Where to Buy Genuine York YVAA Chiller Parts for Industrial Applications

When an industrial cooling system goes down, it’s never just an inconvenience—it’s a serious operational risk. From manufacturing plants and data centers to hospitals and large commercial facilities, chillers are the backbone of temperature control. Among the most trusted machines in the industry are York YVAA Chiller Parts, known for their reliability, efficiency, and long service life.

But even the best equipment needs maintenance, upgrades, and occasional part replacement. That brings us to one of the most common and important questions facility managers and maintenance professionals ask:

The answer is simple and dependable: Midwest Parts Center.

In this in-depth guide, we’ll explore everything you need to know about sourcing York YVAA chiller parts, why certified components matter, what risks come with non-genuine parts, and how Midwest Parts Center supports commercial and industrial customers across the United States.

Understanding York YT & YVAA Chillers in Industrial Applications

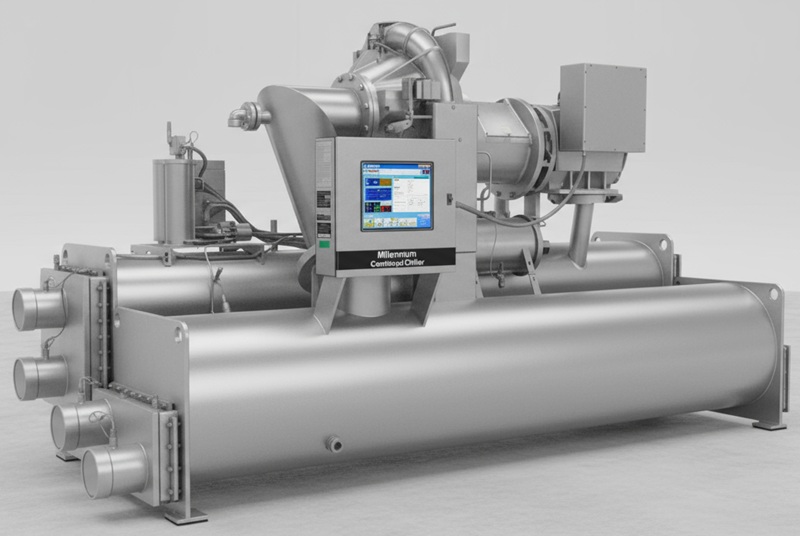

York YT chillers are widely used in large-scale cooling applications because they are engineered for performance, durability, and energy efficiency. Many industrial facilities also rely on YVAA air-cooled chillers, which share design philosophies and critical component requirements.

Because these systems often run continuously and support mission-critical operations, the quality of replacement components is not negotiable. That’s why demand for york yvaa chiller parts remains consistently high in the industrial sector.

Typical Industrial Uses Include:

- Manufacturing plants

- Pharmaceutical facilities

- Food and beverage processing units

- Large commercial buildings

- Healthcare and hospital systems

- Data centers and server farms

In all these environments, downtime is expensive—and sometimes dangerous.

Why Certified York YT Chiller Parts Matter

Not all replacement parts are created equal. Using uncertified or incompatible components may look like a cost-saving move at first, but it often leads to higher long-term expenses.

Benefits of Using Certified York YT Chiller Parts

-

System Compatibility

Certified york yvaa chiller parts are engineered to match the original specifications of your equipment, ensuring perfect fit and function. -

Operational Efficiency

Proper parts help maintain optimal energy efficiency, keeping operating costs under control. -

Extended Equipment Life

Quality components reduce wear and tear on compressors, motors, and control systems. -

Reduced Downtime

Correct parts mean fewer breakdowns and faster repairs. -

Safety & Compliance

Industrial facilities must meet strict safety and regulatory standards. Certified parts help maintain compliance.

When you source parts from Midwest Parts Center, you’re not just buying components—you’re investing in system reliability.

The Risks of Using Non-Genuine or Low-Quality Parts

In industrial HVAC systems, shortcuts can be costly. Using off-brand or uncertified components instead of proper york yvaa chiller parts can result in:

- Increased vibration and noise

- Poor cooling performance

- Higher energy consumption

- Frequent system failures

- Voided warranties

- Unexpected shutdowns

In worst-case scenarios, a single incompatible part can trigger a chain reaction of failures across the chiller system. That’s why industrial buyers consistently turn to Midwest Parts Center for dependable solutions.

