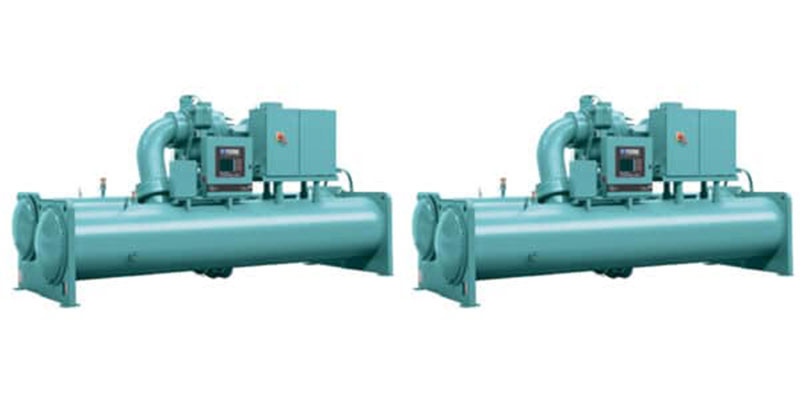

York YK chiller parts are the Backbone of Industry

In the competitive and dynamic industrial landscape, the efficiency and reliability of HVAC (Heating, Ventilation, and Air Conditioning) systems are paramount for the success of businesses operating in commercial and industrial areas. At the core of these HVAC systems are critical components, and among them, York YK Chiller Parts stand out as the backbone of the industry. Trusted providers like Midwest Parts Center, located in Louisville, Kentucky, understand the significance of these parts and offer businesses easy access to genuine York YK Chiller Parts through their toll-free number, 1-800-368-8385. This accessibility empowers industries to thrive by relying on York YK Chiller Parts for the performance and reliability required in their HVAC systems.

The Pivotal Role of York YK Chiller Parts in Industry

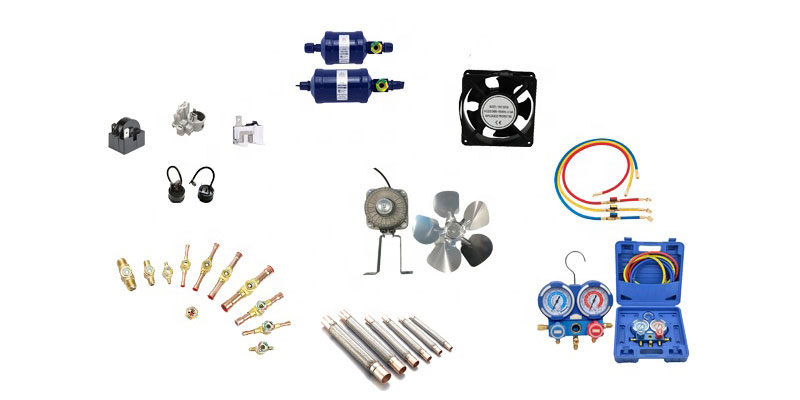

- Optimizing Energy Efficiency: Energy efficiency is a top priority in the modern industrial sector. HVAC systems are significant consumers of energy in commercial and industrial areas. York YK Chiller Parts are designed to optimize the energy efficiency of these systems, reducing energy consumption and operational costs.

- Environmental Responsibility: In an era where environmental concerns are escalating, businesses are under increasing pressure to reduce their carbon footprint. York YK Chiller Parts play a crucial role in environmental responsibility by ensuring that HVAC systems operate efficiently, minimizing energy usage, and aligning with sustainability goals.

- Enhancing Equipment Longevity: Downtime due to equipment failure is not only costly but also disruptive to industrial operations. York YK Chiller Parts help extend the life of HVAC systems by ensuring that they run efficiently, reducing wear and tear. This leads to fewer breakdowns, lower maintenance costs, and increased equipment longevity.

- Ensuring Process Consistency: Many industrial processes depend on precise environmental conditions to maintain product quality and adhere to regulatory standards. York YK Chiller Parts provide consistent cooling, ensuring that these critical environmental conditions are maintained, upholding product quality and regulatory compliance.

