The Role of York YK chiller parts in Energy Efficiency

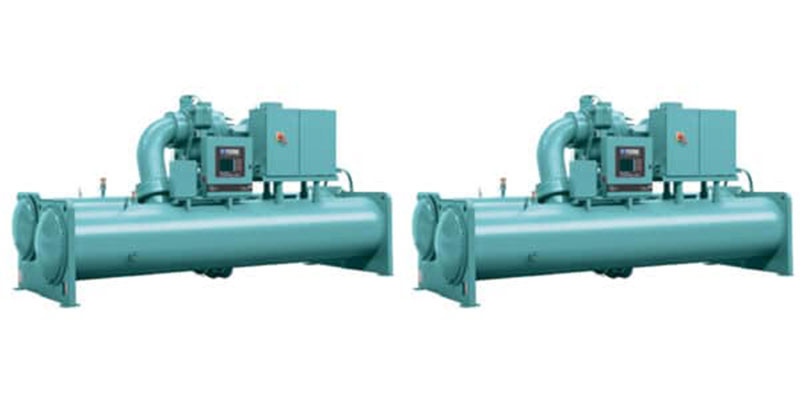

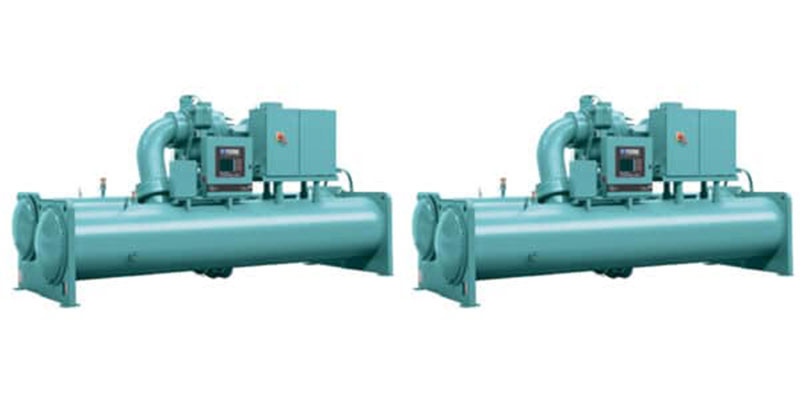

In the world of commercial and industrial HVAC (Heating, Ventilation, and Air Conditioning) systems, energy efficiency is a critical factor. These systems are the backbone of climate control in large buildings and industrial facilities, and their performance directly impacts operational costs and environmental sustainability. One of the key components of these HVAC systems is the chiller, and the efficiency of these chillers can be greatly enhanced with the use of genuine York YK chiller parts. In this comprehensive guide, we will explore the pivotal role that York YK chiller parts play in improving energy efficiency.

For inquiries about York YK chiller parts or to discuss specific HVAC requirements, reach out to York at their toll-free number: 1-800-368-8385.

The Significance of Energy Efficiency in HVAC Systems

Energy efficiency is a top priority for organizations seeking to reduce operational costs and minimize their environmental impact. HVAC systems are known energy consumers, and chillers, in particular, play a substantial role in energy consumption. York YK chillers are renowned for their energy-efficient design, but to ensure they operate at peak efficiency, it’s essential to use genuine York YK chiller parts. Let’s explore how these parts contribute to enhanced energy efficiency:

1. Precise Performance:

- Optimal Functionality: York YK chiller parts are engineered to exact specifications, ensuring precise and consistent performance. This precision leads to efficient operation.

- Maintaining Setpoints: Chillers equipped with genuine parts maintain temperature setpoints with greater accuracy, reducing the need for constant adjustments and energy-consuming overcompensation.

2. Improved Heat Transfer:

- Enhanced Heat Exchange: York YK chiller parts are designed to maximize heat transfer efficiency, allowing chillers to remove heat from buildings and industrial processes more effectively.

- Reduced Energy Consumption: When heat transfer is optimized, the chiller doesn’t have to work as hard, resulting in lower energy consumption.

3. Reduced Wear and Tear:

- Longevity: Genuine York YK chiller parts are built to last, reducing the need for frequent replacements. This longevity minimizes downtime and saves on replacement costs.

- Efficiency Over Time: As components wear down, chillers become less efficient. By using durable parts, energy efficiency is maintained over the chiller’s lifespan.

