When your commercial or industrial HVAC system needs a critical replacement part, time is of the essence. You can’t afford to wait weeks, gamble on compatibility, or risk installing unreliable components. That’s where choosing the right York Replacement Parts Supplier becomes essential.

Searches for “York Replacement Parts Supplier near me” have grown significantly in recent years—and for good reason. Facility managers, building engineers, and HVAC professionals are realizing the value of working with a local, experienced, and reliable supplier who understands the specific demands of York systems.

If you’ve been wondering what to look for in a reliable partner when sourcing York replacement parts, you’re in the right place. In this post, we’ll cover the five most important qualities that define a dependable York Replacement Parts Supplier—and explain why Midwest Parts Center consistently meets and exceeds them.

Why Choosing the Right York Replacement Parts Supplier Matters

Your York HVAC system isn’t just another machine—it’s the backbone of your facility’s comfort, efficiency, and sometimes, mission-critical operations. Whether it’s a YT chiller, air handler, rooftop unit, or VAV box, these systems rely on precision-engineered parts to perform as intended.

Cutting corners or trusting inexperienced vendors can lead to:

- Downtime

- Void warranties

- Increased energy bills

- Emergency repairs

So when you search for a “York Replacement Parts Supplier near me,” don’t just choose the closest option—choose the most qualified one.

Let’s explore the top 5 things you should expect from a trusted York Replacement Parts Supplier.

1. In-Depth Knowledge of York Systems

First and foremost, a great York Replacement Parts Supplier must have comprehensive expertise in York equipment. That includes understanding:

- The full York product catalog

- Compatibility between models and generations

- Proper diagnostics and troubleshooting

- Common failure points and upgrade opportunities

At Midwest Parts Center, our specialists work with York systems exclusively in commercial and industrial settings. We understand the engineering behind York chillers, air systems, and packaged units. We can identify parts quickly—even for older or hard-to-find models.

Why This Matters:

Imagine ordering a fan motor, compressor sensor, or control board—only to find it doesn’t fit or isn’t compatible. That mistake costs time, money, and trust. By working with a team that knows York systems inside and out, you prevent those headaches before they start.

📞 Have a question about your York system? Call +1 800 368 8385 and speak directly to a York parts expert at Midwest Parts Center.

2. Access to Authentic York Replacement Parts

There’s a big difference between “compatible” and “genuine.” A real York Replacement Parts Supplier should provide only OEM-certified parts—not third-party knockoffs that might compromise your system.

At Midwest Parts Center, we carry only York-authorized replacement parts. That means:

- Factory-tested for reliability and performance

- Guaranteed compatibility with York equipment

- Backed by original equipment warranties

This includes everything from:

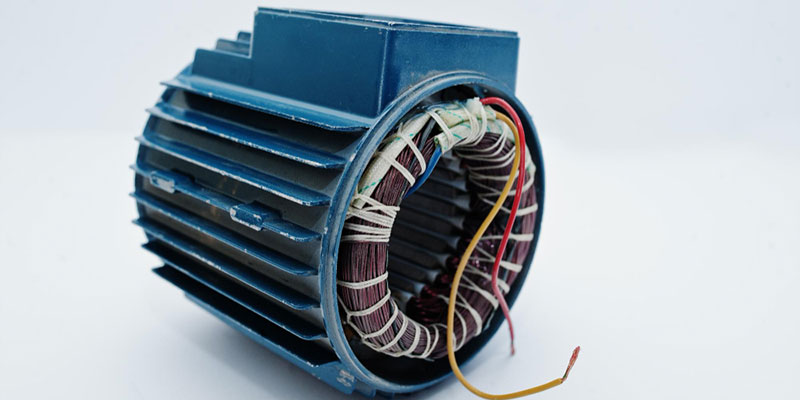

- Compressors and motor assemblies

- Control boards and sensors

- Valves, gaskets, and seals

- Bearings, belts, and filters

- And more for all York commercial product lines

Why OEM Matters:

Using non-genuine parts may lead to poor system performance, faster degradation, and voided warranties. In contrast, York Replacement Parts maintain your equipment’s original engineering standards—preserving your investment and long-term reliability.

3. Fast Turnaround and Local Availability

When you search for a “York Replacement Parts Supplier near me,” speed is a top priority. Your HVAC system may be down, or you might need parts for scheduled maintenance within a narrow window.

