Benefits and Importance of York Genuine Parts Midwest

Relying on York genuine Parts Midwest guarantees a high level of dependability. You can trust York to Source and propose the best York genuine parts Midwest for your HVAC system because they are the industry’s leading manufacturer and have the expertise to do so. Using factory invoices and serial numbers, we can discover the information you need in our extensive inventory and ship it directly to your location.

Relying on York genuine Parts Midwest guarantees a high level of dependability. You can trust York to Source and propose the best York genuine parts Midwest for your HVAC system because they are the industry’s leading manufacturer and have the expertise to do so. Using factory invoices and serial numbers, we can discover the information you need in our extensive inventory and ship it directly to your location.

Genuine parts for your chiller system may be necessary from time to time. It can be challenging to track down the specific components you require, but we are here to help. Each YORK system has unique features and can sort through them all. In genuine parts inventory, you can rely on the names you know and expect.

How to Pick a York Original Part

May find all of your genuine York components right here. This tool makes routine and maintenance easy by using a wide range of proprietary and nonproprietary parts.

A list of HVAC (heating, ventilation, and air conditioning) applications has been compiled by our organization for your convenience. Replacement parts for York products are available.

- Express mail delivery directly to your door

- Troubleshooting support for YORK chiller parts

- You can quickly and easily order the parts you require.

Additional service components, numbering in the thousands, can be obtained upon request. To ensure long-term dependability and lower repair costs, use only genuine OEM components.

Additional service components, numbering in the thousands, can be obtained upon request. To ensure long-term dependability and lower repair costs, use only genuine OEM components.

You may research and order YORK chiller components online from our database and parts center service platform, and we’ll ship them to you quickly. It simplifies the ordering process and ensures that genuine details are always available for your customers’ facilities. With great features of the website:

- It’s a snap to find the right replacement components.

- Customers can view Real-time pricing and lead times.

- Order status, shipping timelines, and tracking information are updated in real-time.

You may search for orders based on various criteria. Including the purchaser, purchase order reference, order confirmation, etc. You can place your order at any time of day or night, and you’ll have access to real-time updates and information.

Benefits and Importance of York Genuine parts Midwest

An original, high-quality YORK part is guaranteed when you buy from Source. This will help both your customers and their equipment. YORK home and light commercial HVAC system components and accessories are only available from us.

Used on YORK equipment

Only original parts are utilized to ensure optimal performance. In addition, a two-year manufacturer’s warranty is included.

Two-year money-back guarantee

A two-year limited guarantee on all York Genuine Parts Midwest is now available to assist your business because we stand behind our products! Engineers, manufacturers, and testers adhere to strict criteria when creating our original parts. Using our ready-to-install details lets you rest easy, knowing that the job was done well the first time, saving you time and money.

Provide better services at a lower price point.

Using authentic components from York ensures that you will get the job done right the first time around. It’s a win-win situation because downtime is reduced, and productivity increases. Now, you may order genuine components in only a few minutes. Buying from us means that you will never have to wait for your order to be shipped out.

Using authentic components from York ensures that you will get the job done right the first time around. It’s a win-win situation because downtime is reduced, and productivity increases. Now, you may order genuine components in only a few minutes. Buying from us means that you will never have to wait for your order to be shipped out.

Your YORK Genuine Parts Midwest is guaranteed to fit perfectly. You don’t have to be concerned about retrofitting non-name-brand parts that may or may not be compatible with your device. Avoid any confusion; consider YORK components compatible with any york systems.

Contact us to know more about YORK Genuine Parts Midwest.

Midwest York YVAA chiller parts have another business benefit: they lessen both short-term and long-term environmental impacts. As you can see, the refrigerant in this model is harmful to the ozone layer because of its toxicity. Design factors limit the amount of refrigerant used.

