Where to Buy Genuine York YT Chiller Parts and Components in the USA

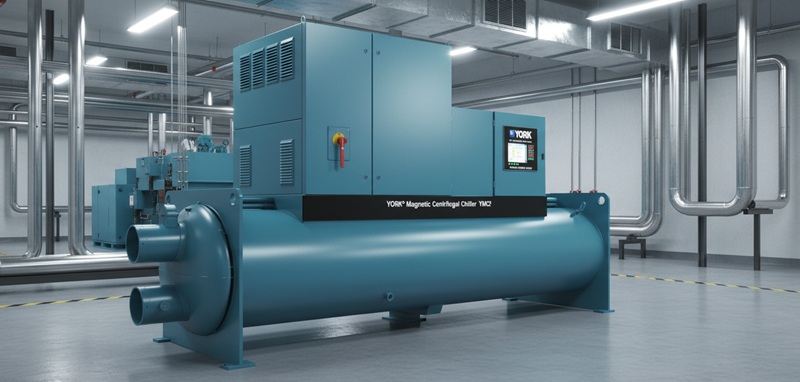

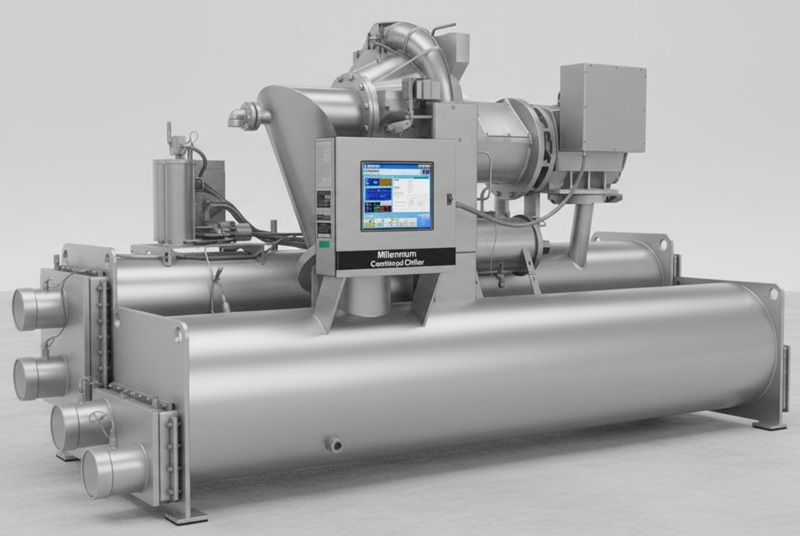

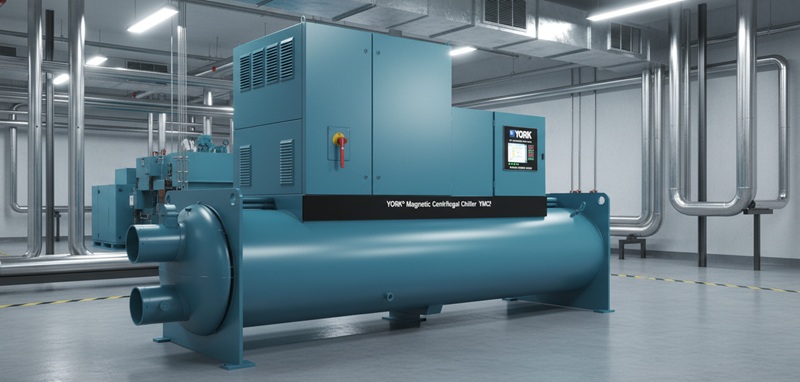

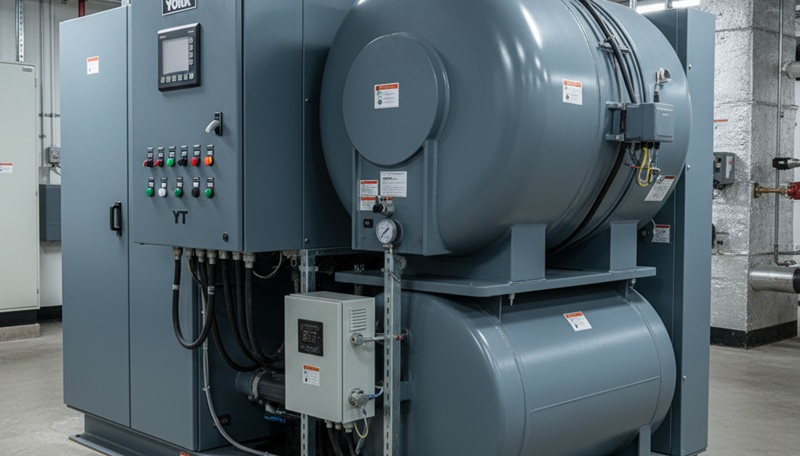

In large commercial buildings and industrial facilities across the United States, chillers are the backbone of climate control systems. Among the most recognized and widely installed centrifugal chillers is the York YT chiller. Known for its efficiency, advanced engineering, and dependable performance, the York YT chiller plays a critical role in maintaining temperature stability in hospitals, manufacturing plants, data centers, universities, office towers, and processing facilities.

However, even the most advanced chiller requires maintenance and occasional component replacement. When that time comes, knowing where to buy genuine York YT chiller parts and components in the USA becomes essential. The wrong supplier can lead to compatibility issues, operational inefficiencies, and costly downtime. The right supplier ensures reliability, performance, and long-term protection of your equipment investment.

Midwest Parts Center specializes in supporting commercial and industrial facilities with genuine parts for the York YT chiller. As a company focused exclusively on commercial and industrial areas, Midwest Parts Center understands the complexity and urgency associated with chiller systems. For immediate assistance or parts inquiries, you can contact Midwest Parts Center at +1 800 368 8385.

Understanding the Importance of Genuine York YT Chiller Components

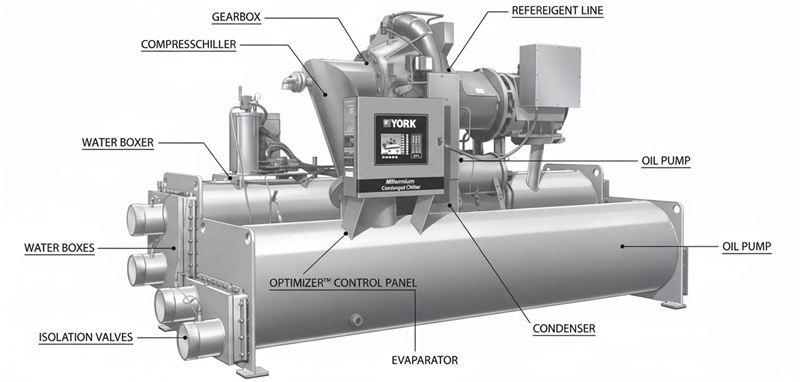

The York YT chiller is engineered for high-capacity cooling applications. It operates under demanding conditions, often running continuously to maintain strict environmental standards. In such systems, every component matters. From impellers and bearings to control panels and sensors, each part works in precise coordination.

Using genuine components ensures that your York YT chiller continues to operate according to original engineering specifications. These chillers are designed with advanced technology that depends on exact tolerances and calibrated performance. Installing non-genuine or mismatched components can disrupt this balance.

In commercial and industrial settings, even minor inefficiencies can result in significant energy costs over time. An improperly matched part can increase vibration, strain motors, or disrupt refrigerant flow. That is why purchasing genuine York YT chiller parts from a reliable source is critical.

Midwest Parts Center provides dependable access to genuine components specifically designed for the York YT chiller. Our experience in commercial and industrial applications allows us to guide facility managers toward the correct parts quickly and accurately.

Why Commercial and Industrial Facilities Need a Specialized Supplier

The Complexity of Large-Scale Chiller Systems

Unlike smaller HVAC units, the York YT chiller is a sophisticated centrifugal system designed for high-performance environments. It involves complex mechanical assemblies, electronic controls, and precise refrigerant management. Maintenance and repairs require technical understanding and access to properly engineered components.