A trusted supplier should offer:

- Same-day or next-day shipping

- In-stock inventory of high-demand parts

- Emergency service and fulfillment

- Regional availability for faster response

At Midwest Parts Center, we understand that time is money. That’s why we keep a robust local inventory and offer expedited order processing for all York replacement parts.

Real-World Example:

Recently, a regional hospital’s York chiller experienced a sensor failure that threatened their cooling load. We identified the exact OEM part, processed the order within minutes, and arranged for same-day delivery—avoiding a potential shutdown.

That’s the type of rapid support you should expect from your York Replacement Parts Supplier.

4. Dedicated Customer Support and Technical Guidance

Your partner shouldn’t just sell parts—they should solve problems. A high-quality York Replacement Parts Supplier provides personalized support, technical insight, and project-specific guidance.

At Midwest Parts Center, we pride ourselves on being more than a parts warehouse. We are an extension of your operations team, offering:

- Help identifying unknown part numbers

- Troubleshooting assistance

- Retrofit consultation

- Preventive maintenance planning

Our experienced professionals understand the stakes in commercial and industrial HVAC environments and deliver tailored solutions—not guesswork.

📞 Need guidance? Call +1 800 368 8385 to speak with one of our York-trained specialists.

5. Proven Track Record and Industry Reputation

When selecting a York Replacement Parts Supplier, don’t overlook their reputation. Longevity, client testimonials, and repeat business all signal that you’re dealing with a dependable partner.

Midwest Parts Center has earned its reputation through:

- Years of hands-on experience in commercial and industrial markets

- Long-standing relationships with facility managers, contractors, and engineers

- Positive feedback from a wide variety of sectors—healthcare, education, manufacturing, retail, and more

We are known not just for delivering parts, but for delivering solutions that keep systems running, costs under control, and compliance intact.

What to Avoid in a York Replacement Parts Supplier

Knowing what not to accept is just as important. Be wary of suppliers that:

- Offer non-OEM or “compatible” parts without explanation

- Can’t verify part numbers or system compatibility

- Have slow response times or minimal inventory

- Offer little or no technical support

- Don’t specialize in commercial or industrial systems

Your HVAC systems are too critical to trust to anyone but an experienced, certified partner.

Bonus: Supporting Your Long-Term HVAC Strategy

A quality York Replacement Parts Supplier doesn’t just fix today’s issue—they help you prepare for the future. At Midwest Parts Center, we assist clients in:

- Building a parts replacement roadmap

- Budgeting for lifecycle maintenance

- Upgrading older systems with newer York innovations

- Understanding regulatory requirements (like refrigerant changes)

This strategic approach helps you reduce total cost of ownership, improve system reliability, and minimize emergency calls.

Frequently Asked Questions (FAQ)

Q: Can Midwest Parts Center ship parts nationwide?

Yes! While we serve clients locally, our logistics network allows us to ship York Replacement Parts to facilities across the country with expedited delivery options.

Q: How do I identify the correct York part number?

You can call us at +1 800 368 8385 with your equipment’s model and serial number, and our experts will do the rest.

Q: What if I need help installing the part?

We provide full documentation with all parts, and we can refer you to certified York technicians in your region for support if needed.

Q: Does Midwest Parts Center work with facility managers and contractors?

Absolutely. We regularly partner with contractors, facility engineers, and building managers to streamline sourcing and keep systems operating at peak performance.

Why Midwest Parts Center Is Your Ideal York Replacement Parts Supplier

When you choose Midwest Parts Center as your York Replacement Parts Supplier, you’re getting:

✅ Expert knowledge of all York commercial and industrial systems

✅ Fast, accurate parts fulfillment with OEM-certified components

✅ Personalized service tailored to your facility’s unique needs

✅ Reliable support from professionals who understand your equipment

✅ Peace of mind knowing you’re protecting your investment

We don’t just supply parts—we build partnerships that last.

📞 Call +1 800 368 8385 now to speak with a York specialist and get the parts you need—delivered fast, fitted right, and built to last.

Final Thoughts: Don’t Settle—Choose the Right Partner

Finding the right York Replacement Parts Supplier near me shouldn’t be a gamble. It should be a strategic decision rooted in quality, experience, and trust.

With Midwest Parts Center, you get all of that—and more. We’re here to make sure your York systems stay reliable, efficient, and compliant for years to come.