Midwest Parts Center: Your Trusted Source for York YT Chiller Parts

Midwest Parts Center is a dedicated supplier serving commercial and industrial areas across the USA. The company focuses on providing reliable, certified HVAC and chiller components that meet the demanding needs of industrial operations.

📞 Toll-Free Number: +1 800 368 8385

When you contact Midwest Parts Center, you’re working with a team that understands industrial cooling—not a generic parts reseller.

What Sets Midwest Parts Center Apart?

- Deep understanding of industrial chiller systems

- Access to certified york yvaa chiller parts

- Fast response times for urgent requirements

- Support tailored to commercial and industrial environments

- Clear communication and knowledgeable assistance

Comprehensive Range of York YT & YVAA Chiller Parts

Industrial chillers are complex systems with many interdependent components. Midwest Parts Center helps simplify sourcing by offering a wide range of critical York YVAA chiller parts, including:

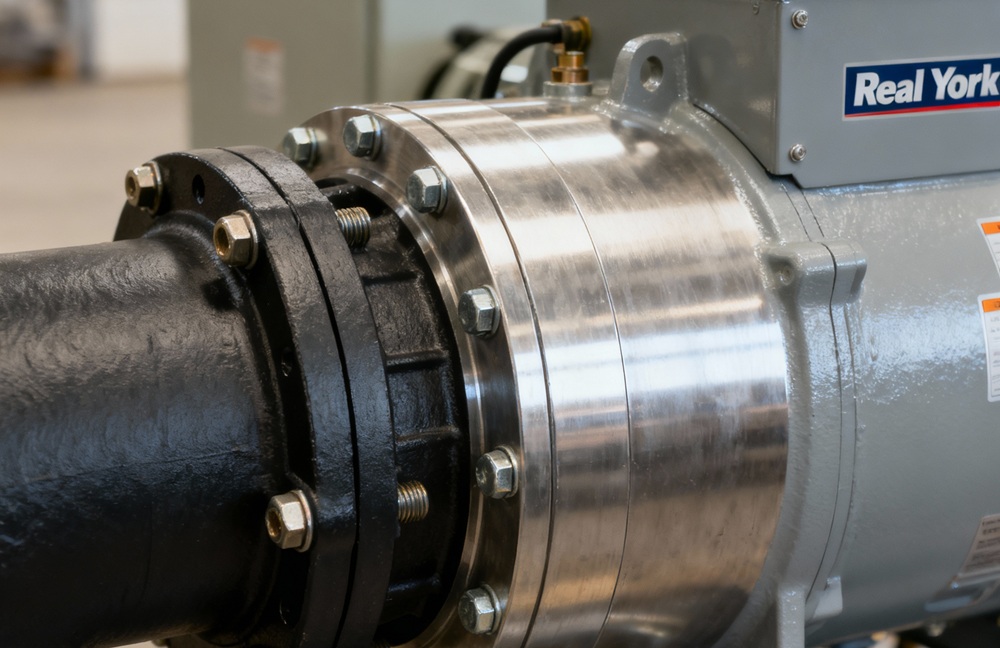

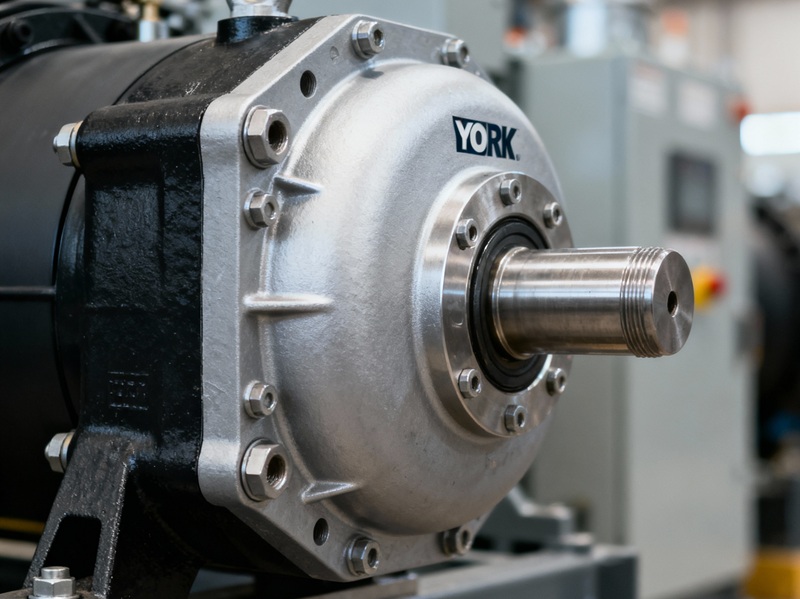

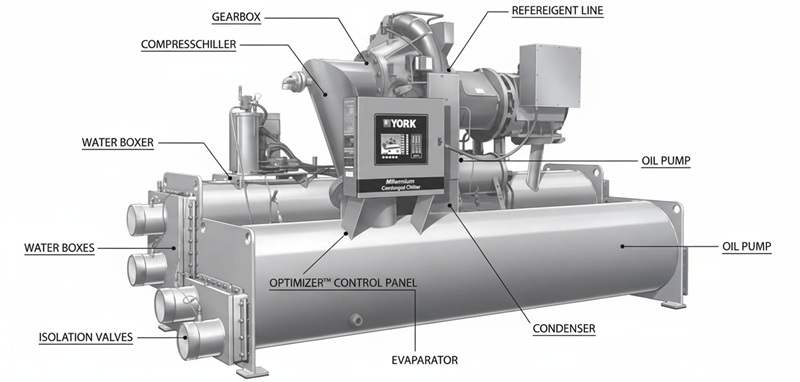

1. Compressor Components

Compressors are the heart of York YT chillers. High-quality parts ensure smooth operation and consistent cooling output.

2. Heat Exchanger & Condenser Parts

These components are essential for efficient heat transfer and energy performance.

3. Control Panels & Sensors

Precision controls keep chillers running within safe parameters. Reliable electronics are crucial in industrial environments.

4. Valves & Flow Control Parts

Proper refrigerant and water flow is key to maintaining system balance and preventing failures.

5. Electrical & Motor Components

From starters to contactors, every electrical part plays a role in dependable operation.

Each category of york yvaa chiller parts is selected with industrial durability and performance in mind.

