The Role of York YVAA Chiller Parts in Environmental Responsibility

In an era where environmental responsibility is paramount, businesses are increasingly seeking ways to reduce their carbon footprint and minimize the impact of their operations on the planet. York YVAA chiller parts play a pivotal role in this endeavor by offering environmentally friendly solutions that not only enhance the performance of HVAC systems but also contribute to sustainability and compliance with environmental regulations. This article delves into the critical role that York YVAA chiller parts play in environmental responsibility and how they align with the broader goals of eco-conscious businesses.

For inquiries about York YVAA chiller parts or to discuss your HVAC requirements, contact York at their toll-free number: 1-800-368-8385.

The Green Imperative

Environmental responsibility has evolved from a moral obligation to a business imperative. Companies are under increasing pressure from customers, regulators, and shareholders to adopt sustainable practices and reduce their environmental impact. This shift is driven by several factors, including climate change concerns, resource scarcity, and the rising demand for environmentally friendly products and services.

In this context, HVAC systems, which account for a significant portion of a building’s energy consumption, have become a focal point for environmental efforts. York, a leading provider of HVAC solutions, understands this urgency and has designed its YVAA chiller parts with a strong emphasis on environmental responsibility.

Eco-Friendly Refrigerants

One of the key contributions of York YVAA chiller parts to environmental responsibility is the use of eco-friendly refrigerants. Traditional HVAC systems often rely on refrigerants with high global warming potential (GWP). In contrast, York YVAA chillers utilize next-generation refrigerants with low GWP, such as R-134a or R-1234ze, which have significantly less impact on the environment. This transition to eco-friendly refrigerants helps businesses reduce their carbon footprint and align with international agreements like the Kigali Amendment to the Montreal Protocol.

Energy Efficiency and Reduced Emissions

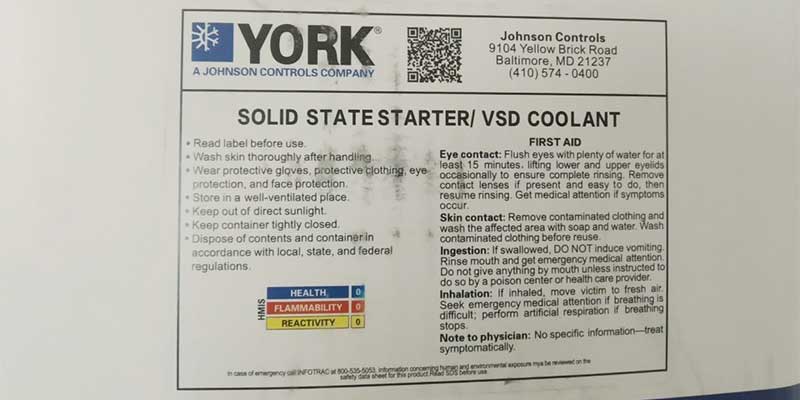

York YVAA chiller parts are engineered for optimal energy efficiency. Their variable-speed drive (VSD) compressors adjust the chiller’s cooling capacity to match real-time demand, reducing energy consumption. By operating at higher efficiency levels, businesses not only lower their energy bills but also reduce greenhouse gas emissions. This reduction in emissions is a crucial aspect of environmental responsibility and helps organizations meet sustainability goals.

Compliance with Regulations

Environmental responsibility often involves compliance with stringent environmental regulations. York YVAA chiller parts are designed to meet or exceed industry standards and regulations. By choosing York, businesses can ensure that their HVAC systems adhere to environmental laws and avoid potential fines or penalties associated with non-compliance. This commitment to regulatory compliance is a cornerstone of environmental responsibility.

Sustainable Operations

York YVAA chiller parts are built to last, reducing the need for frequent replacements and minimizing waste. Their durability and reliability contribute to the long-term sustainability of HVAC systems. Additionally, some York chiller parts incorporate predictive maintenance technology, enabling proactive issue detection and timely repairs. This proactive approach not only extends the lifespan of HVAC equipment but also reduces resource consumption and waste generation.

Environmental responsibility is a shared responsibility that extends across industries and businesses of all sizes. York YVAA chiller parts are at the forefront of this effort, offering eco-friendly solutions that prioritize energy efficiency, reduced emissions, regulatory compliance, and sustainable operations. By choosing York YVAA chiller parts, businesses can play a significant role in protecting the environment while enjoying the benefits of lower operational costs and enhanced system performance.

