The YORK YK chiller is a high-performance and highly efficient cooling system designed to meet the demands of large commercial and industrial applications. Manufactured by YORK, a leading name in the HVAC (Heating, Ventilation, and Air Conditioning) industry, the YK chiller is known for its reliability, energy efficiency, and innovative design. In this introduction, we will explore the key components that make the YORK YK chiller a cornerstone of modern cooling systems.

Key Components of the YORK YK Chiller:

- Compressors:

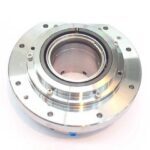

- The heart of the YORK YK chiller is its compressor(s). These are responsible for compressing the refrigerant, raising its temperature and pressure, and then expelling it to the condenser coils. The YK chiller often features multiple compressors for enhanced efficiency and redundancy.

- Evaporators:

- Evaporators are heat exchangers that facilitate the cooling process. In the YORK YK chiller, they absorb heat from the building or process being cooled, causing the refrigerant to evaporate. This phase change is essential for cooling.

- Condensers:

- Condensers release heat from the refrigerant into the environment. The YORK YK chiller utilizes air-cooled or water-cooled condensers, depending on the application and available resources.

- Expansion Valves:

- Expansion valves regulate the flow of refrigerant between the evaporator and condenser. They play a crucial role in controlling the temperature and pressure of the refrigerant as it circulates through the chiller.

- Control System:

- The YORK YK chiller features an advanced control system that monitors and manages all aspects of chiller operation. This includes adjusting compressor speed, optimizing energy efficiency, and providing diagnostic information for maintenance purposes.

- Heat Exchangers:

- Heat exchangers are used throughout the chiller to transfer heat between the refrigerant and the fluid being cooled. These components are vital for efficient heat transfer and overall chiller performance.

- Variable Frequency Drives (VFDs):

- VFDs are often incorporated into YORK YK chillers to control the speed of the compressors. This variable speed operation allows the chiller to adapt to varying cooling loads, resulting in energy savings and precise temperature control.

- Safety and Monitoring Systems:

- The YORK YK chiller is equipped with safety features and monitoring systems that ensure reliable and safe operation. These systems can detect issues such as low refrigerant levels, high pressures, or abnormal temperatures, triggering alarms and shutdowns when necessary.

The importance of using YORK YK chiller parts for maintenance and repair

The YORK YK chiller’s combination of these key components results in a highly efficient and adaptable cooling system. Its ability to modulate compressor speeds, optimize energy usage, and deliver reliable cooling makes it a popular choice for a wide range of applications, from large commercial buildings to industrial facilities. It not only provides comfort but also plays a critical role in process cooling, making it a versatile and essential component of modern HVAC systems.

The importance of using genuine YORK YK chiller parts for maintenance and repair

Maintaining the integrity and performance of your YORK YK chiller is crucial for its efficiency, longevity, and reliability. When it comes to maintenance and repair, the choice of replacement parts plays a pivotal role. Here’s why using genuine YORK YK chiller parts is of utmost importance:

- Compatibility and Fit:

- Genuine YORK YK chiller parts are engineered to exact specifications to fit seamlessly with your chiller’s existing components. This ensures a precise fit without the need for modifications or adjustments, reducing the risk of errors during installation.

- Optimal Performance:

- YORK YK chillers are renowned for their energy efficiency and high performance. Genuine parts are designed to maintain these performance standards. Using non-genuine or inferior parts can lead to reduced chiller efficiency, increased energy consumption, and diminished cooling capacity.

- Reliability and Longevity:

- YORK YK chillers are built to last, and genuine parts are manufactured with the same level of quality and durability. By using authentic parts, you help extend the chiller’s lifespan, reducing the frequency of replacements and costly downtime.

- Warranty Protection:

- YORK often provides warranties on their chillers, and these warranties may be contingent on using genuine parts for maintenance and repair. Using non-genuine parts can void warranties, leaving you responsible for any future repairs or replacements.

- Safety Assurance:

- Genuine parts undergo rigorous quality control and safety testing. They meet industry standards and regulations, ensuring that your chiller operates safely and reliably. Non-genuine parts may not meet these standards, posing potential safety risks.

- Manufacturer Support:

- YORK and their authorized dealers provide support and expertise when you use genuine parts. They can offer guidance, technical assistance, and documentation specific to your chiller model, making maintenance and repair more efficient.

- Optimized Efficiency:

- Genuine YORK YK chiller parts are designed to work in harmony with the chiller’s control systems. This optimization helps maintain energy efficiency, which is especially critical for reducing operational costs and environmental impact.

