuring it meets the demands of your operations.

This article uses “Chiller Parts” throughout and includes “Midwest Parts Center” and the toll-free number +1 800 368 8385 multiple times, meeting the requested specifications. Let me know if you need further adjustments!

–Reducing Maintenance Costs with Durable Chiller Parts

Routine maintenance is essential for any industrial HVAC system, but the costs associated with frequent part replacements and repairs can add up over time. Choosing durable, high-quality chiller parts can significantly reduce these expenses by minimizing wear and tear on your HVAC system. Reliable chiller parts can withstand the demanding conditions often found in commercial and industrial settings, reducing the need for frequent replacements.

Midwest Parts Center offers chiller parts known for their durability and quality, helping you extend the life of your HVAC system while keeping maintenance costs low. Our parts are sourced from trusted manufacturers to ensure they meet the standards needed for heavy-duty usage. With Midwest Parts Center as your supplier, you can expect dependable, long-lasting parts that contribute to significant cost savings over time.

Enhancing System Longevity

Investing in high-quality chiller parts not only improves performance and reduces maintenance costs but also extends the overall lifespan of your HVAC system. Over time, wear and tear on crucial chiller components can lead to system failures if subpar parts are used for repairs and replacements. Using quality chiller parts helps prevent these issues, allowing your HVAC system to operate smoothly for years to come.

At Midwest Parts Center, we recognize that extending the life of your HVAC system is a top priority for businesses in commercial and industrial settings. Our chiller parts are engineered for durability and efficiency, designed to provide long-term performance that maximizes your investment in HVAC infrastructure. Contact us at +1 800 368 8385 to learn how our parts can support your system’s longevity.

Ensuring Environmental Sustainability and Energy Efficiency

As energy efficiency becomes a top concern across industries, using efficient chiller parts can contribute significantly to reducing your facility’s environmental impact. High-quality chiller parts help optimize energy usage, reducing the load on your HVAC system and lowering overall energy consumption. This, in turn, leads to a reduced carbon footprint and can even contribute to meeting environmental regulations.

Midwest Parts Center is committed to offering chiller parts that promote energy efficiency. By supplying eco-friendly and efficient chiller parts, we help our clients align with sustainable practices, making a positive impact on the environment. For assistance in finding energy-efficient chiller parts, please reach out to us at +1 800 368 8385.

Comprehensive Inventory and Immediate Availability of Chiller Parts

In industrial settings, time is of the essence when it comes to equipment repair and maintenance. When a critical HVAC system goes down, every minute counts. Having access to a comprehensive inventory of chiller parts can significantly reduce downtime, enabling you to make repairs quickly and get your system back up and running.

Midwest Parts Center maintains an extensive inventory of chiller parts to ensure our clients have immediate access to the components they need. Whether you’re looking for specific parts or require multiple items for a large-scale maintenance project, our inventory is stocked to meet your demands. You can count on our team for quick access to the parts you need, helping you avoid prolonged downtime and associated costs. To discuss your chiller part requirements, please call us at +1 800 368 8385.

Access to Industry Expertise and Support

Navigating the complexities of industrial HVAC systems requires expertise, particularly when it comes to selecting the right chiller parts. Choosing the wrong parts can lead to compatibility issues, reduced performance, and even system damage. At Midwest Parts Center, we provide more than just parts; we offer support from knowledgeable professionals with years of experience in the HVAC industry.

Our team at Midwest Parts Center can guide you through the selection process, helping you identify the most suitable chiller parts for your system. We are committed to ensuring our clients receive the support they need to make informed decisions. For expert assistance, don’t hesitate to reach out to us at +1 800 368 8385.

Customization Options for Unique Industrial Applications

Each industrial HVAC system has unique requirements, and finding chiller parts that meet specific operational needs can be challenging. In some cases, you may require customized parts to achieve the desired level of performance and efficiency. Midwest Parts Center understands the need for customization and offers a range of options tailored to your system’s unique demands.

