Why Businesses Prefer York YT Chillers for Superior Energy Efficiency

In today’s commercial and industrial sectors, energy efficiency is a top priority. Businesses are constantly looking for ways to optimize their HVAC systems, reduce energy costs, and maintain sustainability goals. One of the most trusted solutions for energy-efficient cooling is the York YT chiller. Known for its innovative design, superior performance, and long-term reliability, the York YT chiller is the preferred choice for businesses that demand the best in cooling technology.

At Midwest Parts Center, we specialize in providing high-quality York HVAC components, including the York YT chiller and its essential replacement parts. If you’re looking to enhance the efficiency of your cooling system, contact us at +1 800 368 8385 today.

What Makes the York YT Chiller the Best Choice?

The York YT chiller stands out in the HVAC industry for its unique features and energy-efficient technology. Businesses across various sectors choose this chiller due to its numerous advantages, such as:

- Unmatched Energy Efficiency – Designed with advanced centrifugal technology, the York YT chiller significantly reduces energy consumption.

- Reliability and Longevity – With durable components and minimal maintenance requirements, this chiller offers long-term performance.

- Smart Controls and Automation – Integrated control systems allow for real-time monitoring and optimization.

- Eco-Friendly Operation – Lower energy usage and sustainable refrigerants contribute to environmentally responsible cooling.

1. Advanced Centrifugal Technology for Maximum Efficiency

One of the key reasons why businesses prefer the York YT chiller is its centrifugal technology. This design allows for:

- Reduced power consumption compared to traditional chillers

- Efficient cooling even at partial load conditions

- Lower operational costs due to optimized performance

The York YT chiller adapts to varying cooling demands, ensuring that your business only uses the energy necessary to maintain optimal conditions.

2. High-Efficiency Compressors for Lower Energy Bills

The heart of any chiller is its compressor, and the York YT chiller is equipped with high-efficiency centrifugal compressors. These compressors:

- Operate at variable speeds to match cooling demand

- Reduce energy wastage and improve cost-effectiveness

- Provide smooth and quiet operation for commercial settings

For businesses that prioritize energy savings, investing in a York YT chiller can lead to substantial reductions in monthly energy bills.

3. Smart Controls for Precision Cooling

Modern businesses require smart technology to optimize energy use, and the York YT chiller delivers just that. With advanced microprocessor controls, businesses can:

- Monitor real-time performance

- Adjust settings for maximum efficiency

- Receive alerts for maintenance needs

This level of automation ensures that your cooling system operates at peak performance while keeping operational costs low.

4. Environmentally Friendly Refrigerants

Sustainability is a growing concern for many businesses, and the York YT chiller is designed with eco-friendly refrigerants that comply with environmental regulations. These refrigerants:

- Reduce carbon footprint

- Improve overall system efficiency

- Comply with global sustainability initiatives

Using a York YT chiller helps businesses align with green initiatives while maintaining powerful cooling capabilities.

5. Minimal Maintenance Requirements

Downtime can be costly for any business, which is why reliability is key when choosing an HVAC system. The York YT chiller is built for:

- Fewer breakdowns and reduced maintenance frequency

- Easy access to replacement parts through Midwest Parts Center

- Long-term durability with high-quality components

By choosing the York YT chiller, businesses can minimize disruptions and maintain efficient cooling without frequent maintenance hassles.

6. Versatile Applications Across Industries

The York YT chiller is widely used across various industries, including:

- Manufacturing – Ensuring consistent cooling for industrial processes

- Healthcare – Maintaining precise temperature control in hospitals

- Data Centers – Preventing overheating of critical IT equipment

- Hospitality – Providing comfort cooling for hotels and resorts

No matter the industry, the York YT chiller delivers unparalleled performance and reliability.

7. Cost-Effective Long-Term Investment

While the initial investment in a York YT chiller may be higher than other cooling solutions, its long-term benefits outweigh the costs. Businesses save money through:

- Reduced energy consumption

- Lower repair and maintenance costs

- Extended lifespan of the equipment

At Midwest Parts Center, we help businesses get the most value out of their investment by providing genuine York components and expert support.

8. Easy Integration with Existing HVAC Systems

Many businesses hesitate to upgrade their HVAC systems due to compatibility concerns. However, the York YT chiller is designed for seamless integration with existing cooling infrastructures. Its flexibility allows businesses to:

- Upgrade their systems without major overhauls

- Optimize efficiency without downtime

- Improve cooling capacity while maintaining system stability

9. Exceptional Support from Midwest Parts Center

At Midwest Parts Center, we provide businesses with:

- Genuine York YT chiller parts

- Expert guidance on system optimization

- Fast and reliable customer support

Our team is dedicated to helping businesses maintain efficient cooling solutions by providing high-quality parts and professional advice. Call us at +1 800 368 8385 for expert assistance.

