Midwest Antiviral Sanitizer Method for HVAC & Air Quality

Once utilize in HVAC units, needlepoint bi-polar ionization provides many positive aspects within a commercial center. Our Midwest antiviral sanitizer method for HVAC to start with regulating airflow in buildings. What’s more, the method covers the basis of germs by killing them instantly. From temperature control to enhanced efficiency, our Midwest antiviral sanitizer method is certain to improve industrial HVAC operation.

Once utilize in HVAC units, needlepoint bi-polar ionization provides many positive aspects within a commercial center. Our Midwest antiviral sanitizer method for HVAC to start with regulating airflow in buildings. What’s more, the method covers the basis of germs by killing them instantly. From temperature control to enhanced efficiency, our Midwest antiviral sanitizer method is certain to improve industrial HVAC operation.

Midwest Antiviral sanitizer remedies through Midwest Parts Center are the perfect choice for commercial heating and cooling units. Furthermore, our service technicians can install Global Plasma Solutions into air-conditioning units. During a process called needlepoint ionization, free radicals attack germs and viruses. Additionally, bipolar ionization is capable of killing mold and mildew in air-conditioning systems. What’s more, germs may also cause foul odors. Global Plasma Solutions removes foul smells while also controlling outdoor air. Outdoor contributes to the poor air quality inside buildings.

The fact of the matter is that our Midwest antiviral sanitizer method is effective in commercial facilities. In fact, the CDC has advocated that businesses consider improving air quality by using HVAC systems. The issue with the coronavirus is that it is airborne. Proper ventilation is necessary to avoid the viruses’ effects.

Midwest Antiviral Sanitizer & Long-Term Productivity

The issue with developing the illness is that people are not able to work. Furthermore, the loss of employees results in a loss of productivity. Declined productivity will lead companies and staff to lose profits and income. What’s more, there are economic consequences for widespread outbreaks. Clean air contributes at least to a healthy environment. Additionally, breathable air is totally free of toxins, pollutants, and also viruses. Addressing air quality with HVAC Midwest antiviral sanitizer is an excellent method.

The issue with developing the illness is that people are not able to work. Furthermore, the loss of employees results in a loss of productivity. Declined productivity will lead companies and staff to lose profits and income. What’s more, there are economic consequences for widespread outbreaks. Clean air contributes at least to a healthy environment. Additionally, breathable air is totally free of toxins, pollutants, and also viruses. Addressing air quality with HVAC Midwest antiviral sanitizer is an excellent method.

Our service technicians use an apparatus called Global Plasma Solutions to enhance heating and cooling systems in facilities. Increased air quality is important for organizations, especially during the coronavirus pandemic. HVAC components are not only for providing temperature control; they are also responsible for providing better air quality.

Sanitizers used to remove viruses from HVAC systems work well to remove pollutants that cause disease. Additionally, Global Plasma Solutions performs a wide range of functions that deliver high-quality outcomes.

Viral outbreaks are not uncommon in large facilities. In truth, recent outbreaks have made organizations rethink the way to attain improved air quality. Sterile facilities are critical for employers, no matter what size. Furthermore, many individuals spend up to 8 hours or longer in business facilities to perform job-related functions. Due to the amount of time spent in buildings, clean air quality is a must.

Needlepoint Bipolar Ionization

During the deployment of bipolar ionization, Global Plasma Solutions reduces contaminants and kills the spores that infect heating and cooling systems. What’s more, the technology removes volatile organic compounds, which are also harmful. In fact, Global Plasma Solutions kills germs, and microorganisms, and decimates viruses. Quite put, needlepoint bi-polar ionization is an innovative method that delivers numerous benefits for buildings.

During the deployment of bipolar ionization, Global Plasma Solutions reduces contaminants and kills the spores that infect heating and cooling systems. What’s more, the technology removes volatile organic compounds, which are also harmful. In fact, Global Plasma Solutions kills germs, and microorganisms, and decimates viruses. Quite put, needlepoint bi-polar ionization is an innovative method that delivers numerous benefits for buildings.

Consider the benefits of Global Plasma Solutions in commercial and industrial facilities. Explore our exclusive services available to commercial end-users.

Contact us to inquire about antiviral treatments for HVAC units.

Industrial facilities achieve breathable air with Global Plasma Solutions. The air in commercial buildings is purified with Global Plasma Solutions. An experienced service technician can apply Global Plasma Solutions to existing air systems. The device attacks viruses and VOCs by using free radicals. The free radicals in Global Plasma Solutions are formed when a hydrogen bond is broken within a molecule. Additionally, the ions neutralize foul odors and kill mold and mildew. Additionally, the ions inactive otherwise harmful viruses.

Industrial facilities achieve breathable air with Global Plasma Solutions. The air in commercial buildings is purified with Global Plasma Solutions. An experienced service technician can apply Global Plasma Solutions to existing air systems. The device attacks viruses and VOCs by using free radicals. The free radicals in Global Plasma Solutions are formed when a hydrogen bond is broken within a molecule. Additionally, the ions neutralize foul odors and kill mold and mildew. Additionally, the ions inactive otherwise harmful viruses. Global Plasma Solutions provides many benefits as a potential infection control treatment. First, technology controls outdoor air. Exposure to outdoor air introduces VOCs into facilities. VOCs are volatile organic compounds. Moreover, Global Plasma Solutions removes the bad odors that are linked to mold and mildew. For many individuals, mold exposure can lead to long-term illness. Finally, Global Plasma Solutions is an enhancement that improves the efficiency of heating and cooling units. The efficient operation of air-conditioning units is important because it ultimately saves money for businesses.

