A Guide to York YLAA Chiller Parts

As the heart of modern cooling systems, York YLAA chillers have gained recognition for their efficiency, reliability, and innovative design. At the core of these high-performing chillers lie the essential components that work together to deliver optimal cooling performance. In this comprehensive guide, we explore the York YLAA chillers parts and their roles in ensuring efficient and reliable cooling for various applications.

1. Compressor: The Powerhouse of Cooling

The compressor is the heart of any chiller system, including York YLAA chillers. It plays a pivotal role in pressurizing and circulating the refrigerant throughout the system, facilitating the heat transfer process. York YLAA chillers are equipped with advanced compressors designed for energy efficiency and durability, ensuring optimal cooling performance while minimizing energy consumption.

2. Condenser: Facilitating Heat Release

The condenser is responsible for releasing heat absorbed from the building or process being cooled. In York YLAA chillers, the condenser operates with high-efficiency microchannel coils that enhance heat transfer. The condenser’s efficient operation allows the chiller to maintain consistent cooling performance, even under varying load conditions.

3. Evaporator: Absorbing Heat for Cooling

The evaporator is where the refrigerant absorbs heat from the cooling water or air. This process results in cooling the desired space or application. York YLAA chillers feature highly efficient evaporators that ensure maximum heat transfer and cooling capacity. The evaporator’s performance directly impacts the chiller’s overall efficiency and ability to provide optimal cooling.

4. Expansion Device: Regulating Refrigerant Flow

The expansion device is responsible for controlling the flow of refrigerant into the evaporator, where it undergoes a phase change from liquid to vapor. This controlled flow ensures that the refrigerant absorbs heat efficiently, leading to effective cooling. York YLAA chillers are equipped with precision expansion devices that optimize the refrigerant flow for energy-efficient cooling.

5. Control Panel: Managing Chiller Operations

The control panel is the brain of York YLAA chillers, managing and monitoring various system operations. It regulates the compressor’s speed, adjusts water flow rates, and optimizes chiller performance. The advanced control algorithms in York YLAA chillers contribute to precise temperature control and efficient operation, ensuring the chiller operates at its peak performance.

Conclusion

Understanding the essential components of York YLAA chillers is crucial for optimizing their performance and efficiency. The compressor, condenser, evaporator, expansion device, and control panel work in harmony to deliver efficient and reliable cooling for various applications. The innovative design and engineering of York YLAA chiller parts ensure that businesses and industries can rely on these cooling systems for their diverse cooling needs. As the demand for energy-efficient and sustainable cooling solutions continues to grow, York YLAA chillers and their essential components stand at the forefront, providing efficient and eco-friendly cooling solutions for a greener future.

The Role of York YLAA Chiller Parts in HVAC Systems

In the ever-evolving HVAC industry, the demand for high-performing, energy-efficient, and reliable cooling systems is on the rise. York YLAA chillers have emerged as a preferred choice for meeting these demands, offering cutting-edge technology and innovative design. At the heart of these high-performing chillers lie the essential components that play a crucial role in optimizing their performance. In this article, we delve into the role of York YLAA chiller parts in HVAC systems and how they contribute to achieving peak cooling performance.

1. Compressor: Efficiency and Reliability

The compressor is a critical component of York YLAA chillers, serving as the powerhouse that pressurizes and circulates the refrigerant. The compressor’s efficiency and reliability are essential for ensuring optimal cooling performance. York YLAA chillers are equipped with advanced compressors designed for energy efficiency and reduced maintenance requirements. These compressors operate smoothly, ensuring efficient cooling while minimizing energy consumption and maximizing the chiller’s reliability.

2. Condenser: Enhancing Heat Transfer

The condenser is responsible for releasing heat absorbed during the cooling process. In York YLAA chillers, the condenser features high-efficiency microchannel coils that enhance heat transfer capabilities. This efficient heat release ensures that the chiller can maintain consistent cooling performance, even under varying load conditions. The condenser’s role in optimizing heat transfer is essential for the overall efficiency of the chiller.