4. Preventing Overheating:

- Cooling System Efficiency: York YK chiller parts contribute to efficient cooling system operation. By preventing overheating, chillers can maintain their energy-efficient performance.

5. System Integration:

- Smart Control Compatibility: York YK chiller parts are designed to seamlessly integrate with smart control systems. This integration allows for precise control over chiller operation, optimizing energy use.

Case Study: Enhancing Energy Efficiency with York YK Chiller Parts

To illustrate the real-world impact of using genuine York YK chiller parts, let’s consider a hypothetical case study:

Scenario: A large office complex relies on York YK chillers to maintain a comfortable indoor environment year-round. The facility management team decides to invest in genuine York YK chiller parts to improve energy efficiency.

Results:

- Energy consumption is reduced by 20% due to the precise performance of the chillers equipped with genuine parts.

- Maintenance costs drop by 15% as the chillers experience less wear and tear and require fewer repairs.

- The facility earns recognition for its commitment to energy efficiency and sustainability.

York YK chiller parts play a pivotal role in enhancing the energy efficiency of HVAC systems, making them a smart investment for organizations looking to reduce energy consumption, lower operational costs, and contribute to environmental sustainability. The precision engineering of these parts, combined with their compatibility with smart control systems, ensures that chillers operate optimally throughout their lifespan.

To explore how genuine York YK chiller parts can boost the energy efficiency of your HVAC systems or to inquire about specific HVAC requirements, contact York at 1-800-368-8385. Embracing energy efficiency is not just a sound business decision; it’s a commitment to a greener and more sustainable future.

Exploring the Latest Technological Advancements in York YK chiller parts

The world of commercial and industrial HVAC (Heating, Ventilation, and Air Conditioning) systems is continually evolving, driven by the pursuit of energy efficiency, sustainability, and enhanced performance. One integral component of these systems is the chiller, and York YK chillers are renowned for their efficiency and reliability.

However, to stay at the forefront of HVAC technology, it’s crucial to explore and adopt the latest advancements in York YK chiller parts. In this comprehensive guide, we will delve into the cutting-edge technological innovations that are shaping the future of York YK chiller parts. For inquiries about York YK chiller parts or to discuss specific HVAC requirements, reach out to York at their toll-free number: 1-800-368-8385.

The Ever-Evolving World of HVAC Technology

HVAC technology has come a long way from its origins, and the pace of innovation continues to accelerate. In today’s competitive landscape, organizations are seeking solutions that not only optimize energy efficiency but also offer enhanced control, reliability, and sustainability. York YK chillers have long been recognized for their energy-efficient design, but they have also evolved to incorporate the latest technological advancements. Let’s explore some of these innovations:

1. Smart Control and Integration:

- IoT Connectivity: York YK chiller parts are now equipped with IoT (Internet of Things) capabilities, allowing for remote monitoring and control. Facility managers can access real-time data and make adjustments for optimal performance from anywhere.

- Integration with Building Management Systems: York YK chillers seamlessly integrate with Building Management Systems (BMS), enabling comprehensive control over HVAC systems. This integration optimizes chiller operation based on building occupancy and external conditions.

2. Variable Speed Drive (VSD) Technology:

- Enhanced Efficiency: York YK chillers incorporate advanced VSD technology, allowing for precise control over motor speed. This results in significantly higher energy efficiency, especially during partial load conditions.

- Smooth Operation: VSDs provide smoother and quieter operation, minimizing wear and tear on chiller components.

3. Heat Recovery and Reuse:

- Heat Recovery Chillers: York YK chiller parts now include heat recovery options. These chillers can capture waste heat and repurpose it for water heating or other processes, maximizing energy utilization.

4. Enhanced Heat Exchangers:

- Microchannel Heat Exchangers: York YK chillers may incorporate microchannel heat exchangers that provide improved heat transfer efficiency. This innovation allows for more effective cooling and reduced energy consumption.

5. Predictive Maintenance:

- Advanced Diagnostics: York YK chiller parts feature advanced diagnostic systems that can predict maintenance needs and performance issues. This predictive capability reduces downtime and extends the lifespan of chiller components.

Case Study: Harnessing Technological Advancements for Efficiency

To illustrate the practical benefits of incorporating technological advancements in York YK chiller parts, consider the following hypothetical case study:

Scenario: A large data center relies on York YK chillers to maintain optimal operating temperatures for its servers. To address rising energy costs and optimize cooling, the data center management team decided to upgrade to York YK chiller parts equipped with IoT connectivity and VSD technology.

