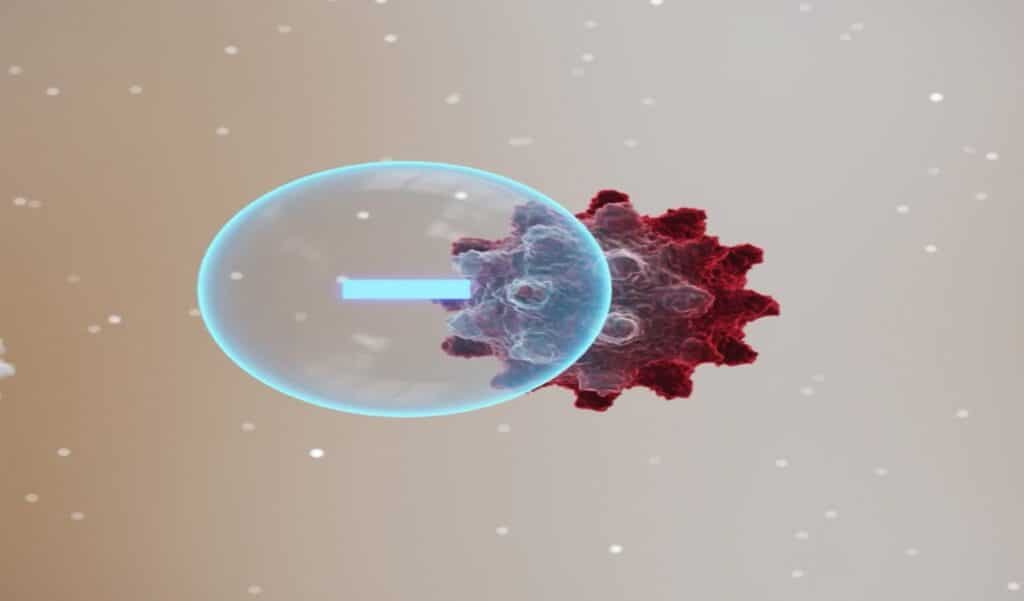

The results generated from needlepoint bipolar ionization are notable as they are used in the war against COVID 19. One may need to understand first the needlepoint bipolar ionization to establish its use. This is a technology-based on the concepts of charged particles on the cleaners. It is used in HVAC systems or portable/moveable air cleaners. The main aim of selling these products is to remove viruses, not necessarily COVID 19 but other types of viruses. They enable surface fumigation of surfaces thus are essential in ensuring hygiene and reducing the infection rate.

The results generated from needlepoint bipolar ionization are notable as they are used in the war against COVID 19. One may need to understand first the needlepoint bipolar ionization to establish its use. This is a technology-based on the concepts of charged particles on the cleaners. It is used in HVAC systems or portable/moveable air cleaners. The main aim of selling these products is to remove viruses, not necessarily COVID 19 but other types of viruses. They enable surface fumigation of surfaces thus are essential in ensuring hygiene and reducing the infection rate.

Scientific information related to needlepoint bipolar ionization

According to scientists, the needlepoint bipolar ionization’s primary use is to clean indoor air, primarily appropriate for rooms prone to infection of the virus. They are safe for use as they do not expose someone to harmful ozone levels or other by-products. So the question is, what is an ion? Basically, it can be defined as a molecule or atom that can be either positively or negatively charged; for the ion to attain neutrality, it must gain or lose electrons. The fact that ions are present in nature means everywhere now activates them to clean the air by creating them through the use of rushing water, crashing waves, and sunlight.