Midwest York YVAA chiller parts have another business benefit: they lessen both short-term and long-term environmental impacts. As you can see, the refrigerant in this model is harmful to the ozone layer because of its toxicity. Design factors limit the amount of refrigerant used. York’s products, known for their high levels of energy efficiency and performance, are suitable for a wide range of commercial and industrial settings. When it comes to York YVAA chiller repairs or replacements, you don’t have to worry because we only use the best parts. An excellent idea is to check out the replacement chiller parts offered by

York’s products, known for their high levels of energy efficiency and performance, are suitable for a wide range of commercial and industrial settings. When it comes to York YVAA chiller repairs or replacements, you don’t have to worry because we only use the best parts. An excellent idea is to check out the replacement chiller parts offered by

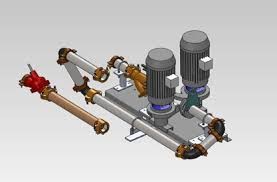

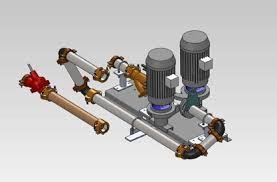

Midwest YORK Genuine Parts Center can assist you in locating Midwest YORK Genuine Parts that are tailored to the brand’s systems. We offer a variety of YORK-designed components that can be used in various applications. Our customers appreciate that we are an excellent source for replacement components for VRF, DX, chilled water, and air systems.

Midwest YORK Genuine Parts Center can assist you in locating Midwest YORK Genuine Parts that are tailored to the brand’s systems. We offer a variety of YORK-designed components that can be used in various applications. Our customers appreciate that we are an excellent source for replacement components for VRF, DX, chilled water, and air systems. Exceeding consumer expectations necessitates constant innovation and meticulous attention to detail. As a result, we believe that quality comes first for home comfort systems. Because your YORK heating and cooling equipment is designed and engineered in the United States, we can closely monitor and improve procedures that directly affect quality. A YORK heating and cooling unit comprise more than just metal and circuitry; it also requires people with integrity and a commitment to quality.

Exceeding consumer expectations necessitates constant innovation and meticulous attention to detail. As a result, we believe that quality comes first for home comfort systems. Because your YORK heating and cooling equipment is designed and engineered in the United States, we can closely monitor and improve procedures that directly affect quality. A YORK heating and cooling unit comprise more than just metal and circuitry; it also requires people with integrity and a commitment to quality.

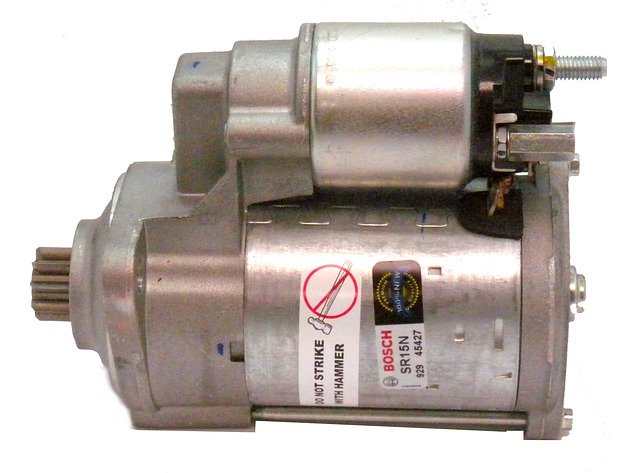

Changing a filter, for example, appears to be a simple industrial HVAC maintenance task. It may be tempting to troubleshoot and repair a home comfort system if you’re mechanically inclined.

Changing a filter, for example, appears to be a simple industrial HVAC maintenance task. It may be tempting to troubleshoot and repair a home comfort system if you’re mechanically inclined. Professionals who work as contractors or technicians

Professionals who work as contractors or technicians For suitable Genuine YORK replacement parts contact us. We have access to the brand’s current inventory. We can provide you with details for repair, servicing, and maintenance. Commercial structures, industrial buildings, and office buildings all require new features.

For suitable Genuine YORK replacement parts contact us. We have access to the brand’s current inventory. We can provide you with details for repair, servicing, and maintenance. Commercial structures, industrial buildings, and office buildings all require new features.

