In the fast-paced world of commercial and industrial HVAC systems, downtime is more than just an inconvenience—it’s a threat to productivity, safety, and profitability. Whether you’re operating a hospital, university, manufacturing facility, or data center, keeping your heating and cooling systems running efficiently is critical. That’s why having a trusted York Parts Distributor nearby isn’t just a convenience—it’s a necessity.

If you’ve ever searched online for “York Parts Distributor near me,” chances are you were in immediate need of a reliable supplier who could deliver genuine HVAC parts fast and with expert knowledge. Look no further than Midwest Parts Center, your local HVAC parts authority serving commercial and industrial facilities with unmatched dedication, technical expertise, and access to York Genuine Parts.

This in-depth guide will explain why having a local York Parts Distributor like Midwest Parts Center is invaluable to your operations. Read on to learn how we solve your HVAC challenges with authentic parts, expert guidance, and tailored solutions.

📞 Need immediate assistance? Call +1 800 368 8385 now for same-day support.

What is a York Parts Distributor?

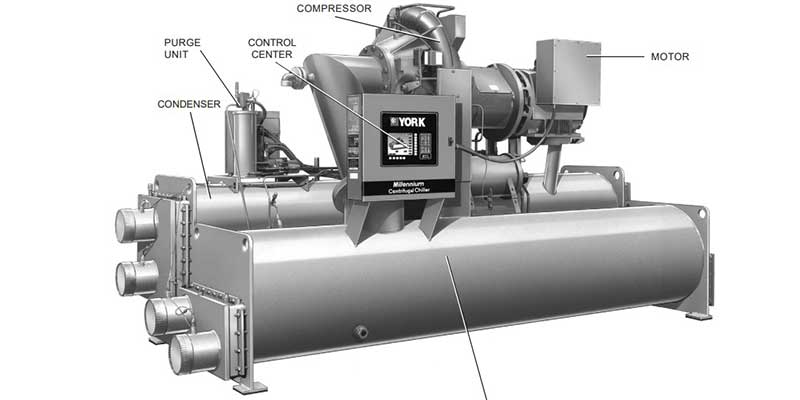

A York Parts Distributor is an authorized provider of OEM (Original Equipment Manufacturer) parts specifically designed for York HVAC systems. These parts are built to the exact specifications of York’s engineering standards, ensuring seamless integration, superior performance, and long-term reliability.

As a York Parts Distributor, Midwest Parts Center gives facility managers, HVAC technicians, and building engineers direct access to:

- Compressors

- Coils

- Expansion valves

- Sensors

- Controls and circuit boards

- Belts and gaskets

- Refrigerant components

- Preventative maintenance kits

We don’t just sell parts—we provide HVAC system solutions tailored for your facility’s unique needs.

Why Local Matters: Benefits of a York Parts Distributor Near You

The closer your York Parts Distributor, the faster and more responsive your service can be. When a chiller goes down or a rooftop unit needs immediate attention, you can’t wait days for a part to ship from halfway across the country. Here’s why working with a local distributor like Midwest Parts Center is a game-changer:

1. Faster Turnaround Time

With local warehousing and logistical support, we can get your critical parts to you faster—sometimes the very same day.

2. On-Site Pickup Options

Need that evaporator coil immediately? Visit our local facility and get the parts without delay. It’s like having a York parts warehouse in your backyard.

3. Hands-On Expertise

Our local HVAC experts understand your region’s climate challenges, facility types, and system configurations. We provide localized, knowledgeable advice you won’t get from an online mega-retailer.

4. Emergency Support

Downtime is costly. Our team is ready to assist in emergencies with rapid diagnostics and access to replacement parts that will get your system back online quickly.

📍 Searching for a “York Parts Distributor near me”? Midwest Parts Center is your answer. Call +1 800 368 8385.

York Genuine Parts vs. Aftermarket: Why It Matters

In a time where budget cuts and quick fixes are tempting, some facilities are drawn to aftermarket parts. But let us be clear—aftermarket is not OEM, and the difference can cost you in the long run.

Here’s why choosing York Genuine Parts through an authorized York Parts Distributor like Midwest Parts Center is the smart choice:

- Perfect Fit: York parts are designed specifically for York equipment—no guesswork.

- Warranty Protection: OEM parts often carry manufacturer warranties; aftermarket voids them.

- Longevity: York parts last longer, reducing the frequency and cost of replacements.