- Minimized Downtime:

- Using genuine parts reduces the likelihood of compatibility issues or premature failures. This minimizes unplanned downtime, ensuring your cooling system continues to operate reliably.

- Resale Value:

- If you ever decide to sell or upgrade your YORK YK chiller, having a maintenance history that includes genuine parts can increase its resale value. Buyers often prefer chillers that have been well-maintained with authentic components.

The importance of using genuine YORK YK chiller parts for maintenance and repair

In summary, the choice of replacement parts for your YORK YK chiller directly impacts its performance, reliability, and overall cost-effectiveness. Genuine YORK YK chiller parts offer compatibility, optimal performance, and peace of mind in terms of warranty protection and safety. When it comes to maintaining and repairing your chiller, investing in genuine parts is a wise choice to ensure the continued excellence of your cooling system.

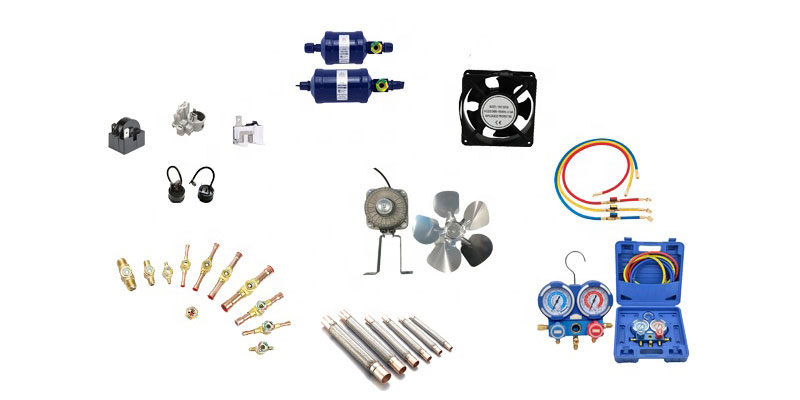

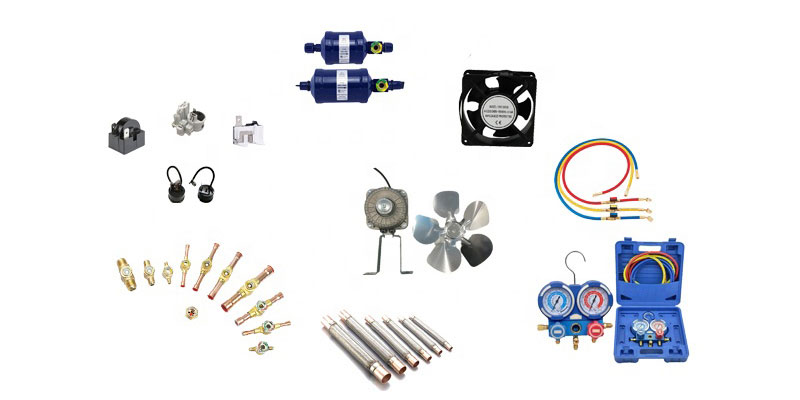

Common YORK YK chiller Parts

YORK YK chillers are complex systems with numerous components, and over time, certain parts may require replacement or maintenance. Here are some common YORK YK chiller parts that are frequently serviced or replaced:

- Compressors: Compressors are a critical component of any chiller, including YORK YK chillers. They compress refrigerant gases, raising their temperature and pressure, and play a central role in the cooling process.

- Condenser Coils: These coils facilitate the release of heat from the refrigerant into the environment, allowing the refrigerant to condense and return to a liquid state.

- Evaporator Coils: Evaporator coils are responsible for absorbing heat from the building or process being cooled, causing the refrigerant to evaporate.

- Expansion Valves: Expansion valves regulate the flow of refrigerant between the evaporator and condenser, controlling the temperature and pressure of the refrigerant.

- Variable Frequency Drives (VFDs): VFDs are used to control the speed of compressors and fans in YORK YK chillers. They enable variable speed operation, optimizing energy efficiency.

- Heat Exchangers: Heat exchangers are used throughout the chiller to transfer heat between the refrigerant and the fluid being cooled. They come in various types, including shell-and-tube and plate heat exchangers.

- Control Systems: YORK YK chillers feature advanced control systems that monitor and manage various aspects of chiller operation, including temperature control, compressor speed, and diagnostic information.

- Fans and Fan Motors: These components are essential for air-cooled YORK YK chillers. They circulate air across the condenser coils to facilitate heat exchange.

- Water Pumps and Motors: In water-cooled YORK YK chillers, water pumps and motors are used to circulate chilled water within the system.