In the long run, these parts will save time and money. Reduced downtime is a benefit of

In the long run, these parts will save time and money. Reduced downtime is a benefit of  Much more than just a convenience for commercial buildings, the York YT chiller element is worth its weight in gold. This ventilation system’s primary objective is to keep moisture and mildew at bay while reducing the likelihood of structural damage. Keep your HVAC system at the appropriate temperature with York YT chillers. As a starting point, York YT Chiller Components.

Much more than just a convenience for commercial buildings, the York YT chiller element is worth its weight in gold. This ventilation system’s primary objective is to keep moisture and mildew at bay while reducing the likelihood of structural damage. Keep your HVAC system at the appropriate temperature with York YT chillers. As a starting point, York YT Chiller Components.

Now that you’ve decided to acquire the

Now that you’ve decided to acquire the  Head gaskets for the evaporator and condenser are offered in 25-foot and 50-foot rolls in either channel or bulb form. Each machine requires a different length.

Head gaskets for the evaporator and condenser are offered in 25-foot and 50-foot rolls in either channel or bulb form. Each machine requires a different length. York York’s preventative maintenance packages offer five key benefits. York’s preventive maintenance kits for coolers also help to improve efficiency and effectiveness. Chiller maintenance and facilities management experts buy spare parts in case of future breakdowns or repairs.

York York’s preventative maintenance packages offer five key benefits. York’s preventive maintenance kits for coolers also help to improve efficiency and effectiveness. Chiller maintenance and facilities management experts buy spare parts in case of future breakdowns or repairs.

When precise temperature control is needed, industrial chillers are typically employed. YLAA chillers, for example, are used by wineries to maintain the fermentation and storage temperatures of the beverage.

When precise temperature control is needed, industrial chillers are typically employed. YLAA chillers, for example, are used by wineries to maintain the fermentation and storage temperatures of the beverage. When deciding on the right chiller size for your cooling needs, there are numerous things to keep in mind. York YLAA Chillers’ sizing tool can help you quickly establish your chiller’s capacity and freight weight.

When deciding on the right chiller size for your cooling needs, there are numerous things to keep in mind. York YLAA Chillers’ sizing tool can help you quickly establish your chiller’s capacity and freight weight.

Use our lightning-fast search engine if you want to enhance your talents swiftly and generate high-quality replacement parts like York components. You can find York components a fraction of the time you’d need to search for them elsewhere.

Use our lightning-fast search engine if you want to enhance your talents swiftly and generate high-quality replacement parts like York components. You can find York components a fraction of the time you’d need to search for them elsewhere. Commercial HVAC customers rely on us because we want to help them succeed in their business. This might help your business develop if you require York parts quickly. Using our super-fast search engine, you’ll find much faster what you’re looking for.

Commercial HVAC customers rely on us because we want to help them succeed in their business. This might help your business develop if you require York parts quickly. Using our super-fast search engine, you’ll find much faster what you’re looking for.

Customers and clients choose the York brand because of its high-quality attributes. They are confident that this brand provides nothing but the most superior quality products with unbeatable durability.

Customers and clients choose the York brand because of its high-quality attributes. They are confident that this brand provides nothing but the most superior quality products with unbeatable durability. Wear and tear are nothing new in the commercial and industrial sectors; however, with proper and professional maintenance, HVAC parts assist in smoothing out the repair assignments.

Wear and tear are nothing new in the commercial and industrial sectors; however, with proper and professional maintenance, HVAC parts assist in smoothing out the repair assignments.

YK chillers are built to withstand high temperatures. Even if you think your equipment is long-lasting, it can break down and require maintenance. The best method to keep your equipment in good operating order is preventative maintenance according to the manufacturer’s instructions.

YK chillers are built to withstand high temperatures. Even if you think your equipment is long-lasting, it can break down and require maintenance. The best method to keep your equipment in good operating order is preventative maintenance according to the manufacturer’s instructions. Being able to inhale fresh, cool air is something we take for granted wherever we go, whether it’s a workplace or a public area like a school or a café. A person’s mood will almost certainly be affected by the air conditioning in a given space at a particular time.

Being able to inhale fresh, cool air is something we take for granted wherever we go, whether it’s a workplace or a public area like a school or a café. A person’s mood will almost certainly be affected by the air conditioning in a given space at a particular time.