Understanding York VSD Coolant

- Introduction to York VSD Coolant:

- Benefits of VSD Coolant:

- Energy Efficiency: Discuss how York VSD coolant contributes to improved energy efficiency by enhancing heat transfer.

- Reduced Operating Costs: Explain how the enhanced heat transfer leads to reduced energy consumption and, consequently, lower operational costs.

- Extended Equipment Lifespan: Highlight how proper cooling can extend the lifespan of equipment like chillers and heat exchangers.

- Environmental Impact: Mention the eco-friendly aspects of York VSD coolant, such as its potential to lower carbon emissions due to reduced energy usage.

- Applications of York VSD Coolant:

- HVAC Systems: Describe how VSD coolant can optimize heating, ventilation, and air conditioning systems, leading to better comfort and efficiency.

- Industrial Refrigeration: Discuss how the coolant is utilized in industrial settings to maintain precise temperatures and prevent overheating.

- Data Centers: Explain the importance of York VSD coolant in cooling high-performance computing environments.

- Commercial Buildings: Explore its role in maintaining consistent cooling in shopping malls, hotels, and office spaces.

- Manufacturing Processes: Touch on how the coolant can aid in managing temperatures during various manufacturing processes.

- Comparative Analysis:

- Compare VSD coolant with traditional coolant options, highlighting its superior performance and efficiency.

- Provide data or case studies that showcase the advantages of York VSD coolant in real-world scenarios.

- Considerations and Implementation:

- Discuss the factors to consider when implementing VSD coolant, including compatibility with existing systems and proper maintenance.

- Offer insights into best practices for integrating the coolant into different cooling systems.

- Future Trends and Innovations:

- Touch on potential advancements in York VSD coolant technology and how it might evolve in the coming years.

- Speculate on its role in emerging cooling technologies and sustainable practices.

- Conclusion:

- Summarize the key benefits and applications of VSD coolant.

- Emphasize the importance of informed decision-making when selecting coolant options for various cooling systems.

By structuring the article this way, readers will gain a comprehensive understanding of the benefits and applications of York VSD coolant, and how it can contribute to efficient and sustainable cooling solutions.

Exploring the Chemistry Behind York VSD Coolant

Exploring the Chemistry Behind York VSD Coolant

- Introduction to VSD Coolant Chemistry:

- Briefly explain the significance of coolant in heat transfer and temperature regulation.

- Introduce York VSD coolant and its relevance in modern cooling systems.

- Chemical Composition of VSD Coolant:

- Detail the primary components of York VSD coolant, including base fluids and additives.

- Explain the purpose of each component and how they contribute to the overall performance of the coolant.

- Heat Transfer Mechanisms:

- Explore the various heat transfer mechanisms involved in cooling systems and how the coolant interacts with them.

- Discuss the role of VSD coolant in enhancing these heat transfer mechanisms.

- Thermodynamics and Fluid Dynamics:

- Explain the thermodynamic principles governing heat transfer and fluid behavior in cooling systems.

- Relate these principles to the behavior of York VSD coolant under different temperature and pressure conditions.

- Corrosion Inhibition and Anti-Fouling Properties:

- Highlight the additives in VSD coolant that prevent corrosion and fouling in cooling systems.

- Discuss the chemical reactions that take place to protect equipment surfaces from degradation.

- pH Balance and Chemical Stability:

- Detail the importance of maintaining proper pH levels in cooling systems and how the coolant contributes to pH balance.

- Discuss the chemical stability of York VSD coolant over extended periods of use.

- Compatibility and Material Interactions:

- Explain the considerations regarding the compatibility of the coolant with different materials commonly found in cooling systems.

- Describe how chemical interactions are managed to prevent degradation of system components.

- Environmental Impact and Sustainability:

- Discuss the eco-friendliness of VSD coolant in terms of its chemical composition and potential environmental consequences.

- Advancements in Coolant Chemistry:

- Touch on recent innovations and research in coolant chemistry, including efforts to develop more efficient and environmentally friendly formulations.

- Case Studies and Real-World Applications:

- Provide examples of how the specific chemistry of York VSD coolant has led to improved cooling in various industries.

- Future Directions in Coolant Chemistry:

- Speculate on the future trends and developments in coolant chemistry, such as the integration of nanotechnology and smart materials.

