Working with an approved York brand distributor will save you time because York is at the top of its game. You will find reliable York YLAA Chiller Parts suitable for commercial and industrial purposes. YLAA chiller is the most essential and dependable piece of the cooling system.

Working with an approved York brand distributor will save you time because York is at the top of its game. You will find reliable York YLAA Chiller Parts suitable for commercial and industrial purposes. YLAA chiller is the most essential and dependable piece of the cooling system.

This beautiful brand is an environmental pioneer in all air-conditioning applications, giving remarkable efficiency. Several accessories and options are available, such as:

- Factory packaged variable speed pumps,

- Controls Connected Chillers

- Intelligent performance monitoring,

- And low sound packages. YLAA chillers are lightweight and compact for easy installation.

York YLAA Chiller Parts

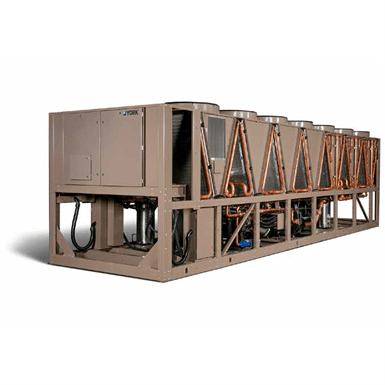

YORK YLAA CHILLER PARTS have a solid reputation for quality, uses cutting-edge technology, and delivers outstanding real-world results. More efficient heat transfer is made possible by brazed evaporators and microchannel condensers, resulting in lower life-cycle costs. They are a plug-and-play solution that reduces energy expenses and is environmentally friendly.

Performance of the York YLAA parts

Most importantly, the YORK YLAA CHILLER PARTS compressor and other parts are so unique compared to other products. With the best cooling air, comfort, and safety equipment.

Most importantly, the YORK YLAA CHILLER PARTS compressor and other parts are so unique compared to other products. With the best cooling air, comfort, and safety equipment.

When used as a preventative measure, YORK YLAA CHILLER PARTS assist in extending the life of a system. Once minor repairs are taken care of, users will get more years out of their chiller. To get the best performance out of your HVAC system, all chiller parts must work together seamlessly.

Also, the chiller can manage climate control systems more efficiently with the availability of a wide range of high-quality parts. Many commercial end-users prefer the YORK YLAA CHILLER PARTS as a cost-effective cooling solution. Because it serves a wide range of purposes, from cooling buildings to cooling machinery and other products, the equipment is vital, but we must maintain it to have the best results.

The energy use of the York parts

The cooling processes carried out by chillers consume a lot of energy due to their inability to function. If a chiller shows symptoms of wear or is underperforming, it has to be evaluated. With suitable instruments, a service expert can check for any issues. If any, It will be recommendable to replace York YLAA chiller parts if required. In addition to helping a machine get back to full functionality, replacement parts can also aid energy efficiency. Every facility is different, but they all require professional maintenance.

When it comes to operational expenditures, chiller components give facility managers and business owners more control. In comparison to  purchasing a new unit, having your existing unit repaired saves you money.

purchasing a new unit, having your existing unit repaired saves you money.

Rather than buying a unique temperature control system, consider whether parts replacement is a more cost-effective option for extending the lifespan of your current system. To keep operations operating effectively, companies must weigh the costs and benefits of installing new air systems to buy reliable YLAA chiller parts.

We offer equipment and parts manufactured by a globally recognized brand (York). Check-in here if you need a replacement for your YLAA chiller parts.

With accessibility to a large selection of quality components, like

With accessibility to a large selection of quality components, like

The heater performs numerous functions as part of the chiller, including cutting off the heat exchanger valve while the heater is activated and submerged in a reservoir and keeping the valve open when no heat spikes are visible. Small heaters are attached to the powerhead on the YLAA chiller parts and are used to combat low ambient difficulties. The chillers are also built to the highest possible standards to maximize their effectiveness, reliability, and flexibility.

The heater performs numerous functions as part of the chiller, including cutting off the heat exchanger valve while the heater is activated and submerged in a reservoir and keeping the valve open when no heat spikes are visible. Small heaters are attached to the powerhead on the YLAA chiller parts and are used to combat low ambient difficulties. The chillers are also built to the highest possible standards to maximize their effectiveness, reliability, and flexibility.

