Coolant is one of the most crucial HVAC parts required to keep a system running. Healthy—anti-corrosive properties of coolant safeguard system components from wear and tear. The material keeps a climate control system running smoothly by preventing dust and other debris from accumulating. Maintaining your York VSD Coolant is the best gift you could give your industrial environs.

Coolant is one of the most crucial HVAC parts required to keep a system running. Healthy—anti-corrosive properties of coolant safeguard system components from wear and tear. The material keeps a climate control system running smoothly by preventing dust and other debris from accumulating. Maintaining your York VSD Coolant is the best gift you could give your industrial environs.

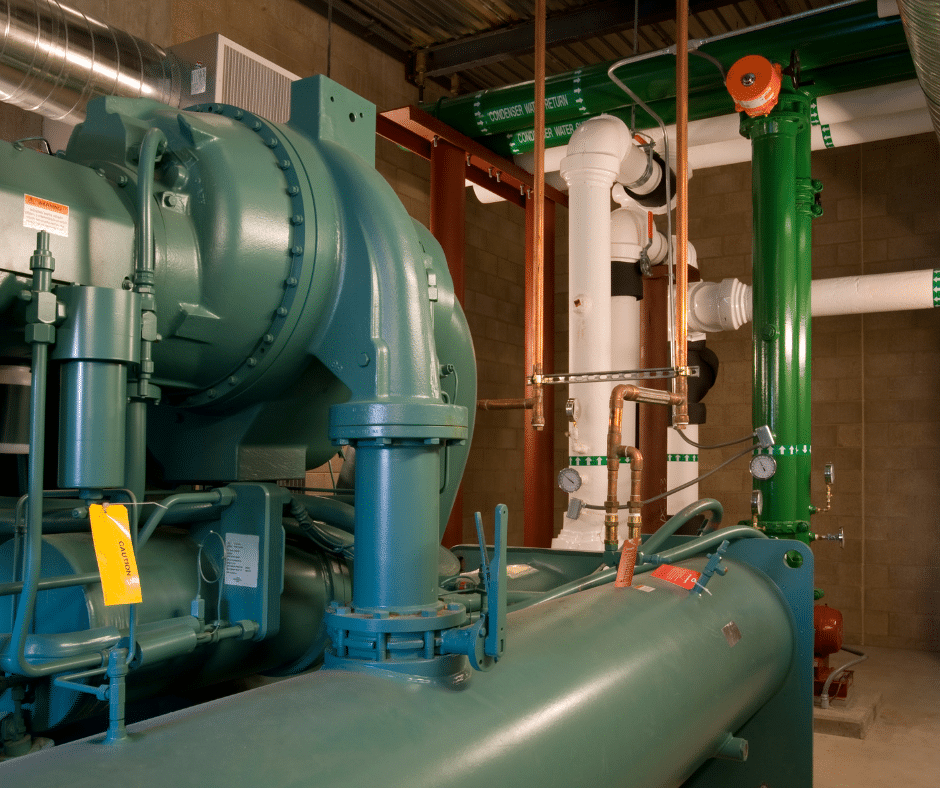

Because your chiller is vital to your HVAC system and business, it is recommendable to use high-quality replacement components made specifically for your machine.

How to repair and maintain your York VSD Coolers

You may need to replace your chiller’s York VSD Coolant if they are not working correctly. If you feel that your system requires coolant, it’s best not to try to fix it on your own. Instead, make arrangements for professionals to take care of the problem.

These professionals are versed in the intricacies of chillers. They can assist you in deciding the parts you’ll need for equipment repairs or maintenance. YORK equipment’s cooling systems may be complicated, but the components that make up the systems are aligned together. When using your chiller, stick with YORK products alone.

Suitable Uses of York VSD Coolant

Commercial and industrial are the best markets for York’s chillers. To enhance the chiller’s performance, engineers used York VSD coolant. Due to the high demand for a clean and purified environment, large establishments widely use the York brand. Because they are:

Commercial and industrial are the best markets for York’s chillers. To enhance the chiller’s performance, engineers used York VSD coolant. Due to the high demand for a clean and purified environment, large establishments widely use the York brand. Because they are:

- Energy-efficient,

- Very effective,

- And long-lasting.

York VSD coolers are an excellent choice for commercial and industrial buildings that require a lot of cooling.

Coolant York VSD

The purpose of air conditioners is to remove humidity from the air, thereby improving the quality of the indoor environment. Chillers use York VSD coolant, which keeps them running smoothly and efficiently. Regardless of outside temperatures shifting, HVAC equipment regulates the expected airflow level in the building’s interior; ventilation and air conditioning systems are essential for purified air requirements.

For clean and comfortable air standards, york is preferred in a wide range of establishments such as:

- Hospitals

- Educational institutions

- Foodservice establishments and hotels,

- And the manufacturing industry, among many others.