- System Efficiency: Non-OEM parts can reduce efficiency and increase energy usage.

- Safety: Using unauthorized parts can create safety hazards, especially in mission-critical environments.

Don’t risk your HVAC investment. Trust only a certified York Parts Distributor.

Industries We Serve: Commercial & Industrial HVAC Experts

Midwest Parts Center is not a one-size-fits-all operation. Our team specializes in commercial and industrial environments—where HVAC systems are complex, mission-critical, and often run 24/7.

We proudly serve:

- Hospitals & Healthcare Facilities: Where temperature control is critical to patient care.

- Universities & Schools: Providing safe, comfortable learning environments.

- Data Centers: Where cooling systems protect millions in digital infrastructure.

- Manufacturing Plants: Where equipment performance depends on ambient conditions.

- Office Buildings & Retail Centers: Where comfort influences productivity and sales.

If your facility needs reliable HVAC performance, Midwest Parts Center is your go-to York Parts Distributor.

Top Reasons to Choose Midwest Parts Center as Your York Parts Distributor

Still wondering why Midwest Parts Center stands out from the rest? Let’s break it down.

1. Authorized York Distributor

We’re not just another parts seller—we’re officially authorized to carry and distribute York Genuine Parts, ensuring quality and compliance.

2. Technical HVAC Experts

Our team is trained in York equipment and understands the complexities of modern commercial HVAC systems.

3. Extensive Inventory

We stock a vast range of parts locally to minimize wait times and keep your system running.

4. Custom Order Fulfillment

Need a specialty item or rare component? We source directly from the York manufacturing network and get it fast.

5. Responsive Service

From emergency requests to maintenance planning, we’re on standby with answers and parts.

📞 Call +1 800 368 8385 today and experience the Midwest Parts Center difference.

The Importance of Preventative Maintenance and Reliable Parts

Every facility manager knows: a small part can cause a big problem. The key to system longevity and reduced operating costs lies in proactive maintenance—and that requires authentic parts.

At Midwest Parts Center, we support your maintenance team with:

- Seasonal maintenance kits

- OEM replacement schedules

- Filter, belt, and gasket replacements

- Customized part packages

- Long-term service planning

By partnering with a York Parts Distributor like us, you’re not just maintaining your HVAC system—you’re preserving your building’s infrastructure and improving energy efficiency.

Emergency Part Replacement: We’ve Got You Covered

HVAC emergencies don’t wait for business hours. When the temperature spikes or plummets and your system fails, every second counts. That’s where Midwest Parts Center steps in.

We provide emergency access to:

- Compressors

- Sensors and transducers

- Refrigerant management tools

- Motor and electrical components

- Pressure switches and control panels

If it’s York and it’s vital, we can get it to you—FAST.

Need help now? 📞 Call +1 800 368 8385.

Supporting Your Technicians and Engineering Teams

We work directly with:

- HVAC Contractors

- Facility Managers

- Mechanical Engineers

- Building Operators

- Energy Managers

Our goal is to empower your team with knowledge, resources, and the parts they need—when they need them. We offer technical guidance, spec sheets, and live assistance to ensure proper part selection and installation.

When your internal team needs a hand, trust Midwest Parts Center, the most knowledgeable York Parts Distributor near you.

FAQ: York Parts Distributor Near Me

Q: Can I get same-day pickup for parts?

A: Yes! Many of our parts are stocked locally for same-day pickup or delivery.

Q: Are your parts covered under warranty?

A: Absolutely. All York Genuine Parts from Midwest Parts Center come with full manufacturer-backed warranties.

Q: How do I confirm if a part is compatible?

A: Just call our technical team with your equipment model and serial number—we’ll do the rest.

Q: Can you ship parts if I’m out of state?

A: Yes, we support clients across the U.S. and offer expedited shipping.

Contact Midwest Parts Center Today

If you’re still searching for a York Parts Distributor near me, let us end the search. Midwest Parts Center is your local solution with the inventory, insight, and integrity you deserve.

✅ York-authorized

✅ Commercial and industrial specialists

✅ Emergency support

✅ OEM parts guaranteed

✅ Over a decade of trusted service

📞 Call us today at +1 800 368 8385 to order parts, schedule a consultation, or speak with a York HVAC expert. Your system deserves the best—and that’s what we deliver.