3. Evaporator: Effective Heat Absorption

The evaporator is where the refrigerant absorbs heat from the cooling water or air, initiating the cooling process. In York YLAA chillers, highly efficient evaporators maximize heat absorption, leading to effective cooling. The evaporator’s performance directly impacts the chiller’s overall efficiency and ability to provide optimal cooling for various applications.

The Role of York YLAA Chiller Parts in HVAC Systems

4. Expansion Device: Precise Refrigerant Control

The expansion device in York YLAA chillers regulates the flow of refrigerant into the evaporator, where it undergoes a phase change from liquid to vapor. This controlled refrigerant flow ensures that the refrigerant absorbs heat efficiently during the cooling process. York YLAA chillers are equipped with precision expansion devices that optimize the refrigerant flow, contributing to energy-efficient cooling and peak chiller performance.

5. Control Panel: Smart Management

The control panel is the brain of York YLAA chillers, responsible for managing and monitoring various system operations. It regulates the compressor’s speed, adjusts water flow rates, and optimizes chiller performance. The advanced control algorithms in York YLAA chillers allow for precise temperature control and efficient operation. The control panel’s intelligent management ensures that the chiller operates at its peak performance, adapting to changing cooling demands.

Conclusion

York YLAA chiller parts play a pivotal role in optimizing the performance of HVAC systems. The compressor, condenser, evaporator, expansion device, and control panel work in synergy to deliver efficient, reliable, and high-performing cooling solutions. The innovative design and engineering of these essential components ensure that York YLAA chillers can meet the demands of various applications and industries. With a focus on energy efficiency, reliability, and precise temperature control, York YLAA chiller parts set a benchmark for achieving peak cooling performance in today’s HVAC landscape. As businesses and industries continue to prioritize efficiency and sustainability, York YLAA chillers and their essential components remain at the forefront of providing optimal cooling solutions for a diverse range of cooling needs.

The Benefits of Genuine York YLAA Chiller Parts

When it comes to cooling systems, efficiency and reliability are paramount. HVAC systems, especially chillers, play a crucial role in maintaining comfortable indoor environments and supporting various industrial processes. For optimal performance and peace of mind, using genuine York YLAA chiller parts is essential. In this article, we explore the benefits of using authentic York YLAA chiller parts, focusing on their efficiency and reliability.

1. Energy Efficiency: Lowering Operational Costs

Genuine York YLAA chiller parts are engineered with a focus on energy efficiency. Each component is designed to minimize energy consumption while delivering superior cooling performance. From the high-efficiency compressors to the advanced heat transfer coils in the condenser and evaporator, every part is optimized for energy savings. By using authentic York YLAA chiller parts, businesses can significantly lower their operational costs and reduce their environmental impact.

2. Improved Performance and Cooling Capacity

York YLAA chiller parts are designed to work seamlessly together, ensuring efficient and reliable cooling performance. The compressors, condensers, evaporators, expansion devices, and control panels are all meticulously engineered to achieve optimal performance. By using genuine parts, businesses can rest assured that their chillers will operate at peak efficiency, delivering the cooling capacity required for their specific applications.

3. Extended Service Life and Reduced Downtime

Investing in genuine York YLAA chiller parts contributes to the extended service life of the chiller. Authentic parts are built to withstand the demands of continuous operation, reducing the risk of premature failures and breakdowns. As a result, businesses can avoid costly downtime and minimize disruptions to their operations. Regular maintenance and using genuine parts also ensure that the chiller remains reliable and performs optimally throughout its lifespan.

4. Warranty and Product Support

Using genuine York YLAA chiller parts provides the added benefit of manufacturer warranties and product support. York stands behind the quality and performance of its genuine parts, offering peace of mind to customers. In the rare event of any issues, businesses can rely on the manufacturer’s support and expertise to resolve the matter promptly.

