In today’s fast-paced industrial and commercial world, efficient HVAC systems are the lifeblood of productivity, comfort, and energy savings. When these systems operate optimally, they ensure stable temperatures, protect equipment from overheating, and maintain ideal air quality—crucial factors for warehouses, factories, hospitals, and large office buildings. To achieve this high level of performance, partnering with a trusted York Replacement Parts Supplier is absolutely essential.

At Midwest Parts Center, we specialize in providing genuine York replacement parts for commercial and industrial HVAC systems. With our extensive inventory, deep technical expertise, and fast service, we make sure your systems continue running at peak efficiency. Our certified York parts are engineered for precision, durability, and performance—helping businesses avoid costly downtime and unnecessary repairs.

📞 For expert assistance, call Midwest Parts Center today at +1 800-368-8385.

🧊 Why Choosing a Certified York Replacement Parts Supplier Matters

Your HVAC system is a major investment—and like any investment, it requires proper care. Using the wrong replacement components can lead to inefficiencies, performance issues, and even premature equipment failure. That’s why choosing a certified York Replacement Parts Supplier like Midwest Parts Center makes all the difference.

York systems are designed with advanced engineering, and each part—whether a compressor, filter, coil, or valve—is manufactured to exact specifications. When a component needs replacement, only genuine York parts can guarantee compatibility and performance.

As a certified York Replacement Parts Supplier, Midwest Parts Center ensures that every part you receive meets York’s high-quality manufacturing standards. You won’t get generic or imitation parts—only authentic replacements that protect your system’s performance and warranty.

⚙️ The Importance of Genuine York Replacement Parts

Using genuine York parts is not just about maintaining performance—it’s also about safety and long-term cost efficiency. Here’s why:

-

Perfect Compatibility

Every York system is unique. Each model is designed with specific performance parameters and part designs. Genuine York replacement parts fit precisely, eliminating the risk of poor installation or malfunction. -

Extended Equipment Lifespan

Non-genuine parts may work temporarily, but over time they can strain your HVAC system. Genuine York parts, however, maintain the mechanical harmony of your equipment—extending its lifespan and saving you from frequent replacements. -

Consistent Energy Efficiency

Using certified components helps your system maintain its energy efficiency ratings. This means lower electricity costs and a smaller carbon footprint for your facility. -

Warranty Protection

Many HVAC systems lose their manufacturer warranty coverage if non-genuine parts are used. Working with a certified York Replacement Parts Supplier like Midwest Parts Center ensures your warranty remains valid.

🌬️ How York Replacement Parts Improve HVAC Efficiency

At Midwest Parts Center, we understand that energy efficiency is a top priority for commercial and industrial facility managers. Every kilowatt saved translates into reduced operational costs. Genuine York replacement parts are specifically designed to enhance the energy performance of your system.

Let’s take a closer look at how they do that:

-

Optimized Airflow: Original York filters, blowers, and fans ensure consistent airflow, reducing strain on motors and improving air circulation.

-

Enhanced Refrigerant Control: Genuine York coils and expansion valves precisely regulate refrigerant flow, helping maintain optimal cooling performance.

-

Reduced Heat Loss: Properly fitted York components prevent heat leakage, maintaining stable temperature control across your facility.

-

Advanced Compressor Efficiency: York compressors are engineered to deliver maximum output with minimal energy consumption, directly influencing energy savings.

When you use authentic York parts from Midwest Parts Center, you’re not just maintaining your HVAC system—you’re investing in sustained efficiency and reliability.

🏭 Why Industrial and Commercial Facilities Choose Midwest Parts Center

Industrial and commercial HVAC systems operate under extreme conditions—often 24/7. These systems demand reliability, and downtime can lead to production delays, employee discomfort, and costly losses.

That’s where Midwest Parts Center comes in. As a certified York Replacement Parts Supplier, we are committed to supporting the demanding needs of commercial and industrial environments.

Here’s why businesses across the USA trust us:

-

Extensive Inventory: We stock a comprehensive range of genuine York replacement parts for all major models and series.

-

Fast Turnaround: We understand the urgency of HVAC downtime. Our team ensures quick order processing and delivery.

-

Technical Expertise: Our professionals have in-depth knowledge of York systems, helping you identify the exact part you need.

