When it comes to maintaining industrial HVAC systems, reliability is everything. Industrial chillers are the backbone of cooling operations for countless facilities across the United States—ranging from manufacturing plants and hospitals to data centers and power generation facilities. These systems work tirelessly to ensure temperature stability and efficient cooling under demanding conditions. Among the most trusted names in the HVAC industry, York chillers have set the gold standard for performance, efficiency, and longevity.

But like all complex machines, chillers require maintenance and occasional part replacements to keep them operating at peak performance. That’s why having access to certified York chiller parts is essential. And when it comes to sourcing authentic components for your system, Midwest Parts Center is the leading name you can trust.

Certified York Chiller Parts for Industrial Applications in the USA

With years of experience in serving commercial and industrial HVAC systems across the USA, Midwest Parts Center specializes in providing York chiller parts that meet OEM specifications, ensuring durability, performance, and perfect compatibility. Whether you need compressor components, control modules, sensors, gaskets, or condenser coils, we’ve got you covered. For expert assistance or to order genuine York components, contact us today at +1 800 368 8385.

🧊 Why Industrial Facilities Depend on York Chillers

York chillers are known for their innovation, engineering excellence, and reliability. They are designed to deliver optimal cooling performance in even the harshest industrial environments. From air-cooled to water-cooled models, York chillers come with advanced features such as variable-speed drives, smart control systems, and high-efficiency compressors that ensure consistent performance and reduced energy consumption.

However, like any sophisticated equipment, continuous use leads to natural wear and tear. That’s where York chiller parts play a vital role. Using certified replacement parts ensures your chiller maintains its designed efficiency, prevents system failures, and extends its service life.

At Midwest Parts Center, we understand the importance of keeping your systems running without interruption. Our goal is to provide you with fast, reliable access to genuine York chiller parts that restore your equipment to factory standards.

⚙️ The Importance of Using Certified York Chiller Parts

Choosing genuine, certified parts for your York chiller is not just a matter of brand loyalty—it’s a matter of performance, safety, and efficiency.

Here’s why using certified York chiller parts from Midwest Parts Center makes all the difference:

-

Guaranteed Compatibility:

Genuine York parts are manufactured according to precise engineering standards, ensuring perfect compatibility with your existing system. This eliminates the risk of improper fitting or operational issues that can arise from non-certified components. -

Long-Term Reliability:

Authentic York parts are built to last. They’re designed using high-quality materials that withstand industrial stress and environmental challenges, giving you consistent performance for years. -

Preserves Energy Efficiency:

Using the correct York chiller parts helps your system maintain its original energy rating, ensuring it continues to operate efficiently and economically. -

Protects Your Warranty:

Non-OEM parts can void your manufacturer’s warranty. Certified York parts keep your warranty intact and ensure full coverage in case of future issues. -

Prevents Costly Downtime:

Industrial operations can’t afford downtime. With certified York components from Midwest Parts Center, you can prevent breakdowns before they happen and keep your facility running smoothly.

🏭 Common Industrial Applications for York Chillers

York chillers are found in nearly every industrial and commercial sector due to their versatility and robust design. Some of the most common applications include:

-

Manufacturing Facilities: Maintain consistent cooling for machinery and process control.

-

Hospitals and Laboratories: Regulate temperature-sensitive environments and medical equipment.

-

Data Centers: Keep servers cool to prevent overheating and data loss.

-

Food Processing Plants: Ensure product quality by maintaining stable refrigeration cycles.

-

Power Plants: Support turbine and generator cooling operations.

In each of these environments, the reliability of the chiller system is paramount. And that reliability is directly tied to using authentic, high-performance York chiller parts.

🔍 Where to Buy Certified York Chiller Parts in the USA

If you’re looking for certified York chiller parts for your industrial HVAC systems, Midwest Parts Center is your one-stop destination. We are a trusted U.S.-based distributor specializing in supplying genuine York parts designed specifically for industrial and commercial use.