Trust the Best, Get the Best

In the world of commercial and industrial HVAC, the stakes are high. Using the wrong part, working with an unreliable supplier, or waiting too long for repairs can cost you thousands—or more. That’s why having a dependable York Parts Distributor in your corner is essential.

Midwest Parts Center is not just another distributor. We’re your local HVAC partner, committed to helping your systems run smarter, longer, and more efficiently. Whether you need urgent support or a long-term supplier, we’re ready.

York systems deserve York parts—and you deserve the service of Midwest Parts Center.

📞 Let’s talk today: +1 800 368 8385

How Our York Parts Distributor Services Ensure Long-Lasting HVAC Performance

When you manage a commercial or industrial facility, one of your top priorities is keeping your HVAC systems operating reliably. Heating, ventilation, and air conditioning equipment are at the heart of indoor climate control, and they need to be maintained with precision. This is especially true for facilities where system failure isn’t just an inconvenience—it’s a potential disaster. That’s where working with a trusted York Parts Distributor like Midwest Parts Center becomes more than just a choice—it’s an operational necessity.

At Midwest Parts Center, we pride ourselves on being more than just a parts provider. As a certified York Parts Distributor, we help clients throughout the commercial and industrial sectors ensure their HVAC systems remain in peak condition for years to come. With our extensive knowledge, genuine OEM inventory, and commitment to rapid service, we offer performance-based solutions—not just product lists.

So, how exactly do our York Parts Distributor services help ensure long-lasting HVAC performance? Read on to find out.

📞 Need expert help now? Call us at +1 800 368 8385.

1. Why a Trusted York Parts Distributor Matters More Than Ever

Let’s start with the basics. A York Parts Distributor isn’t just a vendor—they are your lifeline to maintaining system integrity. In commercial and industrial environments, equipment stress levels are much higher than in residential settings. Chillers, air handlers, rooftop units, and VRF systems are expected to perform without fail, often 24/7.

Without the right parts and the right partner you risk:

- System inefficiency

- Frequent breakdowns

- Skyrocketing energy bills

- Reduced equipment lifespan

- Costly emergency repairs

Midwest Parts Center, as your local York Parts Distributor, exists to eliminate those risks. With our access to York Genuine Parts, we help your systems perform optimally and stand the test of time.

2. We Only Use York Genuine Parts—Here’s Why That’s Critical

Let’s face it: you can find HVAC parts almost anywhere these days. But the difference between aftermarket and OEM is the difference between “fits okay” and “fits perfectly.” As a certified York Parts Distributor, we only deal with York Genuine Parts, which are engineered and manufactured to exact OEM specifications.

Why OEM Parts from Midwest Parts Center Outperform Aftermarket Alternatives:

- Exact Compatibility – No guesswork. York parts are designed for York systems.

- Greater Efficiency – Maintain original performance levels, keeping energy use low.

- Reduced Wear & Tear – Precision fitment reduces stress on neighboring components.

- Extended System Lifespan – Using the right parts helps your equipment last longer.

- Full Warranty Protection – OEM parts preserve your original equipment warranties.

Want to protect your investment? Don’t settle. Partner with the best—Midwest Parts Center.

📞 Call +1 800 368 8385 to order your genuine York parts today.

3. Faster Access, Less Downtime with Local Inventory

Downtime is the enemy of productivity. Whether you operate a hospital, university, manufacturing facility, or commercial building, every moment your HVAC system is offline means discomfort, safety risks, and operational delays.

That’s why Midwest Parts Center maintains an extensive local inventory of commonly used York Genuine Parts, allowing us to deliver the following benefits:

- Same-Day Fulfillment on most standard parts

- Local Pickup options for urgent repairs

- Next-Day Delivery for specialized orders

- Real-Time Inventory Checks with our expert team

As a trusted York Parts Distributor, we understand the urgency of your HVAC needs. We work hard to eliminate wait times and delays so your system can stay up and running without interruption.

4. Expert Technical Support—From People Who Understand York Systems Inside and Out

Sourcing a part is just step one. Knowing how and when to use it, and what alternatives exist for obsolete components, requires technical expertise. At Midwest Parts Center, our team of York-certified professionals provides:

- Guided part selection

- Troubleshooting assistance

- Product compatibility advice

- Preventative maintenance strategies

- Technical manuals and documentation

Unlike generalist distributors, we specialize in York systems. Our team speaks the language of HVAC engineers, building managers, and field technicians.

When you work with Midwest Parts Center, you’re not just getting a part—you’re getting a partner.