- Conclusion:

- Summarize the key takeaways about the chemistry of VSD coolant and its pivotal role in optimizing cooling systems.

The Role of York VSD Coolant in Sustainable Cooling Solutions

- Introduction to Sustainable Cooling:

- Define the concept of sustainable cooling and its importance in addressing energy consumption and environmental concerns.

- Overview of York VSD Coolant:

- Introduce VSD coolant and its unique characteristics that make it conducive to sustainable cooling solutions.

- Energy Efficiency and Reduced Carbon Footprint:

- Explain how the properties of York VSD coolant optimize heat transfer, leading to reduced energy consumption.

- Discuss how lowered energy usage directly contributes to a decrease in carbon emissions.

- Heat Recovery and Waste Heat Utilization:

- Highlight how VSD coolant can be utilized in heat recovery systems to repurpose waste heat for other processes.

- Provide examples of industries or applications where waste heat recovery is particularly effective.

- Enhanced System Performance and Reliability:

- Explain how proper cooling with York VSD coolant improves the overall efficiency and reliability of cooling systems.

- Discuss how reduced heat-related stress on equipment components can lead to extended lifespans and fewer maintenance requirements.

- Optimized HVAC Systems for Buildings:

- Explore how sustainable cooling solutions with VSD coolant can enhance the performance of heating, ventilation, and air conditioning (HVAC) systems in buildings.

- Discuss potential energy savings in commercial and residential structures.

- Data Center Cooling and Energy Efficiency:

- Detail the role of York VSD coolant in maintaining optimal temperatures in data centers while minimizing energy consumption.

- Explain how this contributes to the sustainability of data center operations.

- Reducing Refrigerant Emissions and Environmental Impact:

- Discuss how VSD coolant’s composition can contribute to lower refrigerant leakage and emissions, which are significant environmental concerns.

- Green Building Certifications and Compliance:

- Highlight how the adoption of York VSD coolant can align with green building standards and certifications.

- Provide examples of certifications that recognize sustainable cooling practices.

- Case Studies and Success Stories:

- Present real-world examples of organizations that have successfully implemented VSD coolant to achieve sustainable cooling solutions.

- Future Trends and Innovations:

- Discuss potential advancements in sustainable cooling technology, including how York VSD coolant might continue to evolve.

- Conclusion:

- Summarize the key points regarding the role of VSD coolant in promoting sustainable cooling solutions.

- Emphasize the importance of adopting such solutions for a more environmentally conscious future.

The Role of York VSD Coolant in Sustainable Cooling Solutions

Advantages of Using York VSD Coolant in Industrial Refrigeration

- Introduction to Industrial Refrigeration:

- Briefly explain the significance of industrial refrigeration systems in various industries, such as food processing, pharmaceuticals, and cold storage.

- Overview of York VSD Coolant:

- Introduce VSD coolant and its specific properties that make it suitable for industrial refrigeration applications.

- Energy Efficiency and Cost Savings:

- Detail how the enhanced heat transfer capabilities of York VSD coolant lead to reduced energy consumption and operational costs.

- Provide examples or case studies illustrating energy savings achieved by using the coolant in industrial refrigeration.

- Optimized Chiller Performance:

- Explain how VSD coolant contributes to improved chiller efficiency by maintaining consistent heat transfer rates.

- Discuss the impact of efficient cooling on overall system performance and reliability.

- Precise Temperature Control:

- Highlight how the coolant’s properties enable precise temperature control, critical for industries requiring specific temperature ranges for storage and production.

- Reduced Downtime and Maintenance:

- Discuss how efficient cooling with York VSD coolant minimizes wear and tear on equipment, leading to fewer breakdowns and maintenance needs.

- Explain the financial and operational benefits of reduced downtime.

- Heat Recovery and Secondary Uses:

- Explore how industrial facilities can utilize waste heat from refrigeration systems for other processes, enhancing overall energy efficiency.

- Provide examples of how waste heat recovery can be implemented effectively.

- Environmental Impact and Compliance:

- Discuss how the use of VSD coolant can help industries reduce their carbon footprint and comply with environmental regulations.

- Highlight the significance of sustainable practices in modern industrial operations.