Here’s why Midwest Parts Center is the preferred choice for facility managers and HVAC technicians across the country:

1. Extensive Inventory of Genuine York Chiller Parts

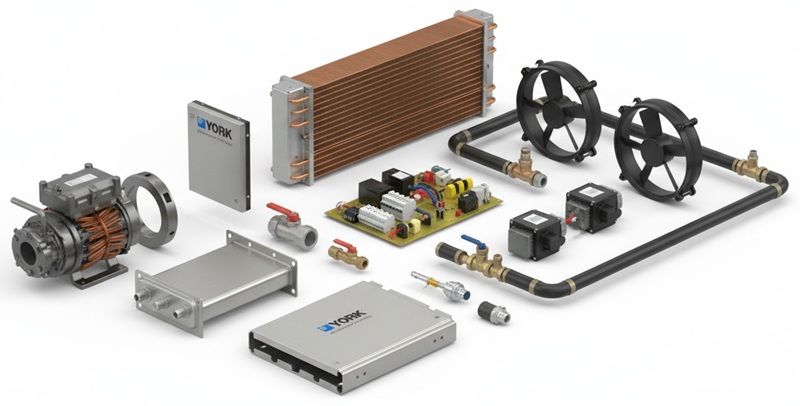

We maintain one of the largest inventories of York chiller parts in the United States, including:

-

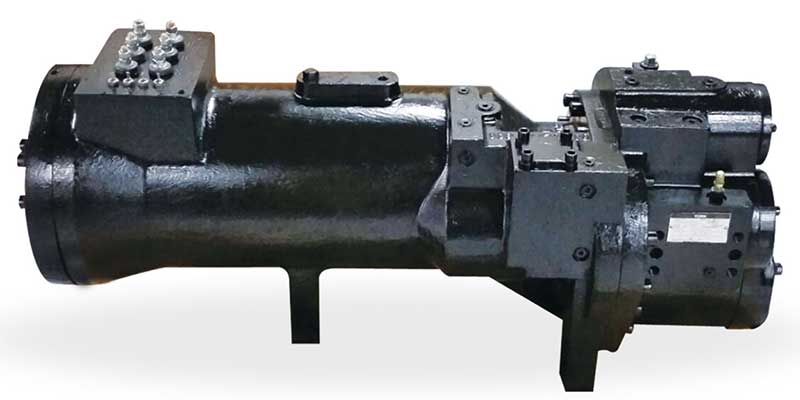

Compressors and compressor kits

-

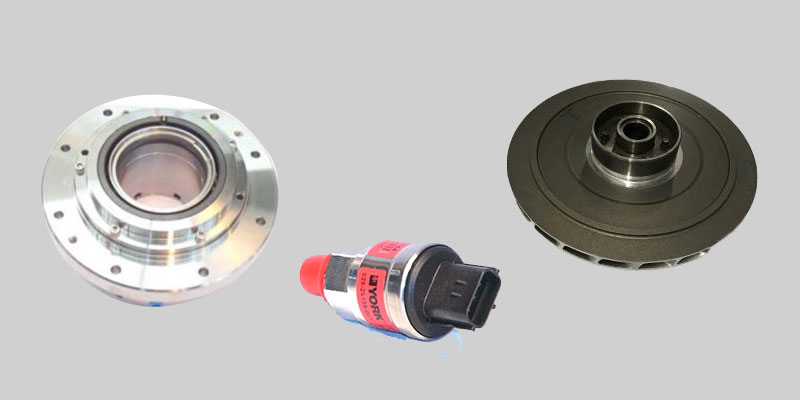

Control boards and sensors

-

Condenser and evaporator coils

-

Pressure switches

-

Expansion valves

-

Gaskets and seals

-

Motors, bearings, and fans

-

Oil filters and refrigerant components

Whether you need replacement parts for a York YLAA, YT, or YVAA chiller model, Midwest Parts Center has exactly what you need—ready for immediate dispatch.

2. OEM Certified Products

Every component we supply is OEM-certified, ensuring that it meets York’s original manufacturing and performance standards. This gives you peace of mind knowing you’re using parts that are 100% compatible with your system.

3. Expert Guidance and Technical Support

At Midwest Parts Center, we don’t just sell parts—we provide solutions. Our team of HVAC experts has in-depth knowledge of York systems and can help you identify the right parts for your specific model. Whether you’re troubleshooting a performance issue or performing preventive maintenance, we’ll ensure you get the correct part every time.

4. Fast Nationwide Delivery

We understand that time is critical in industrial operations. That’s why we offer fast and reliable nationwide shipping, so you get your York chiller parts when you need them. Our quick turnaround time helps minimize downtime and keeps your business running efficiently.

