In commercial and industrial HVAC systems, every detail matters — from the compressors that generate cooling power to the coolant that ensures frictionless performance. One essential yet often overlooked component in maintaining chiller efficiency and longevity is the use of high-quality VSD Coolant.

Whether operating massive industrial cooling systems or managing HVAC equipment for commercial spaces, the right coolant plays a pivotal role in preserving performance, energy efficiency, and mechanical reliability. Midwest Parts Center supplies superior-grade VSD Coolant that keeps variable speed drive chillers operating smoothly, minimizes wear, and prevents costly downtime.

Longevity with High-Quality VSD Coolant

If your facility relies on dependable cooling year-round, choosing the correct VSD Coolant can make the difference between optimized performance and premature system fatigue. For product inquiries or expert advice, contact Midwest Parts Center at +1 800 368 8385.

Understanding the Role of VSD Coolant

To appreciate the importance of VSD Coolant, it helps to understand what happens inside a variable speed drive (VSD) chiller. A VSD regulates motor speed and adjusts compressor output according to real-time load demand. This dynamic modulation helps save energy and improve operational precision.

However, this high-performance capability also generates significant heat within the chiller’s drive. Without proper cooling, the motor could overheat, leading to performance degradation or complete drive failure. VSD Coolant functions as a thermal barrier, transferring the heat away from electronic and mechanical components, maintaining stable temperatures, and protecting the integrity of the entire unit.

As the heart of smooth VSD operation, coolant must not only manage heat but also prevent corrosion, reduce electrical conduction, and maintain viscosity across temperature extremes. Midwest Parts Center’s line of VSD Coolant meets these exact standards and is engineered specifically for demanding industrial and commercial use.

Why Using the Right VSD Coolant Is Critical

Cutting costs with substandard or generic coolant may seem appealing, but it can seriously compromise system health. Not all fluids are chemically formulated to meet the performance or safety requirements of VSD chillers.

Here’s why high-quality VSD Coolant is essential for your equipment:

-

Efficient Thermal Regulation: The coolant maintains temperature consistency within the motor and drive, ensuring electronics remain stable during high-load operation.

-

Material Compatibility: Proper coolant prevents corrosion and degradation in sensitive VSD materials like copper, plastic, and rubber.

-

Electrical Insulation: It offers dielectric protection, reducing electrical arcing risks in high-voltage modules.

-

Extended Component Life: Clean and reliable coolant keeps inner systems free from debris buildup that can damage internal parts.

-

Lower Energy Consumption: Systems running at optimal temperatures require less electricity, enhancing overall energy efficiency.

Midwest Parts Center delivers VSD Coolant verified to provide long-term protection across tough industrial conditions, reducing costly service interventions.

Signs It’s Time to Replace VSD Coolant

Like motor oil in engines, VSD Coolant eventually degrades and loses its thermal effectiveness. Knowing the warning signs helps prevent overheating and component damage.

Common indicators that your system needs a VSD Coolant replacement include:

-

Temperature Fluctuations: If the system display shows unstable internal temperatures or rising drive heat, the coolant may have lost its efficiency.

-

Discoloration or Cloudiness: Contamination or chemical breakdown causes coolant to appear cloudy, dark, or sludgy.

-

Frequent VSD Alarms or Shutdowns: Overheated electrical modules may trigger operating errors.

-

Decreased Cooling Capacity: As coolant loses its thermal transfer capabilities, system performance drops noticeably.

-

Visible Leaks or Residue: Any residue near fittings or drive panels may suggest coolant deterioration.

Midwest Parts Center offers the correct VSD Coolant formulated for all seasonal and operational demands. Regular replacement not only restores efficiency but also protects expensive electronic control systems from premature aging.

The Benefits of High-Quality VSD Coolant in Commercial and Industrial Applications

Commercial and industrial buildings depend on uninterrupted HVAC performance, requiring systems that can handle extended operating hours and fluctuating conditions.

High-quality VSD Coolant provides the following key benefits:

1. Enhanced Energy Performance

Efficient temperature regulation allows motors to operate at lower energy levels. By improving thermal transfer properties, VSD Coolant helps reduce electricity consumption and balances drive temperatures during heavy loads.