-

Customer-Centric Service: We prioritize long-term relationships with our clients, providing dedicated support and personalized solutions.

📞 Call us today at +1 800-368-8385 to discuss your HVAC replacement part needs.

🔍 Common York Replacement Parts for HVAC Systems

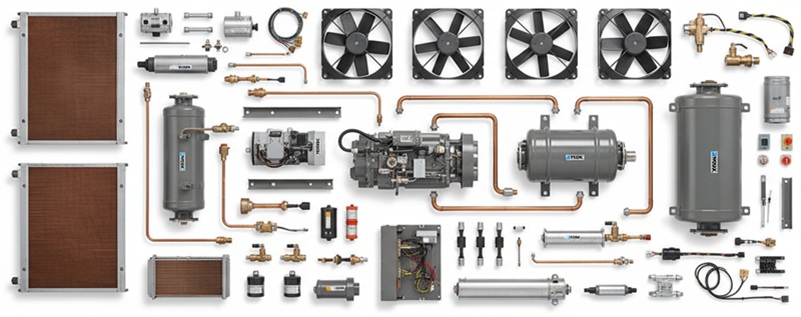

If you manage a large facility, you already know that HVAC systems are complex assemblies of interconnected components. Here are some of the most requested York parts available at Midwest Parts Center:

-

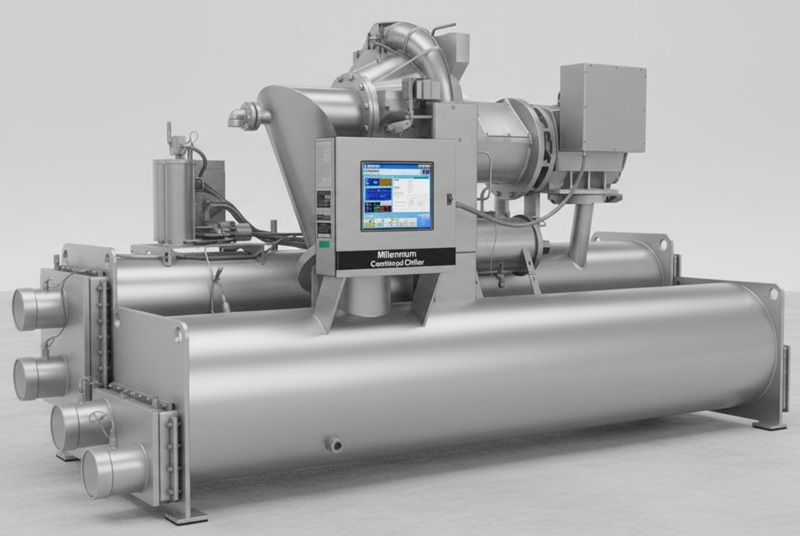

Compressors – The heart of your cooling system. Genuine York compressors maintain the right pressure and flow of refrigerant for consistent cooling performance.

-

Coils and Condensers – These regulate heat exchange, ensuring maximum efficiency in heating and cooling cycles.

-

Expansion Valves – They control refrigerant flow for optimal temperature regulation and energy use.

-

Air Filters – Proper filtration ensures clean air and protects sensitive components from dust and debris.

-

Thermostats and Sensors – Maintain precise control over system operations for balanced comfort and efficiency.

-

Motors and Belts – Power and motion components that drive your HVAC systems reliably.

-

Refrigerant Components – From lines to regulators, genuine York refrigerant parts maintain cooling stability and efficiency.

Each part is designed for performance, safety, and longevity—helping your HVAC system deliver continuous comfort and reliability.

🧠 Expert Tips from Midwest Parts Center on HVAC Maintenance

While replacing worn-out parts with genuine York replacements is crucial, proactive maintenance also plays a major role in maximizing your system’s performance.

Here are some expert tips from Midwest Parts Center:

-

Schedule Routine Inspections: Regular maintenance allows early detection of worn-out or inefficient parts.

-

Replace Filters Frequently: Clean filters improve airflow, enhance air quality, and reduce energy use.

-

Monitor Refrigerant Levels: Proper refrigerant balance ensures efficient heat transfer and prevents compressor stress.