Serving Commercial and Industrial Facilities Nationwide

Midwest Parts Center is built around the needs of large-scale operations. Industrial buyers often face tight timelines, high load demands, and complex system configurations.

That’s why the company focuses exclusively on commercial and industrial areas, ensuring every interaction is aligned with professional, high-capacity cooling requirements.

Whether you’re managing a single facility or overseeing multiple sites across different states, Midwest Parts Center can support your sourcing needs.

How Midwest Parts Center Supports Emergency Repairs

Chiller failures don’t wait for convenient times. A breakdown during peak production or extreme weather can be devastating.

Midwest Parts Center understands the urgency behind sourcing york yvaa chiller parts in emergency situations.

Emergency Support Advantages:

- Quick identification of required parts

- Knowledgeable guidance to avoid ordering mistakes

- Streamlined communication

- Focus on minimizing downtime

One phone call to +1 800 368 8385 can make the difference between hours of downtime and days of lost productivity.

Long-Term Maintenance & Planned Upgrades

Not every purchase is driven by an emergency. Many industrial facilities plan ahead with preventive maintenance programs and scheduled upgrades.

By partnering with Midwest Parts Center, you gain access to consistent supply of york yvaa chiller parts, helping you:

- Reduce unexpected breakdowns

- Improve energy efficiency

- Extend chiller lifespan

- Budget maintenance costs more accurately

Planned sourcing is always more cost-effective than last-minute scrambling.

Why Industrial Buyers Choose Midwest Parts Center Again and Again

Industrial procurement teams value reliability, transparency, and expertise. Midwest Parts Center has built a strong reputation by focusing on those exact principles.