Why Industries Depend on York YK Chiller Parts as the Backbone

- Proven Performance: The York brand is synonymous with quality and reliability in the HVAC industry. York YK Chiller Parts continue this tradition, maintaining the same high standards. Their proven performance is well-regarded and trusted by industries seeking reliable HVAC solutions.

- Precision Manufacturing: York YK Chiller Parts are manufactured with precision to meet the unique requirements of chiller systems. Their precise design and engineering ensure they optimize performance and energy efficiency.

- Quality Assurance: York YK Chiller Parts undergo rigorous quality control processes and testing to ensure they meet the exact specifications required for chiller systems. Industries trust these parts because they offer unwavering quality, reliability, and precision – essential for operational efficiency.

- Expert Knowledge: York YK Chiller Parts are specialized components, and their proper use demands expertise. Trusted suppliers like Midwest Parts Center offer a team of experts with comprehensive knowledge of York HVAC equipment and the parts themselves. This expertise ensures industries make informed decisions about their HVAC systems, enhancing their competitive edge.

- Accessibility and Convenience: Quick access to York YK Chiller Parts is vital in the fast-paced world of industrial operations. Midwest Parts Center offers a toll-free number (1-800-368-8385) for businesses in need of these critical parts, reaffirming the company’s commitment to delivering seamless service. This ensures industries maintain their operations without interruption.

- Reliable Supply Chain: Timely access to York YK Chiller Parts is indispensable in industries where downtime can result in substantial losses. Reputable suppliers maintain a dependable supply chain, ensuring businesses can source the parts they need promptly. This minimizes disruptions and helps industries remain competitive by avoiding unnecessary downtime.

- Local Presence: Midwest Parts Center’s local presence in Louisville offers industries a significant advantage. The company understands the unique HVAC equipment requirements of the region and can provide tailored solutions, which are invaluable for maintaining competitive operations.

In conclusion, York YK Chiller Parts are the backbone of the industrial sector, offering energy efficiency, environmental responsibility, equipment longevity, and process consistency for HVAC systems. Their proven performance, precise manufacturing, quality assurance, and the accessibility and expertise they offer empower industries to maintain consistent operations, reduce energy costs, minimize downtime, and meet environmental and sustainability goals.

In an environment where energy efficiency, environmental responsibility, and operational reliability are paramount, a reputable supplier of York YK Chiller Parts has consistently demonstrated its value, cementing its role as a trusted partner for industries seeking excellence in commercial and industrial areas. Companies can rely on York YK Chiller Parts to provide the reliability and performance they need to outperform competitors and secure their market position.

Why Companies Trust York YK chiller parts for Reliability

In the competitive and ever-evolving world of commercial and industrial operations, the reliability and efficiency of HVAC (Heating, Ventilation, and Air Conditioning) systems are of paramount importance. Within these systems, the critical components known as York YK Chiller Parts play a pivotal role. Trusted suppliers like Midwest Parts Center, headquartered in Louisville, Kentucky, understand the significance of these parts and offer businesses easy access to genuine York YK Chiller Parts through their toll-free number, 1-800-368-8385. This accessibility empowers industries to thrive by relying on York YK Chiller Parts for the performance and reliability required in their HVAC systems.

The Essence of Reliability in York YK Chiller Parts

- Enhancing Energy Efficiency: In an age where energy efficiency is a top priority, HVAC systems are pivotal contributors to energy consumption in commercial and industrial areas. York YK Chiller Parts are meticulously designed to optimize the energy efficiency of these systems, thereby reducing energy consumption and operating costs.

- Environmental Responsibility: With growing environmental concerns, businesses are under increasing pressure to reduce their carbon footprint. York YK Chiller Parts contribute to environmental responsibility by ensuring that HVAC systems operate efficiently, thereby minimizing energy usage and aligning with sustainability goals.

- Extending Equipment Lifespan: Equipment downtime due to breakdowns can be both costly and disruptive. York YK Chiller Parts play a vital role in extending the life of HVAC systems by ensuring they operate efficiently, reducing wear and tear. This results in fewer breakdowns, lower maintenance costs, and increased equipment longevity.