In a world where environmental consciousness is a driving force in decision-making, York YVAA chiller parts provide a pathway to HVAC solutions that are both environmentally responsible and economically advantageous. To explore how York YVAA chiller parts can be integrated into your HVAC system and contribute to your environmental responsibility goals, contact York at 1-800-368-8385. Join the ranks of businesses committed to a greener, more sustainable future with York’s eco-friendly HVAC solutions.

Maximizing Cooling Capacity with York YVAA Chiller Parts

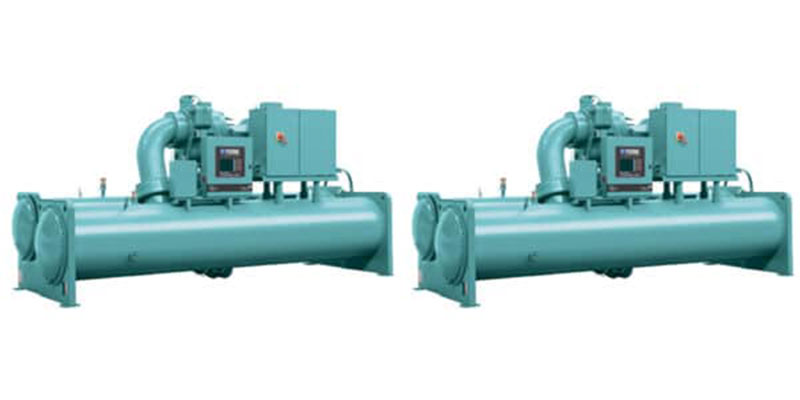

When it comes to commercial and industrial HVAC systems, one of the primary objectives is to provide efficient and reliable cooling. In this pursuit, York YVAA chiller parts emerge as a cornerstone of cooling capacity optimization. These parts, designed and manufactured by York, a trusted name in HVAC solutions, play a pivotal role in ensuring that businesses can maintain precise temperature control while optimizing energy consumption. This article explores the significance of York YVAA chiller parts in maximizing cooling capacity and their contribution to efficient HVAC systems.

For inquiries about York YVAA chiller parts or to discuss your HVAC requirements, contact York at their toll-free number: 1-800-368-8385.

The Essence of Cooling Capacity

Cooling capacity is the core function of any chiller system. It determines the amount of heat energy that can be effectively removed from a space, ensuring that the environment remains comfortable and within specified temperature ranges. In commercial and industrial settings, where HVAC systems are tasked with cooling large spaces, cooling capacity becomes paramount.

Challenges in Cooling Capacity

Maximizing cooling capacity is not without its challenges. Some of the common hurdles faced by businesses include:

- Energy Efficiency: Achieving higher cooling capacity often requires more energy, which can lead to increased operational costs and a larger carbon footprint.

- Environmental Responsibility: In an era of environmental consciousness, businesses are increasingly inclined to adopt eco-friendly practices and minimize their environmental impact.

- Space Constraints: Commercial and industrial spaces may have limited room for expanding HVAC equipment to accommodate higher cooling capacity.

York YVAA Chiller Parts: The Solution

York YVAA chiller parts are engineered to address these challenges while enhancing cooling capacity. Here’s how they achieve this:

1. Variable-Speed Drive (VSD) Technology: York YVAA chillers are equipped with VSD compressors that adjust the chiller’s cooling output to match the actual demand. This technology ensures that the chiller operates at optimal capacity, providing precise cooling without unnecessary energy consumption. As a result, businesses can enjoy enhanced cooling capacity without the associated energy inefficiency.

2. High Energy Efficiency: York YVAA chiller parts are designed with energy efficiency in mind. By reducing energy waste and optimizing the use of power, these parts allow businesses to get the most out of their cooling capacity while keeping operational costs in check. This is especially critical in environments where cooling demand fluctuates throughout the day or across seasons.

3. Environmental Responsibility: York YVAA chiller parts prioritize environmental responsibility. The use of eco-friendly refrigerants with low global warming potential (GWP) minimizes the environmental impact of cooling operations. This aligns with the sustainability goals of businesses aiming to reduce their carbon footprint and comply with environmental regulations.

4. Space-Efficient Design: York YVAA chiller parts are designed with a compact footprint, making them suitable for installations with space constraints. This space efficiency allows businesses to maximize cooling capacity without requiring extensive facility modifications.

5. Reliability and Durability: York YVAA chiller parts are renowned for their reliability and durability. By minimizing downtime due to maintenance and repairs, these parts ensure uninterrupted cooling capacity, critical for businesses that rely on consistent temperature control.