5. Dedicated Customer Service

Our customer-first philosophy ensures you receive personalized service from the moment you contact us. Have a question about part compatibility or availability? Just call +1 800 368 8385—our experts are ready to assist you.

🧰 How to Identify the Right York Chiller Parts for Your System

Before ordering replacement parts, it’s important to correctly identify what your system needs. Here’s a simple process to ensure accuracy:

-

Locate the Model and Serial Number:

You can find these details on the nameplate attached to your chiller unit. -

Check the Maintenance Records:

Reviewing service logs can help identify previously replaced components and determine which parts may require attention next. -

Consult with Experts:

Contact Midwest Parts Center for help identifying compatible parts. Our technicians can guide you through part selection and provide quotes quickly.

By following this process, you can avoid ordering incorrect components and ensure a smooth, efficient repair or maintenance cycle.

🌡️ The Role of York Chiller Parts in Preventive Maintenance

Preventive maintenance is key to maximizing chiller efficiency and minimizing operational costs. Using certified York chiller parts as part of your maintenance plan can significantly improve system performance and prevent breakdowns.

Here are some examples of how genuine parts contribute to better maintenance outcomes:

-

Oil Filters and Refrigerant Components: Keep the compressor lubricated and free of contaminants.

-

Pressure Switches and Sensors: Ensure accurate system control and temperature regulation.

-

Fans and Motors: Maintain optimal airflow and prevent overheating.

-

Gaskets and Seals: Prevent refrigerant leaks and maintain system pressure.

By sourcing these components from Midwest Parts Center, you ensure every part of your system performs as intended—reducing energy waste, preventing premature wear, and saving money in the long run.

💡 Benefits of Partnering with Midwest Parts Center

When you choose Midwest Parts Center as your York parts supplier, you’re not just getting access to quality products—you’re partnering with a team that understands industrial HVAC challenges.

Here’s why industrial clients across the USA trust us:

-

Specialization in York Systems: We deal exclusively in genuine York products, ensuring technical accuracy and full compatibility.

-

Experience in Industrial Applications: We understand the operational pressures of industrial environments and provide tailored solutions.

-

Reliable Support: From initial consultation to after-sales assistance, we’re committed to your satisfaction.

-

Nationwide Reach: No matter where your facility is located, we can supply you with York chiller parts quickly and efficiently.

🔧 Common Replacement York Chiller Parts Available at Midwest Parts Center

To give you a better idea of what’s available, here’s a list of commonly requested York chiller parts:

-

Compressors

-

Condenser coils

-

Expansion valves

-

Oil filters

-

Thermistors

-

Pressure transducers

-

Evaporator tubes

-

Control boards

-

Fan blades and motors

-

Refrigerant circuit components

Each of these parts plays a crucial role in keeping your chiller running efficiently. By replacing worn or damaged parts with genuine York components, you’re investing in system longevity and performance stability.

🧠 Why Certified Parts Make a Difference

Using non-certified or counterfeit parts may seem cost-effective at first, but it often leads to expensive repairs and energy inefficiency down the line. Certified York chiller parts ensure:

-

Proper airflow and pressure management

-

Accurate temperature control

-

Reduced energy consumption

-

Compliance with safety standards

-

Longer component life

In short, genuine York parts protect your investment and deliver measurable value over time.

🚀 The Smart Choice for Industrial Facilities

For industrial facilities across the USA, choosing the right HVAC parts supplier is critical to operational success. Midwest Parts Center is proud to serve as the trusted source for certified York chiller parts, providing unmatched reliability, expertise, and service.

By partnering with us, you gain:

-

Quick access to OEM-certified components

-

Reduced downtime through fast shipping

-

Expert technical support

-

Long-term cost savings through system efficiency

When your business depends on uninterrupted cooling performance, you can’t afford to take chances with inferior parts or unreliable suppliers.

If you’re searching for certified York chiller parts for your industrial facility, look no further than Midwest Parts Center. We are dedicated to helping businesses maintain peak HVAC performance through Genuine York components, expert support, and responsive service.

📞 Call us today at +1 800 368 8385 to speak with one of our specialists or request a quote.

With Midwest Parts Center, you’ll get the right York chiller parts, the right service, and the right results—every time.