2. Reduced Maintenance Costs

When VSD components remain clean and stable, they experience less thermal and electrical stress. Genuine coolant minimizes service frequency, meaning maintenance intervals are extended, and costs are reduced.

3. Improved Drive Reliability

A clean and thermally balanced environment extends electronic component lifespan. With the right coolant, drives remain stable under varying speed and torque conditions.

4. System Longevity

Regular coolant replacement with authentic, high-quality formulas keeps your equipment closer to factory performance. It provides continuous protection against scaling and corrosion, ensuring years of dependable operation.

5. Reduced Environmental Impact

Modern VSD Coolants are formulated for eco-efficiency, using non-toxic and biodegradable ingredients that reduce waste and help facilities meet sustainability goals.

Midwest Parts Center emphasizes these benefits by supplying top-grade VSD Coolant developed for maximum performance under the most demanding commercial and industrial HVAC environments.

Common VSD Issues Prevented by Correct Coolant Use

Failure to maintain proper coolant levels can lead to a range of drive-related issues, many of which can cause costly downtime or total system failure. Below are some frequent problems avoided with consistent coolant monitoring and replacement.

Overheating

The most obvious risk is excessive motor and drive heat. Depleted or ineffective coolant disrupts heat transfer efficiency, causing overheating that can damage circuit boards and power modules.

Electrical Shorting

Improper or contaminated coolant decreases dielectric strength, increasing the chance of electrical current leakage inside the system. Genuine VSD Coolant protects against short-circuiting and overheating.

Component Corrosion

When the coolant formula breaks down, it can become acidic and start corroding internal surfaces. High-quality coolant resists chemical degradation, protecting critical components.

Performance Drops

Dirty or old coolant limits thermal efficiency and increases friction, resulting in less consistent drive performance and longer operating cycles.

With Midwest Parts Center as your VSD Coolant supplier, you can prevent these issues through correct product selection and timely replacement scheduling.

Methods for Maintaining VSD Coolant Effectiveness

To maximize your equipment’s life and efficiency, establish consistent coolant care practices. Midwest Parts Center supports maintenance professionals with proactive recommendations tailored to each system’s operating conditions.

Key maintenance practices include:

-

Scheduled Fluid Replacement: Replace coolant according to manufacturer-recommended intervals or after system runtime thresholds.

-

Monitoring Color and Clarity: Inspect coolant for discoloration, foaming, or contamination.

-

Testing Dielectric Strength: Verify fluid insulation levels to ensure electrical protection.

-

Checking Temperature Readings: Monitor VSD and compressor inlet temperatures for overheating symptoms.

-

Storing Coolant Properly: Keep replacement VSD Coolant in sealed, temperature-controlled containers before use to maintain stability.

Midwest Parts Center not only provides the coolant but also offers guidance on system maintenance protocols to help businesses extend their chiller investment value.

The Role of VSD Coolant in Variable Speed System Efficiency

Variable speed drives revolutionized HVAC system efficiency by adapting motor speeds to precise load conditions rather than operating at constant full capacity. But the energy benefits depend on cooling consistency. Without proper coolant, temperature fluctuations can compromise drive electronics, causing inefficiency and risk of breakdown.

High-grade VSD Coolant stabilizes that delicate balance. It ensures voltage and current remain stable across components, allowing motors to function precisely without overheating. This process directly impacts system efficiency, reducing energy waste and preserving mechanical strength.

Midwest Parts Center supports clients who understand that authentic coolant isn’t just another consumable—it is a performance-critical component fundamental to continued VSD success.

Why Midwest Parts Center Is the Trusted Source

Midwest Parts Center leads the commercial and industrial HVAC parts market with reliable access to genuine VSD Coolant and related maintenance products.

Businesses choose Midwest Parts Center for several reasons:

-

Industry expertise in HVAC systems and chiller operations

-

Quick nationwide access to original, verified VSD Coolant supplies

-

Personalized consultation to select coolants suited for system type and environment

-

High-stock availability to avoid downtime

-

Commitment to delivering cost-efficient, long-term solutions

The company’s long-standing record of service and dedication ensures clients receive not just coolant but peace of mind in their cooling operations. To order verified VSD Coolant or inquire about your specific chiller requirements, call +1 800 368 8385.