10. Proven Track Record of Performance

The York YT chiller has been trusted by businesses for decades due to its superior performance and energy efficiency. With thousands of installations worldwide, it remains one of the most reliable choices for commercial and industrial cooling.

For businesses that prioritize energy efficiency, reliability, and sustainability, the York YT chiller is the ultimate cooling solution. With advanced technology, smart controls, and long-term cost savings, this chiller outperforms competitors in every aspect.

At Midwest Parts Center, we are committed to providing businesses with top-quality York products and expert HVAC solutions. Whether you need a new York YT chiller or replacement parts to maintain your existing system, we have you covered.

Contact us today at +1 800 368 8385 to learn more about how a York YT chiller can enhance your business’s cooling efficiency. Don’t settle for anything less than the best—choose Midwest Parts Center for all your HVAC needs!

The Ultimate Troubleshooting Guide for York YT Chiller Systems

The York YT chiller is one of the most efficient and reliable cooling systems used in commercial and industrial settings. However, like any sophisticated HVAC equipment, it can occasionally experience issues that require troubleshooting. Understanding common problems and their solutions can save businesses time and money while ensuring optimal system performance.

At Midwest Parts Center, we specialize in providing high-quality parts and expert support for York YT chillers. If you need assistance or replacement parts, call us at +1 800 368 8385 for prompt and professional service.

Common York YT Chiller Issues and Troubleshooting Solutions

1. Chiller Not Starting

A York YT chiller that fails to start can be caused by various factors. Here’s how to troubleshoot:

Possible Causes:

- Power supply issues (tripped circuit breaker, loose connections)

- Faulty starter or control board

- Low refrigerant levels

- Safety control lockout due to high/low pressure issues

Troubleshooting Steps:

- Check the main power supply and ensure the chiller is receiving the correct voltage.

- Inspect electrical connections for any loose or damaged wires.

- Reset safety controls and check for system fault codes.

- Verify refrigerant levels and recharge if necessary.

2. Insufficient Cooling Performance

If your York YT chiller is running but not providing adequate cooling, several factors might be at play.

Possible Causes:

- Dirty or clogged condenser and evaporator coils

- Low refrigerant charge

- Faulty expansion valve

- Inefficient compressor operation

Troubleshooting Steps:

- Clean condenser and evaporator coils to improve heat exchange efficiency.

- Inspect refrigerant levels and ensure there are no leaks.

- Check and replace the expansion valve if necessary.

- Monitor compressor performance and check for unusual noises or vibrations.

3. Chiller Overheating

Overheating is a serious issue that can lead to system failure if not addressed promptly.

Possible Causes:

- Poor airflow around the chiller unit

- Blocked or dirty air filters

- Overloaded compressor

- Faulty temperature sensors

Troubleshooting Steps:

- Ensure proper ventilation and remove any obstructions around the chiller.

- Replace or clean air filters to maintain efficient airflow.

- Monitor compressor workload and ensure it’s operating within recommended parameters.

- Test temperature sensors and replace if readings are inaccurate.

4. Excessive Noise or Vibrations

A York YT chiller should operate smoothly with minimal noise. Unusual sounds or vibrations may indicate a problem.

Possible Causes:

- Loose components or mounting bolts

- Worn-out bearings or motor parts

- Refrigerant flow issues

- Misaligned compressor components

Troubleshooting Steps:

- Tighten all loose components and ensure proper alignment.

- Inspect bearings and replace if worn out.

- Check refrigerant lines for restrictions or leaks.

- If necessary, realign or replace faulty compressor components.

5. High Energy Consumption

If your York YT chiller is consuming more energy than usual, it may indicate inefficiencies in the system.

Possible Causes:

- Dirty heat exchanger surfaces

- Incorrect refrigerant charge

- Malfunctioning controls or sensors

- Worn-out compressor components

Troubleshooting Steps:

- Clean heat exchanger surfaces to improve efficiency.

- Check and adjust refrigerant charge.

- Test control settings and recalibrate if needed.

- Inspect compressor components and replace if they show signs of wear.

6. Refrigerant Leaks

Refrigerant leaks can severely impact the performance of a York YT chiller.