Commercial and industrial facilities cannot afford guesswork when sourcing parts. A supplier that lacks expertise in large-scale chillers may provide incompatible components that compromise performance. Midwest Parts Center focuses exclusively on commercial and industrial sectors, ensuring that the parts supplied align with high-capacity operational requirements.

When your York YT chiller requires attention, contacting Midwest Parts Center at +1 800 368 8385 connects you with professionals who understand the specific demands of industrial cooling systems.

Minimizing Downtime in Critical Operations

Chillers often support mission-critical operations. In hospitals, they maintain controlled environments. In data centers, they prevent equipment overheating. In manufacturing plants, they regulate temperatures necessary for production quality. When a York YT chiller goes offline, the consequences can be immediate and costly.

Sourcing genuine parts quickly becomes a priority. Midwest Parts Center understands the urgency associated with chiller downtime. By serving commercial and industrial facilities across the USA, we help ensure that replacement components for your York YT chiller are accessible when needed.

Protecting the Performance of Your York YT Chiller

Maintaining Energy Efficiency

One of the major advantages of the York YT chiller is its energy-efficient design. These chillers are engineered to reduce operational costs while delivering powerful cooling capacity. Maintaining that efficiency depends on using parts that match original specifications.

A non-genuine component may appear similar in size or shape, but even slight differences in materials or design can reduce efficiency. Over time, this can increase electricity consumption and operational expenses.

Midwest Parts Center helps facilities protect the energy performance of their York YT chiller by providing components engineered for compatibility. When each part performs as intended, the entire system operates smoothly and efficiently.

Extending Equipment Lifespan

A York YT chiller represents a substantial investment for any commercial or industrial facility. Protecting that investment requires proper maintenance and the use of genuine components.

Installing inferior or incompatible parts can introduce unnecessary wear on surrounding components. Increased vibration, improper lubrication, or electrical inconsistencies can shorten equipment lifespan.

By sourcing genuine York YT chiller components from Midwest Parts Center, facilities can extend the life of their equipment and reduce long-term replacement costs. Protecting system integrity today helps prevent major capital expenditures in the future.

Where to Buy Genuine York YT Chiller Parts in the USA

Finding a trusted source for genuine York YT chiller parts in the USA requires careful consideration. The supplier must understand large-scale HVAC systems and prioritize commercial and industrial needs.

Midwest Parts Center stands out as a reliable provider of genuine York YT chiller components. Our company is dedicated to serving commercial and industrial areas, focusing on the unique challenges faced by large facilities.

When you partner with Midwest Parts Center, you gain access to knowledgeable professionals who understand the technical requirements of the York YT chiller. Whether you need replacement sensors, control modules, mechanical components, or specialized assemblies, we are equipped to assist.

For direct support, contacting +1 800 368 8385 ensures that you receive accurate information and responsive service tailored to your facility’s needs.

Technical Support That Makes a Difference

Accurate Part Identification

One of the most common challenges in chiller maintenance is identifying the correct replacement component. Even small variations in model configurations can affect compatibility.

Midwest Parts Center assists in identifying the proper parts for your specific York YT chiller configuration. This reduces ordering errors and ensures that repairs proceed without unnecessary delays.

Accurate part identification is especially important in industrial environments where downtime can impact production schedules. Working with a specialized supplier eliminates uncertainty.

Guidance for Maintenance Teams

Commercial and industrial maintenance teams often handle multiple systems across large facilities. Having access to a dependable supplier simplifies procurement and technical clarification.

Midwest Parts Center serves as a reliable partner for facilities managing York YT chiller systems. Our team understands the operational demands placed on chillers and can guide to support efficient repairs.

Supporting Preventive Maintenance Strategies

Preventive maintenance is essential for maximizing the performance of a York YT chiller. Regular inspections and timely replacement of wear components help prevent unexpected breakdowns.