The only drawback is that it has a significant amount of energy consumption. Coolers take a lot of electricity when it’s hot outside, so you need to be prepared to maintain them when energy costs rise. Also, coolers impact operating expenses, but they’re also good for the environment.

Heat Extraction Maintenance

Adopting a heat extraction process is a great way to offer a cooling effect while maintaining a constant temperature. Aside from that, it is a labor-intensive process with many functions. While converting liquids and vapors, the coolant serves as an essential heat transfer component. As a result, many businesses have suffered from excessive energy costs due to their efforts to manage York VSD coolant for their chillers and the VSD coolant.

Adopting a heat extraction process is a great way to offer a cooling effect while maintaining a constant temperature. Aside from that, it is a labor-intensive process with many functions. While converting liquids and vapors, the coolant serves as an essential heat transfer component. As a result, many businesses have suffered from excessive energy costs due to their efforts to manage York VSD coolant for their chillers and the VSD coolant.

York VSD coolants are seen as an alternative unit in commercial and industrial facilities; chillers cannot satisfy the substantial transfers required to generate the necessary clean and sanitary environment without high-quality coolant.

Our goal is to provide the best York VSD coolant to our clients and customers. Don’t hesitate to get in touch with us if you have any questions.

In particular, the HVAC system maintains a cool environment within the space. Air conditioning systems aim to remove moisture from the air to make it more pleasant and relaxing inside.

In particular, the HVAC system maintains a cool environment within the space. Air conditioning systems aim to remove moisture from the air to make it more pleasant and relaxing inside.

Besides, chillers are mounted in tremendous establishments, including the hospitals, restaurants, hotels, learning institutions, manufacturing industries, and many others; they apply coolers to provide clean and comfortable air standards. However, the only challenge is that they utilize a considerable quantity of energy due to their large sizes. During hot times, a cooler might use at least fifty percent of electricity; rising energy bills mean that the cost of operations will also increase. Also, coolers influence the cost of operation, but they are also very gentle to the environment.

Besides, chillers are mounted in tremendous establishments, including the hospitals, restaurants, hotels, learning institutions, manufacturing industries, and many others; they apply coolers to provide clean and comfortable air standards. However, the only challenge is that they utilize a considerable quantity of energy due to their large sizes. During hot times, a cooler might use at least fifty percent of electricity; rising energy bills mean that the cost of operations will also increase. Also, coolers influence the cost of operation, but they are also very gentle to the environment.

Midwest York VSD Coolant Centre is the right partner when looking for VSD parts or buying the best component to improve your chiller performance. The

Midwest York VSD Coolant Centre is the right partner when looking for VSD parts or buying the best component to improve your chiller performance. The  You can avoid replacing the entire power assembly by initially identifying the right power cables when buying equipment parts and disconnecting the main power cable before connecting them. You must also change fluids from the system, and replace the old fluids by changing them with fresh fluids. These fluids are mainly coolant oils. Using the right coolant oil is essential to the operation of the chiller.

You can avoid replacing the entire power assembly by initially identifying the right power cables when buying equipment parts and disconnecting the main power cable before connecting them. You must also change fluids from the system, and replace the old fluids by changing them with fresh fluids. These fluids are mainly coolant oils. Using the right coolant oil is essential to the operation of the chiller. Connect the whole new assembly to power cables and make sure the shipping tape and all wires are connected tight enough and the pipes are connected to the right buttons. Take care of the plugs, and inhibitors, tie all the hanging wires and place the VSD so that everything fits in, the chargers m the inverter, and the compressors following each other for easy control. Ensuring that the screws fit in their right parts Ensuring that the system is properly connected is vital for its durability.

Connect the whole new assembly to power cables and make sure the shipping tape and all wires are connected tight enough and the pipes are connected to the right buttons. Take care of the plugs, and inhibitors, tie all the hanging wires and place the VSD so that everything fits in, the chargers m the inverter, and the compressors following each other for easy control. Ensuring that the screws fit in their right parts Ensuring that the system is properly connected is vital for its durability.

The

The  Chillers are installed in many facilities; restaurants, hospitals, manufacturing firms, and hotels utilize chillers to offer a comfortable air level. Although the problem is that they use an immense amount of energy because they are so colossal. During the successful seasons, a chiller may use at least fifty percent of electricity. Escalating energy expenses imply that operational cost will also increase. Not only do chillers affect operating expenditure, but they also have environmental changes.

Chillers are installed in many facilities; restaurants, hospitals, manufacturing firms, and hotels utilize chillers to offer a comfortable air level. Although the problem is that they use an immense amount of energy because they are so colossal. During the successful seasons, a chiller may use at least fifty percent of electricity. Escalating energy expenses imply that operational cost will also increase. Not only do chillers affect operating expenditure, but they also have environmental changes. Facilities are aware of the effect high consumption of energy can bring; they manage Midwest York VSD coolant for chillers; the VSD coolant is an incentive for chillers. The material helps a chiller process air effectively. Besides, the coolant aids in facilitating the flow of air in air conditioner systems. The York VSD model uses vapor compression; the system produces heat from the compressor’s water and heat. Commercial premises choose the chiller model because they need minimal maintenance compared to other models, are energy conservative, and provide high-quality cooling.

