3 Prospects of Commercial York YK Chiller Parts

Commercial York YK Chiller Parts: York’s temperature control systems are essential to the proper operation of commercial and industrial buildings. This chiller from York features a large selection of parts since we know that reliable performance is critical. It’s also a brilliant alternative for your current and future parts requirements.

Commercial York YK Chiller Parts: York’s temperature control systems are essential to the proper operation of commercial and industrial buildings. This chiller from York features a large selection of parts since we know that reliable performance is critical. It’s also a brilliant alternative for your current and future parts requirements.

Are you interested in purchasing these replacement parts to keep your current device running well? Commercial York YK Chiller parts are available through us. Because of the nature of the equipment, only a qualified technician should be tasked with installing new features. Care must be used when working with Commercial York YK chiller parts. However, if you meant well for commercial HVAC you must invest in YK chiller Part now and in the future.

A high success rate

YK chillers are built to withstand high temperatures. Even if you think your equipment is long-lasting, it can break down and require maintenance. The best method to keep your equipment in good operating order is preventative maintenance according to the manufacturer’s instructions.

YK chillers are built to withstand high temperatures. Even if you think your equipment is long-lasting, it can break down and require maintenance. The best method to keep your equipment in good operating order is preventative maintenance according to the manufacturer’s instructions.

No surprise that York parts are made to the highest possible quality standard. We can answer any questions about the names of functions. Components that don’t work correctly with your equipment can cause performance concerns. With us, you can rest assured that the details you purchase for your car will be authentic. An additional benefit to York’s warranties, which cover manufacturing faults, is included with your parts.

Exceptional Capability

Being able to inhale fresh, cool air is something we take for granted wherever we go, whether it’s a workplace or a public area like a school or a café. A person’s mood will almost certainly be affected by the air conditioning in a given space at a particular time.

Being able to inhale fresh, cool air is something we take for granted wherever we go, whether it’s a workplace or a public area like a school or a café. A person’s mood will almost certainly be affected by the air conditioning in a given space at a particular time.

As a result, workplaces with low air conditioning risk slowing down overall production. Commercial York YK Chiller Parts is committed to providing the best YK chiller parts to improve the atmosphere in diverse areas.

The York YK chiller model is generally regarded for its efficiency in using energy and producing cool air. With the Midwest Parts Center on your side, getting high-quality parts worth your time and money is simple.

Constructing a model

In contrast, York YK chillers use centrifugal air conditioning. The water in this chiller is cooled by compressing vapour, which removes heat. Subsequently, the water is cooled in the York YK chiller, creating superb air.

York’s YK chiller parts may become overworked and break down frequently due to their work in cooling the air. York, a firm based in New York, is committed to providing.

To cool a large area, you may require an expensive chiller to acquire and operate; if it breaks down rapidly, you’ll have to spend more money fixing it. Choosing quality over quantity is essential to achieving the most exemplary cooler.

We are here to assist you in making an informed selection about a York YK chiller to meet your cooling requirements.

Repairs Are a Snap!

Let’s say you wish to keep your chiller from getting any further damage. A well-versed specialist in diagnosing and fixing it should be consulted since, if you have inaccurate inspection reports or bad repair and replacement, you may need to get a new York YT chiller.

Because of this, everyone, including customers and employees, could be affected by the damage to the facility. You may find a wide range of Commercial York YK chiller parts here. All your price and quality needs are solved as you invest in YK Chiller.

The primary mover in the chiller system is the compressor, which generates a pressure differential to transport the refrigerant. Centrifugal, screw, scroll, and reciprocating compressors are the most popular types of refrigerant compressors. The advantages and disadvantages of each variety are different. The condenser is always situated between the evaporator and condenser.

The primary mover in the chiller system is the compressor, which generates a pressure differential to transport the refrigerant. Centrifugal, screw, scroll, and reciprocating compressors are the most popular types of refrigerant compressors. The advantages and disadvantages of each variety are different. The condenser is always situated between the evaporator and condenser. After the compressor and before the expansion valve comes the condenser. The condenser’s job is to extract the refrigerant’s heat from the evaporator, where it was captured. Air-cooled and water-cooled condensers are the two most common types of condensers.