The Cost of Neglecting Coolant Maintenance

While some facility teams focus heavily on mechanics and electronics, coolant upkeep is often neglected until performance declines. Unfortunately, by that point, problems have usually spread to the drive and compressor.

Without regular coolant replacement, you can expect:

-

Drive component failures due to heat accumulation

-

Electrical shorts from degraded dielectric protection

-

Material damage on seals and connectors

-

Unplanned maintenance costs and downtime losses

By maintaining a coolant replacement schedule with genuine VSD Coolant, commercial and industrial facilities save significant repair costs and preserve valuable uptime. Midwest Parts Center makes it simple to track and manage these routine service needs.

Sustainable Practices and Environmental Safety

Quality VSD Coolant not only supports system efficiency but also aligns with sustainable operational practices. The advanced formulations available through Midwest Parts Center minimize waste disposal challenges and reduce environmental risk.

Environmentally conscious facilities can rely on mid-viscosity VSD Coolant products that offer long service life, low evaporation rate, and easier recyclability. Such products help businesses meet strict environmental compliance standards while still achieving high operational performance.

How Midwest Parts Center Supports Facility Operations

At Midwest Parts Center, the focus goes beyond product delivery. The company acts as a strategic partner for facility managers, engineers, and service technicians who value reliability and quality.

Through continuous support, part verification, and prompt response, Midwest Parts Center ensures every system retains full cooling capability. Industrial clients trust the company to provide durable, high-performance products like VSD Coolant that stand the test of time.

Whether operating a large manufacturing hub or a state-of-the-art office complex, Midwest Parts Center offers consistent supply solutions to keep your HVAC equipment efficient and protected.

Extend Equipment Life and Reduce Costs with Midwest Parts Center

Cooling systems are vital assets—each part influences efficiency, cost, and sustainability. Among them, VSD Coolant holds exceptional importance because it touches both performance and protection. Regular maintenance, paired with the use of authentic coolant, guarantees extended lifespan and reduced risk of costly breakdowns.

Midwest Parts Center understands this balance better than anyone. With the right VSD Coolant matched to your system’s specifications, you can maintain consistent performance, lower energy use, and protect your investment year after year.

If you’re ready to maximize your chiller’s lifespan and efficiency with the industry’s most reliable VSD Coolant, contact Midwest Parts Center today at +1 800 368 8385.

The Ultimate Guide to Choosing the Right VSD Coolant for Industrial Applications

In the world of industrial and commercial HVAC systems, performance consistency is not just desirable—it is essential. Whether you operate a large-scale manufacturing facility, a data center, or a commercial property, your equipment’s efficiency relies on precision, maintenance, and the quality of its components. One of the most overlooked yet critical elements in maintaining these systems is the use of high-quality VSD Coolant.

Selecting the right VSD Coolant can make the difference between an efficiently running chiller system and one plagued by costly repair cycles. This guide will explain why VSD Coolant is essential for industrial applications, what factors determine coolant quality, and how Midwest Parts Center helps businesses across the country select the right solution for their systems.

If your facility’s cooling systems use variable speed drive (VSD) technology, this guide is for you. For expert parts assistance, call +1 800 368 8385 and speak with the HVAC specialists at Midwest Parts Center.

Understanding the Role of VSD Coolant in Industrial Systems

Variable Speed Drives (VSDs) are advanced motor controllers that regulate compressor speed to match load requirements efficiently. This technology allows chillers to use less energy when demand is low and ramp up only when necessary, offering significant savings and smoother system operation.

But with great efficiency comes an added challenge: heat management. As drives and compressors adjust continuously, significant electrical and mechanical heat is generated. Without an effective means of dissipating that heat, system components such as transistors, boards, and connectors can overheat, resulting in failures and unplanned downtime.

That’s where VSD Coolant steps in.

VSD Coolant essentially serves as a protective and thermal balancing medium within the system. It absorbs and transfers heat safely away from sensitive electronics and keeps operating temperatures within optimal ranges. Beyond temperature control, high-grade coolant also prevents corrosion, insulates electrical currents, and minimizes long-term material degradation.