- Case Studies and Success Stories:

- Showcase real-world examples of industries that have successfully integrated York VSD coolant into their refrigeration systems to achieve various advantages.

- Long-Term Investment and ROI:

- Analyze the long-term benefits of using York VSD coolant, including improved equipment lifespan and the potential for return on investment.

- Considerations for Implementation:

- Provide insights into factors to consider when integrating York VSD coolant into existing refrigeration systems, including compatibility and system adjustments.

- Future of Industrial Refrigeration:

- Discuss the evolving trends in industrial refrigeration and how coolant technology might adapt to future industry needs.

- Conclusion:

- Summarize the key advantages of using VSD coolant in industrial refrigeration and emphasize its role in driving efficiency and cost-effectiveness.

York VSD Coolant Maintenance and Best Practices

- Introduction to Coolant Maintenance:

- Explain the importance of regular coolant maintenance in ensuring optimal system performance and longevity.

- Introduce the focus of the article on York VSD coolant and its specific maintenance requirements.

- Understanding York VSD Coolant Properties:

- Recap the key properties of York VSD coolant that contribute to its performance in cooling systems.

- Highlight how these properties influence maintenance considerations.

- Regular Monitoring and Inspection:

- Emphasize the need for routine monitoring of coolant levels, temperature, and pressure in cooling systems.

- Explain how consistent inspections can help identify potential issues before they escalate.

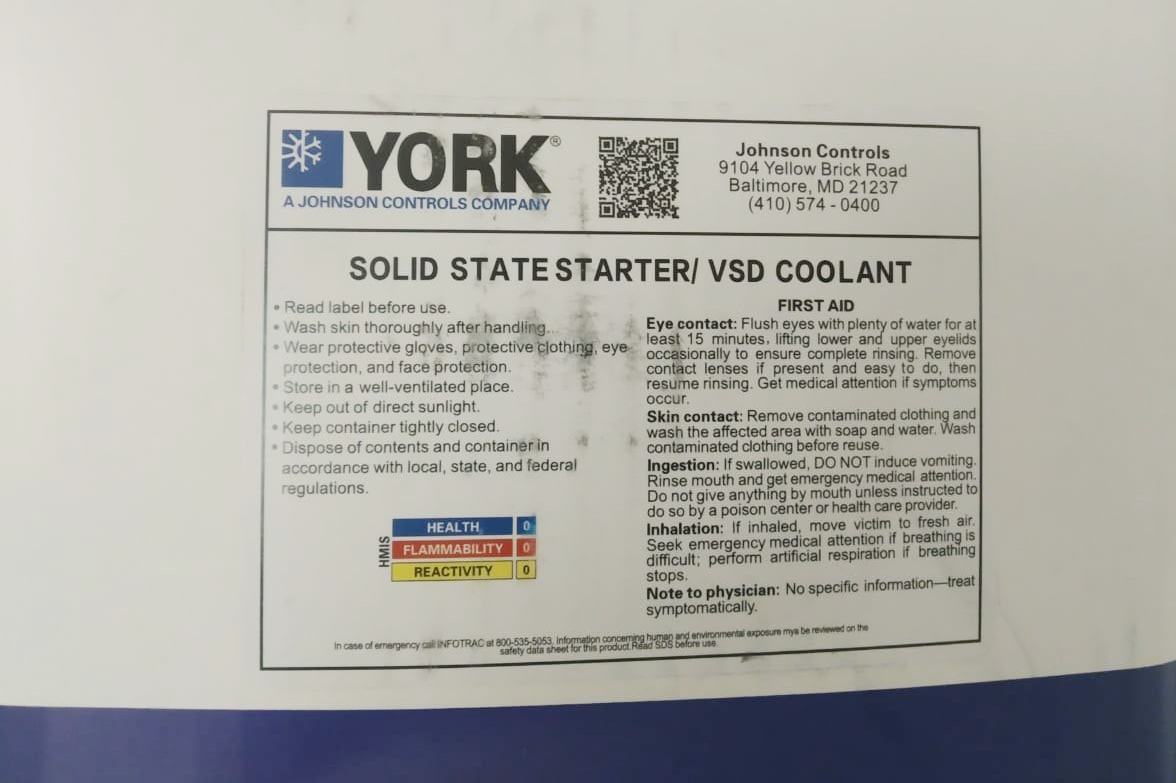

- Coolant Contamination Prevention:

- Discuss the sources of coolant contamination, such as air and water ingress, and how to prevent them.