Sourcing genuine parts from Midwest Parts Center supports proactive maintenance programs. When maintenance teams have reliable access to the correct components, they can schedule service confidently and reduce the risk of emergency repairs.

Preventive strategies not only improve reliability but also stabilize operational costs. Maintaining your York YT chiller with genuine components helps ensure consistent performance throughout the year.

Reliability in High-Demand Environments

Industrial facilities often operate under extreme conditions. High temperatures, heavy usage cycles, and continuous operation place significant demands on cooling equipment.

The York YT chiller is designed to meet these challenges, but its performance depends on the quality of its components. Using genuine parts sourced from Midwest Parts Center ensures that your system maintains its designed resilience.

Commercial buildings with large occupancy levels also rely on stable cooling performance. Tenants, employees, and clients expect comfortable environments regardless of external conditions. Properly maintained York YT chiller systems help meet those expectations.

A Trusted Partner for Commercial and Industrial Facilities

Midwest Parts Center is committed to serving commercial and industrial clients across the USA. Our focus is on providing genuine components that support reliable HVAC performance in large-scale facilities.

When sourcing parts for a York YT chiller, trust and expertise matter. Midwest Parts Center offers a dependable solution for facilities seeking accuracy, reliability, and responsive service.

If your facility requires genuine York YT chiller parts and components, contact Midwest Parts Center at +1 800 368 8385. Our team is prepared to assist with part identification, availability inquiries, and technical guidance.

Choosing the right supplier ensures that your York YT chiller continues to deliver efficient, powerful cooling performance. With Midwest Parts Center as your trusted source, you gain more than a parts provider. You gain a dedicated partner focused on supporting the long-term success of your commercial and industrial operations.

York YT Chiller Troubleshooting Tips for Peak Commercial HVAC Performance | Call 800-368-8385

In commercial and industrial facilities, uninterrupted cooling is not a luxury—it is a necessity. Large office buildings, manufacturing plants, hospitals, universities, and data centers rely heavily on centrifugal chiller systems to maintain controlled environments. Among the most widely installed and respected systems in these applications is the York YT chiller. Known for its efficiency and high-capacity performance, the York YT chiller is engineered to operate under demanding conditions. However, like any complex mechanical system, it requires proper maintenance and troubleshooting to sustain peak performance.

When operational issues arise, understanding how to approach York YT chiller troubleshooting can make the difference between a quick resolution and extended downtime. For commercial and industrial facilities across the United States, Midwest Parts Center serves as a trusted resource for expert guidance and genuine components. If your facility needs immediate support, call +1 800 368 8385 to connect with Midwest Parts Center.

Understanding the Critical Role of the York YT Chiller in Commercial Facilities

The York YT chiller is designed for high-efficiency cooling in large-scale applications. It uses advanced centrifugal technology to deliver consistent performance while managing energy consumption effectively. In industrial settings, these chillers often operate continuously, supporting processes that require precise temperature control.

Because the York YT chiller handles such heavy workloads, even minor performance irregularities can escalate if not addressed quickly. Monitoring system behavior and recognizing early warning signs are essential for preventing costly breakdowns. Troubleshooting should always be approached methodically, with attention to system diagnostics and operating data.

Midwest Parts Center specializes in supporting commercial and industrial environments, understanding the operational demands placed on high-capacity chillers. When troubleshooting becomes complex, expert assistance is just a call away at +1 800 368 8385.

Recognizing Early Warning Signs of Performance Issues

Fluctuating Cooling Capacity

One of the most noticeable indicators of a potential problem is inconsistent cooling output. If the York YT chiller struggles to maintain set temperatures, it may signal issues such as refrigerant imbalance, sensor malfunction, or mechanical wear.

In commercial facilities, fluctuating temperatures can affect occupant comfort and operational stability. Industrial processes that depend on precise temperature regulation may also be impacted. Early intervention is key. Checking system data, reviewing pressure readings, and verifying control settings can help narrow down the cause.