Midwest Parts Center supplies specialized industrial-grade VSD Coolant designed specifically for modern HVAC and chiller systems to maintain stable operation, maximize service life, and ensure energy efficiency.

Why Choosing the Right VSD Coolant Matters

When it comes to your cooling system’s drives and motors, the cooling medium you select matters just as much as the hardware itself. Using inferior, contaminated, or incompatible coolant can lead to catastrophic system inefficiencies and failures.

Here are key reasons why using the correct VSD Coolant from Midwest Parts Center is essential:

-

System Performance Stability

The right coolant maintains thermal equilibrium across all operating ranges. It ensures motor components remain within safe temperature thresholds for consistent performance. -

Electrical Insulation and Safety

A premium coolant offers dielectric properties that prevent electrical conductivity and short circuits—a vital factor in electronic-driven chillers. -

Extended Condition of Equipment

High-performance VSD Coolant reduces wear on critical drive electronics and seals, preserving the mechanical and electrical integrity of components. -

Corrosion Resistance

Corrosion is a silent destroyer of HVAC systems. The right coolant prevents oxidation inside piping and drive circuits, preventing long-term equipment damage. -

Energy Efficiency Preservation

Optimal thermal conductivity means fewer hours lost to cooling inefficiency. A good coolant keeps overall system energy use in line with the original factory design.

Each of these characteristics contributes to improved reliability and reduced maintenance costs, which is why Midwest Parts Center emphasizes proper coolant selection for industrial and commercial clients.

How VSD Coolant Works

The science behind VSD Coolant is straightforward yet vital to understand for industrial users. The coolant flows through various components of the chiller’s drive and electronic sections to dissipate heat, prevent oxidation, and act as an electrical insulator.

It must function under a variety of demanding conditions—extreme temperature swings, long continuous operation, and heavy electrical loads. The composition of the coolant directly affects its ability to manage these challenges.

An ideal industrial-grade VSD Coolant should:

-

Maintain stable viscosity under both hot and cold temperatures

-

Possess superior thermal conductivity properties

-

Offer high dielectric strength to resist electrical breakdown

-

Contain anti-corrosion additives that protect metal and non-metal components

-

Remain chemically stable over time

By supplying only high-quality coolants that meet these standards, Midwest Parts Center ensures that industrial facilities benefit from consistent and trustworthy temperature regulation year-round.

Signs That It’s Time to Replace Your VSD Coolant

Even the best coolant degrades over time. Understanding the signs of deterioration helps prevent more severe system issues later.

Here are several warning signs that your coolant needs replacement:

-

Temperature Spikes: An unexplained rise in internal drive temperature usually signals reduced coolant performance.

-

Discoloration or Odor: Cloudy, darkened, or foul-smelling coolant indicates contamination or chemical breakdown.

-

Sediment or Sludge Formation: Debris particles or a thickened consistency can obstruct circulation pathways.

-

Corrosion Evidence: Visual signs of metal discoloration suggest inadequate coolant protection.

-

Frequent System Faults: Overheating alarms and random shutdowns might mean thermal performance has declined.

When these signs appear, it’s time to act. Midwest Parts Center can supply the correct VSD Coolant for your system and provide guidance on replacement intervals or storage protocols.

Factors to Consider When Selecting VSD Coolant

Industrial operations vary in cooling requirements, ambient conditions, and equipment types. Choosing the right coolant involves evaluating multiple factors to ensure optimal compatibility and performance.

-

System Design and Material Compatibility

Each chiller design features specific material combinations—copper, aluminum, plastic, or stainless steel—that may react differently to certain fluids. Always confirm that the chosen VSD Coolant is compatible with your materials to avoid corrosion or degradation. -

Operating Temperature Range

The working environment determines which coolant viscosity and heat transfer properties are suitable. High-heat applications require a coolant with strong thermal endurance. -

Electrical Insulation Needs

Drives dealing with high voltage require fluids that withstand voltage stress without breaking down. Choosing coolant with high dielectric strength ensures consistent insulation. -

Maintenance Intervals

Long-life coolants reduce the frequency of change-outs, helping lower overall maintenance costs. Quality coolant from Midwest Parts Center maintains performance stability over longer intervals. -

Environmental Regulations

Industrial operations often must adhere to environmental regulations. Selecting low-toxicity, eco-friendly VSD Coolant helps meet sustainability standards and minimize waste disposal challenges. -

Cost Efficiency and Availability

Using high-quality coolant might seem like a higher upfront investment, but it prevents major repair costs later. Midwest Parts Center provides cost-efficient purchasing options for both short-term and long-term operational strategies.

