In the demanding world of commercial and industrial HVAC systems, the quality of your components determines the reliability of your entire operation. From large-scale factories and hospitals to data centers and office complexes, maintaining an efficient HVAC system isn’t optional—it’s a necessity. The secret to ensuring consistent performance and longevity lies in using authentic replacement parts from a trusted York parts supplier.

York HVAC Components from an Authorized York Parts Supplier

That’s where Midwest Parts Center comes in. As a leading York parts supplier serving commercial and industrial sectors across the United States, Midwest Parts Center provides access to genuine York components that meet the highest standards of quality, performance, and durability.

📞 Toll-Free Number: +1 800 368 8385

Whether you’re performing a system upgrade, replacing a damaged part, or planning preventative maintenance, choosing the right supplier makes all the difference. Let’s explore why working with an authorized York parts supplier like Midwest Parts Center is the key to keeping your HVAC systems running efficiently for years to come.

Why Genuine York Parts Matter for Your HVAC System

Your HVAC system is a complex network of components engineered to perform in perfect harmony. Each part—whether it’s a compressor, coil, or thermostat—plays a critical role in maintaining optimal climate conditions. Using non-genuine or third-party parts can disrupt that balance, leading to inefficiencies, malfunctions, or even costly breakdowns.

Here’s why it’s crucial to rely on genuine York parts:

-

Perfect Compatibility

Every authentic York component is designed to fit seamlessly into York HVAC systems. There’s no guesswork, no adjustments, and no risk of performance loss. -

Extended Equipment Lifespan

Genuine York parts help prevent premature wear and tear, ensuring your system lasts longer and operates at peak efficiency. -

Energy Efficiency

Authentic components help your HVAC units maintain their energy ratings, reducing utility costs and promoting sustainability. -

Warranty Protection

Non-genuine parts often void manufacturer warranties. Genuine parts keep your coverage intact, protecting your investment. -

Peace of Mind

With real York parts, you can rest easy knowing your system is supported by quality and precision engineering.

When you buy from Midwest Parts Center, an authorized York parts supplier, you’re not just purchasing parts—you’re investing in the continued reliability of your HVAC system.

Midwest Parts Center — Your Trusted York Parts Supplier

As a dedicated York parts supplier, Midwest Parts Center has become a go-to resource for businesses that depend on high-performing HVAC systems. Our company specializes in commercial and industrial applications, offering a complete line of authentic York components that keep facilities operating efficiently and safely.

Why Choose Midwest Parts Center?

-

Authorized Access to Genuine York Parts

We are proud to be an authorized York parts supplier, which means our customers receive 100% authentic, OEM-certified components. We never deal in imitations or generic alternatives. -

Extensive Inventory for Fast Fulfillment

From chillers to rooftop units, we stock a wide selection of York parts for all types of systems. Whether you need a replacement compressor, fan motor, coil, or sensor, Midwest Parts Center has you covered. -

Nationwide Shipping and Support

We understand that downtime costs money. That’s why we offer quick delivery across the USA, helping you get your systems up and running as soon as possible. -

Expert Assistance and Technical Knowledge

Our team of HVAC specialists understands York systems inside and out. We help clients identify the right part the first time, saving valuable time and effort. -

Dedicated Customer Care

When you contact Midwest Parts Center, you won’t be passed around between departments—you’ll get real answers from professionals who care about your business.

📞 Call our team today at +1 800 368 8385 for expert assistance with your next York parts order.

The Role of a York Parts Supplier in HVAC Maintenance

Maintenance is at the heart of every high-performing HVAC system. Over time, even the most reliable equipment experiences wear. Filters clog, belts loosen, and electrical components degrade. Replacing these parts with genuine York components ensures that your system maintains its original performance and efficiency.

As a professional York parts supplier, Midwest Parts Center helps clients manage this maintenance cycle effectively. Our genuine parts help:

-

Reduce energy costs by keeping systems running efficiently.

-

Prevent unexpected failures through proactive component replacement.

-

Extend equipment life, delaying the need for full system replacements.

-

Ensure consistent air quality and comfort in commercial spaces.

We work with a variety of industrial and commercial clients who rely on York systems for climate control, refrigeration, and ventilation. Our expertise ensures that each part we supply contributes to smoother operations and lower long-term costs.