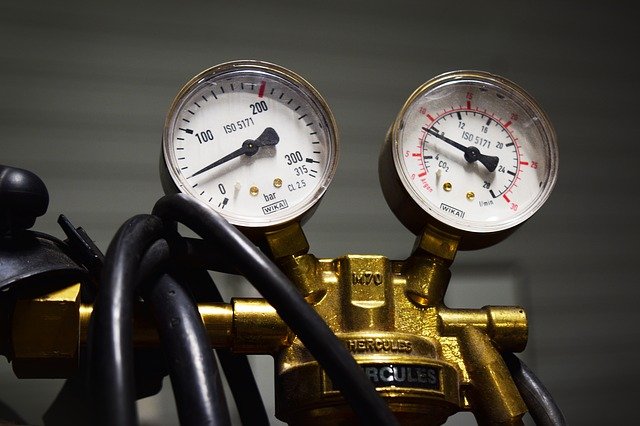

The HVAC system

The technologies developed by needlepoint bipolar ionization (NPBI) is the one responsible for the generation of ions that are not harmful and therefore take up the role of cleaning the air in the rooms. The process has to be completed by an HVAC system that generates and releases ions into the airstream. The ions, after release, form bonds with the particles. Thus they cluster together, making it easier for the system to flash out the air. Moreover, they are various platforms that the needlepoint bipolar ionization can be used.

The technologies developed by needlepoint bipolar ionization (NPBI) is the one responsible for the generation of ions that are not harmful and therefore take up the role of cleaning the air in the rooms. The process has to be completed by an HVAC system that generates and releases ions into the airstream. The ions, after release, form bonds with the particles. Thus they cluster together, making it easier for the system to flash out the air. Moreover, they are various platforms that the needlepoint bipolar ionization can be used.

Where and when has needlepoint bipolar ionization been used? The NPBI technology has been available for use in the medical industry even before the COVID 19 pandemic. It has recently gained traction due to the infection rate caused by the COVID 19 virus. Therefore, it is being used in schools, airports, and business premises. The most common area that has embraced this technology is the airports. An example is Boeing which has established the practice of corona discharge air ionization.

Other benefits of Needlepoint Bipolar Ionization

The other benefits that come with the use of the technology include reducing the rate of energy consumption, reducing or minimal carbon footprint, and meeting the passenger’s needs in terms of assurance for safety. The spread of the virus is entirely caused mainly by  intercontinental traveling hubs such as airports. It can be agreed that the leading cause for infection in some countries was due to interaction with people from the infected countries leading to the need to establish such available technologies to reduce the spread.

intercontinental traveling hubs such as airports. It can be agreed that the leading cause for infection in some countries was due to interaction with people from the infected countries leading to the need to establish such available technologies to reduce the spread.

In summary, the use of the needlepoint bipolar ionization though not quite fully exploited has helped to reduce the infection rate of the COVID 19 virus. Its benefits are notable as they do not interfere whatsoever with human health. Installation of the system in the airplanes is a lifesaving idea.

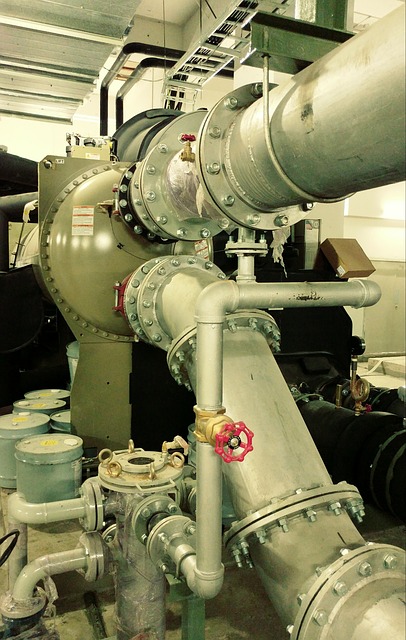

York Chiller Parts can be found in industrial and commercial buildings and are used for a variety of purposes. It’s critical to maintain them up to date because they’re such significant machines. Chillers, like any other piece of equipment, can suffer from a loss of function if they are not properly maintained. Neglected maintenance concerns might deteriorate over time, necessitating costly repairs.

York Chiller Parts can be found in industrial and commercial buildings and are used for a variety of purposes. It’s critical to maintain them up to date because they’re such significant machines. Chillers, like any other piece of equipment, can suffer from a loss of function if they are not properly maintained. Neglected maintenance concerns might deteriorate over time, necessitating costly repairs.

Obtaining York YT chiller parts can save you the time and effort of going from store to store in quest of the perfect fit for your cooling system. Furthermore, searching for components on the internet is not always easy; it may be tiresome and stressful because you never know if what you see is what you get.

Obtaining York YT chiller parts can save you the time and effort of going from store to store in quest of the perfect fit for your cooling system. Furthermore, searching for components on the internet is not always easy; it may be tiresome and stressful because you never know if what you see is what you get.