- Provide guidance on maintaining proper coolant purity to ensure efficient heat transfer.

- pH Balance and Additive Management:

- Explain the significance of maintaining the proper pH level of the coolant and how to monitor and adjust it as needed.

- Detail the role of additives and how to manage their concentrations for optimal performance.

- Cleaning and Flushing Procedures:

- Describe the importance of periodic coolant system cleaning and flushing to remove contaminants and scale buildup.

- Provide step-by-step instructions for performing effective cleaning procedures.

- Filter Maintenance and Replacement:

- Discuss the role of filters in coolant systems and the importance of regular cleaning or replacement.

- Offer guidelines for determining the appropriate filter maintenance schedule.

- Temperature and Pressure Regulation:

- Explain the impact of coolant temperature and pressure on system efficiency and longevity.

- Provide tips for maintaining proper temperature and pressure levels.

- Coolant System Leaks and Repairs:

- Address the issue of coolant leaks and the steps to identify, locate, and repair leaks promptly.

- Highlight the consequences of unresolved leaks on system performance.

- Documentation and Record Keeping:

- Stress the importance of maintaining thorough records of coolant maintenance activities, inspections, and repairs.

- Explain how proper documentation can aid in tracking system health over time.

- Training and Personnel:

- Highlight the need for adequately trained personnel to perform coolant maintenance tasks.

- Discuss the benefits of ongoing training and knowledge sharing within maintenance teams.

- Emergency Response and Contingency Plans:

- Touch on the development of contingency plans to address unexpected coolant-related issues.

- Provide guidance on how to respond to coolant-related emergencies effectively.

- Conclusion:

- Summarize the key best practices for maintaining York VSD coolant in cooling systems.

- Emphasize the role of proper maintenance in achieving optimal system performance and longevity.