- Maintaining Process Consistency: Many industrial processes require precise environmental conditions to maintain product quality and adhere to regulatory standards. York YK Chiller Parts provide consistent cooling, ensuring that these critical environmental conditions are maintained, thereby upholding product quality and regulatory compliance.

Why Industries Trust York YK Chiller Parts for Reliability

- Proven Performance: The York brand has a long-standing reputation for quality and reliability in the HVAC industry. York YK Chiller Parts continue this tradition, upholding the same high standards. Their proven performance is well-regarded and trusted by industries seeking reliable HVAC solutions.

- Precision Engineering: York YK Chiller Parts are engineered with precision to meet the unique requirements of chiller systems. This precise design and engineering ensure that these parts optimize performance and energy efficiency, contributing to the overall reliability of the systems.

- Stringent Quality Control: York YK Chiller Parts undergo rigorous quality control processes and testing to ensure they meet the exact specifications required for chiller systems. Industries trust these parts because they offer unwavering quality, reliability, and precision – all essential for operational efficiency.

- Expert Knowledge: York YK Chiller Parts are specialized components, and their proper use demands expertise. Trusted suppliers like Midwest Parts Center provide a team of experts with comprehensive knowledge of York HVAC equipment and the parts themselves. This expertise ensures that industries make informed decisions about their HVAC systems, enhancing their competitive edge.

- Accessibility and Convenience: Quick access to York YK Chiller Parts is crucial in the fast-paced world of industrial operations. Midwest Parts Center offers a toll-free number (1-800-368-8385) for businesses in need of these critical parts, reaffirming the company’s commitment to delivering seamless service. This ensures that industries can maintain their operations without interruption.

- Reliable Supply Chain: Timely access to York YK Chiller Parts is indispensable in industries where downtime can result in substantial losses. Reputable suppliers maintain a dependable supply chain, ensuring that businesses can source the parts they need promptly. This minimizes disruptions and helps industries remain competitive by avoiding unnecessary downtime.

- Local Presence: Midwest Parts Center’s local presence in Louisville offers industries a significant advantage. The company understands the unique HVAC equipment requirements of the region and can provide tailored solutions, which are invaluable for maintaining competitive operations.

In conclusion, York YK Chiller Parts are the bedrock of the industrial sector, offering energy efficiency, environmental responsibility, equipment longevity, and process consistency for HVAC systems. Their proven performance, precision engineering, quality assurance, and the accessibility and expertise they offer empower industries to maintain consistent operations, reduce energy costs, minimize downtime, and meet environmental and sustainability goals.

In an environment where energy efficiency, environmental responsibility, and operational reliability are non-negotiable, a reputable supplier of York YK Chiller Parts has consistently demonstrated its value, cementing its role as a trusted partner for industries looking to excel in commercial and industrial areas. Companies can rely on York YK Chiller Parts to provide the reliability and performance they need to outperform competitors and secure their market position.

The Role of York YK chiller parts in a Competitive Market

In the fiercely competitive landscape of commercial and industrial sectors, maintaining a competitive edge requires a relentless commitment to efficiency and reliability. Among the myriad components that keep these sectors running smoothly, York YK Chiller Parts stand as crucial players. Trusted providers like Midwest Parts Center, situated in Louisville, Kentucky, recognize the significance of these parts and offer businesses convenient access to genuine York YK Chiller Parts through their toll-free number, 1-800-368-8385. This accessibility empowers industries to stay competitive by relying on York YK Chiller Parts for the superior performance and dependability required in their HVAC systems.

The Crucial Role of York YK Chiller Parts in a Competitive Market

- Elevating Energy Efficiency: In an era when energy efficiency is a top priority, HVAC systems are significant consumers of energy in commercial and industrial domains. York YK Chiller Parts are meticulously engineered to optimize the energy efficiency of these systems, resulting in reduced energy consumption and operational costs.