Possible Causes:

- Damaged refrigerant lines or connections

- Faulty valve seals

- Worn-out gaskets or O-rings

Troubleshooting Steps:

- Use a leak detection tool to identify leaks.

- Repair or replace damaged refrigerant lines.

- Replace faulty valve seals and worn-out gaskets.

Preventive Maintenance for York YT Chillers

Regular maintenance is the key to avoiding costly breakdowns and ensuring optimal performance of your York YT chiller.

1. Schedule Regular Inspections

Routine inspections help identify potential issues before they become major problems. Inspect:

- Electrical connections

- Refrigerant levels

- Compressor and motor performance

- Heat exchangers and coils

2. Clean Components Regularly

- Keep condenser and evaporator coils clean.

- Replace air filters periodically.

- Remove dust and debris from moving parts.

3. Monitor System Performance

Use the chiller’s control panel to track performance metrics and identify irregularities in:

- Temperature settings

- Compressor efficiency

- Energy consumption

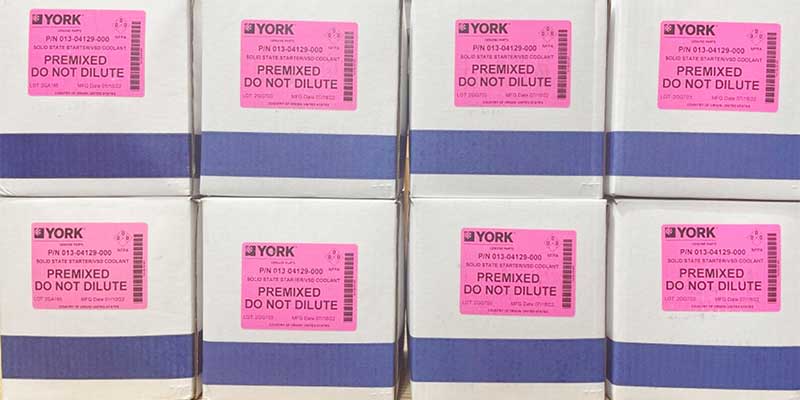

4. Use Genuine Replacement Parts

When repairs are needed, always use genuine York YT chiller parts from Midwest Parts Center to ensure reliability and longevity.

Why Choose Midwest Parts Center for York YT Chiller Support?

At Midwest Parts Center, we provide top-quality parts and expert support for York YT chillers. Here’s why businesses trust us:

1. Authorized Supplier of Genuine York Parts

We offer original York YT chiller replacement parts, ensuring top performance and durability.

2. Fast and Reliable Service

We understand that HVAC downtime can be costly. That’s why we provide quick and efficient service to keep your chiller running smoothly.

3. Expert Technical Support

Our team of experienced HVAC professionals is available to assist with troubleshooting and system optimization.

4. Cost-Effective Solutions

We offer competitive pricing and cost-effective solutions to keep your HVAC systems in peak condition.

5. Nationwide Availability

No matter where your business is located, we can deliver genuine York YT chiller parts quickly and efficiently.

Contact Midwest Parts Center Today

If your York YT chiller is experiencing issues, don’t wait for the problem to escalate. Contact Midwest Parts Center for expert troubleshooting support and high-quality replacement parts.

📞 Call us at +1 800 368 8385 to speak with our HVAC specialists today!

York YT Chiller Installation: 5 Key Factors to Ensure Smooth Operation

When it comes to industrial and commercial cooling solutions, the York YT chiller stands out for its superior energy efficiency, reliability, and long-lasting performance. However, to maximize its benefits, proper installation is crucial. A poorly installed chiller can lead to inefficiencies, increased maintenance costs, and even premature system failure. Ensuring a smooth installation process will help businesses avoid costly downtime and optimize performance from the start.

At Midwest Parts Center, we specialize in providing high-quality York YT chiller parts and expert guidance for installation and maintenance. If you need assistance, don’t hesitate to call us at +1 800 368 8385 for professional support.

The Importance of Proper York YT Chiller Installation

A York YT chiller is a significant investment for any business. To get the most out of it, the installation process must be handled with precision. From selecting the right location to ensuring proper electrical connections, every step plays a crucial role in the long-term efficiency of your HVAC system.

Here are five key factors to consider for a seamless York YT chiller installation:

1. Choosing the Right Location for Installation

The placement of your York YT chiller directly impacts its performance and efficiency. An improperly positioned chiller can lead to restricted airflow, overheating, and increased energy consumption.

Key Considerations for Location:

- Adequate Space: Ensure there is sufficient room around the chiller for maintenance and ventilation.

- Proper Ventilation: Avoid installing the chiller in a confined space that may cause overheating.