-

Inspect Electrical Components: Ensure wiring, controls, and sensors function correctly to avoid system failures.

-

Use Genuine York Parts Only: Always choose certified components to ensure compatibility and performance stability.

If your system requires replacement parts or maintenance support, our experts are always ready to assist.

💡 The Midwest Parts Center Advantage

When you partner with Midwest Parts Center, you gain access to more than just replacement parts—you gain a team dedicated to your HVAC success. We stand by every product we sell, ensuring that our customers receive genuine York components backed by professional support.

Our commitment to excellence has made us one of the most trusted York Replacement Parts Suppliers in the United States. Whether you operate a factory, a hospital, or an office complex, we understand the demands your facility faces and provide solutions that enhance performance, reduce energy consumption, and minimize downtime.

With Midwest Parts Center, you’re not just getting parts—you’re getting a partner who prioritizes your comfort, efficiency, and operational continuity.

🌎 Building a Sustainable Future with York Replacement Parts

Sustainability is becoming increasingly important across industries. Genuine York parts contribute to greener, more sustainable operations by reducing energy consumption, minimizing waste, and improving system longevity.

When HVAC systems run efficiently, they require less energy to produce the same cooling or heating output, leading to reduced greenhouse gas emissions. Partnering with a certified York Replacement Parts Supplier like Midwest Parts Center helps your facility stay compliant with modern energy standards while supporting environmental responsibility.

🚀 Take Your HVAC System to the Next Level

Every efficient HVAC system starts with high-quality parts and a reliable supplier. With Midwest Parts Center, you get both. Our certified York replacement parts keep your equipment performing like new, ensuring reliability, energy efficiency, and long-term savings.

Whether you’re upgrading, maintaining, or repairing your existing system, our expert team is here to help you find exactly what you need.

✅ Enhance system performance

✅ Extend equipment life

✅ Save on energy and maintenance costs

✅ Enjoy peace of mind with certified York parts

📞 Contact Midwest Parts Center Today

Don’t let subpar components compromise your system’s performance. Choose the trusted York Replacement Parts Supplier that industrial and commercial businesses rely on.

📍 Midwest Parts Center

📞 Toll-Free: +1 800-368-8385

Let us help you maintain the power and performance of your York HVAC systems with certified replacement parts that deliver results. From consultation to delivery, Midwest Parts Center is your go-to destination for all your York replacement part needs.

In Summary:

Boosting HVAC system efficiency requires the right components and a trusted partner. Midwest Parts Center, your certified York Replacement Parts Supplier, provides the reliability, expertise, and quality you need to keep your HVAC systems running at their best. With genuine York parts, you not only enhance performance and energy efficiency—you invest in the future stability of your facility.

📞 For expert assistance and high-quality York replacement parts, call Midwest Parts Center today at +1 800-368-8385.

Reliable York Replacement Parts Supplier Serving Industrial and Commercial Facilities | Call +1 800-368-8385

In the world of industrial and commercial HVAC systems, reliability is not just an option — it’s a necessity. When massive facilities rely on climate control systems to maintain temperature-sensitive environments, support worker comfort, or protect critical machinery, even the smallest HVAC malfunction can cause serious downtime and expensive repairs. That’s why partnering with a reliable York Replacement Parts Supplier is one of the smartest investments facility managers can make.

At Midwest Parts Center, we take pride in being a trusted and certified York Replacement Parts Supplier serving commercial and industrial facilities across the United States. Our mission is simple — to keep your systems running efficiently, your downtime minimal, and your energy savings maximized. We understand how vital it is to maintain the integrity and performance of your HVAC systems, and that’s exactly what we deliver — quality York parts, expert support, and dependable service.

📞 Contact Midwest Parts Center today at +1 800-368-8385 for genuine York replacement parts that guarantee performance and reliability.