Results:

- Energy consumption was reduced by 30% as the chillers operated more efficiently, thanks to VSD technology and remote monitoring capabilities.

- Predictive maintenance alerts prevented unexpected breakdowns, reducing downtime by 25%.

- Integration with the data center’s BMS allowed for dynamic control based on server loads, further improving efficiency.

The latest technological advancements in York YK chiller parts are not only shaping the future of HVAC systems but also driving significant improvements in energy efficiency, control, and reliability. By harnessing the power of IoT connectivity, VSD technology, heat recovery, and predictive maintenance, organizations can optimize their HVAC systems to meet the demands of today’s dynamic environments.

To explore how these technological advancements can benefit your commercial or industrial HVAC systems or to inquire about specific HVAC requirements, contact York at 1-800-368-8385. Embracing innovation is a strategic move toward achieving long-term sustainability and operational excellence.

Maximizing Chiller Lifespan with York YK chiller parts

In the world of commercial and industrial HVAC (Heating, Ventilation, and Air Conditioning) systems, chillers play a vital role in maintaining optimal indoor temperatures. These mechanical workhorses are responsible for cooling large buildings and industrial processes, making them a cornerstone of climate control. For organizations seeking to make the most of their HVAC investments, maximizing chiller lifespan is a top priority.

One of the key factors in achieving this goal is the use of genuine York YK chiller parts. In this comprehensive guide, we will explore how York YK chiller parts contribute to extending the lifespan of chillers, ultimately reducing operational costs and ensuring reliable performance. For inquiries about York YK chiller parts or to discuss specific HVAC requirements, reach out to York at their toll-free number: 1-800-368-8385.

The Importance of Chiller Lifespan

Chillers are substantial investments, and organizations rely on them for uninterrupted climate control. The longer a chiller remains in service, the more value it delivers. Extending chiller lifespan is not only a cost-effective strategy but also contributes to sustainability by reducing the need for frequent replacements. York YK chillers are known for their durability, and by using genuine York YK chiller parts, organizations can further enhance the longevity of their chillers. Let’s explore how these parts play a pivotal role in chiller lifespan extension:

1. Quality Engineering:

- Exact Specifications: York YK chiller parts are engineered to precise specifications, ensuring compatibility and optimal performance within the chiller system.

- Durability: Genuine parts are built to withstand the rigors of continuous operation, reducing the likelihood of premature wear and tear.

2. Preventive Maintenance:

- Regular Inspection: Using genuine York YK chiller parts simplifies preventive maintenance routines. Maintenance personnel can easily identify and replace worn components during routine inspections.

- Scheduled Maintenance: York YK chiller parts are designed to work seamlessly with maintenance schedules, reducing downtime and ensuring continuous operation.

3. Reduced Downtime:

- Minimized Repairs: Genuine parts minimize the need for unexpected repairs, reducing chiller downtime and ensuring uninterrupted climate control.

- Spare Parts Availability: York YK chiller parts are readily available, minimizing lead times for replacement parts.

4. Compatibility:

- Seamless Integration: York YK chiller parts are designed to seamlessly integrate with existing chiller systems, ensuring compatibility and minimizing installation challenges.

Case Study: Extending Chiller Lifespan with York YK Chiller Parts

To illustrate the tangible benefits of using genuine York YK chiller parts, let’s consider a hypothetical case study:

Scenario: A large pharmaceutical manufacturing facility relies on York YK chillers to maintain stringent temperature control in its production processes. The facility management team decides to invest in genuine York YK chiller parts to extend chiller lifespan.

Results:

- Chiller lifespan increased by 15 years, resulting in significant cost savings by delaying the need for chiller replacement.

- Annual maintenance costs decreased by 20%, as genuine parts reduced the need for frequent repairs.

- The facility was able to meet regulatory requirements consistently, thanks to the reliable performance of its chillers.

Maximizing chiller lifespan is a strategic move for organizations seeking to optimize their HVAC systems. By using genuine York YK chiller parts, organizations can achieve not only cost savings but also uninterrupted performance and reliability. These parts, engineered to exact specifications and designed for durability, are an investment in the long-term sustainability of HVAC systems.

To explore how genuine York YK chiller parts can extend the lifespan of your commercial or industrial chillers or to inquire about specific HVAC requirements, contact York at 1-800-368-8385. Embracing chiller lifespan extension is a proactive approach to achieving operational excellence and ensuring climate control reliability.