Whether you’re dealing with an urgent breakdown or planning your next maintenance cycle, make sure you’re backed by a partner who knows your equipment better than anyone else.

✅ York expertise.

✅ OEM parts.

✅ Fast service.

✅ Industrial-grade support.

📞 Call Midwest Parts Center today at +1 800 368 8385 — your trusted York Replacement Parts Supplier in the commercial and industrial HVAC space.

Why Our York Replacement Parts Supplier Services Are the Best Choice for Your HVAC System

If you’re managing a commercial or industrial facility, you already know that your HVAC system is not just another utility—it’s the heart of your operation. When that system goes down or shows signs of wear, the pressure to fix it quickly and correctly is immense. That’s where choosing the right York Replacement Parts Supplier becomes not only essential but business-critical.

At Midwest Parts Center, we understand those pressures better than anyone. As a trusted and long-standing York Replacement Parts Supplier, we’ve built our reputation on reliability, expert service, and a fierce commitment to supporting commercial and industrial HVAC operations.

With more facilities now relying on York systems due to their robust design and long-term energy efficiency, the need for an experienced supplier who provides authentic York parts has never been greater. In this post, we’ll explore exactly why our York Replacement Parts Supplier services stand out from the rest, and how we help you protect your HVAC investment, lower operating costs, and ensure uninterrupted comfort and performance.

What Does a York Replacement Parts Supplier Do—And Why Does It Matter?

Before we dive into why Midwest Parts Center is your best choice, let’s clarify the role of a York Replacement Parts Supplier. We’re not just here to sell a few parts—we’re an essential extension of your facility maintenance strategy.

A quality York Replacement Parts Supplier offers:

- Fast, accurate sourcing of genuine York components

- Knowledge of part compatibility, especially with older systems

- Technical guidance for maintenance and repairs

- Access to high-demand inventory

- Peace of mind that you’re not using substandard third-party alternatives

For organizations operating York HVAC systems across factories, office buildings, data centers, hospitals, or schools, the reliability of your parts supplier can directly affect your facility’s uptime and energy efficiency.

1. We Specialize Exclusively in Commercial and Industrial HVAC Systems

Unlike general suppliers who serve a wide range of customers without deep knowledge of any single domain, Midwest Parts Center focuses exclusively on commercial and industrial environments. We understand the scale, urgency, and complexity involved in large-scale HVAC operations.

That specialization makes a world of difference when choosing a York Replacement Parts Supplier. From understanding the intricate components in a YT chiller to identifying the correct variable frequency drive for a York rooftop unit, our team has done it all—and we do it every day.

Real Impact:

When a large manufacturing plant faced a system shutdown due to a faulty sensor in their York chiller, our team not only sourced the exact OEM replacement part but walked them through the installation steps. Within hours, their system was up and running—saving tens of thousands in downtime losses.

📞 Need commercial HVAC support? Call us today at +1 800 368 8385 and talk to a York parts specialist.

2. Authentic York Parts—No Guesswork, No Knockoffs

One of the biggest mistakes a facility can make is installing non-genuine parts into a York system. While some suppliers push third-party components to increase profit margins, those parts can:

- Void manufacturer warranties

- Cause system malfunctions

- Reduce energy efficiency

- Shorten the life of your HVAC system

At Midwest Parts Center, we are committed to supplying only genuine York replacement parts, ensuring full compatibility and optimal system performance.

Whether it’s:

- Compressors

- Fan motors

- Thermostats

- Expansion valves

- Gaskets

- Control boards

- You can rest assured every part we provide is engineered and approved by York for use in their systems.

Why It Matters:

Even minor components, when substituted with inferior parts, can lead to cascading failures. A failed gasket might cause a refrigerant leak. A third-party sensor might give inaccurate readings that lead to overuse of energy.

A reliable York Replacement Parts Supplier doesn’t just send you something that fits—it ensures it functions flawlessly.

3. Rapid Fulfillment and Local Availability

When you search for a “York Replacement Parts Supplier near me,” you’re often doing so with urgency. Time is money—and in HVAC, downtime can mean discomfort, lost productivity, and compliance violations.

Midwest Parts Center takes pride in our rapid order fulfillment system. With a strong regional distribution network and real-time inventory tracking, we can often ship parts the same day or next day.