🧊 The Role of a York Replacement Parts Supplier in Industrial and Commercial Operations

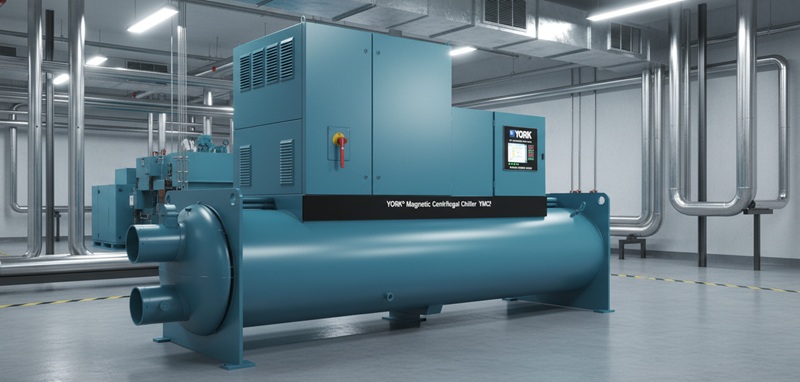

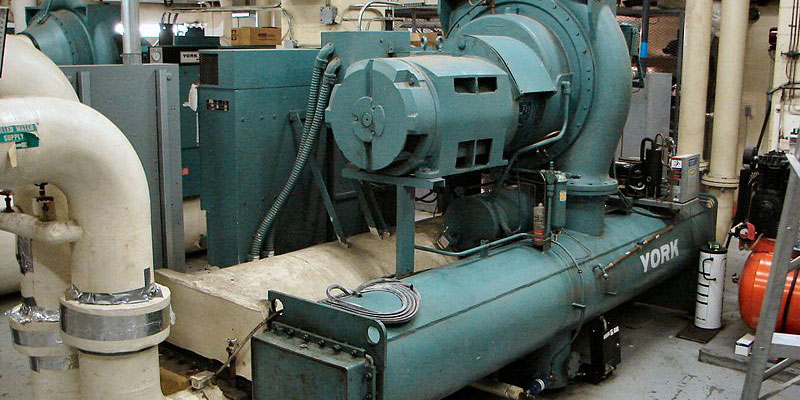

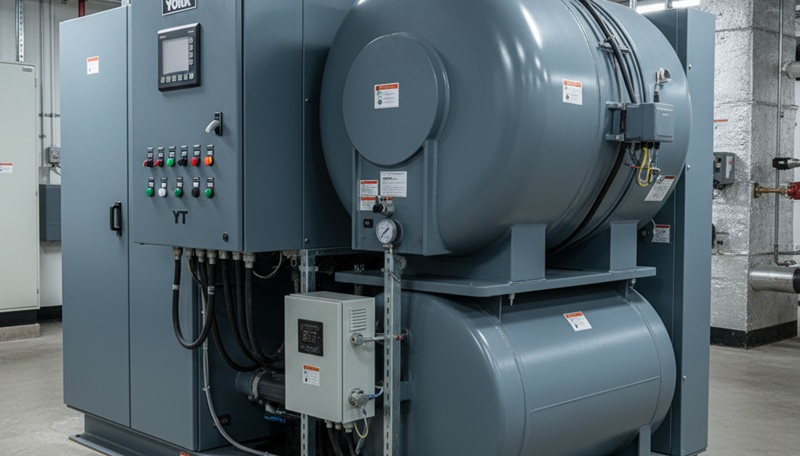

Industrial and commercial HVAC systems are the backbone of climate management in large buildings such as manufacturing facilities, hospitals, schools, and warehouses. These systems are designed for performance and longevity, but like any mechanical equipment, they require maintenance, repairs, and part replacements over time.

This is where a York Replacement Parts Supplier like Midwest Parts Center steps in. Our primary role is to provide facility managers, contractors, and technicians with access to genuine York parts that ensure optimal HVAC performance. Whether it’s a replacement compressor, motor, filter, sensor, or coil, every component we supply is manufactured to exact York engineering standards.

When your HVAC equipment requires servicing, getting the right parts quickly can be the difference between a minor maintenance check and a major system failure. Midwest Parts Center eliminates that worry by providing fast access to authentic York components — ensuring your systems stay operational when you need them most.

⚙️ Why Genuine York Replacement Parts Matter

In HVAC systems, precision is everything. Each York component is designed to integrate seamlessly within a complex system of compressors, coils, valves, and sensors. Substituting genuine parts with low-quality or generic alternatives can lead to system inefficiencies, reduced performance, and even safety hazards.