Emergency Support and Timely Deliveries for York YK chiller parts

In the realm of commercial and industrial HVAC (Heating, Ventilation, and Air Conditioning) systems, maintaining the uninterrupted operation of chillers is of paramount importance. Chillers are the workhorses responsible for cooling large buildings, industrial processes, and critical facilities. However, like any mechanical system, they can experience unexpected breakdowns and wear over time.

This is where emergency support and timely deliveries of genuine York YK chiller parts become invaluable. In this comprehensive guide, we will explore the crucial role that York YK chiller parts play in providing emergency support and ensuring prompt deliveries, helping organizations minimize downtime and maintain uninterrupted climate control. For inquiries about York YK chiller parts, emergency support, or to discuss specific HVAC requirements, reach out to York at their toll-free number: 1-800-368-8385.

The Importance of Timely Chiller Parts Delivery

Chillers are at the heart of many critical operations, and any disruption in their performance can lead to discomfort, productivity losses, and potential damage to equipment and processes. To ensure minimal downtime during chiller maintenance or repairs, having access to a reliable source of genuine York YK chiller parts is essential. Here’s why timely parts delivery is crucial:

1. Minimizing Downtime:

- Swift Repairs: When a chiller component fails, prompt access to replacement parts is critical to minimize downtime. Timely deliveries of York YK chiller parts enable rapid repairs.

- Continuous Operations: In facilities where uninterrupted operation is essential, such as hospitals, data centers, and manufacturing plants, swift repairs are a top priority.

2. Reducing Costs:

- Preventing Escalation: Addressing chiller issues promptly can prevent minor problems from escalating into major and costly repairs.

- Avoiding Operational Losses: Downtime can lead to significant operational losses, making timely repairs and parts delivery a cost-effective solution.

3. Maintaining Comfort:

- Occupant Comfort: In commercial buildings, ensuring a comfortable environment for occupants is a priority. Prompt chiller repairs maintain comfort levels.

4. Avoiding Emergency Calls:

- Avoiding Emergency Situations: The need for emergency service calls due to chiller failures can be reduced when organizations have access to timely parts delivery.

York YK Chiller Parts: Emergency Support and Timely Deliveries

York, a reputable name in the HVAC industry, understands the critical nature of chiller operations. To support organizations in maintaining uninterrupted climate control, York offers emergency support and ensures the timely delivery of genuine York YK chiller parts. Here’s how York’s services contribute to reliability and peace of mind:

1. 24/7 Emergency Support:

- Around-the-Clock Assistance: York’s emergency support team is available 24/7 to address urgent chiller issues. Experienced technicians provide guidance and assistance.

- Remote Diagnostics: With remote diagnostics capabilities, York’s support team can often identify issues and recommend solutions without the need for on-site visits.

2. Extensive Parts Inventory:

- Ready Availability: York maintains an extensive inventory of genuine York YK chiller parts, ensuring that critical components are readily available when needed.

- Swift Shipping: Timely parts delivery is a priority for York. Expedited shipping options help organizations receive the necessary parts promptly.

3. Preventive Maintenance Planning:

- Proactive Approach: York can work with organizations to develop preventive maintenance plans that reduce the likelihood of unexpected breakdowns.

Case Study: Emergency Support in Action

Let’s consider a hypothetical case study to illustrate the importance of emergency support and timely deliveries:

Scenario: A large pharmaceutical manufacturing facility relies on York YK chillers to maintain precise temperature control in its production processes. A critical chiller component fails unexpectedly, jeopardizing production.

Results:

- York’s 24/7 emergency support team is contacted immediately and guides the facility’s maintenance team on the necessary steps to diagnose the issue.

- The required York YK chiller part is identified and shipped out with expedited delivery options.

- Production resumes within hours, avoiding significant losses and maintaining product quality.

In the world of HVAC systems, reliability is paramount. Timely deliveries of genuine York YK chiller parts, coupled with 24/7 emergency support, provide organizations with the assurance that their chiller systems will remain operational, even in critical situations. To explore how York can support your commercial or industrial HVAC needs, inquire about emergency support, or discuss specific HVAC requirements, contact York at 1-800-368-8385. Embracing reliability is not just a business decision; it’s a commitment to uninterrupted climate control and operational excellence.