Industries That Depend on Midwest Parts Center

As an experienced York parts supplier, Midwest Parts Center serves diverse industries that depend on reliable HVAC systems for day-to-day operations.

Some of the sectors we support include:

-

Manufacturing Plants – Precision climate control keeps machinery and materials in ideal conditions.

-

Healthcare Facilities – Hospitals and labs rely on HVAC systems for safety and comfort.

-

Data Centers – Maintaining precise temperature and humidity levels is crucial for server protection.

-

Educational Institutions – Consistent air quality and comfort enhance learning environments.

-

Corporate and Retail Spaces – Reliable systems ensure comfort for customers and employees alike.

Each industry has unique demands, but they all rely on one constant: the reliability of genuine York parts supplied by Midwest Parts Center.

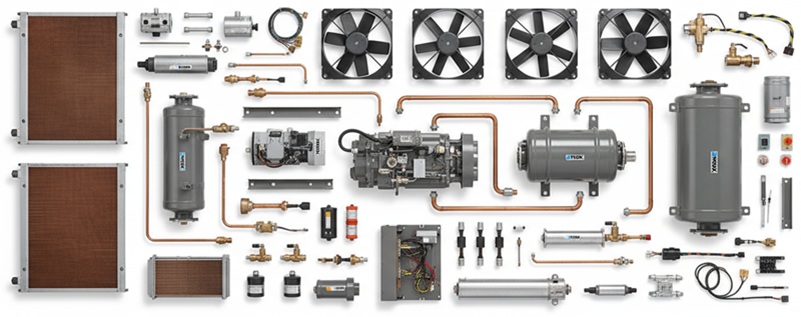

Common York Components We Supply

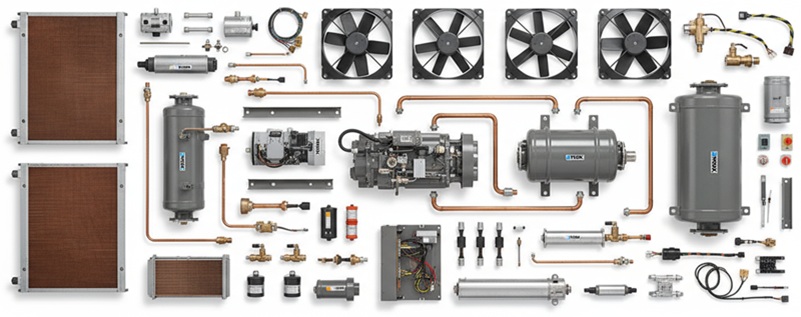

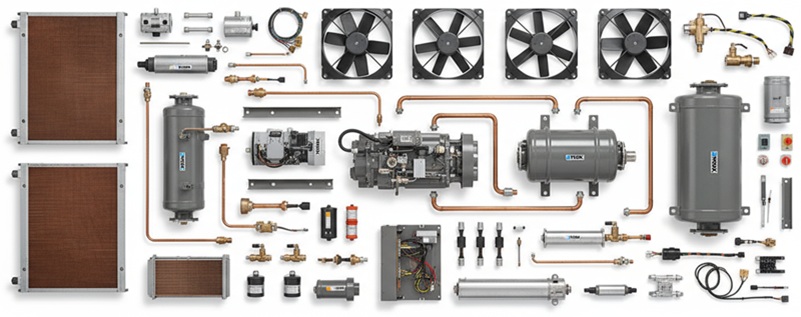

At Midwest Parts Center, our inventory covers every essential York component your HVAC system might require.

Here are some of the most requested parts we provide:

-

Compressors: The powerhouse of HVAC systems, responsible for maintaining cooling performance.

-

Coils: Enable efficient heat exchange for consistent temperature control.

-

Filters: Keep air clean and protect internal components from dust and debris.

-

Thermostats and Sensors: Ensure precise monitoring and environmental regulation.

-

Motors and Blades: Maintain strong airflow and ventilation.

-

Valves and Switches: Support seamless system operation and safety.

-

Refrigeration Components: Maintain proper cooling in chillers and refrigeration units.

Every part we deliver comes directly from York’s authorized supply chain — no knockoffs, no imitations, just authentic quality from a trusted York parts supplier.