By considering these factors before purchase, facility managers can ensure worry-free, efficient operation for their HVAC systems.

Advantages of Using VSD Coolant Supplied by Midwest Parts Center

Midwest Parts Center stands out as one of the most trusted names in commercial and industrial HVAC part distribution. When it comes to your VSD Coolant needs, here’s what you can expect:

-

Assured Product Authenticity: Every coolant supplied is verified for quality and compatibility.

-

Expert Guidance: Knowledgeable staff guide customers through the selection process for their specific system model.

-

Fast Nationwide Supply: Midwest Parts Center offers timely delivery to minimize operational interruptions.

-

Comprehensive Inventory: High-stock availability ensures quick access to required coolants and related products.

-

Commitment to Long-Term Efficiency: Each coolant provided meets high-performance standards suited for demanding applications.

For personalized service or coolant recommendations, call +1 800 368 8385 to speak directly with an HVAC product expert.

Maintenance Best Practices for VSD Coolant

Even with high-quality product selection, routine maintenance ensures maximum coolant life and system stability. Incorporate these practices into your maintenance schedule:

-

Monitor Coolant Level Regularly: Always maintain recommended fill levels to ensure consistent heat transfer.

-

Check for Leaks: Inspect seals and joints around VSD drives for any sign of leakage.

-

Test Coolant Quality: Conduct periodic dielectric and thermal performance tests to verify coolant effectiveness.

-

Flush Before Replacement: Always flush the old coolant before replenishment to prevent chemical cross-contamination.

-

Store Properly: Keep VSD Coolant sealed in its original container and at room temperature to preserve stability.

Midwest Parts Center can assist maintenance teams by recommending appropriate testing intervals and establishing replacement schedules to maintain system reliability.

The Impact of VSD Coolant on Energy Efficiency

Industrial and commercial facilities constantly seek strategies to reduce operational costs. Energy efficiency plays a primary role, and VSD Coolant directly contributes to that goal.

By maintaining stable operating temperatures, coolant prevents unnecessary power draw from motors and electrical systems. Cooler system components run smoother, reducing mechanical friction and electrical resistance. These functions combined lower the total cost of ownership and reduce strain on the overall HVAC system.

Simply put, well-maintained VSD Coolant equals lower energy use and reduced environmental impact. Midwest Parts Center’s premium coolants are formulated specifically to sustain long-term performance, helping customers meet both economic and environmental efficiency goals.

The Relationship Between Downtime and Coolant Health

System downtime is the biggest cost for any industrial operation. Drives that overheat or trip unexpectedly cause delays, production halts, or even equipment damage.

Maintaining proper coolant condition is a simple yet powerful way to prevent this. Properly managed VSD Coolant ensures smooth performance even under extreme load cycles. It also prevents drive-related faults that could otherwise halt production processes.

Midwest Parts Center’s partnerships with industrial clients illustrate that regular coolant tracking is one of the smartest preventive actions to keep facilities productive and profitable.

Environmental Considerations in VSD Coolant Selection

Modern industrial operations place growing emphasis on sustainability. VSD Coolant, developed by responsible manufacturers, is engineered to meet environmental standards while providing peak thermal management.

Features include:

-

Reduced toxicity levels to safeguard worker and environmental safety

-

Long fluid lifespans minimize disposal frequency

-

Easy recyclability through eco-safe filtration processes

-

Improved overall performance, enhancing system energy profiles

Midwest Parts Center helps businesses meet operational goals while supporting environmental initiatives through eco-conscious coolant solutions suited for large-scale industrial settings.

The Midwest Parts Center Approach to Reliability

What sets Midwest Parts Center apart is its deep focus on customer reliability. Beyond providing superior VSD Coolant, the company prioritizes understanding the client’s industrial environment and performance expectations.

