The Impact of YT York Chillers on Indoor Air Quality: Creating Comfortable and Healthy Environments

In today’s commercial and industrial settings, maintaining optimal indoor air quality (IAQ) is crucial for ensuring the health, comfort, and productivity of occupants. The role of HVAC systems in achieving this cannot be overstated. Among the various components that contribute to effective HVAC performance, chillers play a vital role. Specifically, YT York chillers have set a benchmark in the industry for their ability to enhance indoor air quality while providing efficient cooling solutions.

At Midwest Parts Center, we recognize the importance of YT York chillers in creating comfortable and healthy environments for businesses. In this article, we delve into the impact of YT York chillers on indoor air quality and how they contribute to maintaining superior IAQ in commercial and industrial spaces. For inquiries, you can reach us at +1 800 368 8385.

Understanding YT York Chillers

What Are YT York Chillers?

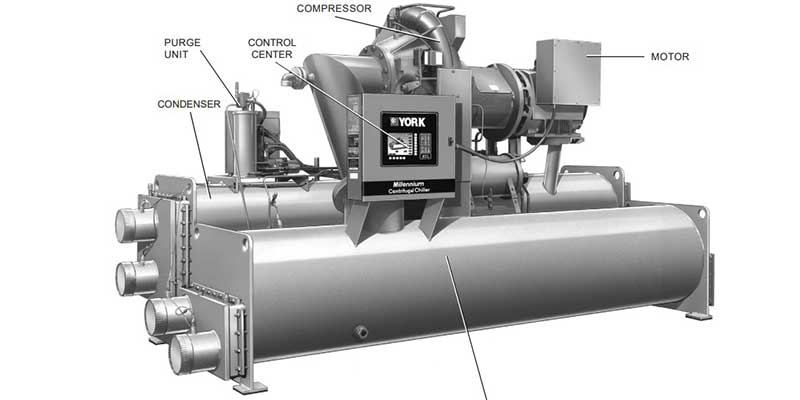

YT York chillers are a product of Johnson Controls, a leading name in the HVAC industry. These chillers are renowned for their high efficiency, reliability, and advanced technology. They are designed to provide precise temperature control and consistent cooling, making them ideal for a wide range of applications in commercial and industrial environments.

Key Features of YT York Chillers

- High Efficiency: YT York chillers are designed to operate at peak efficiency, reducing energy consumption and operational costs. Their advanced engineering ensures that they deliver optimal performance even under varying load conditions.

- Reliability: Built with robust components and cutting-edge technology, YT York chillers are known for their durability and long service life. They require minimal maintenance, ensuring consistent operation.

- Advanced Controls: These chillers come equipped with sophisticated control systems that allow for precise temperature regulation and monitoring. This helps in maintaining consistent indoor conditions and improving overall IAQ.

- Environmentally Friendly: YT York chillers use environmentally friendly refrigerants and are designed to minimize greenhouse gas emissions, contributing to sustainable building practices.

The Role of YT York Chillers in Enhancing Indoor Air Quality

1. Temperature and Humidity Control

Consistent Cooling

One of the primary ways YT York chillers impact indoor air quality is through precise temperature control. Maintaining a consistent indoor temperature is essential for occupant comfort and health. Fluctuations in temperature can lead to discomfort and affect productivity. YT York chillers ensure a steady cooling output, preventing temperature variations and creating a comfortable indoor environment.

Humidity Regulation

In addition to temperature control, YT York chillers play a crucial role in regulating indoor humidity levels. Excess humidity can lead to mold growth, musty odors, and respiratory issues. On the other hand, low humidity can cause dry skin, irritate respiratory passages, and increase static electricity. YT York chillers help maintain optimal humidity levels, reducing the risk of these issues and promoting healthier indoor air.

2. Improved Ventilation

Enhanced Airflow

Effective ventilation is vital for maintaining good indoor air quality. YT York chillers, when integrated with advanced HVAC systems, contribute to enhanced airflow and ventilation. Proper ventilation helps dilute indoor pollutants, bringing in fresh outdoor air and exhausting stale indoor air. This process is essential for reducing the concentration of harmful contaminants and ensuring a continuous supply of clean air.