The Risk of Non-Genuine Components

Using non-genuine or counterfeit HVAC parts might save you a few dollars upfront, but it can cost you thousands later.

Here’s what can happen when you choose unauthorized replacements:

-

Performance Loss – Non-genuine parts rarely meet York’s precision engineering standards.

-

Increased Energy Consumption – Poor-quality parts can reduce system efficiency.

-

Frequent Repairs – Imitation components wear out faster, leading to repeated maintenance issues.

-

Voided Warranty – Unauthorized parts can nullify your system’s warranty coverage.

-

Reduced Safety – Inferior parts may fail under pressure, creating safety risks in critical environments.

To protect your investment and ensure lasting performance, always buy from a certified York parts supplier like Midwest Parts Center.

Energy Efficiency and Sustainability with York Components

Sustainability is no longer just a buzzword—it’s a responsibility. Businesses across the USA are working to lower energy use and reduce carbon emissions. York’s HVAC technology is designed with efficiency in mind, and genuine parts are a key part of that commitment.

When you use authentic components from Midwest Parts Center, your system operates exactly as designed — at maximum efficiency. That means:

-

Lower energy bills

-

Reduced strain on system components

-

Longer operational life

-

Lower environmental impact

Being an eco-conscious business doesn’t have to mean sacrificing performance. With the help of an authorized York parts supplier, you can achieve both sustainability and system reliability.

How Midwest Parts Center Makes Sourcing Easy

Finding the right HVAC parts can be stressful, especially when your system is down. That’s why Midwest Parts Center simplifies the entire process for our customers.

Here’s how we make ordering easy:

-

Contact Our Experts

Reach out to us at +1 800 368 8385 or via our website. Our HVAC professionals will help you identify the exact York part you need. -

Get a Fast and Transparent Quote

We provide clear pricing and availability so you can plan your maintenance or repair with confidence. -

Quick Order Fulfillment

Once confirmed, we ship your order promptly to minimize downtime. -

Ongoing Support

Need help with installation guidance or part compatibility? Our experienced support team is just a call away.

With Midwest Parts Center, there’s no guesswork — just genuine York components and reliable service.

Customer-Centric Commitment

At Midwest Parts Center, we value every customer relationship. Our mission goes beyond selling parts—we aim to provide lasting solutions that strengthen your operations.

We know that every facility, large or small, depends on its HVAC system for comfort, safety, and productivity. That’s why we take pride in being a York parts supplier that you can trust for accuracy, quality, and dependability.

When you call +1 800 368 8385, you’ll speak with a knowledgeable representative who understands York systems and can provide the right answers quickly. Our dedication to customer satisfaction has made Midwest Parts Center a trusted name nationwide.

The Midwest Advantage

When you partner with Midwest Parts Center, you’re not just buying parts — you’re gaining a maintenance ally.

Here’s what sets us apart:

✅ Authorized York Parts Supplier – 100% genuine OEM parts guaranteed.

✅ Industrial and Commercial Expertise – We specialize in large-scale HVAC systems.

✅ Fast Nationwide Shipping – Minimize downtime with quick delivery.

✅ Knowledgeable Support Team – Expert advice from people who know York systems inside out.

✅ Commitment to Quality – We never compromise on authenticity or service.

When it comes to maintaining commercial and industrial HVAC systems, the importance of genuine replacement parts cannot be overstated. Partnering with a trusted York parts supplier like Midwest Parts Center ensures that your system operates efficiently, safely, and reliably — today and for years to come.

By choosing authentic York components, you’re protecting your investment, maintaining warranty coverage, and maximizing system performance. Whether it’s a small replacement or a major system upgrade, Midwest Parts Center has the experience, inventory, and dedication to meet your needs.

Don’t compromise your system’s reliability with imitation parts or unauthorized dealers. Choose the expert York parts supplier that businesses across the USA trust.

📞 Call Midwest Parts Center today at +1 800 368 8385 to speak with our experts and find the genuine York HVAC components your facility needs.

Why Leading U.S. Companies Depend on a Trusted York Parts Supplier

In the competitive world of industrial and commercial HVAC systems, reliability and efficiency are non-negotiable. Every minute of downtime can cost thousands of dollars in lost productivity, discomfort, and even equipment damage. That’s why leading companies across the United States rely on a trusted York parts supplier like Midwest Parts Center to keep their systems operating at peak performance. With decades of experience, industry expertise, and a deep inventory of authentic York HVAC components, Midwest Parts Center has become the go-to source for businesses that value quality, dependability, and cost-effective solutions.