- Meeting Environmental Expectations: As environmental concerns continue to grow, businesses are under mounting pressure to reduce their carbon footprint and operate sustainably. York YK Chiller Parts contribute to environmental responsibility by ensuring that HVAC systems run efficiently, minimizing energy usage, and aligning with sustainability goals.

- Extending Equipment Lifespan: Downtime caused by equipment breakdowns can be financially detrimental and operationally disruptive. York YK Chiller Parts play an essential role in extending the life of HVAC systems by ensuring they operate efficiently, reducing wear and tear. This results in fewer breakdowns, lower maintenance costs, and prolonged equipment longevity.

- Maintaining Process Consistency: Many industrial processes rely on precise environmental conditions to maintain product quality and meet regulatory standards. York YK Chiller Parts provide consistent cooling, ensuring that these critical environmental conditions are upheld, safeguarding product quality and regulatory compliance.

Why Industries Rely on York YK Chiller Parts in a Competitive Market

- Proven Performance: The York brand is synonymous with quality and reliability in the HVAC industry. York YK Chiller Parts continue this tradition, upholding the same high standards. Their proven performance is well-regarded and trusted by industries seeking reliable HVAC solutions.

- Precision Engineering: York YK Chiller Parts are designed and manufactured with precision to meet the unique requirements of chiller systems. This precise engineering ensures they optimize performance and energy efficiency, key factors in their reliability.

- Stringent Quality Control: York YK Chiller Parts undergo rigorous quality control processes and testing to ensure they meet the exact specifications required for chiller systems. Industries trust these parts because they offer unwavering quality, reliability, and precision – essential for operational efficiency.

- Expert Knowledge: York YK Chiller Parts are specialized components, and their proper use demands expertise. Trusted suppliers like Midwest Parts Center provide a team of experts with comprehensive knowledge of York HVAC equipment and the parts themselves. This expertise ensures that industries make informed decisions about their HVAC systems, enhancing their competitive edge.

- Accessibility and Convenience: Quick access to York YK Chiller Parts is imperative in the fast-paced world of industrial operations. Midwest Parts Center offers a toll-free number (1-800-368-8385) for businesses in need of these critical parts, reaffirming the company’s commitment to delivering seamless service. This ensures industries can maintain their operations without interruption.

- Reliable Supply Chain: Timely access to York YK Chiller Parts is indispensable in industries where downtime can result in substantial losses. Reputable suppliers maintain a dependable supply chain, ensuring that businesses can source the parts they need promptly. This minimizes disruptions and helps industries remain competitive by avoiding unnecessary downtime.

- Local Presence: Midwest Parts Center’s local presence in Louisville offers industries a significant advantage. The company understands the unique HVAC equipment requirements of the region and can provide tailored solutions, which are invaluable for maintaining competitive operations.

In conclusion, York YK Chiller Parts are the linchpin of the competitive market, offering energy efficiency, environmental responsibility, equipment longevity, and process consistency for HVAC systems. Their proven performance, precision engineering, quality assurance, and the accessibility and expertise they offer empower industries to maintain consistent operations, reduce energy costs, minimize downtime, and meet environmental and sustainability goals.

In an environment where energy efficiency, environmental responsibility, and operational reliability are non-negotiable, a reputable supplier of York YK Chiller Parts has consistently demonstrated its value, cementing its role as a trusted partner for industries looking to excel in commercial and industrial areas. Companies can rely on York YK Chiller Parts to provide the reliability and performance they need to outperform competitors and secure their market position.

The role of York YK chiller parts in industrial sector.

In the heart of the bustling industrial sector, where precision, reliability, and efficiency are the cornerstones of success, HVAC (Heating, Ventilation, and Air Conditioning) systems play a pivotal role. Within these complex systems, York YK Chiller Parts emerge as indispensable components that ensure industrial operations run seamlessly. Recognizing the significance of these parts, trusted suppliers like Midwest Parts Center, based in Louisville, Kentucky, offer businesses convenient access to authentic York YK Chiller Parts through their toll-free number, 1-800-368-8385. This accessibility empowers industries to thrive by relying on York YK Chiller Parts for the superior performance and reliability required in their HVAC systems within the commercial and industrial sectors.