5. Compliance with Industry Standards

Genuine York YLAA chiller parts comply with industry standards and regulations. These components are tested and certified to meet rigorous performance and safety requirements. By using authentic parts, businesses can ensure that their cooling systems are in line with industry standards, promoting safety and reliability.

The Benefits of Genuine York YLAA Chiller Parts

Efficiency and reliability are crucial considerations when it comes to cooling systems, and using genuine York YLAA chiller parts is the key to achieving these benefits. The energy-efficient design and superior performance of authentic components result in lower operational costs and a reduced environmental footprint. The extended service life and reduced downtime contribute to uninterrupted cooling and enhanced productivity. Moreover, the warranty and product support from the manufacturer offer added assurance and peace of mind. For businesses seeking efficient and reliable cooling solutions, investing in genuine York YLAA chiller parts is a wise decision that delivers long-term benefits and ensures optimal performance of their HVAC systems.

Understanding York YLAA Chiller Parts and Maintenance

York YLAA chillers have earned a reputation for their efficiency, reliability, and high-performance cooling capabilities. To ensure these chillers continue to deliver peak performance throughout their operational life, proper maintenance and understanding of York YLAA chiller parts are essential. In this article, we explore the significance of regular maintenance, the role of key chiller components, and how businesses can effectively maintain their York YLAA chillers for optimal performance.

1. Regular Maintenance: The Key to Peak Performance

Regular maintenance is the foundation of preserving the efficiency and reliability of York YLAA chillers. Scheduled maintenance ensures that all components are functioning optimally, prevents potential issues from escalating, and extends the chiller’s service life. Implementing a proactive maintenance program can significantly reduce unexpected breakdowns, minimize downtime, and save on costly repairs.

2. Essential Chiller Components and Their Functions

Understanding the role of key chiller components is crucial for effective maintenance. Some of the essential York YLAA chiller parts and their functions include:

- Compressor: The heart of the chiller, the compressor pressurizes and circulates the refrigerant, playing a critical role in the cooling process.

- Condenser: Responsible for releasing heat absorbed during the cooling process, the condenser ensures efficient heat transfer and consistent cooling performance.

- Evaporator: This component absorbs heat from the cooling water or air, initiating the cooling process.

- Expansion Device: Regulating the flow of refrigerant into the evaporator, the expansion device ensures controlled heat absorption for efficient cooling.

- Control Panel: The intelligent brain of the chiller, the control panel manages and monitors various system operations, optimizing chiller performance.

3. Comprehensive Maintenance Practices

An effective maintenance program for York YLAA chillers should include the following practices:

- Regular Inspections: Scheduled inspections help identify potential issues early and allow for timely repairs, preventing major breakdowns.

- Cleaning and Coil Maintenance: Regularly cleaning the condenser and evaporator coils prevents efficiency losses due to dirt buildup.

- Lubrication and Component Checks: Proper lubrication of moving parts and routine checks of critical components ensure smooth operation and reduce wear and tear.

- Refrigerant Level and Leak Checks: Ensuring proper refrigerant levels and detecting and repairing leaks prevent cooling inefficiencies and environmental impacts.

4. Manufacturer-Recommended Maintenance

Following the manufacturer’s recommended maintenance schedule is crucial for York YLAA chillers. The manufacturer’s guidelines are designed based on extensive testing and engineering expertise, ensuring that the chiller continues to operate at its peak performance.

5. Professional Service and Expertise

Engaging the services of qualified HVAC technicians with expertise in York YLAA chillers is essential for effective maintenance. These professionals are familiar with the unique characteristics of York YLAA chillers and can identify and address issues efficiently.

Conclusion

Understanding York YLAA chiller parts and implementing a proactive maintenance program are essential for maintaining peak chiller performance. Regular maintenance, comprehensive practices, and adherence to the manufacturer’s recommendations contribute to the efficiency, reliability, and extended service life of York YLAA chillers. By investing in proper maintenance and seeking professional expertise, businesses can ensure that their cooling systems continue to operate at optimal performance, providing efficient and reliable cooling for their diverse applications.