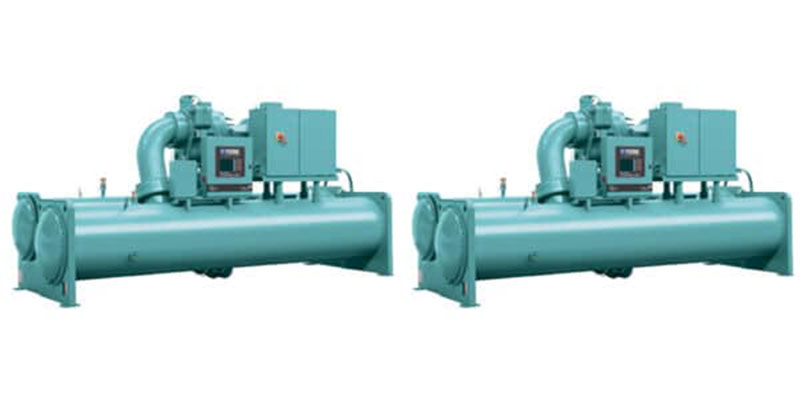

York VSD Coolant in Chiller Systems

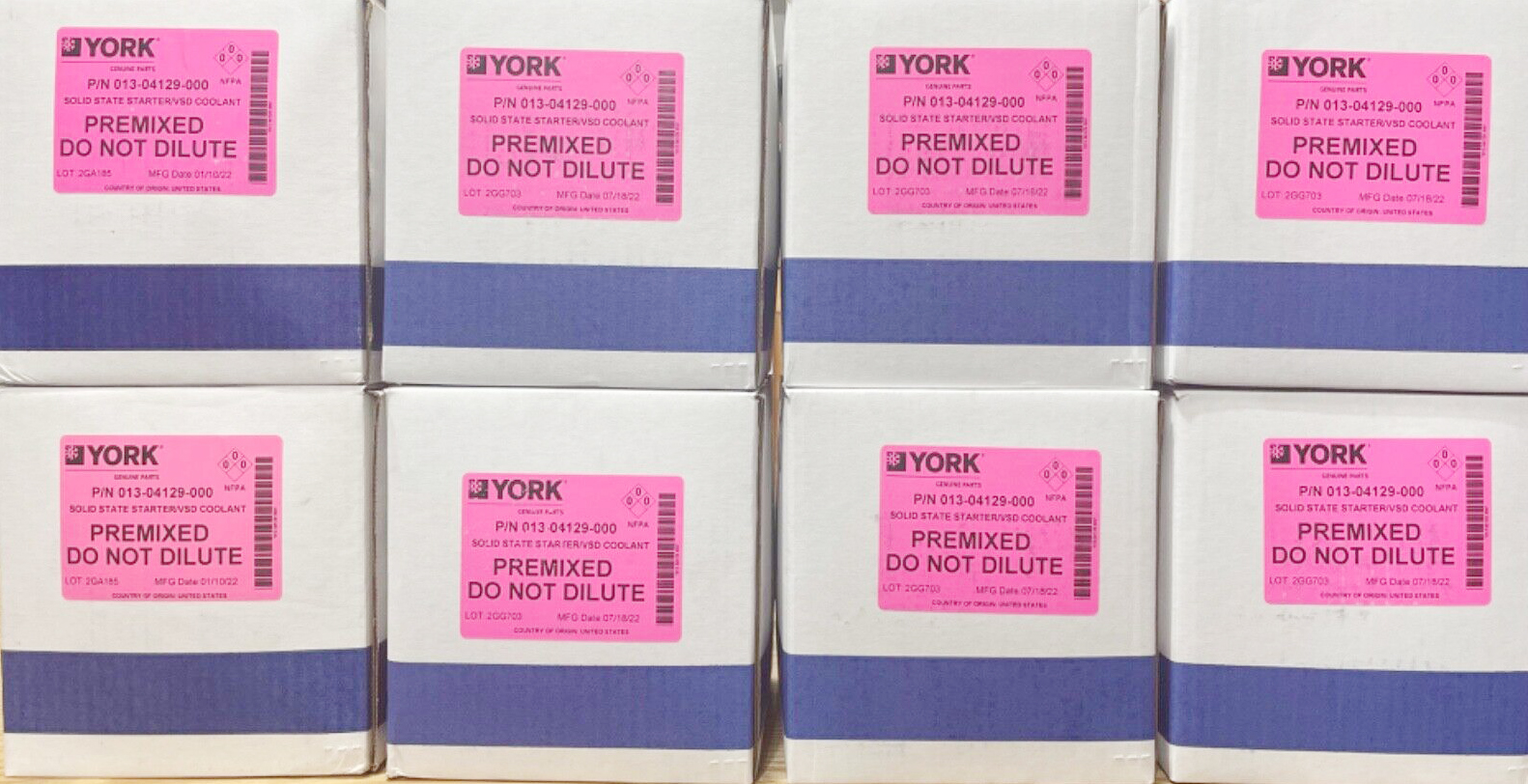

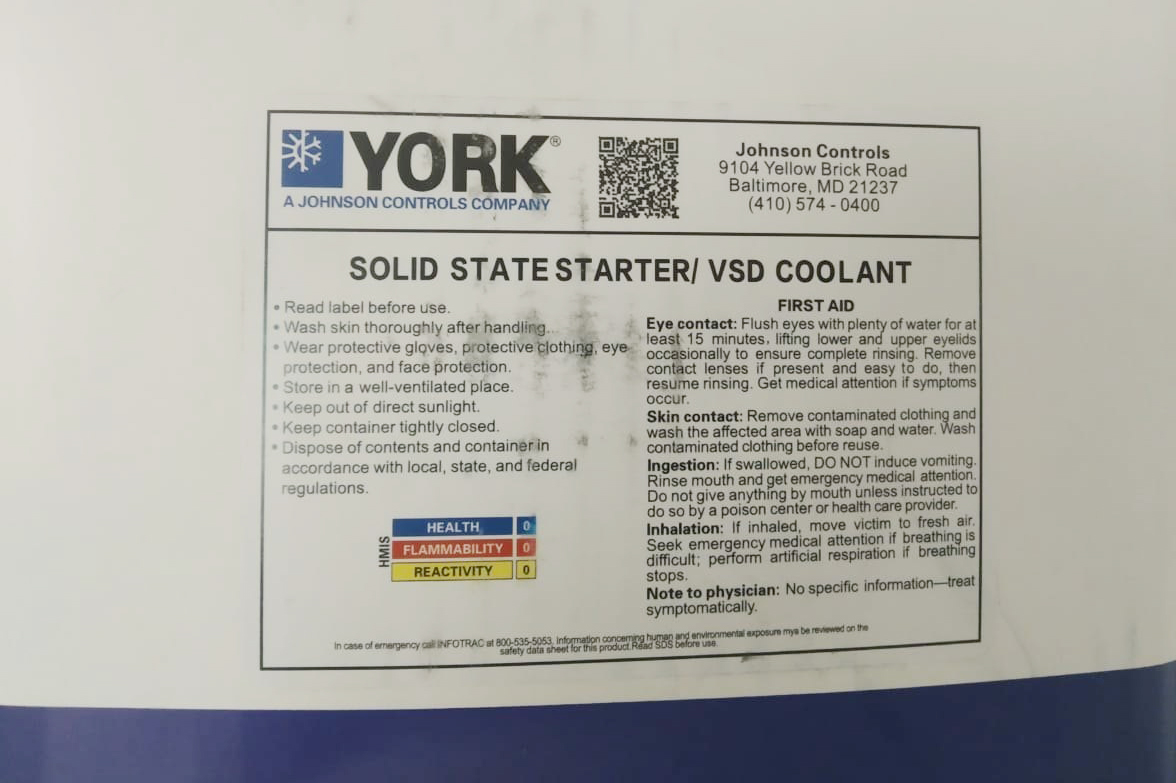

York VSD Coolant is a specialized cooling solution designed for use in Variable Speed Drive (VSD) systems, particularly those manufactured by YORK, a well-known brand in the HVAC (Heating, Ventilation, and Air Conditioning) industry. Below is an overview of York VSD Coolant:

1. Purpose and Function: York VSD Coolant serves the critical function of maintaining the optimal operating temperature within VSD systems, especially those integrated into chillers and other HVAC equipment. These systems rely on advanced technology, including variable speed drives, to control the speed of motors and compressors, thus enhancing energy efficiency and overall performance. To ensure these systems operate at their best, appropriate cooling is essential.