- Vibration Control: Place the chiller on a stable surface to minimize vibrations that can damage components.

- Environmental Conditions: Protect the chiller from extreme temperatures, direct sunlight, and potential sources of contamination.

By selecting the ideal location, businesses can enhance the longevity and efficiency of their York YT chiller while minimizing operational disruptions.

2. Ensuring Correct Electrical and Piping Connections

Proper electrical and piping connections are vital to the safe and efficient operation of a York YT chiller. Faulty wiring or inadequate piping can lead to inefficiencies, breakdowns, and even safety hazards.

Electrical Installation Guidelines:

- Use the correct voltage and amperage to avoid overloading the system.

- Ensure secure and insulated wiring to prevent electrical failures.

- Follow the manufacturer’s guidelines for circuit breaker and fuse ratings.

- Conduct a thorough inspection to check for loose or exposed wires.

Piping and Refrigerant Considerations:

- Use high-quality, insulated pipes to prevent refrigerant loss and condensation.

- Ensure proper alignment and support to prevent leaks or mechanical stress.

- Follow refrigerant handling guidelines to comply with environmental regulations.

- Pressure-test the system before startup to detect any leaks.

By adhering to proper electrical and piping guidelines, businesses can ensure their York YT chiller operates safely and efficiently.

3. Optimizing Water Flow and Pump Configuration

A York YT chiller relies on an efficient water flow system for optimal performance. Poor water flow can lead to system inefficiencies, increased energy costs, and potential equipment failure.

Best Practices for Water Flow Optimization:

- Use appropriately sized pumps to match the chiller’s cooling capacity.

- Maintain consistent water flow rates to prevent fluctuations in temperature and pressure.

- Install flow meters and pressure gauges for real-time monitoring and adjustments.

- Regularly clean filters and strainers to prevent clogs and blockages.

By optimizing water flow and pump configuration, businesses can maximize the cooling efficiency of their York YT chiller while reducing wear and tear on system components.

4. Implementing Proper Control and Monitoring Systems

Advanced control systems are essential for monitoring and maintaining the performance of a York YT chiller. Modern chillers come equipped with digital controls that provide real-time data on system operations.

Key Features of Effective Chiller Control Systems:

- Temperature Monitoring: Ensures the chiller operates within the desired cooling range.

- Energy Management: Helps optimize power consumption and reduce operational costs.

- Fault Detection Alerts: Identifies potential issues before they become major problems.

- Remote Access Capabilities: Allows facility managers to monitor the system from any location.

Installing a robust control system ensures that the York YT chiller operates efficiently while minimizing downtime and maintenance costs.

5. Conducting Thorough Testing and Startup Procedures

Before placing a York YT chiller into full operation, it is essential to conduct thorough testing and a proper startup procedure. This ensures that all components are functioning correctly and that the system is ready for long-term operation.

Testing and Startup Checklist:

- Leak Detection: Ensure that refrigerant and water lines are properly sealed.

- Electrical Safety Checks: Verify all connections and test the circuit breakers.

- Performance Calibration: Adjust system settings for optimal efficiency.

- Load Testing: Simulate full-capacity operation to identify potential issues.

- Final Inspection: Conduct a complete walkthrough and documentation for future reference.

By following these steps, businesses can confidently start up their York YT chiller with minimal risk of operational disruptions.

Why Choose Midwest Parts Center for Your York YT Chiller Needs?

At Midwest Parts Center, we understand the importance of a well-installed and properly maintained York YT chiller. Our team offers expert guidance, high-quality replacement parts, and professional support to ensure your chiller operates at peak performance.

Here’s why businesses trust us:

- Authorized Supplier of Genuine York Parts: We provide authentic York YT chiller components for reliable performance.

- Expert Technical Support: Our experienced professionals help troubleshoot and optimize system installation.

- Fast and Reliable Service: We understand the urgency of HVAC needs and provide prompt solutions.

- Competitive Pricing: Get the best quality products at cost-effective rates.

- Comprehensive Inventory: We stock a wide range of York YT chiller parts to ensure quick availability.

Final Thoughts

A York YT chiller is an investment in long-term cooling efficiency and reliability. By following the five key installation factors outlined above, businesses can ensure a smooth operation and avoid costly maintenance issues. From selecting the right location to optimizing control systems, every step plays a vital role in maximizing the performance of your chiller.

For expert assistance and high-quality York YT chiller parts, contact Midwest Parts Center today.

📞 Call us at +1 800 368 8385 for professional support and guidance!