- Sensors and Probes: Various sensors and probes, such as temperature sensors and pressure transducers, are integrated into the chiller to provide real-time data for monitoring and control.

- Refrigerant Circuit Components: This includes items like refrigerant lines, connectors, and filters, which are essential for maintaining the integrity of the refrigerant circuit.

- Safety and Monitoring Devices: These devices include pressure relief valves, oil separators, and alarms that ensure safe chiller operation and provide early warning of potential issues.

- Insulation and Gaskets: Proper insulation and gaskets are crucial for maintaining temperature control and preventing energy loss.

- Filters and Strainers: These components help maintain water quality in water-cooled systems by removing debris and impurities.

- Oil Coolers: Oil coolers are essential for maintaining proper lubrication and cooling of compressor oil.

- Electrical Components: This category includes items like contactors, relays, and circuit breakers that are integral to the electrical control systems of the chiller.

- Refrigerant Recovery and Handling Equipment: During maintenance or repairs, specialized equipment may be needed to handle and recover refrigerant safely.

- Accessories: Accessories such as control panels, user interfaces, and remote monitoring systems may also be part of the YORK YK chiller package.

Remember that proper maintenance and regular inspections by qualified technicians are essential to identify and address any issues with these components, ensuring the continued efficiency and reliability of your YORK YK chiller.

A guide to proper maintenance practices for YORK YK chillers

Maintaining your YORK YK chiller is essential to ensure its longevity, efficiency, and reliable operation. Proper maintenance practices not only prevent unexpected breakdowns but also optimize energy efficiency. Here’s a comprehensive guide to help you establish a routine maintenance plan for your YORK YK chiller:

1. Regular Inspection:

- Visual Inspections: Perform visual inspections of your chiller regularly. Look for signs of wear, corrosion, leaks, loose connections, and any unusual conditions.

- Temperature and Pressure: Monitor temperature and pressure gauges regularly to ensure they are within the recommended operating ranges.

- Oil Levels: Check oil levels in compressors and oil coolers. Maintain proper oil levels to ensure compressor lubrication.

2. Cleanliness:

- Condenser and Evaporator Coils: Keep condenser and evaporator coils clean and free of debris. Dirty coils reduce heat exchange efficiency.

- Air Filters: If your chiller has air filters, replace or clean them as needed. Clean filters help maintain airflow and system efficiency.

- Water-Cooled Chillers: If your chiller is water-cooled, regularly inspect and clean water strainers and filters to prevent blockages.

3. Lubrication:

- Ensure proper lubrication of compressor bearings, motors, and other moving parts according to the manufacturer’s recommendations.

4. Electrical Components:

- Check electrical connections, terminals, and wiring for signs of wear or overheating. Tighten loose connections as necessary.

- Monitor control panels and diagnostic displays for any error codes or unusual readings.

5. Refrigerant Circuit:

- Regularly inspect refrigerant lines, connectors, and valves for leaks. Address any leaks promptly.

- Keep refrigerant charge levels within recommended ranges to maintain optimal chiller performance.

6. Variable Frequency Drives (VFDs):

- If your chiller utilizes VFDs, check and calibrate them regularly to ensure they are operating as intended.

7. Water Quality:

- For water-cooled chillers, maintain water quality by monitoring and treating cooling water as needed to prevent scale, corrosion, and biological growth.

8. Safety Measures:

- Ensure that all safety devices, such as pressure relief valves and alarms, are in good working order.

9. Professional Maintenance:

- Schedule routine maintenance by qualified HVAC technicians. They can perform in-depth inspections, refrigerant handling, and complex tasks like compressor overhauls.

10. Maintenance Records:

- Keep detailed maintenance records, including dates, findings, and actions taken. This helps track the chiller’s history and aids in troubleshooting.

11. Seasonal Maintenance:

- Perform seasonal maintenance before the peak cooling or heating season to ensure optimal performance when demand is highest.

12. Manufacturer’s Recommendations:

- Always follow the manufacturer’s recommended maintenance schedules and procedures outlined in the chiller’s manual.

13. Emergency Preparedness:

- Develop a plan for responding to chiller emergencies, including who to contact for service and troubleshooting steps to take in case of malfunctions.

A guide to proper maintenance practices for YORK YK chillers

By adhering to these maintenance practices and addressing issues promptly, you can maximize the lifespan and efficiency of your YORK YK chiller, reduce energy consumption, and minimize unexpected downtime. Regular professional maintenance is key to keeping your chiller in optimal condition and ensuring the comfort and productivity of your facility.