Extend the Life of Your HVAC System with OEM York Chiller Parts

When it comes to industrial and commercial cooling, a reliable HVAC system is the heartbeat of your operations. Whether it’s a sprawling manufacturing plant, a large-scale data center, or a high-capacity hospital, maintaining the perfect indoor environment is essential for safety, comfort, and productivity. But every HVAC system, no matter how advanced, relies heavily on one thing — the quality of its parts. That’s where York chiller parts make the difference.

At Midwest Parts Center, we understand how important it is to keep your HVAC system running smoothly, efficiently, and without interruption. As a trusted provider of OEM York chiller parts for commercial and industrial applications, we help businesses across the USA extend the life of their HVAC systems and reduce costly downtime. Whether you need replacement components, maintenance parts, or technical guidance, we’re just a call away at +1 800 368 8385.

Let’s explore how you can maximize your HVAC investment and ensure long-term performance with genuine York chiller parts.

🌬️ Why Industrial HVAC Systems Depend on York Chillers

York chillers have long been at the forefront of HVAC innovation. Designed for energy efficiency, reliability, and durability, York chillers are engineered to handle the rigorous demands of industrial and commercial facilities. From cooling manufacturing processes to maintaining precise temperatures in laboratories and data centers, York systems are built for performance.

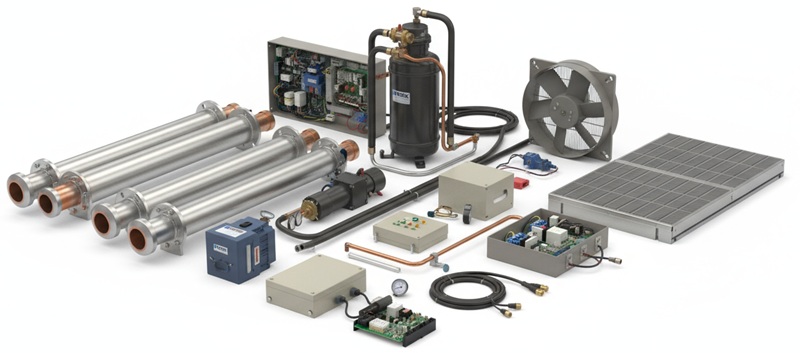

However, the key to keeping these advanced chillers performing at their best lies in proper maintenance and the use of OEM York chiller parts. These components are designed to integrate seamlessly into York systems, maintaining their original engineering integrity and efficiency.

When facility managers or service technicians opt for genuine York chiller parts, they ensure that every component—from compressors to valves—works in perfect harmony with the rest of the system. The result? Longer system life, reduced energy costs, and fewer breakdowns.

⚙️ Understanding the Importance of OEM York Chiller Parts

“Why should I choose OEM parts when there are cheaper alternatives?”

This is a question many facility owners ask—and the answer lies in long-term value. OEM York chiller parts (Original Equipment Manufacturer parts) are specifically designed and tested by York engineers to meet strict quality and performance standards. These parts are not generic or one-size-fits-all; they are purpose-built to match the exact specifications of York chillers.

Here’s why OEM parts matter:

-

Perfect Fit and Compatibility:

OEM parts are designed to fit seamlessly into your York chiller system. This ensures smooth operation, minimizes vibration, and prevents wear and tear caused by mismatched components. -

Superior Quality Materials:

York uses high-grade materials in its OEM components to withstand the extreme conditions of industrial HVAC applications. That means your system runs longer and more reliably. -

Preserves Warranty and System Integrity:

Using non-OEM parts can void your warranty and lead to operational issues. Genuine York chiller parts from Midwest Parts Center keep your warranty intact and your system protected. -

Optimal Energy Efficiency:

Original York components are designed to maintain your system’s original energy efficiency levels. Generic parts may seem cheaper, but they can cause your chiller to work harder and consume more power—costing you more in the long run. -

Enhanced Safety and Reliability:

Industrial systems operate under high pressure and temperatures. OEM parts ensure safe operation, reducing the risk of malfunctions or hazardous situations.

When you choose Midwest Parts Center, you’re not just buying a component—you’re investing in reliability, performance, and peace of mind.