Furthermore, climate control demands are different for every chiller system purchased. It is the reason why we are here to make life easier; whether you need a chiller as a part of a unit to lower the energy consumption or perhaps offer that cool air, we got you covered. When you get a supplier that offers you reliable and high-quality York YLAA chiller parts, it is such a relief. Midwest Parts Center Is here to ensure you access these parts and take you through all you need to know about air conditioning equipment.

Furthermore, climate control demands are different for every chiller system purchased. It is the reason why we are here to make life easier; whether you need a chiller as a part of a unit to lower the energy consumption or perhaps offer that cool air, we got you covered. When you get a supplier that offers you reliable and high-quality York YLAA chiller parts, it is such a relief. Midwest Parts Center Is here to ensure you access these parts and take you through all you need to know about air conditioning equipment.

At the mention of York YLAA commercial chiller parts, the protection of budgets and the environment is a priority. The

At the mention of York YLAA commercial chiller parts, the protection of budgets and the environment is a priority. The  Midwest Parts Centre offers you the best chiller parts; thanks to York YLAA’s stability, chiller units can now be adapted to the cooling requirements up to a rated output of about 100KW. The main purpose of the

Midwest Parts Centre offers you the best chiller parts; thanks to York YLAA’s stability, chiller units can now be adapted to the cooling requirements up to a rated output of about 100KW. The main purpose of the  We ensure that we stick to all the procedures detailed in the parts manuscript, including the installation process, commissioning, and maintenance duties, and must only be performed perfectly by trained professionals and a qualified team. Midwest Parts Centre also gives you a warranty for the parts you purchase from us. However, it is important to note that our warranty is restricted to services and maintenances for the parts only. Among these will be replacements, shipping of parts, and failure of certain parts which have failed due to maintenance. Our chiller parts warranty specifies the chiller unit model, and manufacturer’s details such as serial number, among many things, paramount to YLAA parts.

We ensure that we stick to all the procedures detailed in the parts manuscript, including the installation process, commissioning, and maintenance duties, and must only be performed perfectly by trained professionals and a qualified team. Midwest Parts Centre also gives you a warranty for the parts you purchase from us. However, it is important to note that our warranty is restricted to services and maintenances for the parts only. Among these will be replacements, shipping of parts, and failure of certain parts which have failed due to maintenance. Our chiller parts warranty specifies the chiller unit model, and manufacturer’s details such as serial number, among many things, paramount to YLAA parts.

Midwest Parts Center is the best place to stop when looking for chiller parts, from the YK chiller parts to the YLAA chiller parts and now

Midwest Parts Center is the best place to stop when looking for chiller parts, from the YK chiller parts to the YLAA chiller parts and now  Commercial establishments are unique and at times, finding the right fit of equipment that is not problematic for the establishment structure is hard work. However, Midwest Parts Center has had years of experience that have proven useful. In the end, we have a deep understanding of how commercial establishments are and can work to ensure that whatever these parts you need can be installed and facilitated to your liking.

Commercial establishments are unique and at times, finding the right fit of equipment that is not problematic for the establishment structure is hard work. However, Midwest Parts Center has had years of experience that have proven useful. In the end, we have a deep understanding of how commercial establishments are and can work to ensure that whatever these parts you need can be installed and facilitated to your liking. Midwest Parts Center helps you identify and pick the correct York YLAA industrial chiller parts that meet your needs and can be integrated into your equipment without further interfering with your existing air system equipment. There is an extensive list of models you can choose from. We help you make the right selection because it saves you the time and expenses of replacing the parts shortly after reinstalling them. If you install a faulty chiller part, you risk having costly repairs, and that is not our aim. Midwest Parts Center is your go-to supplier for sound advice and

Midwest Parts Center helps you identify and pick the correct York YLAA industrial chiller parts that meet your needs and can be integrated into your equipment without further interfering with your existing air system equipment. There is an extensive list of models you can choose from. We help you make the right selection because it saves you the time and expenses of replacing the parts shortly after reinstalling them. If you install a faulty chiller part, you risk having costly repairs, and that is not our aim. Midwest Parts Center is your go-to supplier for sound advice and