Key Reasons Customers Return:

- Confidence in part authenticity

- Industrial-grade quality standards

- Responsive customer service

- Clear focus on York YT and YVAA chiller systems

- Commitment to long-term customer relationships

When you consistently need york yvaa chiller parts, working with a trusted supplier simplifies your entire maintenance strategy.

Choosing the Right Supplier Is as Important as Choosing the Right Part

In industrial HVAC, the supplier you choose can directly impact system performance and operational continuity. Midwest Parts Center is not just a vendor—it’s a resource for professionals who take cooling reliability seriously.

By focusing exclusively on certified york yvaa chiller parts and serving only commercial and industrial markets, Midwest Parts Center ensures that every part delivered meets high expectations.

Your Go-To Source for York YT Chiller Parts in the USA

If you’re responsible for maintaining, repairing, or upgrading York YT or YVAA chillers, the choice of parts supplier matters. Certified components protect your equipment, your budget, and your peace of mind.

Midwest Parts Center stands out as a dependable solution for industrial facilities across the United States. From routine maintenance to urgent repairs, their expertise and commitment make them a reliable partner.

📞 Call Today: +1 800 368 8385

When performance, safety, and reliability matter, trust Midwest Parts Center for all your york yvaa chiller parts needs—today and in the long run.

Extend the Life of Your System with Certified York YVAA Chiller Parts | Call 800-368-8385

In commercial and industrial environments, cooling systems are not optional—they are mission-critical assets. From manufacturing plants and processing facilities to large commercial buildings, a reliable chiller system keeps operations running smoothly, safely, and efficiently. Among the most trusted systems in these demanding settings are York YVAA chillers.

But even the most robust chiller cannot deliver peak performance forever without proper care. The real secret to long system life, consistent efficiency, and reduced downtime lies in one crucial factor: using certified york yvaa chiller parts.

If you’re serious about protecting your investment and extending the life of your cooling system, this guide will show you why certified parts matter, how they improve long-term performance, and why Midwest Parts Center is the trusted choice for commercial and industrial customers across the USA.

📞 Call Today: +1 800 368 8385

Why York YVAA Chillers Are Built for Industrial Performance

York YVAA chillers are designed to handle heavy loads, fluctuating demands, and continuous operation. These systems are commonly found in environments where failure is simply not an option.

Typical Applications Include:

- Industrial manufacturing facilities

- Large commercial buildings

- Warehouses and logistics centers

- Healthcare and institutional campuses

- Data centers and mission-critical spaces

Because these systems operate under intense conditions, every internal component must work in perfect harmony. That’s exactly why the quality of york yvaa chiller parts directly impacts system longevity.

The Real Meaning of “Extending System Life”

Extending the life of a York YVAA chiller isn’t just about keeping it running longer—it’s about ensuring it runs efficiently, safely, and predictably throughout its service life.

When certified york yvaa chiller parts are used consistently:

- Mechanical stress is reduced

- Energy efficiency stays closer to original design levels

- Unplanned shutdowns decrease

- Maintenance becomes more predictable

- Total cost of ownership drops

In contrast, using non-certified or mismatched parts often accelerates wear and shortens system life.

What Makes Certified York YVAA Chiller Parts So Important?

Not all replacement parts are equal. Certified york yvaa chiller parts are designed to meet precise engineering specifications that generic alternatives simply can’t match.

1. Exact Fit & Compatibility

Certified parts are engineered for York YVAA systems, ensuring proper alignment, correct tolerances, and smooth integration with existing components.

2. Consistent Cooling Performance

When parts function as intended, the system maintains stable temperatures and load control—critical for industrial processes.

3. Energy Efficiency Preservation

Improper parts can force the system to work harder. Certified york yvaa chiller parts help maintain original efficiency levels.

4. Reduced Risk of Chain Failures

One low-quality component can stress surrounding parts. Certified components protect the entire system.

5. Long-Term Reliability

Industrial operations demand predictability. Certified parts deliver consistent performance over time.

The Hidden Cost of Non-Certified Parts

Some facility managers are tempted by lower upfront costs. Unfortunately, non-certified components often create expensive long-term problems.