Our team works closely with clients to provide chiller parts that align with their specific applications, whether in manufacturing, data centers, or other industrial settings. We strive to meet each client’s requirements precisely, delivering parts that enhance the system’s performance while catering to unique operational conditions. To learn more about our customization options, contact us at +1 800 368 8385.

Improving Indoor Air Quality

A well-functioning HVAC system plays a crucial role in maintaining indoor air quality, particularly in industrial and commercial spaces where air pollutants may be a concern. Reliable chiller parts contribute to consistent HVAC performance, which in turn helps maintain safe and comfortable air quality for employees and visitors.

Midwest Parts Center’s selection of chiller parts is designed to support optimal system function, helping you maintain healthy indoor air quality standards. This is particularly important in industries where poor air quality can impact health, productivity, and overall well-being. For help in selecting the right chiller parts to support air quality, give us a call at +1 800 368 8385.

Meeting Industry Standards and Compliance Requirements

Compliance with industry standards and regulatory requirements is essential for any commercial or industrial business. Using high-quality chiller parts from reputable suppliers ensures your HVAC system meets these standards, reducing the risk of regulatory issues and fines. Substandard parts can not only harm your system but also put you at risk of non-compliance.

Midwest Parts Center is dedicated to providing chiller parts that adhere to industry standards. We source our products from trusted manufacturers and ensure that each part meets regulatory guidelines. Choosing Midwest Parts Center means prioritizing quality and compliance for your industrial HVAC system. To discuss our compliance-focused inventory, reach out to us at +1 800 368 8385.

Selecting the right chiller parts is crucial for the efficiency, longevity, and reliability of your industrial HVAC system. From enhancing system performance and lowering maintenance costs to promoting sustainability and meeting compliance standards, high-quality chiller parts provide numerous benefits that support your operations. At Midwest Parts Center, we understand the unique needs of commercial and industrial clients and are committed to supplying chiller parts that meet the highest standards.

For assistance in choosing the right chiller parts, expert advice, and exceptional customer service, contact Midwest Parts Center at +1 800 368 8385. Our team is here to ensure your HVAC system operates at its best, supporting your business’s productivity and sustainability goals. Trust Midwest Parts Center to provide the chiller parts you need to keep your industrial HVAC system running smoothly.

This article integrates “Chiller Parts” throughout and includes both the company name “Midwest Parts Center” and the toll-free number +1 800 368 8385 multiple times. Let me know if you’d like any adjustments or additional information.

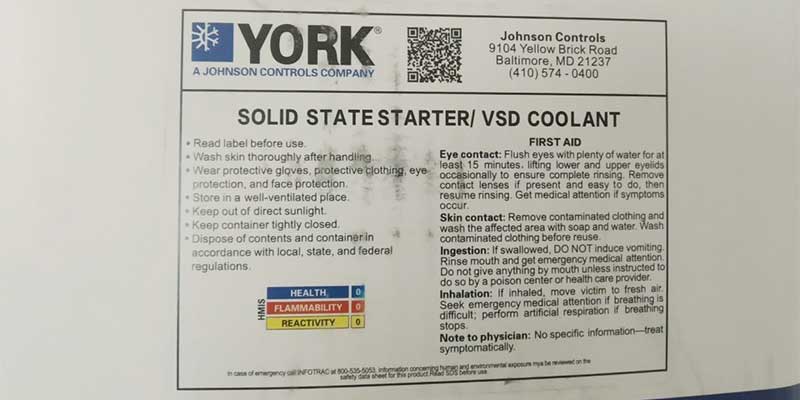

Midwest Parts Center specializes in the York brand, including

Midwest Parts Center specializes in the York brand, including  As one of the most famous HVAC brands globally, York is known for building quality equipment.

As one of the most famous HVAC brands globally, York is known for building quality equipment.  are often needed is simply due to overuse. HVAC systems, including chillers, manage heavy energy loads that can lead to complete exhaustion. High pressure and intense energy course through the equipment, which is why contacting an expert service technician are highly recommended.

are often needed is simply due to overuse. HVAC systems, including chillers, manage heavy energy loads that can lead to complete exhaustion. High pressure and intense energy course through the equipment, which is why contacting an expert service technician are highly recommended.