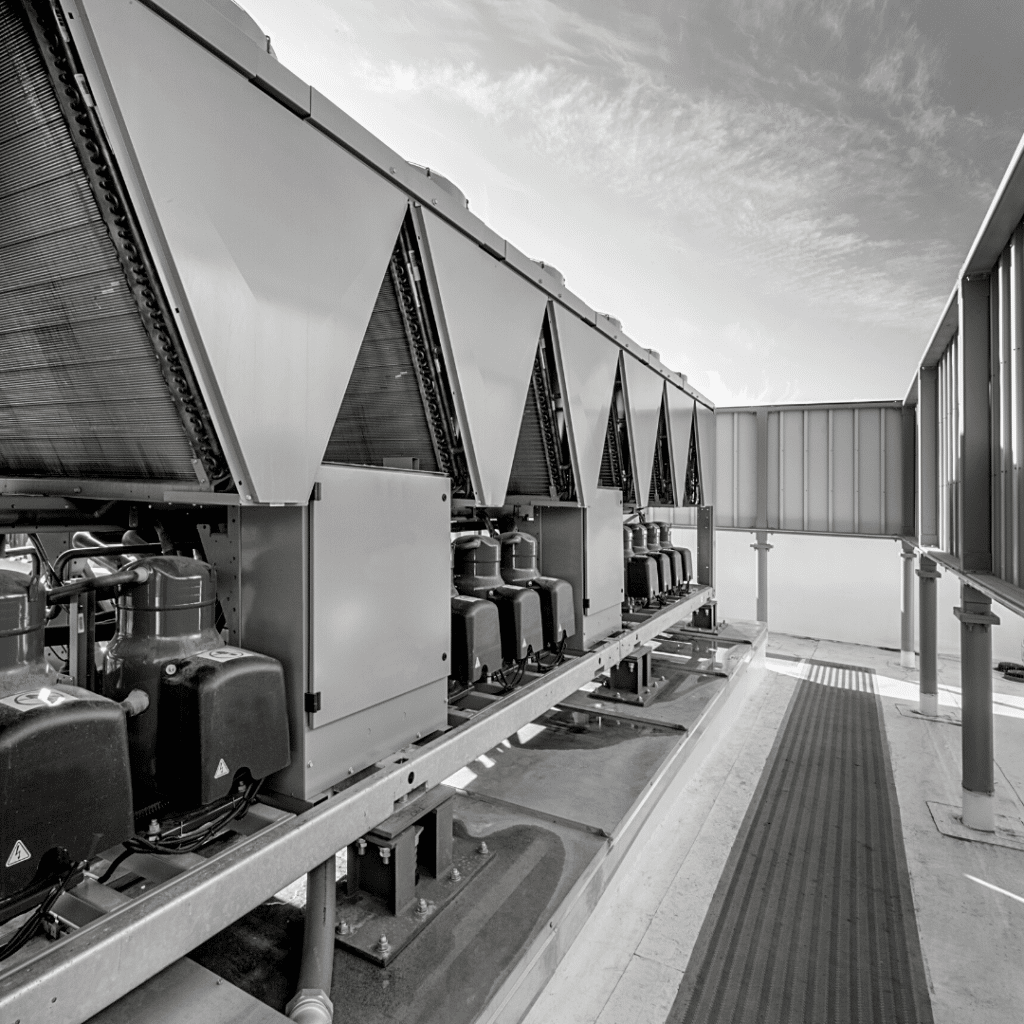

Commercial chillers provide complicated cooling for extensive facilities like industrial plants, offices, and hospitals. Air-Conditioning is applied for comfort, safety, and air quality. York YLAA Midwest chillers help facilities achieve their goals of efficiency as a cost-friendly solution. Midwest Parts Center supplies

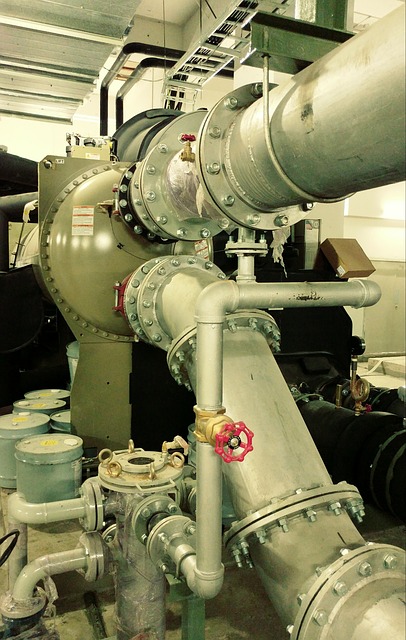

Commercial chillers provide complicated cooling for extensive facilities like industrial plants, offices, and hospitals. Air-Conditioning is applied for comfort, safety, and air quality. York YLAA Midwest chillers help facilities achieve their goals of efficiency as a cost-friendly solution. Midwest Parts Center supplies  Because HVAC units are, in fact, a costly investment for facilities, constant maintenance is needed. Maintenance activities, however, should be performed by a field technician with adequate hands-on experience. Handling the materials inside of a chiller is dangerous without the proper training. Chillers consist of heavy parts, liquids, and electrical components, which can be hazardous.