Here are key reasons why using authentic York replacement parts from a certified York Replacement Parts Supplier like Midwest Parts Center is essential:

-

Perfect Fit and Compatibility

York components are engineered for exact models and configurations. Genuine parts ensure the system runs as intended, avoiding compatibility issues or performance gaps. -

Preserves System Efficiency

Using certified replacement parts maintains the designed energy efficiency of your York system. This results in consistent cooling and heating with minimal power consumption. -

Longer System Lifespan

Genuine York parts reduce system strain, prevent premature wear, and extend the life of your HVAC equipment. -

Manufacturer Warranty Protection

Many HVAC warranties become void when non-genuine parts are installed. By choosing a certified York Replacement Parts Supplier such as Midwest Parts Center, your warranty remains intact and fully valid. -

Reliable Performance Under Pressure

Industrial environments operate continuously — and so should your HVAC system. York’s authentic components are designed for high performance under heavy loads, ensuring uninterrupted operation.

🏭 Why Industrial and Commercial Facilities Trust Midwest Parts Center

Industrial and commercial environments demand precision, speed, and reliability — and that’s exactly what Midwest Parts Center delivers. As a leading York Replacement Parts Supplier, we specialize in providing solutions that meet the rigorous demands of industrial and commercial operations.

Here’s why countless facilities across the U.S. rely on us:

-

Extensive York Inventory: From chillers to air handlers, we carry a full range of authentic York replacement parts for all major systems and models.

-

Fast Turnaround Times: We understand that time is money. Our team ensures prompt order processing and efficient delivery.

-

Expert HVAC Knowledge: Our specialists have in-depth understanding of York systems, allowing us to quickly identify the right parts for your needs.

-

Trusted Industry Experience: With years of service in the HVAC field, we’ve built a reputation for reliability, professionalism, and technical expertise.

-

Commercial and Industrial Focus: Our services are specifically tailored for large-scale facilities where HVAC reliability directly impacts productivity and comfort.

Whether you’re operating a massive production floor, a high-rise office, or a warehouse complex, Midwest Parts Center has the York replacement parts and technical know-how to keep your systems performing efficiently.

📞 For immediate support or to order genuine York parts, call +1 800-368-8385 today.

🌬️ How York Replacement Parts Enhance HVAC System Efficiency

Energy efficiency isn’t just about saving costs — it’s about operational excellence. HVAC systems that use genuine York replacement parts perform more efficiently, consume less energy, and produce fewer emissions. Here’s how:

-

Precision Engineering: York parts are designed to exact tolerances, minimizing air leaks and optimizing system balance.

-

Advanced Filtration and Airflow: Authentic York filters and fan assemblies maintain clean airflow, ensuring air quality and consistent cooling.

-

Optimized Refrigerant Control: Genuine York coils and valves regulate refrigerant flow precisely, preventing system overcooling or overheating.

-

Reduced Wear and Tear: High-quality bearings, belts, and motors reduce friction, extending system life and improving mechanical efficiency.

When you choose Midwest Parts Center, you’re not just buying replacement parts — you’re investing in better performance, lower operational costs, and long-term reliability for your HVAC systems.

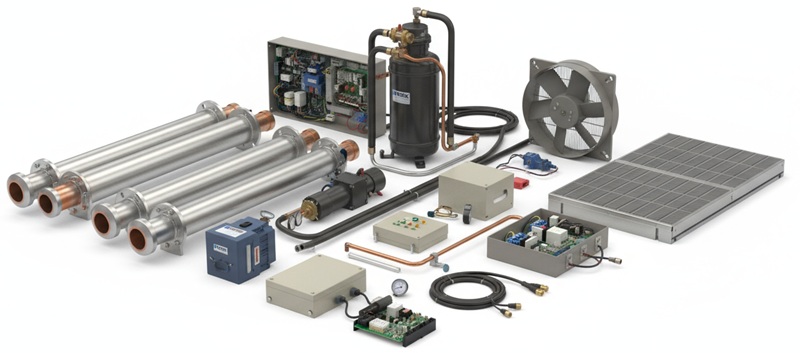

🔩 Most Common York Replacement Parts Supplied by Midwest Parts Center

Industrial and commercial HVAC systems are complex networks of components working together to deliver cooling, heating, and ventilation. Midwest Parts Center, as your trusted York Replacement Parts Supplier, provides all critical components necessary for smooth operation, including:

-

Compressors – Deliver efficient refrigerant compression for reliable cooling performance.