York YLAA Chiller Parts for Eco-Friendly Cooling Solutions

In a world where sustainability has become a top priority, industries are increasingly seeking eco-friendly solutions that align with their environmental goals. The HVAC industry plays a significant role in contributing to sustainability efforts, and York YLAA chillers stand at the forefront of providing eco-friendly cooling solutions. With a focus on energy efficiency, advanced engineering, and innovative technology, York YLAA chiller parts enhance sustainability while delivering superior cooling performance. In this article, we explore how York YLAA chiller parts contribute to eco-friendly cooling solutions and support businesses in their journey towards a greener future.

1. Energy Efficiency: The Foundation of Sustainability

At the heart of eco-friendly cooling solutions lie energy-efficient technologies. York YLAA chillers are designed with a focus on energy efficiency, incorporating features such as variable speed compressors and advanced heat transfer coils. These components optimize energy usage, reducing electricity consumption and minimizing greenhouse gas emissions. By prioritizing energy efficiency, York YLAA chiller parts significantly contribute to sustainability efforts, enabling businesses to reduce their carbon footprint and promote responsible resource management.

2. High Coefficient of Performance (COP): Optimizing Cooling Efficiency

York YLAA chiller parts are engineered to achieve a high Coefficient of Performance (COP). COP measures the cooling output of a chiller in relation to the energy consumed. A higher COP indicates more efficient cooling, as the chiller delivers greater cooling capacity with less energy input. York YLAA chillers consistently achieve high COP values, making them a preferred choice for eco-conscious businesses seeking sustainable cooling solutions.

3. Low Global Warming Potential (GWP) Refrigerants

Refrigerants play a crucial role in cooling systems, and their environmental impact is a key consideration. York YLAA chillers are designed to use low Global Warming Potential (GWP) refrigerants that have a lower impact on the environment compared to traditional refrigerants. Low-GWP refrigerants contribute to reduced greenhouse gas emissions and align with global efforts to mitigate climate change.

York YLAA Chiller Parts for Eco-Friendly Cooling Solutions

4. Smart Controls and Precision Cooling

York YLAA chiller parts feature smart controls and precision cooling capabilities. The control panels optimize chiller operations based on real-time cooling demands, ensuring that the chiller operates at the exact capacity required. This dynamic control minimizes energy wastage and enhances cooling efficiency, supporting eco-friendly cooling practices.

5. Environmental Certifications and Recognition

York YLAA chillers and their components often meet stringent environmental standards and certifications, such as ENERGY STAR® and LEED (Leadership in Energy and Environmental Design). These certifications recognize the energy efficiency and sustainability of the products, providing businesses with assurance that they are investing in eco-friendly cooling solutions.

Conclusion

York YLAA chiller parts offer eco-friendly cooling solutions that align with sustainability goals. Through energy efficiency, high COP values, low-GWP refrigerants, smart controls, and environmental certifications, York YLAA chillers contribute to reduced energy consumption and greenhouse gas emissions. As businesses and industries prioritize sustainable practices and seek eco-friendly solutions, York YLAA chiller parts stand as a reliable and efficient choice. By embracing these eco-friendly cooling solutions, businesses not only promote environmental stewardship but also benefit from cost savings and a smaller environmental footprint, making a positive impact on the planet and supporting a greener future for all.

High-efficiency chillers from YLAA put energy efficiency at the forefront of its industry thanks to their cutting-edge control algorithms. YLAA chillers have some of the best IPLV (off-design) performance in their category.

High-efficiency chillers from YLAA put energy efficiency at the forefront of its industry thanks to their cutting-edge control algorithms. YLAA chillers have some of the best IPLV (off-design) performance in their category. The YLAA chiller offers a diverse selection of options, each designed to perform dependably in a specific setting. It is possible to achieve a capture rate of 85% while maintaining a temperature of no more than 140 degrees Fahrenheit and 60 degrees Celsius.

