York YLAA chiller parts: YLAA is a well-known brand in the heating, and cooling business as York is known for its quality products. There are many aspects to consider while purchasing York YLAA chiller parts.

York YLAA chiller parts: YLAA is a well-known brand in the heating, and cooling business as York is known for its quality products. There are many aspects to consider while purchasing York YLAA chiller parts.

However, they are regarded as the most durable and reliable cooling and temperature control systems. Air conditioners can function better with the help of YLAA parts.

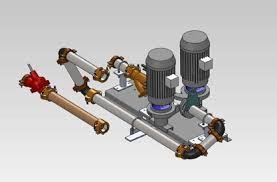

York YLAA chiller parts, for example, are now more easily accessible than ever before. Commercial end-users prefer the YLAA chiller as an efficient cooling solution. In addition to chilling rooms, chillers can also be used to cool machinery and products. For the equipment to function correctly, it must be regularly serviced.

Seven Uses of YLAA Chillers.

A wide range of industries can benefit from YLAA chiller systems. Five industries employ York YLAA chiller parts. Here are some of the most typical uses for the YLAA industrial chiller:

Electrical and Power

The use of chillers necessitates a significant investment in electrical power. When chillers fail, a lot more electricity is used. Any signs of deterioration or poor performance in a chiller should be investigated. A professional can examine any problems you may be experiencing.

It’s possible to repair or replace York YLAA chiller parts. New features can improve the efficiency of a machine and restore its full functioning. Every building requires chiller service from an expert technician, regardless of its uniqueness.

Food Processing Industry

When precise temperature control is needed, industrial chillers are typically employed. YLAA chillers, for example, are used by wineries to maintain the fermentation and storage temperatures of the beverage.

When precise temperature control is needed, industrial chillers are typically employed. YLAA chillers, for example, are used by wineries to maintain the fermentation and storage temperatures of the beverage.

Some of the bakery’s equipment that can benefit from chillers are Yeast Jacketed Tanks, Cooled Mixers, and Potable Water Plastic pieces can be made via injection moulding.

Plastic parts are made via injection moulding, using thermoplastic pellets, moulds, and injection moulding equipment. Temperature management is vital to avoid cracks, warping, and internal stresses in the finished product.

Metal Electroplating

Temperature control is critical for electroplating and electron-less plating, which both require several hundred degrees to bind the metals together. Depending on the type of business, the anodizing liquid is cooled using metal-finishing chillers or glycol/water in a heat exchanger.

Plastic Moulding

Plastic parts are made via injection moulding, using thermoplastic pellets, moulds, and injection moulding equipment. Temperature management is vital to avoid cracks, warping, and internal stresses in the finished product.

Office Use

Reduce temperature extremes by using an office chiller in manufacturing operations with heavy-duty equipment. They also save money in the long term by not requiring additional cooling systems.

The Right Size Chiller is Essential

When deciding on the right chiller size for your cooling needs, there are numerous things to keep in mind. York YLAA Chillers’ sizing tool can help you quickly establish your chiller’s capacity and freight weight.

When deciding on the right chiller size for your cooling needs, there are numerous things to keep in mind. York YLAA Chillers’ sizing tool can help you quickly establish your chiller’s capacity and freight weight.

Look no farther than the specialists at York Ylaa Chillers for all of your chiller needs! Having been in business for more than three decades, Chillers is an industry leader in developing industrial chiller systems.

Chiller repair and replacement services for York YLAA models

The ability to effectively regulate a facility’s temperature directly impacts its profitability and output. York Ylaa Chiller Parts, on the other hand, is a helpful introduction. As a result, building managers and business owners can figure out how to avoid chiller difficulties.

If you need help locating York YLAA chiller spare parts, don’t hesitate to contact us.