5. Proactive Maintenance Support to Prevent Costly Breakdowns

You know the saying: an ounce of prevention is worth a pound of cure. That couldn’t be truer in HVAC maintenance. Preventative care significantly extends system life, enhances performance, and reduces energy costs.

As a proactive York Parts Distributor, Midwest Parts Center helps you:

- Set up customized preventative maintenance kits

- Schedule seasonal maintenance planning

- Access filters, belts, lubricants, coils, and more

- Replace worn parts before they cause damage

Think of us as your HVAC pit crew—ready with everything you need to avoid emergency downtime and extend your system’s lifespan.

6. Scalable Support for Facilities of All Sizes

Whether you manage a single facility or oversee HVAC infrastructure for multiple sites across a region, Midwest Parts Center can scale to meet your needs.

We offer:

- Bulk ordering capabilities

- Multi-site service coordination

- Dedicated account managers

- Tailored supply solutions for large-scale operations

From the corner office building to sprawling industrial campuses, we tailor our York Parts Distributor services to match your facility’s scope and complexity.

7. Emergency Response Services

HVAC emergencies rarely happen at convenient times. Nights, weekends, holidays—when something breaks, it can’t wait. That’s why Midwest Parts Center offers emergency response support with real-time parts sourcing and technical assistance.

We’ve helped clients get back online in critical situations like:

- Frozen data center cooling systems

- Malfunctioning hospital chillers

- Overheated production facilities

- Emergency school closures due to HVAC failure

When time is of the essence, you want a York Parts Distributor that treats your emergency like their own. That’s exactly what we do.

📞 For 24/7 emergency support, call +1 800 368 8385.

8. Competitive Pricing Without Compromising Quality

With budget constraints affecting nearly every industry, we understand the importance of cost-effective solutions. But unlike discount suppliers, Midwest Parts Center never compromises on quality.

We offer:

- Volume discounts

- OEM package pricing

- Transparent cost structures

- No hidden fees or surprise charges

Working with a York Parts Distributor should be both dependable and financially sustainable—and with us, it is.

9. Sustainability and Energy Efficiency Through Smart Parts Selection

Today, HVAC systems must not only work well—they must work cleanly. Using energy-efficient components isn’t just a smart decision for the planet, it’s a smart decision for your operating costs.

As a certified York Parts Distributor, Midwest Parts Center helps your systems stay green with:

- Energy-optimized components

- Upgraded control systems

- Variable frequency drive (VFD) compatible parts

- High-efficiency coils and motors

Sustainability is no longer optional—it’s strategic. Let us help your HVAC system do more with less.

10. End-to-End Partnership: More Than Just a Parts Provider

At Midwest Parts Center, our mission goes beyond selling you a product. As your dedicated York Parts Distributor, we serve as an extension of your operations team. Our success is measured in your system’s reliability and your facility’s comfort.

Here’s what a long-term partnership with us looks like:

- Ongoing parts management

- Customized restocking schedules

- Lifecycle planning for older equipment

- Support for capital improvement projects

- Access to York system upgrades and enhancements

We aim to be your go-to resource—not just for parts, but for progress.

Client Testimonials: What Our Partners Say

“Midwest Parts Center has been our go-to York Parts Distributor for over five years. Their response times are phenomenal, and the team always knows exactly what we need—even before we do.”

— Facility Manager, Regional Hospital

“We manage HVAC systems across 12 buildings. Midwest Parts Center helps us stay organized, stocked, and running year-round. Couldn’t do it without them.”

— Operations Director, State University

“We had a critical part fail on a 30-ton chiller. These guys had the part ready for pickup the same day. That kind of service is priceless.”

— Maintenance Supervisor, Manufacturing Facility

Invest in Performance, Partner with Midwest Parts Center

When your commercial or industrial HVAC system depends on reliability, performance, and efficiency, choosing the right York Parts Distributor makes all the difference. At Midwest Parts Center, we deliver more than parts—we deliver confidence, uptime, and peace of mind.

Our comprehensive services are built around a simple promise: to keep your York systems running stronger, longer, and smarter.

✅ York Genuine Parts

✅ Commercial & Industrial Expertise

✅ Same-Day Service

✅ Technical Support

✅ Trusted by Facilities Nationwide

📞 Ready to get started? Contact Midwest Parts Center today at +1 800 368 8385 and discover how our York Parts Distributor services will transform the way you maintain your HVAC systems.