Because of their unique qualities, York YK Chiller Parts provide high-quality performance. These qualities provide several advantages, including lower overall costs of ownership. As previously stated, chiller parts have lower installations, repairing, and maintenance expenses that pay for themselves in less than a year, depending on the prototype system and options. Another benefit provided by York YK chiller components is improved innovation for your unit’s unequaled performance.

Because of their unique qualities, York YK Chiller Parts provide high-quality performance. These qualities provide several advantages, including lower overall costs of ownership. As previously stated, chiller parts have lower installations, repairing, and maintenance expenses that pay for themselves in less than a year, depending on the prototype system and options. Another benefit provided by York YK chiller components is improved innovation for your unit’s unequaled performance.

When it comes to enhancing productivity and effectiveness,

When it comes to enhancing productivity and effectiveness,

Air systems are vital in any company system, and they should be managed and enhanced to ensure that the business facilities and personnel are comfortable and safe. Air – conditioning system has a greater impact on the environment. Negative environmental effects cause global warming and other climate difficulties, making the world unfit for human habitation. The York YVAA chillers, on the other hand, are all about being environmentally sustainable while yet offering peaceful and fresh breathable air.

Air systems are vital in any company system, and they should be managed and enhanced to ensure that the business facilities and personnel are comfortable and safe. Air – conditioning system has a greater impact on the environment. Negative environmental effects cause global warming and other climate difficulties, making the world unfit for human habitation. The York YVAA chillers, on the other hand, are all about being environmentally sustainable while yet offering peaceful and fresh breathable air.

The heater performs numerous functions as part of the chiller, including cutting off the heat exchanger valve while the heater is activated and submerged in a reservoir and keeping the valve open when no heat spikes are visible. Small heaters are attached to the powerhead on the YLAA chiller parts and are used to combat low ambient difficulties. The chillers are also built to the highest possible standards to maximize their effectiveness, reliability, and flexibility.

The heater performs numerous functions as part of the chiller, including cutting off the heat exchanger valve while the heater is activated and submerged in a reservoir and keeping the valve open when no heat spikes are visible. Small heaters are attached to the powerhead on the YLAA chiller parts and are used to combat low ambient difficulties. The chillers are also built to the highest possible standards to maximize their effectiveness, reliability, and flexibility.

In particular, the HVAC system maintains a cool environment within the space. Air conditioning systems aim to remove moisture from the air to make it more pleasant and relaxing inside.

In particular, the HVAC system maintains a cool environment within the space. Air conditioning systems aim to remove moisture from the air to make it more pleasant and relaxing inside.

Allow professionals to properly inspect your HVAC unit even after it has been fixed to guarantee that the repaired element is not underperforming, is not defective, and is performing the function for which it was designed. It will unquestionably lower your costs. Getting a professional suggestion on the genuine accessories to buy spares your effort and resources that you would otherwise spend searching for these parts aimlessly. Lastly, low-quality chiller systems can be highly expensive, understand that inexpensive is valuable. Replacing the entire HVAC system, but on the other hand, is considerably more costly.

Allow professionals to properly inspect your HVAC unit even after it has been fixed to guarantee that the repaired element is not underperforming, is not defective, and is performing the function for which it was designed. It will unquestionably lower your costs. Getting a professional suggestion on the genuine accessories to buy spares your effort and resources that you would otherwise spend searching for these parts aimlessly. Lastly, low-quality chiller systems can be highly expensive, understand that inexpensive is valuable. Replacing the entire HVAC system, but on the other hand, is considerably more costly.

There are a plethora of HVAC parts suppliers available on the internet, selling products from all over the world; although, not all of these vendors are authorized dealers. While seeking York applied parts, it is recommended that you engage with an authorized provider. While you may save money on outside supply parts, you cannot be sure you are getting an authentic York product if the sellers are not accredited. Original components are also vital because they will suit your system exactly as it was intended to do.

There are a plethora of HVAC parts suppliers available on the internet, selling products from all over the world; although, not all of these vendors are authorized dealers. While seeking York applied parts, it is recommended that you engage with an authorized provider. While you may save money on outside supply parts, you cannot be sure you are getting an authentic York product if the sellers are not accredited. Original components are also vital because they will suit your system exactly as it was intended to do.