Air Filtration

YT York chillers can be paired with high-efficiency air filtration systems to remove particulate matter and pollutants from the air. These filtration systems are capable of capturing dust, pollen, mold spores, and other airborne contaminants, significantly improving IAQ. Clean air filters also prevent the buildup of debris in the chiller components, ensuring optimal performance and longevity.

3. Reduction of Indoor Pollutants

Control of Volatile Organic Compounds (VOCs)

Volatile Organic Compounds (VOCs) are a significant concern in indoor environments, especially in commercial and industrial settings. VOCs are emitted by various sources, including building materials, furnishings, and cleaning products. Prolonged exposure to high levels of VOCs can cause headaches, respiratory issues, and other health problems. YT York chillers, through their efficient operation and advanced ventilation capabilities, help reduce the concentration of VOCs, contributing to healthier indoor air.

Minimization of Biological Contaminants

Biological contaminants such as bacteria, viruses, and mold can thrive in environments with poor air quality and inadequate temperature and humidity control. YT York chillers, by maintaining optimal conditions, help minimize the growth and spread of these contaminants. This is particularly important in commercial and industrial facilities where the health and safety of occupants are paramount.

4. Energy Efficiency and Sustainability

Lower Energy Consumption

YT York chillers are designed with energy efficiency in mind. Their advanced technology ensures that they consume less energy while delivering superior cooling performance. Reduced energy consumption not only lowers operational costs but also contributes to a smaller carbon footprint, aligning with sustainable building practices.

Eco-Friendly Refrigerants

The use of environmentally friendly refrigerants in YT York chillers helps reduce the impact on the ozone layer and global warming. These refrigerants have lower Global Warming Potential (GWP) compared to traditional refrigerants, making YT York chillers a more sustainable choice for HVAC applications.

5. Maintenance and Longevity

Reduced Maintenance Requirements

YT York chillers are known for their reliability and minimal maintenance needs. Their robust construction and advanced design mean fewer breakdowns and less frequent servicing. Regular maintenance of HVAC systems, including chillers, is crucial for maintaining indoor air quality. YT York chillers make this task easier, ensuring that the system operates efficiently and effectively with minimal intervention.

Extended Service Life

The durability and long service life of YT York chillers mean that businesses can rely on them for many years. A longer lifespan translates to fewer replacements and reduced waste, contributing to environmental sustainability. Regular maintenance and timely part replacements further enhance the longevity of these chillers, ensuring they continue to provide optimal indoor air quality for the long term.

The Benefits of YT York Chillers for Commercial and Industrial Environments

1. Enhanced Occupant Comfort

Maintaining a comfortable indoor environment is crucial for the well-being and productivity of occupants. YT York chillers ensure consistent temperature and humidity control, providing a comfortable atmosphere that enhances occupant satisfaction and productivity.

2. Healthier Indoor Air

Good indoor air quality is essential for preventing respiratory issues, allergies, and other health problems. By reducing indoor pollutants, regulating humidity, and improving ventilation, YT York chillers contribute to healthier indoor air, safeguarding the health of occupants.

3. Energy and Cost Savings

The energy-efficient operation of YT York chillers translates to significant cost savings for businesses. Lower energy consumption reduces utility bills, while the minimal maintenance requirements and extended service life of these chillers further contribute to cost savings over time.

4. Environmental Sustainability

YT York chillers support sustainable building practices through their use of eco-friendly refrigerants and energy-efficient operation. By choosing YT York chillers, businesses can reduce their carbon footprint and contribute to environmental conservation.

5. Reliable Performance

The reliability and durability of YT York chillers mean that businesses can depend on them for consistent performance. This reliability is crucial for maintaining uninterrupted operations in commercial and industrial environments.

In the realm of commercial and industrial HVAC systems, YT York chillers stand out for their ability to enhance indoor air quality and create comfortable, healthy environments. At Midwest Parts Center, we recognize the critical role that YT York chillers play in achieving these goals. Their advanced technology, energy efficiency, and reliable performance make them an ideal choice for businesses seeking to improve IAQ and ensure the well-being of their occupants.

By maintaining optimal temperature and humidity levels, enhancing ventilation, reducing indoor pollutants, and supporting sustainable practices, YT York chillers contribute significantly to superior indoor air quality. For all your YT York chiller needs, contact Midwest Parts Center at +1 800 368 8385. Trust us to provide the high-quality products and expert support you need to maintain a comfortable and healthy indoor environment.