Facilities are aware of the effect high consumption of energy can bring; they manage Midwest York VSD coolant for chillers; the VSD coolant is an incentive for chillers. The material helps a chiller process air effectively. Besides, the coolant aids in facilitating the flow of air in air conditioner systems. The York VSD model uses vapor compression; the system produces heat from the compressor’s water and heat. Commercial premises choose the chiller model because they need minimal maintenance compared to other models, are energy conservative, and provide high-quality cooling.

York manufactures chillers used in commercial and industrial settings. The

York manufactures chillers used in commercial and industrial settings. The  HVAC units provide cool air inside buildings. The role of air-conditioning units is to remove humidity from the atmosphere to make indoor air comfortable.

HVAC units provide cool air inside buildings. The role of air-conditioning units is to remove humidity from the atmosphere to make indoor air comfortable.  Because facilities are aware of the impact of high energy consumption, they maintain

Because facilities are aware of the impact of high energy consumption, they maintain

Finding parts that fit in York HVAC units is not complicated. Midwest Parts Center, as a supplier of

Finding parts that fit in York HVAC units is not complicated. Midwest Parts Center, as a supplier of  systems. The coolant allows for a more efficient operation of the ventilation system. Since coolant also contributes to energy saving, it also reduces operating costs. Energy costs are a key factor for companies dealing with a business budget. Since air-conditioning is a major cost factor, appliances often need to offer cost savings.

systems. The coolant allows for a more efficient operation of the ventilation system. Since coolant also contributes to energy saving, it also reduces operating costs. Energy costs are a key factor for companies dealing with a business budget. Since air-conditioning is a major cost factor, appliances often need to offer cost savings.  A service technician can provide coolant to reduce the potential damage to a plant. Indeed, some problems with a cooling system can be insignificant. Minor, trivial A / C problems can quickly get worse if left unattended. The longer a unit remains unrepaired, the more damage a system will suffer. Standby technicians are available throughout the year to meet the challenges of cooling systems.

A service technician can provide coolant to reduce the potential damage to a plant. Indeed, some problems with a cooling system can be insignificant. Minor, trivial A / C problems can quickly get worse if left unattended. The longer a unit remains unrepaired, the more damage a system will suffer. Standby technicians are available throughout the year to meet the challenges of cooling systems.

Finding parts that fit in York HVAC units is not difficult. Midwest Parts Center can assist as a supplier of

Finding parts that fit in York HVAC units is not difficult. Midwest Parts Center can assist as a supplier of

A service technician can provide coolant to reduce potential damage to a plant. In fact, some problems with a cooling system can be insignificant. Minor trivial A / C problems can quickly get worse if left unattended. The longer a unit is not repaired, the more damage a system will suffer. On-call technicians are available all year round to meet the challenges of cooling systems.

A service technician can provide coolant to reduce potential damage to a plant. In fact, some problems with a cooling system can be insignificant. Minor trivial A / C problems can quickly get worse if left unattended. The longer a unit is not repaired, the more damage a system will suffer. On-call technicians are available all year round to meet the challenges of cooling systems.

Finding parts that fit into York HVAC units is not troublesome. Midwest Parts Center can help as a supplier of

Finding parts that fit into York HVAC units is not troublesome. Midwest Parts Center can help as a supplier of  Coolant is an important component of York HVAC systems. The material is used as a finishing material for air-conditioning. Coolant allows for the more efficient operation of the air systems. As coolant also helps save energy, it also lowers operating costs. Energy costs are a key factor for companies that manage an operating budget. Because air-conditioning is a significant cost factor, appliances are needed to save wherever possible.

Coolant is an important component of York HVAC systems. The material is used as a finishing material for air-conditioning. Coolant allows for the more efficient operation of the air systems. As coolant also helps save energy, it also lowers operating costs. Energy costs are a key factor for companies that manage an operating budget. Because air-conditioning is a significant cost factor, appliances are needed to save wherever possible. A service technician can supply coolant to reduce potential damage to a plant. In reality, some problems with a cooling system can be insignificant. However, minor trivial A/C problems can quickly worsen if left unattended. The longer a unit remains unrepaired, the more damage a system will suffer. Standby technicians are available year-round to meet the challenges of cooling systems.

A service technician can supply coolant to reduce potential damage to a plant. In reality, some problems with a cooling system can be insignificant. However, minor trivial A/C problems can quickly worsen if left unattended. The longer a unit remains unrepaired, the more damage a system will suffer. Standby technicians are available year-round to meet the challenges of cooling systems.