The YLAA chiller offers a diverse selection of options, each designed to perform dependably in a specific setting. It is possible to achieve a capture rate of 85% while maintaining a temperature of no more than 140 degrees Fahrenheit and 60 degrees Celsius. The York YLAA chiller parts components have been tried and tested, and they are reliable in reducing the frequency of service calls. Since its introduction, scroll compressors have logged hundreds of thousands of hours of service in various industries.

The York YLAA chiller parts components have been tried and tested, and they are reliable in reducing the frequency of service calls. Since its introduction, scroll compressors have logged hundreds of thousands of hours of service in various industries.

industry, we have a thorough understanding of the requirements for heating and cooling in the industrial and commercial sectors.

industry, we have a thorough understanding of the requirements for heating and cooling in the industrial and commercial sectors. When operating HVAC systems, parts delivery is most effective for York YLAA Commercial Chiller Parts. These parts are available in good quality. It can be challenging to perform maintenance on ventilation systems in industrial facilities or commercial buildings.

When operating HVAC systems, parts delivery is most effective for York YLAA Commercial Chiller Parts. These parts are available in good quality. It can be challenging to perform maintenance on ventilation systems in industrial facilities or commercial buildings. No alternative can adequately take their place regarding high-quality HVAC elements. c can fit all York equipment with York parts without any problems. An exhaustive look through Midwest Parts Center’s inventory for

No alternative can adequately take their place regarding high-quality HVAC elements. c can fit all York equipment with York parts without any problems. An exhaustive look through Midwest Parts Center’s inventory for

Various energy, acoustic, and mechanical combinations are available to suit your needs and preferences. Choose a lighter, more efficient chiller that requires less maintenance in the long term to save money.

Various energy, acoustic, and mechanical combinations are available to suit your needs and preferences. Choose a lighter, more efficient chiller that requires less maintenance in the long term to save money. The York YLAA doesn’t have to spend more money to be a leader in sustainability. An innovative heat exchanger and R-410A refrigerant make the YLAA chiller ideal for use in sensitive environments. Consequently, this cooler is green.

The York YLAA doesn’t have to spend more money to be a leader in sustainability. An innovative heat exchanger and R-410A refrigerant make the YLAA chiller ideal for use in sensitive environments. Consequently, this cooler is green.

When precise temperature control is needed, industrial chillers are typically employed. YLAA chillers, for example, are used by wineries to maintain the fermentation and storage temperatures of the beverage.

When precise temperature control is needed, industrial chillers are typically employed. YLAA chillers, for example, are used by wineries to maintain the fermentation and storage temperatures of the beverage. When deciding on the right chiller size for your cooling needs, there are numerous things to keep in mind. York YLAA Chillers’ sizing tool can help you quickly establish your chiller’s capacity and freight weight.

When deciding on the right chiller size for your cooling needs, there are numerous things to keep in mind. York YLAA Chillers’ sizing tool can help you quickly establish your chiller’s capacity and freight weight.

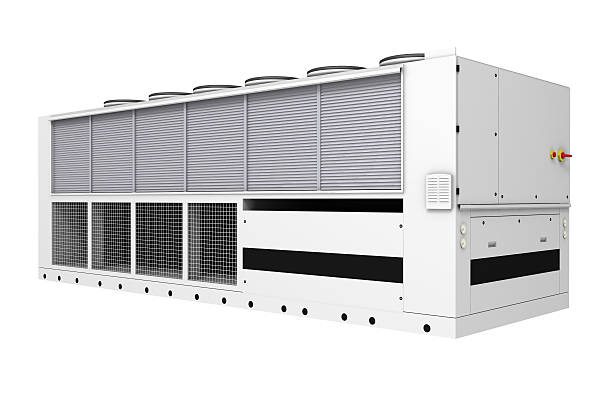

Because of its large capacity and environmentally friendly features, York is a pioneer in air-cooled chiller technology.