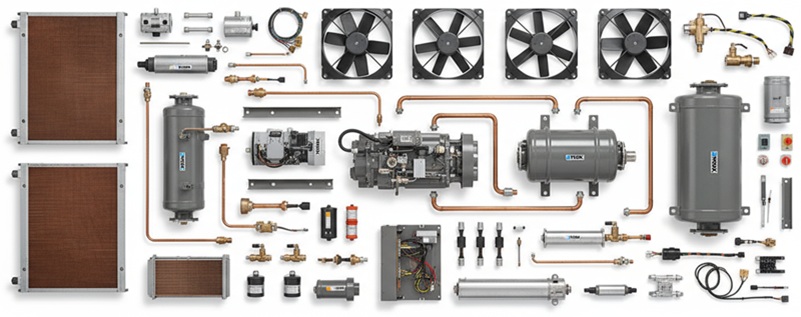

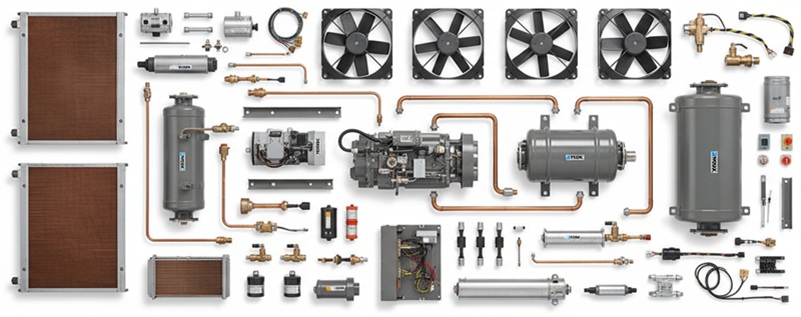

🧰 Common York Chiller Parts That Keep Your System Running

Every component in your York chiller has a specific function that contributes to system performance. Here are some of the most commonly replaced York chiller parts available at Midwest Parts Center:

-

Compressors: The core of the chiller, responsible for compressing refrigerant gas and enabling the cooling cycle.

-

Condenser Coils: Transfer heat out of the refrigerant, ensuring efficient cooling.

-

Evaporator Tubes: Facilitate the absorption of heat from air or water.

-

Expansion Valves: Regulate refrigerant flow within the system.

-

Motors and Fans: Drive air circulation for optimal heat exchange.

-

Sensors and Control Boards: Manage system performance and monitor operating conditions.

-

Gaskets and Seals: Prevent leaks and maintain system pressure.

-

Filters: Keep contaminants out of the refrigerant lines, ensuring longevity.

Each of these York chiller parts plays a crucial role in keeping your HVAC system working at full capacity. Regular replacement of worn components with OEM parts ensures efficiency and prevents system strain.

🏭 How OEM York Chiller Parts Extend HVAC System Life

Your HVAC system represents a significant investment—one that deserves protection and care. By using OEM York chiller parts from Midwest Parts Center, you can extend your system’s lifespan and get the most out of your equipment.

Here’s how:

1. Reduced Wear and Tear

Non-OEM parts may fit loosely or tightly, causing additional friction or strain on the system. Genuine York chiller parts ensure perfect alignment, minimizing mechanical stress and extending component life.

2. Consistent Performance

Original York components maintain factory-level performance over time, ensuring consistent cooling capacity, pressure control, and energy efficiency.

3. Enhanced Preventive Maintenance

Replacing key parts at regular intervals prevents small issues from turning into major breakdowns. At Midwest Parts Center, we supply all the necessary components for a proactive maintenance strategy.

4. Improved Energy Efficiency

A well-maintained chiller equipped with OEM parts uses less energy, reducing operational costs and environmental impact.

5. Minimized Downtime

System failure can lead to costly production halts. By using certified York chiller parts, you reduce the likelihood of unexpected breakdowns, keeping your operations running smoothly.

🔍 Signs That It’s Time to Replace York Chiller Parts

Ignoring small performance issues can lead to major system failures. Here are common warning signs that indicate your HVAC system might need new York chiller parts:

-

Inconsistent cooling performance

-

Unusual noises or vibrations

-

Increased energy bills

-

Frequent system cycling

-

Refrigerant leaks or pressure drops

-

Alarm notifications on your control panel

When you notice any of these signs, it’s best to act quickly. Call Midwest Parts Center at +1 800 368 8385 for expert advice and fast delivery of the correct York parts.

🌡️ The Role of Regular Maintenance in System Longevity

Preventive maintenance is the backbone of HVAC reliability. Even the most advanced York chillers require regular inspections, cleaning, and parts replacement to perform efficiently.