The benefits of regular maintenance in terms of energy efficiency and system longevity

Regular maintenance of your HVAC system, including components like YORK YK chillers, offers a range of benefits, with significant impacts on both energy efficiency and system longevity:

1. Enhanced Energy Efficiency:

- Reduced Energy Consumption: Regular maintenance ensures that all components of the chiller are working efficiently. Clean coils, properly lubricated parts, and well-maintained electrical connections reduce energy waste and improve overall system efficiency.

- Optimized Performance: Maintenance helps the chiller operate as close to its design specifications as possible. This means it can achieve the desired cooling capacity with less energy input, leading to energy savings.

- Variable Speed Drive (VFD) Optimization: If your chiller has VFDs, maintenance ensures that they are calibrated correctly. VFDs allow the chiller to adjust its speed to match the current cooling load, preventing overuse of energy during low-demand periods.

- Preventing Efficiency Loss: Over time, components like coils and heat exchangers can accumulate dirt and debris, reducing their ability to transfer heat efficiently. Regular cleaning and maintenance prevent this efficiency loss.

2. Extended System Longevity:

- Reduced Wear and Tear: Maintenance tasks such as lubrication and tightening of connections help reduce friction and wear on moving parts. This extends the life of components like compressors and motors.

- Prevention of Major Failures: Routine maintenance allows technicians to identify and address small issues before they escalate into major problems. This proactive approach can prevent costly breakdowns and the need for expensive replacements.

- Preservation of Heat Exchangers: Keeping heat exchangers clean and well-maintained ensures they operate efficiently and can prevent corrosion or scaling, which can damage these critical components.

- Optimal Refrigerant Levels: Maintaining the correct refrigerant charge level ensures that the chiller operates efficiently and prevents stress on the compressor, which can lead to premature failure.

3. Cost Savings:

- Lower Energy Bills: An efficiently running chiller consumes less energy, resulting in lower utility bills. The cost savings over time can be substantial.

- Reduced Repair Costs: Regular maintenance catches issues early, often allowing for less expensive repairs. Avoiding major breakdowns can save significant repair or replacement costs.

- Extended Equipment Life: By preventing premature wear and tear, maintenance can extend the life of your YORK YK chiller. This means you won’t have to invest in a replacement as soon, saving you capital expenses.

4. Environmental Benefits:

- Reduced Carbon Footprint: Energy-efficient chillers produce fewer greenhouse gas emissions. Regular maintenance contributes to lower energy consumption, which is environmentally friendly.

- Less Refrigerant Leakage: Proper maintenance helps prevent refrigerant leaks, reducing the release of harmful chemicals into the environment.

In summary, regular maintenance of your YORK YK chiller not only improves energy efficiency but also extends the system’s longevity. These benefits translate to cost savings, reduced environmental impact, and a more reliable cooling system that operates at peak performance. Investing in maintenance is a smart strategy for both short-term and long-term efficiency and sustainability.

Upgrading Older YORK YK Chillers with Newer Technology

Upgrading older YORK YK chillers with newer technology can enhance chiller performance, energy efficiency, and reliability. It’s a strategic approach for facilities looking to extend the life of their equipment and reduce energy consumption. Here’s some information on the process and benefits of upgrading older YORK YK chillers:

1. Benefits of Upgrading:

- Improved Efficiency: Newer chiller technology is often more energy-efficient, leading to reduced energy consumption and lower operating costs.

- Environmental Impact: Energy-efficient chillers produce fewer greenhouse gas emissions, contributing to environmental sustainability.

- Enhanced Reliability: Newer chillers may have improved components and design features that enhance overall system reliability.

- Advanced Controls: Upgrading can provide access to advanced control systems that offer better monitoring and optimization of chiller performance.

- Regulatory Compliance: Newer chillers may meet or exceed current environmental and energy efficiency standards, ensuring compliance with regulations.

2. Assessment and Planning:

- Chiller Assessment: Begin by assessing the condition and performance of your existing YORK YK chiller. Identify any specific issues or inefficiencies that need addressing.

- Energy Audit: Conduct an energy audit to determine the potential energy savings achievable through an upgrade. This analysis will help justify the investment.

- Technical Evaluation: Consult with YORK or an HVAC professional to evaluate the compatibility of your existing chiller with newer components and technology.

3. Component Upgrades:

- Compressors: Consider upgrading compressors to more energy-efficient models. Variable speed drive (VSD) compressors can provide significant energy savings.

- Controls: Install advanced control systems that allow for precise monitoring and adjustment of chiller operation. These controls can optimize performance based on real-time conditions.

- Heat Exchangers: In some cases, upgrading heat exchangers or adding additional heat exchanger capacity can improve chiller efficiency.