York YVAA chiller parts represent a pivotal element in maximizing cooling capacity for commercial and industrial HVAC systems. Their innovative features, including VSD technology, energy efficiency, and eco-friendly refrigerants, address the challenges associated with cooling capacity optimization. With York YVAA chiller parts, businesses can achieve precise temperature control, reduce energy consumption, and minimize their environmental impact.

In a world where efficient cooling is indispensable for comfort and productivity, York YVAA chiller parts offer a sustainable and cost-effective solution. To explore how York YVAA chiller parts can be integrated into your HVAC system to maximize cooling capacity, contact York at 1-800-368-8385. Elevate your cooling capabilities and embrace a more efficient and responsible approach to HVAC with York’s trusted solutions.

Upgrading Your HVAC System with York YVAA Chiller Parts

The efficiency and performance of an HVAC (Heating, Ventilation, and Air Conditioning) system are vital for any commercial or industrial space. In this pursuit of optimal HVAC performance, York YVAA chiller parts emerge as a game-changer. These parts, designed and manufactured by York, a renowned name in HVAC solutions, can significantly enhance your HVAC system’s capabilities. This article delves into the importance of upgrading your HVAC system with York YVAA chiller parts and the myriad benefits they offer for commercial and industrial applications.

For inquiries about York YVAA chiller parts or to discuss your HVAC upgrade needs, contact York at their toll-free number: 1-800-368-8385.

The Need for HVAC System Upgrades

HVAC systems play a pivotal role in maintaining indoor comfort, air quality, and temperature control in commercial and industrial settings. However, over time, these systems can become less efficient due to wear and tear, outdated components, or changing requirements. Here are some common reasons why businesses consider upgrading their HVAC systems:

1. Energy Efficiency: Aging HVAC components may consume more energy than newer, energy-efficient models. Upgrading to more efficient parts can result in significant cost savings and reduced environmental impact.

2. Environmental Responsibility: With increasing awareness of environmental issues, many businesses are committed to sustainability. Upgrading HVAC systems with eco-friendly components, such as those from York, aligns with these sustainability goals.

3. Performance Enhancement: Modern HVAC technology offers superior performance compared to older systems. Upgrading with York YVAA chiller parts can lead to better temperature control, improved air quality, and enhanced comfort for occupants.

4. Reliability: Frequent breakdowns and maintenance issues can disrupt business operations. Upgrading to reliable York YVAA chiller parts can minimize downtime and ensure consistent performance.

5. Adaptation to Changing Needs: As businesses grow or change, their HVAC requirements may evolve. Upgrading allows them to tailor their systems to meet new demands efficiently.

The Role of York YVAA Chiller Parts in Upgrades

York YVAA chiller parts are at the forefront of HVAC system upgrades. Here’s how they contribute to improving your HVAC system:

1. Energy Efficiency: York YVAA chiller parts feature advanced technologies, such as Variable-Speed Drive (VSD) compressors, which optimize energy consumption. These parts can significantly reduce energy costs while providing precise temperature control.

2. Eco-Friendly Design: York YVAA chiller parts use environmentally responsible refrigerants with low global warming potential (GWP). By incorporating these components, your HVAC system can contribute to sustainability efforts and comply with environmental regulations.

3. Enhanced Performance: Upgrading with York YVAA chiller parts ensures that your HVAC system operates at peak performance. This leads to improved indoor air quality, better humidity control, and consistent temperature levels.

4. Reliability: York YVAA chiller parts are renowned for their durability and reliability. Upgrading with these parts can reduce maintenance requirements and minimize downtime, allowing your business to operate smoothly.

5. Customization: York offers a wide range of YVAA chiller parts, allowing you to customize your HVAC system to meet your specific needs. Whether it’s increasing cooling capacity, improving energy efficiency, or enhancing control options, York has the right components for your upgrade.

Upgrading your HVAC system with York YVAA chiller parts is a strategic move to enhance its efficiency, reliability, and environmental responsibility. These high-quality components not only reduce energy consumption but also contribute to a more sustainable and comfortable indoor environment. With a commitment to innovation and performance, York is a trusted partner for businesses seeking to optimize their HVAC systems.

In a competitive business landscape, where operational efficiency and environmental responsibility are paramount, upgrading your HVAC system with York YVAA chiller parts is a smart investment. To explore the full range of York YVAA chiller parts and discuss how they can elevate your HVAC system’s performance, contact York at 1-800-368-8385. Take the first step towards a more efficient and sustainable HVAC solution with York’s proven expertise.