At Midwest Parts Center, we encourage facility managers to integrate OEM York chiller parts into their maintenance programs. Doing so helps in:

-

Maintaining optimal operating temperatures

-

Reducing unexpected breakdowns

-

Ensuring consistent airflow and pressure levels

-

Preventing refrigerant contamination

-

Meeting regulatory and environmental standards

By using genuine York components, you maintain system integrity and performance consistency year after year.

🧠 Why Choose Midwest Parts Center for York Chiller Parts

When it comes to sourcing reliable HVAC parts for industrial use, Midwest Parts Center is the name professionals trust. Here’s what makes us stand out:

✅ Exclusive Focus on York Products

We specialize in genuine York chiller parts, offering a wide range of OEM components for every model. Whether you operate YK, YT, or YLAA chillers, we have the parts you need.

✅ Vast Inventory for Immediate Availability

Downtime costs money. That’s why we maintain a large stock of commonly requested York parts, ready for fast dispatch anywhere in the USA.

✅ Expert Support Team

Our technical specialists understand York systems inside and out. Need help identifying a part? We’ll guide you through the process and ensure you order the right one the first time.

✅ Reliable Nationwide Shipping

No matter where your industrial facility is located, Midwest Parts Center delivers quickly and reliably, ensuring you get your York chiller parts when you need them.

✅ Unmatched Customer Care

We take pride in offering exceptional customer service. From your first call to final delivery, you can count on personalized assistance and professional support.

📞 For immediate assistance, call +1 800 368 8385.

💡 Cost Benefits of Using OEM York Chiller Parts

While OEM components may seem more expensive upfront, they deliver superior value in the long term. Here’s how:

-

Lower Energy Costs: Properly fitting York parts helps your chiller operate efficiently, cutting down power consumption.

-

Reduced Maintenance Costs: OEM parts last longer, meaning fewer replacements and less labor over time.

-

Avoid System Failures: Prevent costly breakdowns that could disrupt operations or damage other components.

-

Preserved Equipment Value: Systems maintained with original parts retain their efficiency and resale value.

In short, investing in genuine York chiller parts is investing in your system’s longevity and operational reliability.

⚡ Real-World Impact: Reliability in Action

Imagine running a manufacturing facility where production depends on precise temperature control. A single malfunction in the cooling system could halt operations, delay shipments, and affect product quality.

Now, imagine avoiding that scenario simply by using genuine York chiller parts supplied by Midwest Parts Center. With the right components installed, your system runs at peak performance—day after day, year after year.

That’s the power of reliability. That’s the confidence you gain when you choose Midwest Parts Center.

🧩 How to Order York Chiller Parts from Midwest Parts Center

Getting the right parts is simple and hassle-free. Here’s how you can order from us:

-

Identify Your Chiller Model:

Locate your unit’s model and serial number—this information helps us find the exact parts you need. -

Contact Our Team:

Call us at +1 800 368 8385 or send a request through our contact page. -

Get Expert Assistance:

Our specialists will confirm the part number, availability, and pricing. -

Fast Shipping:

We’ll ship your parts quickly, ensuring minimal downtime for your facility.

With Midwest Parts Center, you can be confident you’re getting authentic York chiller parts that keep your HVAC system operating like new.

🌍 Supporting Industrial and Commercial Sectors Nationwide

Midwest Parts Center proudly serves a wide range of industrial and commercial clients across the United States. Our focus includes:

-

Manufacturing facilities

-

Data centers

-

Hospitals and medical campuses

-

Universities and research labs

-

Food processing plants

-

Power generation facilities

We understand that every industry has unique cooling demands, and that’s why we tailor our service to meet your specific needs—always providing genuine York chiller parts for dependable performance.

🔧 Keep Your HVAC System Strong for Years to Come

Your HVAC system is one of your facility’s most valuable assets. Keeping it in peak condition requires more than routine maintenance—it requires the right parts. With genuine York chiller parts from Midwest Parts Center, you’re ensuring your system runs efficiently, safely, and for many years to come.

Whether you’re replacing a compressor, installing new sensors, or conducting a major overhaul, we’re here to support your operation every step of the way.

📞 Call Midwest Parts Center today at +1 800 368 8385 to order certified York chiller parts or speak with an expert about your system’s needs.