2. Compatibility with YORK Equipment: One of the standout features of York VSD Coolant is its tailor-made compatibility with YORK equipment. YORK is known for manufacturing high-quality HVAC systems, including chillers and VSD systems. York VSD Coolant is specifically formulated to meet the unique cooling requirements of YORK VSD systems, ensuring maximum efficiency and longevity.

3. Importance of Proper Cooling: In VSD systems, maintaining the right operating temperature is paramount. Overheating can lead to reduced efficiency, increased wear and tear, and potentially costly breakdowns. York VSD Coolant helps dissipate heat effectively, preventing such issues and allowing VSD systems to perform optimally.

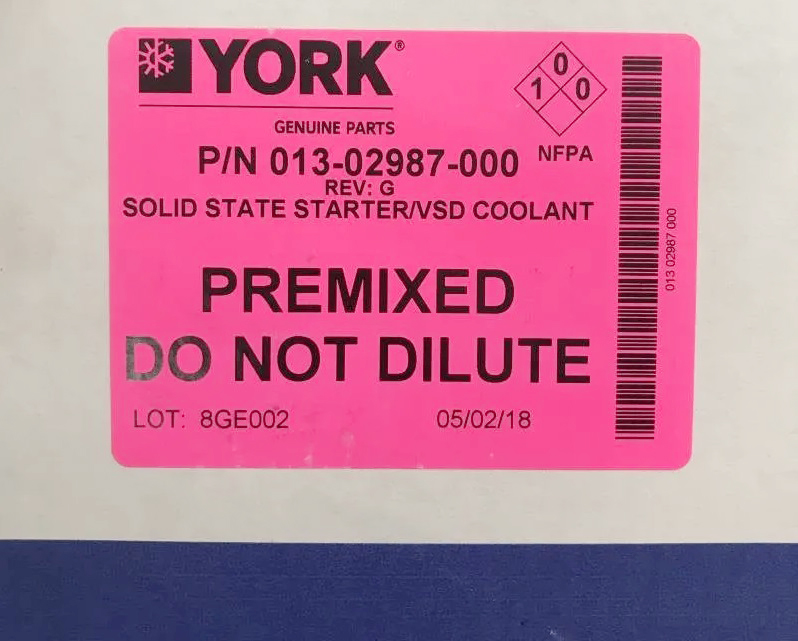

4. Maintenance and Replacement: Like any cooling system, York VSD Coolant may require periodic maintenance and replacement. Over time, coolant properties can degrade, affecting its ability to regulate temperature. Regular maintenance and timely replacement of coolant are essential to keep VSD systems running smoothly.