-

Evaporator and Condenser Coils – Facilitate effective heat transfer between air and refrigerant.

-

Expansion Valves – Regulate refrigerant flow for stable temperature control.

-

Filters and Air Cleaners – Ensure high-quality indoor air and protect sensitive components.

-

Belts and Motors – Power key system functions while ensuring quiet, dependable operation.

-

Thermostats and Controls – Provide precise monitoring and energy-efficient system management.

-

Sensors and Switches – Ensure accurate performance monitoring and safety controls.

Each component from Midwest Parts Center is a certified York replacement, manufactured to deliver peak reliability and performance.

🧠 Maintenance Tips from Midwest Parts Center Experts

Preventive maintenance is the key to extending HVAC equipment life and avoiding costly breakdowns. Here are essential tips from the Midwest Parts Center team to help you get the most out of your York system:

-

Replace Filters Regularly: Dirty filters strain your system, reduce airflow, and increase energy consumption.

-

Inspect Electrical Components: Ensure wiring, controls, and sensors are functioning correctly to prevent system failure.

-

Check Refrigerant Levels: Maintaining proper refrigerant balance helps your system run smoothly and efficiently.

-

Schedule Regular Maintenance: Partner with trained technicians for periodic system inspections.

-

Use Genuine York Parts Only: Avoid performance loss and warranty voiding by sourcing from a certified York Replacement Parts Supplier like Midwest Parts Center.

💡 The Midwest Parts Center Advantage

At Midwest Parts Center, we go beyond simply supplying York parts — we provide reliability, trust, and unmatched customer service. Here’s what makes us stand out:

-

Certified York Partnership: Our status as an official York Replacement Parts Supplier ensures authenticity and quality assurance.

-

Technical Support: Our team offers expert guidance in selecting the correct components for your specific system model.

-

Nationwide Availability: No matter where your facility is located, we ensure timely part delivery.

-

Customized Solutions: From standard replacements to complex part identification, we tailor solutions for your operational needs.

-

Commitment to Excellence: Every transaction is backed by professionalism, accuracy, and a commitment to customer satisfaction.

When you choose Midwest Parts Center, you’re partnering with a supplier that values performance, precision, and dependability.

🌎 A Sustainable Choice for the Future

Energy-efficient HVAC operations not only reduce costs but also contribute to a sustainable future. Genuine York parts from Midwest Parts Center help your systems maintain high efficiency, reducing overall energy use and carbon emissions.

By investing in authentic replacement components, you also extend the life of your HVAC equipment — reducing the frequency of replacements and the environmental impact associated with manufacturing and waste. It’s a win-win for your facility and the planet.

🏆 Why Midwest Parts Center is the Reliable Choice

Reliability is more than a promise — it’s our foundation. At Midwest Parts Center, we understand the challenges industrial and commercial facilities face when HVAC systems fail. Downtime means lost productivity, reduced comfort, and potential safety risks. That’s why we’re committed to providing rapid, reliable, and high-quality York replacement parts when you need them most.

We don’t just deliver parts — we deliver peace of mind. Our clients trust us because they know we’ll get the job done right the first time, every time.

When you need a York Replacement Parts Supplier you can rely on, look no further than Midwest Parts Center. We specialize in supplying genuine York replacement parts to industrial and commercial facilities across the United States. Our goal is to help your business operate efficiently, reliably, and without interruption.

📍 Midwest Parts Center

📞 Toll-Free: +1 800-368-8385

Let us be your trusted source for York replacement parts — where reliability, quality, and performance come together.

Keeping your HVAC system running efficiently requires more than just routine maintenance — it requires the right parts from the right supplier. Midwest Parts Center, your reliable York Replacement Parts Supplier, ensures that your commercial and industrial HVAC systems perform optimally with genuine York components designed for durability and efficiency.

With our certified parts, expert service, and nationwide availability, we are your ultimate partner for HVAC reliability and performance.

📞 Call Midwest Parts Center today at +1 800-368-8385 and experience why industrial and commercial facilities across the country trust us as their go-to York Replacement Parts Supplier.