The Critical Role of York YK Chiller Parts in the Industrial Sector

- Elevating Energy Efficiency: In an era where energy efficiency is a top priority, HVAC systems are significant consumers of energy in commercial and industrial areas. York YK Chiller Parts are engineered to optimize the energy efficiency of these systems, leading to reduced energy consumption and operational costs, a vital consideration in the industrial sector.

- Fulfilling Environmental Responsibility: As concerns over the environment continue to mount, industries face mounting pressure to reduce their carbon footprint and operate sustainably. York YK Chiller Parts actively contribute to environmental responsibility by ensuring that HVAC systems operate efficiently, minimizing energy usage, and aligning with sustainability goals.

- Extending Equipment Lifespan: Unplanned downtime due to equipment breakdowns can be a costly and disruptive affair for industrial operations. York Chiller Parts are integral in extending the life of HVAC systems by ensuring they operate efficiently, reducing wear and tear. This results in fewer breakdowns, lower maintenance costs, and an extended equipment lifespan.

- Maintaining Process Consistency: Numerous industrial processes depend on precise environmental conditions to maintain product quality and adhere to regulatory standards. York YK Chiller Parts provide consistent cooling, ensuring that these critical environmental conditions are upheld, safeguarding product quality and regulatory compliance.

Why Industries Rely on York Chiller Parts in the Industrial Sector

- Proven Performance: The York brand has long been synonymous with quality and reliability in the HVAC industry. York YK Chiller Parts maintain these high standards, delivering proven performance that is well-regarded and trusted by industries seeking reliable HVAC solutions.

- Precision Manufacturing: York YK Chiller Parts are meticulously engineered to meet the unique requirements of chiller systems. Their precise design and manufacturing ensure that they optimize performance and energy efficiency, critical factors in their reliability.

- Stringent Quality Control: York Chiller Parts undergo rigorous quality control processes and testing to ensure they meet the exact specifications required for chiller systems. Industries trust these parts because they offer unwavering quality, reliability, and precision – all vital for operational efficiency.

- Expert Knowledge: York YK Chiller Parts are specialized components, and their proper use demands expertise. Trusted suppliers like Midwest Parts Center provide a team of experts with comprehensive knowledge of York HVAC equipment and the parts themselves. This expertise ensures that industries make informed decisions about their HVAC systems, enhancing their competitive edge.

- Accessibility and Convenience: Quick access to York YK Chiller Parts is essential in the fast-paced world of industrial operations. Midwest Parts Center offers a toll-free number (1-800-368-8385) for businesses in need of these critical parts, reaffirming the company’s commitment to delivering seamless service. This ensures that industries can maintain their operations without interruption.

- Reliable Supply Chain: Timely access to York Chiller Parts is indispensable in industries where downtime can result in substantial losses. Reputable suppliers maintain a dependable supply chain, ensuring that businesses can source the parts they need promptly. This minimizes disruptions and helps industries remain competitive by avoiding unnecessary downtime.

- Local Presence: Midwest Parts Center’s local presence in Louisville offers industries a significant advantage. The company understands the unique HVAC equipment requirements of the region and can provide tailored solutions, which are invaluable for maintaining competitive operations.

In conclusion, York YK Chiller Parts play an integral role in the industrial sector by offering energy efficiency, environmental responsibility, equipment longevity, and process consistency for HVAC systems. Their proven performance, precision manufacturing, quality assurance, and the accessibility and expertise they offer empower industries to maintain consistent operations, reduce energy costs, minimize downtime, and meet environmental and sustainability goals.

In an environment where energy efficiency, environmental responsibility, and operational reliability are critical, a reputable supplier of York YK Chiller Parts has consistently demonstrated its value, cementing its role as a trusted partner for industries looking to excel in the commercial and industrial sectors. Companies can rely on York YK Chiller Parts to provide the reliability and performance they need to outperform competitors and secure their position in the industrial sector.