Using substandard alternatives instead of proper york yvaa chiller parts can lead to:

- Increased vibration and noise

- Higher energy bills

- Frequent service calls

- Premature compressor or motor failure

- Unplanned downtime

- Safety and compliance risks

In industrial and commercial environments, a single failure can halt production, disrupt services, or damage sensitive equipment.

Midwest Parts Center: Focused on Commercial & Industrial Needs

Midwest Parts Center serves customers who cannot afford uncertainty. The company is dedicated exclusively to commercial and industrial areas, ensuring every solution is aligned with professional-grade requirements.

📞 Toll-Free Support: +1 800 368 8385

This focused approach means:

- No residential guesswork

- No mismatched components

- No compromise on quality

Every recommendation is made with system longevity and operational continuity in mind.

Comprehensive Range of York YVAA Chiller Parts

York YVAA chillers are complex systems with multiple critical subsystems. Midwest Parts Center supports them all with dependable york yvaa chiller parts.

Compressor-Related Components

The compressor is the heart of the chiller. High-quality components reduce internal stress and prevent catastrophic failures.

Heat Transfer Components

Parts supporting evaporators and condensers play a major role in efficiency and temperature control.

Electrical & Control Components

Precision electronics ensure safe operation, load management, and system protection.

Valves & Flow Control Parts

Accurate refrigerant and fluid flow protects compressors and improves overall efficiency.

Motors & Electrical Starters

Reliable electrical parts prevent overloads and sudden shutdowns in high-demand environments.

Each category of york yvaa chiller parts is selected to support long-term performance in industrial conditions.

Planned Maintenance: The Smartest Way to Extend System Life

Emergency repairs are costly. Planned maintenance is strategic.

By sourcing certified york yvaa chiller parts ahead of time, facilities can:

- Schedule maintenance during low-demand periods

- Reduce emergency service costs

- Improve system uptime

- Extend overall equipment life

Midwest Parts Center works with maintenance teams to support preventive maintenance programs that keep systems running at peak performance.

Emergency Support When Downtime Is Not an Option

Despite the best planning, emergencies still happen. When they do, speed and accuracy matter.

Midwest Parts Center understands the urgency of industrial cooling failures and helps customers quickly identify the right york yvaa chiller parts—without costly trial and error.

One call can save:

- Hours of downtime

- Thousands in lost productivity

- Stress on maintenance teams

📞 Call +1 800 368 8385 for fast, knowledgeable assistance.

Supporting System Upgrades & Efficiency Improvements

Extending system life doesn’t always mean keeping things exactly the same. Strategic upgrades using certified york yvaa chiller parts can significantly improve performance.

Benefits of upgrading with certified parts include:

- Improved energy efficiency

- Better load handling

- Reduced operating noise

- Enhanced system stability

Midwest Parts Center helps industrial facilities make informed decisions about when and how to upgrade critical components.

Why Midwest Parts Center Is the Trusted Choice

Industrial buyers choose Midwest Parts Center because reliability is non-negotiable.

What Customers Value Most:

- Consistent access to certified york yvaa chiller parts

- Clear communication and expert guidance

- Focus on commercial and industrial systems only

- Long-term partnership mindset

- Dependable support before, during, and after purchase

This reliability is why many facilities continue to rely on Midwest Parts Center year after year.

One Supplier, One Focus, Total Confidence

In industrial HVAC, specialization matters. Midwest Parts Center doesn’t try to be everything to everyone. The company focuses on what it does best—supporting commercial and industrial cooling systems with dependable parts and expert insight.

When your operation depends on a York YVAA chiller, that focus translates directly into confidence and peace of mind.

Protect Your Investment the Smart Way

A York YVAA chiller is a major investment. Protecting it requires more than routine service—it requires the right parts, from the right source, every time.

By choosing certified york yvaa chiller parts from Midwest Parts Center, you:

- Extend system life

- Reduce long-term costs

- Improve reliability

- Minimize downtime

- Support safe, efficient operation

📞 Call Midwest Parts Center today at +1 800 368 8385

When performance, longevity, and reliability matter most, trust Midwest Parts Center to deliver the york yvaa chiller parts your commercial or industrial system depends on—today and for years to come.