After the compressor and before the expansion valve comes the condenser. The condenser’s job is to extract the refrigerant’s heat from the evaporator, where it was captured. Air-cooled and water-cooled condensers are the two most common types of condensers. The evaporator is responsible for capturing the unwanted heat from the building and transferring it to the refrigerant. It is located between the expansion valve and compressor and can be transferred to the cooling tower and rejected.

The evaporator is responsible for capturing the unwanted heat from the building and transferring it to the refrigerant. It is located between the expansion valve and compressor and can be transferred to the cooling tower and rejected.

Why wait for parts to arrive when you have

Why wait for parts to arrive when you have  Preventative maintenance kits for coolers from York can also help improve performance and efficiency. Facility managers and chiller professionals can spot a problem or a requirement for repairs.

Preventative maintenance kits for coolers from York can also help improve performance and efficiency. Facility managers and chiller professionals can spot a problem or a requirement for repairs. York’s preventative kits make it easy to maintain your chiller to avoid high energy expenses. The York preventative maintenance tool kit is a practical and trustworthy solution for professionals and skilled specialists to reduce malfunctions and further reduce the effects of snags with regular servicing. Since reactive treatment was the solution to challenges in the past, we can now give this service promptly and adequately due to our comprehensive knowledge of the technology.

York’s preventative kits make it easy to maintain your chiller to avoid high energy expenses. The York preventative maintenance tool kit is a practical and trustworthy solution for professionals and skilled specialists to reduce malfunctions and further reduce the effects of snags with regular servicing. Since reactive treatment was the solution to challenges in the past, we can now give this service promptly and adequately due to our comprehensive knowledge of the technology.

Because of its large capacity and environmentally friendly features, York is a pioneer in air-cooled chiller technology.

Because of its large capacity and environmentally friendly features, York is a pioneer in air-cooled chiller technology.  Use YORK YLAA Air-Coolant to save money and assist the environment. We can help you set up an air-cooled chiller system for industrial or commercial cooling. Our YLAA Chillers can be used in air-cooled water chiller systems to:

Use YORK YLAA Air-Coolant to save money and assist the environment. We can help you set up an air-cooled chiller system for industrial or commercial cooling. Our YLAA Chillers can be used in air-cooled water chiller systems to: Why York YLAA is the best option, the top five features The YLAA chiller comes with various choices, making it appropriate for many applications. Glycol can be chilled at a temperature of 10°F (-12°C). A capture rate of 85 percent is feasible at a maximum temperature of 140 degrees Fahrenheit.

Why York YLAA is the best option, the top five features The YLAA chiller comes with various choices, making it appropriate for many applications. Glycol can be chilled at a temperature of 10°F (-12°C). A capture rate of 85 percent is feasible at a maximum temperature of 140 degrees Fahrenheit.

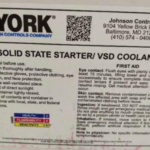

The York VSD coolant Midwest is a crucial component of the heating and cooling system. By reducing energy consumption and running expenses, the coolant improves the performance of ventilation devices. The air conditioning is completed with this material. Clean air conditioning is essential in evaluating a company’s ability to stay on budget; cost-cutting measures are required.

The York VSD coolant Midwest is a crucial component of the heating and cooling system. By reducing energy consumption and running expenses, the coolant improves the performance of ventilation devices. The air conditioning is completed with this material. Clean air conditioning is essential in evaluating a company’s ability to stay on budget; cost-cutting measures are required. VSD Coolants are also utilized in various settings, such as hospitals, restaurants, hotels, schools, and manufacturing sites, to keep the air clean and comfortable. Aside from that, coolers have a significant impact on running expenses while also being very environmentally friendly.

VSD Coolants are also utilized in various settings, such as hospitals, restaurants, hotels, schools, and manufacturing sites, to keep the air clean and comfortable. Aside from that, coolers have a significant impact on running expenses while also being very environmentally friendly.