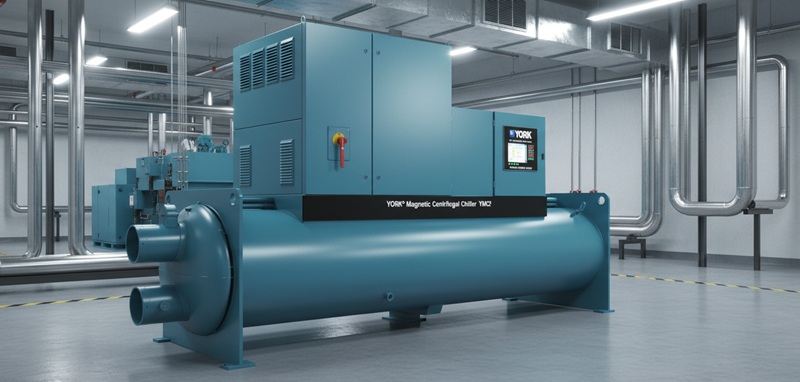

For industrial and commercial facilities, HVAC systems are more than just climate control units—they are the backbone of daily operations. From manufacturing plants and data centers to hospitals and universities, the demand for reliable heating and cooling never ceases. That’s where a York parts supplier steps in to make a significant difference.

🌟 The Importance of a Trusted York Parts Supplier

When it comes to maintaining York HVAC systems, using genuine parts is crucial. York systems are engineered for high performance, and every component plays an essential role in the system’s overall efficiency and longevity. However, even the best machines need maintenance, repair, and replacement parts over time.

A trusted York parts supplier like Midwest Parts Center ensures that facilities receive only authentic components, designed and tested to meet York’s rigorous standards. Counterfeit or generic parts might appear to offer cost savings upfront, but they often lead to inefficiency, frequent breakdowns, and costly repairs later. By working with an authorized York parts supplier, companies safeguard their investment and maintain optimal HVAC system performance for years.

🏭 Midwest Parts Center: A Leader Among York Parts Suppliers

Midwest Parts Center has established itself as a reliable York parts supplier for commercial and industrial sectors throughout the United States. The company’s dedication to providing authentic York products and expert guidance sets it apart from others in the industry.

Headquartered in the U.S. and deeply rooted in serving industrial and commercial areas, Midwest Parts Center has built its reputation by focusing on three key values:

-

Authenticity – Every part supplied by Midwest Parts Center is 100% genuine York. This ensures seamless integration with existing systems and eliminates the risks associated with counterfeit or substandard components.

-

Expertise – The team understands the complexity of industrial HVAC systems. They provide tailored recommendations, ensuring customers get the exact parts they need—nothing more, nothing less.

-

Reliability – With a vast inventory and efficient logistics network, Midwest Parts Center ensures timely delivery, minimizing costly downtime for businesses.

Need expert assistance? Call +1 800 368 8385 today to connect with Midwest Parts Center and experience the service trusted by industries nationwide.