Upgrade Opportunities: Modernizing Your HVAC System with YT York Chillers

In today’s rapidly evolving commercial and industrial landscape, businesses must continually seek ways to improve efficiency, reduce costs, and enhance operational performance. One critical area that often gets overlooked is the HVAC system, which plays a vital role in maintaining optimal indoor conditions. Upgrading to a modern HVAC system with YT York chillers can significantly impact your facility’s performance and cost-efficiency. At Midwest Parts Center, we specialize in helping businesses leverage the advanced technology of YT York chillers to modernize their HVAC systems. For more information, contact us at +1 800 368 8385.

Understanding the Need for HVAC System Upgrades

1. Efficiency Improvements

Old Systems vs. New Technology

Older HVAC systems tend to be less efficient, consuming more energy and leading to higher operational costs. Advances in HVAC technology, particularly with YT York chillers, have introduced systems that are far more energy-efficient, resulting in significant cost savings over time.

Reduced Operational Costs

Upgrading to a YT York chiller can drastically cut down on energy usage, reducing utility bills and lowering the overall cost of operation. These chillers are designed to operate at peak efficiency, even under varying load conditions, ensuring optimal performance year-round.

2. Environmental Sustainability

Eco-Friendly Refrigerants

Older HVAC systems often use refrigerants that are harmful to the environment. YT York chillers, however, utilize environmentally friendly refrigerants with low Global Warming Potential (GWP), contributing to reduced environmental impact.

Lower Carbon Footprint

By upgrading to energy-efficient YT York chillers, businesses can significantly reduce their carbon footprint. This not only benefits the environment but also aligns with corporate sustainability goals, enhancing a company’s reputation as a responsible business.

3. Enhanced Performance and Reliability

Advanced Technology

YT York chillers incorporate cutting-edge technology that ensures reliable and consistent performance. Features such as advanced controls and real-time monitoring allow for precise temperature regulation and efficient operation.

Long-Term Durability

These chillers are built with high-quality materials and robust engineering, ensuring long-term durability and minimal maintenance requirements. This reliability means fewer disruptions and consistent performance over the lifespan of the equipment.

The Benefits of Upgrading to YT York Chillers

1. Energy Efficiency

High SEER Ratings

YT York chillers are designed with high Seasonal Energy Efficiency Ratio (SEER) ratings, which means they provide superior cooling output per unit of energy consumed. This translates to substantial energy savings and lower utility bills.

Variable Speed Drives

Many YT York chillers are equipped with variable speed drives that adjust the chiller’s output based on the cooling demand. This technology allows for more precise control, reducing energy waste and enhancing overall efficiency.

2. Cost Savings

Lower Maintenance Costs

Modern YT York chillers are designed for easy maintenance, with fewer moving parts and advanced diagnostics that simplify troubleshooting and repairs. This leads to lower maintenance costs and less downtime.

Incentives and Rebates

Upgrading to energy-efficient HVAC systems can make businesses eligible for various incentives and rebates from local utility companies and government programs. These financial incentives can offset the initial investment cost, making the upgrade more affordable.

3. Improved Indoor Air Quality

Advanced Filtration Systems

YT York chillers can be integrated with advanced air filtration systems that remove pollutants, allergens, and contaminants from the indoor air. This leads to healthier indoor environments, reducing the risk of respiratory issues and improving overall occupant well-being.

Consistent Temperature and Humidity Control

These chillers provide precise temperature and humidity control, maintaining comfortable indoor conditions and preventing issues such as mold growth and moisture-related damage.

4. Scalability and Flexibility

Modular Design

YT York chillers are available in modular designs, allowing businesses to scale their HVAC systems based on current needs and future growth. This flexibility ensures that the system can be expanded or adjusted as the business evolves.

Customizable Solutions

Midwest Parts Center works closely with clients to provide customized HVAC solutions tailored to their specific requirements. Whether it’s a new installation or an upgrade of an existing system, YT York chillers offer versatile options to meet diverse needs.

Steps to Upgrade Your HVAC System with YT York Chillers

1. Assessment and Planning

Initial Assessment

The first step in upgrading your HVAC system is to conduct a thorough assessment of your current setup. This includes evaluating the efficiency, performance, and condition of your existing equipment. Midwest Parts Center offers comprehensive assessments to identify areas for improvement and potential upgrade opportunities.