5. Professional Service: Working with VSD systems, including coolant replacement, is a complex task best left to trained HVAC technicians. These professionals have the expertise to assess coolant condition, troubleshoot issues, and ensure the correct type and amount of coolant are used, maintaining system integrity.

6. Energy Efficiency and Cost Savings: Proper cooling with York VSD Coolant contributes to the energy efficiency of VSD systems. By preventing overheating and optimizing system performance, businesses can realize significant energy savings and reduced operating costs over time.

7. Environmental Considerations: Efficient HVAC systems, including those using York VSD Coolant, not only save on energy costs but also reduce their environmental impact. Lower energy consumption translates to fewer greenhouse gas emissions, making these systems more environmentally friendly.

In summary, York VSD Coolant is a specialized cooling solution designed for YORK VSD systems, ensuring they operate at peak efficiency and longevity. Proper cooling is vital to maintain the performance of VSD systems, enhance energy efficiency, and reduce operating costs, all while benefiting the environment by lowering energy consumption. Regular maintenance and professional service are key to maximizing the benefits of VSD Coolant in VSD systems.

York VSD Coolant in Chiller Systems

York VSD Coolant is important for the efficient and reliable operation of Variable Speed Drive (VSD) systems, particularly those manufactured by YORK. Here’s why it’s essential:

- Optimal Temperature Regulation: VSD systems, including those used in HVAC equipment like chillers, rely on precise temperature control to operate efficiently. VSD Coolant is formulated to dissipate heat effectively, helping maintain the desired operating temperature. This is critical because overheating can lead to reduced system efficiency and potential damage.

- Compatibility: York VSD Coolant is specifically designed to be compatible with YORK VSD systems. This ensures that the coolant meets the unique cooling requirements of these systems, promoting their longevity and efficiency. Using a coolant not designed for the system can lead to issues and reduced performance.

- Energy Efficiency: Proper cooling with York VSD Coolant contributes to the energy efficiency of VSD systems. When these systems run at their ideal temperature, they operate more efficiently, resulting in lower energy consumption and cost savings over time.

- Preventative Maintenance: Regular maintenance and monitoring of coolant condition are essential for VSD systems. York VSD Coolant helps prevent overheating and potential damage, making it a crucial component of preventative maintenance routines.

- System Longevity: VSD Coolant plays a role in extending the life of VSD systems. By preventing excessive wear and tear due to overheating, it helps ensure that the equipment operates reliably for an extended period, protecting your investment.

- Professional Service: Handling coolant and coolant-related tasks for VSD systems should be performed by trained HVAC technicians. These professionals have the expertise to assess coolant condition, diagnose issues, and ensure that the correct type and amount of coolant are used, maintaining system integrity.

In conclusion, York VSD Coolant is indeed important for the efficient and reliable operation of VSD systems, particularly those manufactured by YORK. It helps regulate temperature, ensures compatibility, enhances energy efficiency, and contributes to the longevity of the equipment. Regular maintenance, including monitoring and replacement of coolant, is essential to keep VSD systems running optimally.

Clean air conditioning is a significant consideration, and units need cost savings, but the energy bill is a major obstacle for companies trying to work efficiently within a budget.

Clean air conditioning is a significant consideration, and units need cost savings, but the energy bill is a major obstacle for companies trying to work efficiently within a budget. The HVAC system performs as designed with little effort, thanks to using York Industrial VSD Coolant for chillers. The heating, ventilation, and air conditioning (HVAC) system in a building is crucial for maintaining a comfortable indoor temperature and meeting regulations.

The HVAC system performs as designed with little effort, thanks to using York Industrial VSD Coolant for chillers. The heating, ventilation, and air conditioning (HVAC) system in a building is crucial for maintaining a comfortable indoor temperature and meeting regulations.