Comparing York YVAA Chiller Parts to Generic Components

When it comes to maintaining and upgrading your commercial or industrial HVAC (Heating, Ventilation, and Air Conditioning) system, choosing the right components is critical. York YVAA chiller parts, designed and manufactured by the reputable York company, offer a compelling alternative to generic components. This article delves into the importance of comparing York YVAA chiller parts to generic counterparts, emphasizing the benefits of making the right choice for your HVAC system.

For inquiries about York YVAA chiller parts or to discuss your HVAC component needs, reach out to York at their toll-free number: 1-800-368-8385.

The Significance of HVAC System Components

HVAC systems are the lifeblood of many commercial and industrial facilities, ensuring optimal indoor comfort, air quality, and temperature control. The choice of components within these systems can significantly impact their performance, efficiency, and reliability. Here are some key factors that highlight the importance of selecting the right HVAC components:

1. Performance: Components such as chillers, compressors, and heat exchangers directly affect the HVAC system’s performance. High-quality parts contribute to efficient operation and consistent temperature control.

2. Energy Efficiency: The HVAC industry is increasingly focused on energy efficiency. Upgrading to energy-efficient components can lead to substantial cost savings by reducing energy consumption.

3. Reliability: Downtime due to equipment failures can be costly and disruptive. Reliable components, backed by a reputable manufacturer, can minimize unexpected maintenance and system downtime.

4. Environmental Impact: Many businesses are committed to reducing their environmental footprint. Choosing components with eco-friendly features can help achieve sustainability goals and comply with environmental regulations.

5. Customization: Every HVAC system is unique, and the choice of components allows businesses to tailor their systems to meet specific requirements, whether it’s for increased cooling capacity or advanced control options.

The Advantages of York YVAA Chiller Parts

York YVAA chiller parts, a product line from York, a renowned name in HVAC solutions, are designed to meet the highest industry standards. Here’s why choosing York YVAA chiller parts over generic components is a wise decision:

1. Superior Quality: York YVAA chiller parts undergo rigorous quality control and testing, ensuring they meet or exceed industry standards. This commitment to quality translates into enhanced durability and reliability.

2. Energy Efficiency: York YVAA chiller parts incorporate advanced technologies such as Variable-Speed Drive (VSD) compressors. These innovations optimize energy consumption, resulting in significant cost savings over time.

3. Environmental Responsibility: York is dedicated to sustainability. Their YVAA chiller parts use refrigerants with low global warming potential (GWP), contributing to a greener HVAC solution and compliance with environmental regulations.

4. Customization: York offers a wide range of YVAA chiller parts, allowing businesses to customize their HVAC systems to meet specific needs. This versatility ensures that your system operates at its best.

5. Expertise and Support: With York, you gain access to a wealth of HVAC expertise and support. Their team can provide guidance on component selection, system design, and maintenance, ensuring your HVAC system operates optimally.

Comparing York YVAA Chiller Parts to Generic Components

Now, let’s delve into a detailed comparison between York YVAA chiller parts and generic components:

Quality and Reliability: York YVAA chiller parts are known for their superior quality and reliability. Generic components may vary in quality, leading to unpredictable performance and potential breakdowns.

Energy Efficiency: York YVAA chiller parts are designed with energy efficiency in mind, utilizing advanced technologies to reduce energy consumption. Generic components may lack these energy-saving features.

Environmental Impact: York prioritizes sustainability by using eco-friendly refrigerants. Generic components may not adhere to the same environmental standards, potentially contributing to higher greenhouse gas emissions.

Warranty and Support: York offers robust warranties and comprehensive support for their YVAA chiller parts. Generic components may come with limited or no warranties, leaving you exposed to unexpected costs.

Compatibility: York YVAA chiller parts are designed to seamlessly integrate into York HVAC systems. Generic components may not offer the same level of compatibility, leading to compatibility issues and inefficiencies.

Choosing York YVAA chiller parts over generic components is a smart investment for your HVAC system. With a strong focus on quality, energy efficiency, environmental responsibility, and customization, York YVAA chiller parts offer a superior solution for commercial and industrial HVAC needs.

For inquiries about York YVAA chiller parts or to explore how they can enhance your HVAC system’s performance, contact York at 1-800-368-8385. Make the right choice for your HVAC system by opting for York’s proven expertise and high-quality components.