Planning and Budgeting

Once the assessment is complete, the next step is to plan the upgrade. This involves determining the scope of the project, selecting the appropriate YT York chiller models, and establishing a budget. Our team of experts will work with you to develop a detailed plan that aligns with your operational goals and financial considerations.

2. Selection of Equipment

Choosing the Right Chiller

Selecting the right YT York chiller is crucial for maximizing the benefits of the upgrade. Factors to consider include the cooling capacity, energy efficiency, and specific features required for your application. Midwest Parts Center offers a range of YT York chillers to suit various commercial and industrial needs.

Integration with Existing Systems

If you’re not opting for a complete overhaul, it’s essential to ensure that the new chillers can be seamlessly integrated with your existing HVAC systems. Our team will provide guidance on compatibility and integration, ensuring a smooth transition and minimal disruption.

3. Installation and Commissioning

Professional Installation

Proper installation is critical for the optimal performance of your new YT York chillers. Midwest Parts Center provides professional installation services, ensuring that all components are correctly installed and configured for maximum efficiency.

Testing and Commissioning

After installation, thorough testing and commissioning are conducted to verify that the system operates as intended. This includes checking for leaks, verifying temperature and humidity control, and ensuring that all controls and monitoring systems are functioning correctly.

4. Maintenance and Support

Regular Maintenance

To maintain the efficiency and longevity of your YT York chillers, regular maintenance is essential. Midwest Parts Center offers comprehensive maintenance plans tailored to your specific needs, ensuring that your HVAC system continues to operate at peak performance.

Ongoing Support

Our commitment to customer satisfaction extends beyond installation. We provide ongoing support and technical assistance to address any issues that may arise. Whether it’s routine maintenance, emergency repairs, or technical advice, our team is here to help.

Case Studies: Successful Upgrades with YT York Chillers

1. Manufacturing Facility Upgrade

Challenge

A large manufacturing facility was experiencing high energy costs and inconsistent cooling with their outdated HVAC system. The facility required a reliable solution that could provide efficient cooling and reduce operational expenses.

Solution

Midwest Parts Center conducted a thorough assessment and recommended upgrading to YT York chillers with variable speed drives. The new system provided precise temperature control and significantly reduced energy consumption.

Result

The manufacturing facility saw a 30% reduction in energy costs and improved indoor air quality. The consistent cooling also enhanced the comfort and productivity of the workforce, contributing to overall operational efficiency.

2. Office Building Modernization

Challenge

An office building with an aging HVAC system faced frequent breakdowns and high maintenance costs. The building management sought a modern solution that could provide reliable performance and improve indoor comfort.

Solution

We recommended replacing the old system with YT York chillers, integrating advanced air filtration systems to enhance indoor air quality. The installation was completed with minimal disruption to the building’s operations.

Result

The office building experienced a noticeable improvement in indoor air quality, with reduced allergens and contaminants. The new chillers provided reliable and efficient cooling, resulting in lower maintenance costs and enhanced occupant satisfaction.

3. Data Center Cooling Upgrade

Challenge

A data center required an efficient and reliable cooling system to maintain optimal operating conditions for its equipment. The existing system was outdated and struggling to keep up with the cooling demand.

Solution

Midwest Parts Center recommended upgrading to high-efficiency YT York chillers with advanced control systems. The new chillers were designed to provide consistent cooling and support the data center’s high-demand environment.

Result

The data center achieved stable and efficient cooling, ensuring the reliability of its critical operations. The energy-efficient YT York chillers also reduced the facility’s overall energy consumption, contributing to significant cost savings.

Upgrading your HVAC system with YT York chillers offers numerous benefits, including enhanced energy efficiency, cost savings, improved indoor air quality, and reliable performance. At Midwest Parts Center, we specialize in helping businesses in commercial and industrial sectors modernize their HVAC systems with advanced YT York chiller technology. Our team of experts is dedicated to providing tailored solutions that meet your specific needs and operational goals.

For more information on how YT York chillers can transform your HVAC system, contact Midwest Parts Center at +1 800 368 8385. Trust us to deliver the quality, reliability, and support that your business needs to thrive in today’s competitive landscape.