From product identification to rapid order fulfillment, Midwest Parts Center provides end-to-end support designed for busy industrial environments. Each client partnership is built on trust, consistency, and a commitment to sustaining long-term equipment value.

Midwest Parts Center’s large-scale inventory ensures that when clients need parts or coolant solutions urgently, they get them quickly and efficiently.

Invest in the Right VSD Coolant for Maximum Returns

In industrial and commercial environments, precision is everything. Every component in a system—from compressors and drives to control sensors and coolants—plays a role in performance, lifespan, and energy efficiency. Choosing high-quality VSD Coolant is not just about maintenance; it is a strategic business decision that impacts safety, reliability, and cost control.

Midwest Parts Center stands at the forefront of supplying authentic, high-performing VSD Coolant solutions designed to meet the most demanding industrial requirements. With professional support, rapid delivery, and proven product integrity, businesses across the country trust Midwest Parts Center to keep their cooling systems performing at their very best.

For expert guidance or to place your next order, contact Midwest Parts Center today at +1 800 368 8385.

Clean air conditioning is a significant consideration, and units need cost savings, but the energy bill is a major obstacle for companies trying to work efficiently within a budget.

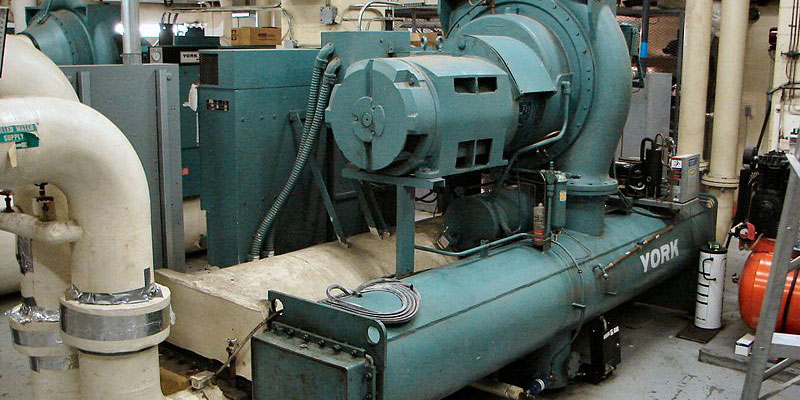

Clean air conditioning is a significant consideration, and units need cost savings, but the energy bill is a major obstacle for companies trying to work efficiently within a budget. The HVAC system performs as designed with little effort, thanks to using York Industrial VSD Coolant for chillers. The heating, ventilation, and air conditioning (HVAC) system in a building is crucial for maintaining a comfortable indoor temperature and meeting regulations.

The HVAC system performs as designed with little effort, thanks to using York Industrial VSD Coolant for chillers. The heating, ventilation, and air conditioning (HVAC) system in a building is crucial for maintaining a comfortable indoor temperature and meeting regulations.

needs coolant, you should probably avoid attempting to fix it on your own. Instead, it would help if you hire trained professionals to resolve the issue.

needs coolant, you should probably avoid attempting to fix it on your own. Instead, it would help if you hire trained professionals to resolve the issue. atmosphere. York VSD coolant, used in chillers, ensures that the machines continue functioning normally and effectively. HVAC equipment manage the expected airflow level within a building’s interior, regardless of the changing temperatures outside; ventilation and air conditioning systems are necessary for meeting the needs for filtered air.

atmosphere. York VSD coolant, used in chillers, ensures that the machines continue functioning normally and effectively. HVAC equipment manage the expected airflow level within a building’s interior, regardless of the changing temperatures outside; ventilation and air conditioning systems are necessary for meeting the needs for filtered air. The coolant is a crucial component for the transfer of heat during the process of converting liquids and vapors. Consequently, some companies have been forced to endure exorbitantly high energy expenses due to their efforts to manage York VSD coolant for their chillers and the VSD coolant.

The coolant is a crucial component for the transfer of heat during the process of converting liquids and vapors. Consequently, some companies have been forced to endure exorbitantly high energy expenses due to their efforts to manage York VSD coolant for their chillers and the VSD coolant.