Global Plasma Solutions provides many benefits as a potential infection control treatment. First, technology controls outdoor air. Exposure to outdoor air introduces VOCs into facilities. VOCs are volatile organic compounds. Moreover, Global Plasma Solutions removes the bad odors that are linked to mold and mildew. For many individuals, mold exposure can lead to long-term illness. Finally, Global Plasma Solutions is an enhancement that improves the efficiency of heating and cooling units. The efficient operation of air-conditioning units is important because it ultimately saves money for businesses.

Commercial facilities are susceptible to viruses and bacteria.

Commercial facilities are susceptible to viruses and bacteria.  Midwest Parts Center specializes in helping industrial facilities achieve better air quality. There is a direct relationship between air quality and the health of occupants in a building. Global Plasma Solutions enhances indoor air quality, which is a highlight for facilities.

Midwest Parts Center specializes in helping industrial facilities achieve better air quality. There is a direct relationship between air quality and the health of occupants in a building. Global Plasma Solutions enhances indoor air quality, which is a highlight for facilities. Global Plasma Solutions offers a wide range of benefits for facilities in need of clean air. First, Global Plasma Solutions removes mold, mildew, and foul odors both in the air and on surfaces. Using the process of bipolar ionization, Global Plasma Solutions generates germ-killing ions. The ions are capable of making changes to pathogens at the molecular level.

Global Plasma Solutions offers a wide range of benefits for facilities in need of clean air. First, Global Plasma Solutions removes mold, mildew, and foul odors both in the air and on surfaces. Using the process of bipolar ionization, Global Plasma Solutions generates germ-killing ions. The ions are capable of making changes to pathogens at the molecular level.

If your facility is hoping to achieve cleaner air, contact Midwest Parts Center to discover our

If your facility is hoping to achieve cleaner air, contact Midwest Parts Center to discover our  There is more to air-conditioning than just cool air. Air-Conditioning controls temperature, which is beneficial in maintaining productivity. Additionally, cool air retains materials and prevents damage from irregular temperatures. Midwest

There is more to air-conditioning than just cool air. Air-Conditioning controls temperature, which is beneficial in maintaining productivity. Additionally, cool air retains materials and prevents damage from irregular temperatures. Midwest  Treating air-conditioning units with purification tools is an economical way to manage air temperature and target the source of germs. There is, however, a way to address the challenge of halting potential outbreaks before they happen in a building.

Treating air-conditioning units with purification tools is an economical way to manage air temperature and target the source of germs. There is, however, a way to address the challenge of halting potential outbreaks before they happen in a building.

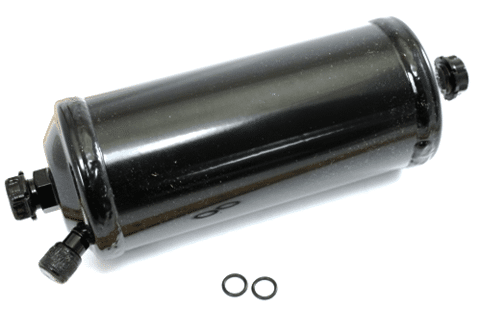

Finding effortless parts integration should not be an issue. Knowing the chiller interior elements and out may assist you with the possible demand for the parts. Your support tech will also have the ability to let you know exactly what parts are needed for replacement or repair. Even the

Finding effortless parts integration should not be an issue. Knowing the chiller interior elements and out may assist you with the possible demand for the parts. Your support tech will also have the ability to let you know exactly what parts are needed for replacement or repair. Even the  Businesses depend on spare parts as an enhancement to achieve improved results in VSD chiller models. Whenever an industrial or commercial chiller isn’t performing regularly, it’s best to presume that service might be critical. First, get in touch with a company tech to request a review of your heating system apparatus. The more that minor matters last, the more troublesome an issue is going to be. Also, damaged chiller pieces could cause serious harm to a unit. If you become aware of gaps in the heating system, odd sounds, or increased energy expenses, your chiller may need repair.

Businesses depend on spare parts as an enhancement to achieve improved results in VSD chiller models. Whenever an industrial or commercial chiller isn’t performing regularly, it’s best to presume that service might be critical. First, get in touch with a company tech to request a review of your heating system apparatus. The more that minor matters last, the more troublesome an issue is going to be. Also, damaged chiller pieces could cause serious harm to a unit. If you become aware of gaps in the heating system, odd sounds, or increased energy expenses, your chiller may need repair. of HVAC components. In fact, chillers are intricate machines that are heavy. Of course, the processes ought to be approached closely with assistance from an industry technician. York has designed its model to a high level of efficiency that clients have come to enjoy.

of HVAC components. In fact, chillers are intricate machines that are heavy. Of course, the processes ought to be approached closely with assistance from an industry technician. York has designed its model to a high level of efficiency that clients have come to enjoy.

Providing a critical aspect to any refrigerant system is the filter-drier. The filter-drier, as in the YORK

Providing a critical aspect to any refrigerant system is the filter-drier. The filter-drier, as in the YORK