Because of its large capacity and environmentally friendly features, York is a pioneer in air-cooled chiller technology.  Use YORK YLAA Air-Coolant to save money and assist the environment. We can help you set up an air-cooled chiller system for industrial or commercial cooling. Our YLAA Chillers can be used in air-cooled water chiller systems to:

Use YORK YLAA Air-Coolant to save money and assist the environment. We can help you set up an air-cooled chiller system for industrial or commercial cooling. Our YLAA Chillers can be used in air-cooled water chiller systems to: Why York YLAA is the best option, the top five features The YLAA chiller comes with various choices, making it appropriate for many applications. Glycol can be chilled at a temperature of 10°F (-12°C). A capture rate of 85 percent is feasible at a maximum temperature of 140 degrees Fahrenheit.

Why York YLAA is the best option, the top five features The YLAA chiller comes with various choices, making it appropriate for many applications. Glycol can be chilled at a temperature of 10°F (-12°C). A capture rate of 85 percent is feasible at a maximum temperature of 140 degrees Fahrenheit.

For their high efficiency and performance. The system is more efficient because of intelligent controls and variable-speed heat exchangers. The value of the

For their high efficiency and performance. The system is more efficient because of intelligent controls and variable-speed heat exchangers. The value of the  An acoustic sound blanket protects the YLAA chiller’s compressors from external noise. The sound blankets are made from one layer of acoustical absorbent textile fiber.

An acoustic sound blanket protects the YLAA chiller’s compressors from external noise. The sound blankets are made from one layer of acoustical absorbent textile fiber. To save energy and reduce fan noise, install Variable Speed Drives (VSD) on the condenser fans of your YVAA air-cooled chiller. Innovative heat exchangers, variable speed compressors, and sophisticated controls are used in YVAA air-cooled chillers to provide remarkable performance and value.

To save energy and reduce fan noise, install Variable Speed Drives (VSD) on the condenser fans of your YVAA air-cooled chiller. Innovative heat exchangers, variable speed compressors, and sophisticated controls are used in YVAA air-cooled chillers to provide remarkable performance and value.

Choose from a wide range of energy, acoustic, and mechanical combinations to meet your specific application requirements and preferences.

Choose from a wide range of energy, acoustic, and mechanical combinations to meet your specific application requirements and preferences. The York YLAA chiller parts have been tested and proven reliable in reducing the frequency of service calls. Scroll compressors have been in operation for tens of thousands of hours in a wide range of industries.

The York YLAA chiller parts have been tested and proven reliable in reducing the frequency of service calls. Scroll compressors have been in operation for tens of thousands of hours in a wide range of industries.

It is common to employ industrial chillers in food-processing processes that demand precise temperature control. Winery YLAA chillers, for example, are used to maintain a consistent temperature during the fermentation and storage of the beverage. Cooling mixers, potable water, and jacketed tanks of yeast are all key bakery components that benefit from bakery chillers. The process of molding plastic via injection

It is common to employ industrial chillers in food-processing processes that demand precise temperature control. Winery YLAA chillers, for example, are used to maintain a consistent temperature during the fermentation and storage of the beverage. Cooling mixers, potable water, and jacketed tanks of yeast are all key bakery components that benefit from bakery chillers. The process of molding plastic via injection h the investment. Building managers and business owners can acquire the necessary solutions to avoid chiller difficulties to lessen the significant impact of unexpected outages.

h the investment. Building managers and business owners can acquire the necessary solutions to avoid chiller difficulties to lessen the significant impact of unexpected outages.

High capacities and environmentally friendly characteristics distinguish York as a pioneer in air-cooled chiller technology. Compact, energy-efficient

High capacities and environmentally friendly characteristics distinguish York as a pioneer in air-cooled chiller technology. Compact, energy-efficient