Because HVAC units are, in fact, a costly investment for facilities, constant maintenance is needed. Maintenance activities, however, should be performed by a field technician with adequate hands-on experience. Handling the materials inside of a chiller is dangerous without the proper training. Chillers consist of heavy parts, liquids, and electrical components, which can be hazardous. The York YLAA Midwest chiller is another energy-efficient model built by York. The chiller includes popular features that enable companies to save money on cool air. The YLAA design is an air-cooled model that provides for a brazed plate heat exchange. An air-cooled-chiller model condenses heat to produce cool air.

The York YLAA Midwest chiller is another energy-efficient model built by York. The chiller includes popular features that enable companies to save money on cool air. The YLAA design is an air-cooled model that provides for a brazed plate heat exchange. An air-cooled-chiller model condenses heat to produce cool air.

A chiller is a sizeable industrial cooling system that uses a process of heat transfer to provide cool air.

A chiller is a sizeable industrial cooling system that uses a process of heat transfer to provide cool air.  The York YVAA chiller is an efficient model chosen by companies across several industries. The chiller, built by York, is an air-cooled style chiller. The system includes the company’s Variable Speed Drive technology, which is exclusive to York. Variable Speed Drive chillers are efficient, which means they save on energy usage. Even though there are variations of the YVAA model on the market, Midwest Parts Center can source York YVAA industrial chiller parts materials for end-users with ease. Having access to York’s robust catalog, commercial clients will find the most expertise with Midwest Parts Center.

The York YVAA chiller is an efficient model chosen by companies across several industries. The chiller, built by York, is an air-cooled style chiller. The system includes the company’s Variable Speed Drive technology, which is exclusive to York. Variable Speed Drive chillers are efficient, which means they save on energy usage. Even though there are variations of the YVAA model on the market, Midwest Parts Center can source York YVAA industrial chiller parts materials for end-users with ease. Having access to York’s robust catalog, commercial clients will find the most expertise with Midwest Parts Center. York chiller models are durable, but they still require service through a professional technician. Because HVAC units in extensive facilities are involved, troubleshooting is left to field and factory-trained experts. Handling repairs with York YVAA industrial chiller parts and other components are dangerous. Chillers contain high pressure, hot liquids, and electrical components that must be handled with care. Access to parts, however, makes the job of repair easier for service technicians. Additionally, facility managers tasked with monitoring chiller performance will find that parts access is essential.

York chiller models are durable, but they still require service through a professional technician. Because HVAC units in extensive facilities are involved, troubleshooting is left to field and factory-trained experts. Handling repairs with York YVAA industrial chiller parts and other components are dangerous. Chillers contain high pressure, hot liquids, and electrical components that must be handled with care. Access to parts, however, makes the job of repair easier for service technicians. Additionally, facility managers tasked with monitoring chiller performance will find that parts access is essential.

The delivery of parts is efficient when HVAC units are under care. The maintenance of air systems within industrial centers and commercial facilities is complex. HVAC units need frequent monitoring and service. Because of the large role that chillers play in facilities, the parts must lend to efficiency.

The delivery of parts is efficient when HVAC units are under care. The maintenance of air systems within industrial centers and commercial facilities is complex. HVAC units need frequent monitoring and service. Because of the large role that chillers play in facilities, the parts must lend to efficiency.  Even though online merchants attempt to sell

Even though online merchants attempt to sell

With our HVAC industry expertise, we have acquired a comprehensive knowledge of

With our HVAC industry expertise, we have acquired a comprehensive knowledge of  Parts deliveries are the most effective in controlling HVAC units. The maintenance of ventilation systems in an industrial plant or a commercial building is complicated. The units require continuous monitoring, regular service, and ongoing status checks. Due to the enormous role of cooling systems in large buildings, components have to help control costs.

Parts deliveries are the most effective in controlling HVAC units. The maintenance of ventilation systems in an industrial plant or a commercial building is complicated. The units require continuous monitoring, regular service, and ongoing status checks. Due to the enormous role of cooling systems in large buildings, components have to help control costs.