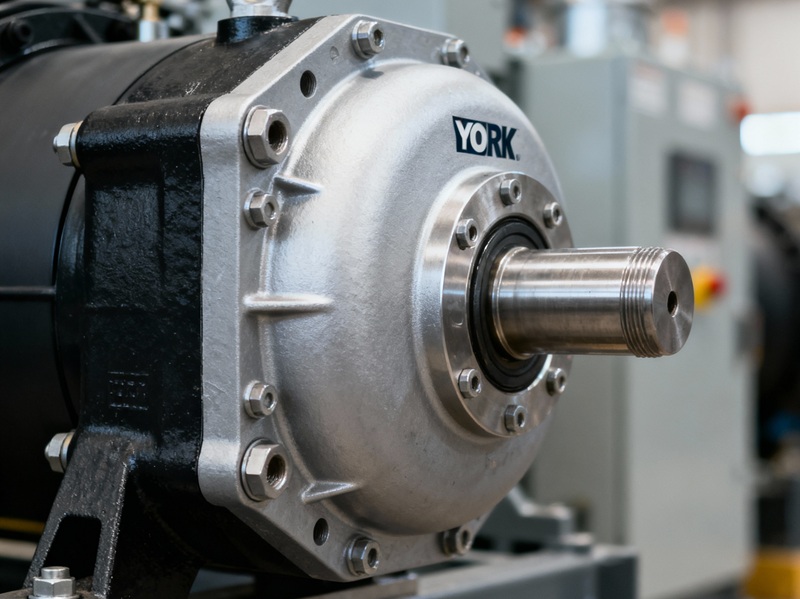

🔧 Why Authentic York Parts Matter for Industrial HVAC Systems

Every component in a York HVAC system is precision-engineered to work in harmony. Whether it’s a compressor, coil, fan motor, or sensor, each part contributes to the system’s performance and energy efficiency. Using non-genuine parts can compromise this balance, leading to:

-

Increased energy consumption

-

Reduced cooling or heating capacity

-

Frequent breakdowns

-

Voided warranties

-

Higher long-term maintenance costs

That’s why partnering with a certified York parts supplier is a smart business decision. Midwest Parts Center helps companies avoid these pitfalls by ensuring that every replacement part is an exact match for the original York design.

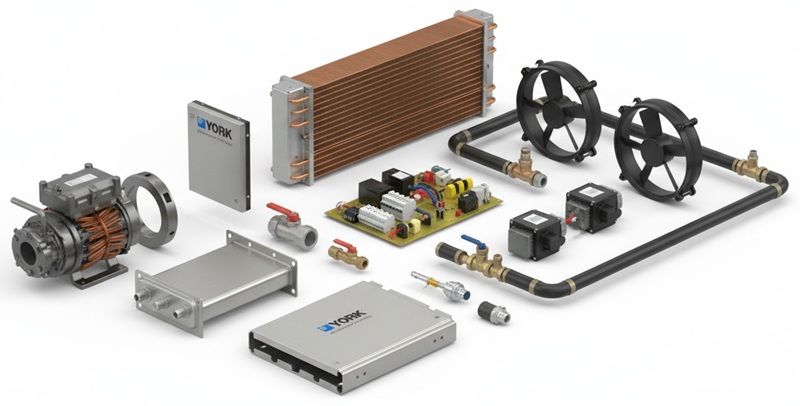

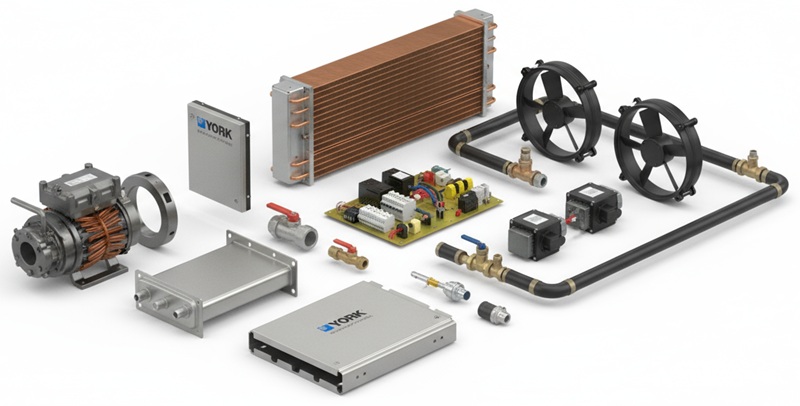

⚙️ A Complete Range of York HVAC Components

As a premier York parts supplier, Midwest Parts Center offers an extensive range of York components to meet every need. The inventory includes but is not limited to:

-

Compressors and Condensers – The heart of any HVAC system, these components require precision and reliability.

-

Evaporator Coils and Heat Exchangers – Essential for efficient thermal transfer.

-

Motors, Belts, and Fans – Ensuring proper airflow and smooth operation.

-

Valves, Filters, and Sensors – Critical for system regulation and safety.

-

Controls and Circuit Boards – The brain of modern HVAC systems, optimizing performance and energy use.

No matter how specific your requirement, Midwest Parts Center can source the right York component promptly. The company’s comprehensive database makes it easy to identify compatible parts for both legacy and modern systems.