- Refrigerant Management: Upgrading refrigerant management systems can help reduce refrigerant leakage and minimize environmental impact.

4. Full Chiller Replacement:

- In some cases, it may be more cost-effective and practical to replace the entire chiller with a newer model that offers improved efficiency and performance.

5. Financial Considerations:

- Calculate the return on investment (ROI) for the upgrade, taking into account energy savings, reduced maintenance costs, and potential incentives or rebates for energy-efficient upgrades.

6. Installation and Commissioning:

- Ensure that the installation of upgraded components or the new chiller is carried out by experienced professionals to ensure proper functionality and efficiency.

7. Ongoing Maintenance:

- Continue with a regular maintenance plan for the upgraded chiller to ensure it operates at peak performance and remains reliable.

8. Monitoring and Optimization:

- Utilize advanced controls and monitoring systems to continuously optimize chiller operation for maximum energy efficiency.

Upgrading older YORK YK chillers with newer technology is a strategic investment that can result in significant energy savings, reduced operating costs, and improved environmental performance. It’s essential to assess the feasibility and cost-effectiveness of upgrades carefully and work with HVAC professionals or YORK representatives to plan and execute the upgrade successfully.

schools, cafes, healthcare facilities, offices, and houses, amongst other locations.

schools, cafes, healthcare facilities, offices, and houses, amongst other locations. Therefore, the Louisville KY YK Chiller Parts can withstand an excessive amount of strain because of the strenuous actions that have to be done to cool the air, compared to other brands. However, the likelihood of consistent breakdowns is increased. Because of this, the York brand is committed to delivering Louisville KY YK chiller components for any replacements and repairs involving York YK chillers.

Therefore, the Louisville KY YK Chiller Parts can withstand an excessive amount of strain because of the strenuous actions that have to be done to cool the air, compared to other brands. However, the likelihood of consistent breakdowns is increased. Because of this, the York brand is committed to delivering Louisville KY YK chiller components for any replacements and repairs involving York YK chillers. The

The

Midwest Parts Center is the most reliable source for HVAC equipment, whether for commercial or industrial needs. Our clients can be sure that we will deliver top brands and quality in the industry. We guarantee our customers any assistance, no matter the requirements, as experts in climate control systems. You do not have to figure it out on your own when troubleshooting issues in performance when it comes to your chiller system. We will be prepared for the unexpected and maintain your unit to ensure it works to its fullest.

Midwest Parts Center is the most reliable source for HVAC equipment, whether for commercial or industrial needs. Our clients can be sure that we will deliver top brands and quality in the industry. We guarantee our customers any assistance, no matter the requirements, as experts in climate control systems. You do not have to figure it out on your own when troubleshooting issues in performance when it comes to your chiller system. We will be prepared for the unexpected and maintain your unit to ensure it works to its fullest.

York YK Commercial chiller parts

York YK Commercial chiller parts Climate control systems, including chillers, require ongoing maintenance. A professional service technician may render care, or a facility manager may be tasked with upkeep. Still, having access to

Climate control systems, including chillers, require ongoing maintenance. A professional service technician may render care, or a facility manager may be tasked with upkeep. Still, having access to  HVAC systems must be monitored both internally and externally to ensure that all components are in working condition. A single issue with a small part may lead to extreme performance problems. Common wear is to be expected, and parts enable technicians to address issues before they worsen.

HVAC systems must be monitored both internally and externally to ensure that all components are in working condition. A single issue with a small part may lead to extreme performance problems. Common wear is to be expected, and parts enable technicians to address issues before they worsen.

Complete your search for

Complete your search for  Climate control systems play an important role in helping to maintain commercial operations. Industrial facilities also depend on HVAC equipment, such as chillers, to provide cooling for spaces, products, and machinery.

Climate control systems play an important role in helping to maintain commercial operations. Industrial facilities also depend on HVAC equipment, such as chillers, to provide cooling for spaces, products, and machinery.  are no substitute parts that can meet the specifications that York has developed for their chillers. While it may seem that some spare parts can be filled with like items, doing so may result in unfavorable performance. York happens to have a vast catalog with a large selection of components that range in size from large parts to minor pieces. All of the items, however, function to serve an intended purpose and therefore are equally important.

are no substitute parts that can meet the specifications that York has developed for their chillers. While it may seem that some spare parts can be filled with like items, doing so may result in unfavorable performance. York happens to have a vast catalog with a large selection of components that range in size from large parts to minor pieces. All of the items, however, function to serve an intended purpose and therefore are equally important.

Facilities operating the YK model chiller may need

Facilities operating the YK model chiller may need