Our Promise:

We never leave you waiting. If the part you need isn’t immediately in stock, we’ll provide you with realistic lead times, and keep you informed every step of the way.

And if you’re in a true emergency, our team will do everything possible to expedite shipping, including after-hours processing and weekend coordination.

4. Expert Support That Goes Beyond the Part

Selling parts is easy. Supporting facilities with technical accuracy, professionalism, and care is what separates the great from the good.

Our staff doesn’t just process orders. Every member of our team is trained to assist with:

- Part identification

- Compatibility confirmation

- Installation guidance

- Preventive maintenance tips

As a specialized York Replacement Parts Supplier, we know the ins and outs of York’s entire line—from legacy models to the newest smart HVAC integrations.

We’re here to be your trusted advisor, not just a vendor.

5. We Understand Your Business Pressures

Whether you’re maintaining a hospital, operating a school district, or overseeing manufacturing environments, your HVAC system is critical to your core operations.

At Midwest Parts Center, we understand:

- You may need multiple parts for scheduled maintenance windows

- Downtime is expensive and stressful

- You can’t always afford to wait for factory production

- Budgeting and planning matter just as much as the emergency fix

As your York Replacement Parts Supplier, we aim to be proactive, not reactive. We’ll help you stock key spares, create a maintenance parts roadmap, and even help you forecast based on previous system behavior.

6. We’re Easy to Reach—And Ready to Help

No one likes chasing down unresponsive suppliers. At Midwest Parts Center, we make it easy to get what you need.

- 📞 Toll-Free Number: +1 800 368 8385

- 🕒 Prompt response time

- 💬 Friendly, knowledgeable staff

- 📦 Fast order confirmation

You’ll always speak to a real person who can provide real answers—not a confusing automated system.

7. Built on Trust and Reputation

In the world of industrial HVAC, trust isn’t built overnight—it’s earned over years of consistent service, reliable delivery, and problem-solving expertise.

Our clients stay with us because we:

- Stand by our recommendations

- Offer fair and transparent pricing

- Deliver as promised

- Understand the full HVAC lifecycle

We’re proud that Midwest Parts Center is considered the go-to York Replacement Parts Supplier by commercial and industrial customers across the region.

8. No Surprises—Just Proven Performance

Some suppliers make promises they can’t keep. They’ll say a part is in stock, then call you two days later with bad news. Others provide vague part numbers or unverified specs that lead to costly mistakes.

That’s not how we operate.

At Midwest Parts Center, our process is designed for precision:

- We confirm part numbers before processing

- Provide written confirmations and delivery timelines

- Send tracking information promptly

- Offer support through the entire lifecycle of your order

There’s no guessing—just confidence.

9. Full Lifecycle Support for York HVAC Systems

Being a great York Replacement Parts Supplier isn’t just about delivering one part—it’s about helping you get the most out of your HVAC system for years to come.

We can assist with:

- Replacing aging components in legacy systems

- Sourcing obsolete or hard-to-find York parts

- Planning for future system upgrades

- Identifying efficiency-boosting parts like VFDs or advanced sensors

Whether your goal is sustainability, compliance, or long-term cost savings, Midwest Parts Center is your long-term HVAC partner.

10. One Call Does It All—Midwest Parts Center Is Your Solution

At the end of the day, your job is hard enough without chasing parts, guessing at compatibility, or dealing with unreliable suppliers.

When you work with Midwest Parts Center, your job gets easier. You’ll get:

✅ Fast answers

✅ Reliable parts

✅ Knowledgeable support

✅ Proven performance

And above all, you’ll have a York Replacement Parts Supplier you can trust.

📞 Call +1 800 368 8385 now and experience the Midwest Parts Center difference for yourself.

Final Thoughts: Don’t Settle—Partner With the Best

Your HVAC system is one of the most valuable and mission-critical assets your business relies on. Why risk it with subpar parts or underqualified suppliers?

Make the smart choice. Choose a York Replacement Parts Supplier who:

- Specializes in commercial and industrial HVAC

- Offers authentic OEM parts

- Provides fast and dependable service

- Delivers unmatched technical expertise

Midwest Parts Center is not just a supplier—we are your HVAC partner, your efficiency strategist, and your system safeguard.

📞 Ready to get started? Call +1 800 368 8385 or reach out to our team and let us help you power performance with genuine York parts.