🧰 The Role of a York Parts Supplier in Preventive Maintenance

Preventive maintenance is one of the most effective strategies to maximize HVAC system lifespan. However, maintenance programs are only as good as the parts used. A dependable York parts supplier like Midwest Parts Center ensures maintenance teams always have access to genuine parts for scheduled servicing and emergency repairs.

Routine replacement of filters, belts, and sensors using authentic York parts can:

-

Extend system life

-

Maintain manufacturer warranties

-

Improve energy efficiency

-

Prevent unexpected shutdowns

With Midwest Parts Center, facility managers gain peace of mind knowing that they’re getting genuine parts that deliver consistent performance.

💡 Energy Efficiency Through Authentic York Components

In today’s environmentally conscious world, energy efficiency is a top priority. York systems are known for their energy-saving designs, but their performance depends heavily on the integrity of individual parts. Using authentic components supplied by a trusted York parts supplier ensures that your HVAC system operates at its designed efficiency.

Midwest Parts Center helps clients reduce their carbon footprint and operational costs by maintaining system integrity with genuine York parts. From energy-efficient compressors to advanced control modules, every part contributes to lower utility bills and sustainable operation.

🏢 Supporting Industrial and Commercial Facilities Across the USA

Industrial and commercial sectors face unique HVAC challenges. Large spaces, round-the-clock operations, and strict temperature requirements demand dependable solutions. Midwest Parts Center, as a leading York parts supplier, caters specifically to these industries, offering customized parts solutions that meet diverse facility needs.

Examples include:

-

Manufacturing Plants – Where temperature control affects product quality and employee comfort.

-

Data Centers – Requiring constant cooling to prevent equipment overheating.

-

Hospitals – Needing reliable climate control for patient safety.

-

Universities and Office Buildings – Seeking consistent comfort and energy savings.

By partnering with Midwest Parts Center, these facilities ensure uninterrupted operations backed by top-quality York components.

🔍 Fast and Accurate York Parts Identification

One of the biggest challenges in HVAC maintenance is identifying the right replacement part. With thousands of components available, even minor errors can lead to compatibility issues. As an experienced York parts supplier, Midwest Parts Center simplifies this process.

Using York’s official part identification system, the company’s experts help customers match model numbers, serial data, and technical specifications accurately. This precision saves time, eliminates guesswork, and ensures a perfect fit every time.

📞 Expert Support When You Need It Most

Downtime is costly, and when your system needs parts urgently, you need a supplier who can deliver fast. Midwest Parts Center stands out as a responsive York parts supplier with a customer-first approach. Their support team is available to provide immediate assistance, ensuring that clients get their HVAC systems back online quickly.

For inquiries or emergency support, call +1 800 368 8385 to speak directly with a Midwest Parts Center expert.

🧩 The Midwest Parts Center Advantage

Choosing Midwest Parts Center as your York parts supplier means gaining a strategic partner dedicated to your success. Some key advantages include:

-

Nationwide Coverage – Serving businesses across the United States.

-

Extensive Inventory – Thousands of York parts in stock.

-

Technical Expertise – Decades of experience with industrial HVAC systems.

-

Competitive Pricing – Genuine parts at cost-effective rates.

-

Unmatched Customer Service – Fast response and professional guidance.

This combination of strengths makes Midwest Parts Center the preferred supplier for countless industrial and commercial clients.

🚀 Future-Focused Support for Evolving HVAC Needs

The HVAC industry continues to evolve with innovations in automation, sustainability, and smart technology. York leads these advancements with high-efficiency systems and intelligent control solutions. As a forward-thinking York parts supplier, Midwest Parts Center stays at the forefront of these trends, ensuring clients always have access to the latest components and upgrades.

Whether you’re upgrading an existing system or installing new equipment, Midwest Parts Center offers expert advice and genuine York parts to support your project from start to finish.

✅ Partner with Midwest Parts Center Today

Industrial and commercial businesses across the U.S. trust Midwest Parts Center because they know reliability matters. Every component supplied by this trusted York parts supplier contributes to smoother operations, lower costs, and long-term performance.

With a commitment to authenticity, efficiency, and customer satisfaction, Midwest Parts Center continues to set the benchmark for York HVAC parts distribution.

Don’t compromise on quality—choose the supplier that leading companies depend on.

📞 Call Midwest Parts Center today at +1 800 368 8385 to order genuine York components and experience unmatched service from the nation’s most reliable York parts supplier.