If cooling inconsistencies persist, Midwest Parts Center can assist in identifying whether replacement components are needed for your York YT chiller.

Unusual Noises or Vibrations

The York YT chiller is designed to operate smoothly. While some operational sound is normal, sudden increases in vibration or unfamiliar noises should not be ignored. These may indicate bearing wear, alignment issues, or impeller imbalance.

In industrial settings, vibration can quickly lead to mechanical stress on surrounding components. Inspecting mounting structures and monitoring vibration levels helps prevent further damage. If mechanical components require replacement, sourcing genuine parts from Midwest Parts Center ensures compatibility and durability.

Addressing Common Operational Challenges

Monitoring Refrigerant Performance

Proper refrigerant levels are crucial for the efficient operation of the York YT chiller. Low refrigerant levels may reduce cooling capacity, while overcharging can create pressure imbalances. Monitoring suction and discharge pressures provides valuable insight into refrigerant performance.

If system readings indicate abnormalities, checking for leaks or restrictions is necessary. Commercial and industrial facilities should prioritize prompt evaluation to avoid compressor strain. Midwest Parts Center supports facilities by providing genuine components designed for reliable performance within York YT chiller systems.

Evaluating Electrical Components

Electrical components such as control boards, sensors, and wiring connections play a significant role in York YT chiller functionality. Faulty sensors can send inaccurate data to the control system, leading to improper operation.

During troubleshooting, it is important to verify voltage levels, inspect connections for corrosion, and confirm sensor calibration. Electrical irregularities can sometimes mimic mechanical issues, so careful evaluation is essential.

If a replacement part is required, Midwest Parts Center offers dependable access to components engineered specifically for the York YT chiller. For assistance, contact +1 800 368 8385.

Optimizing System Controls for Peak Performance

Reviewing Operating Parameters

The York YT chiller incorporates advanced control systems designed to optimize efficiency. Reviewing operating parameters, including temperature setpoints, pressure limits, and load demand, can reveal opportunities for performance improvement.

Commercial facilities often adjust settings seasonally or in response to occupancy changes. Ensuring that these settings align with manufacturer recommendations supports efficient operation. Incorrect parameter configuration may lead to unnecessary cycling or energy waste.

Midwest Parts Center understands the importance of maintaining optimal control settings. When troubleshooting complex performance concerns, consulting experienced professionals can help clarify system behavior.

Ensuring Proper Sensor Calibration

Sensors provide critical feedback that allows the York YT chiller to operate accurately. Temperature and pressure sensors must remain calibrated to prevent misinterpretation of system conditions.

Routine calibration checks should be part of any preventive maintenance program. If sensor discrepancies are detected, replacing them with genuine components ensures precise system monitoring.

Preventive Maintenance as a Troubleshooting Strategy

Preventive maintenance is often the most effective troubleshooting approach. By identifying wear patterns and replacing components before failure occurs, facilities can avoid unexpected downtime.

Regular inspections of bearings, seals, and lubrication systems help maintain smooth mechanical performance. Monitoring oil quality and ensuring proper lubrication levels protect internal components from excessive wear.

Midwest Parts Center supports preventive maintenance efforts by supplying genuine parts designed specifically for the York YT chiller. Having access to reliable components enables maintenance teams to act proactively rather than reactively.

Managing Energy Efficiency Concerns

Energy efficiency is a major priority in commercial and industrial operations. If a York YT chiller begins consuming more power than expected, it may indicate underlying issues.

Reduced heat transfer efficiency, fouled heat exchangers, or improper refrigerant levels can increase energy demand. Monitoring energy usage trends and comparing them to historical data provides valuable diagnostic insight.

Restoring peak efficiency often involves cleaning, recalibration, or component replacement. Midwest Parts Center helps facilities maintain energy-conscious operations by providing genuine York YT chiller components that support optimal system performance.

When to Seek Professional Support

Troubleshooting the York YT chiller requires technical understanding and careful analysis. While in-house maintenance teams can address many routine issues, complex mechanical or control-related concerns may require additional expertise.

Persistent alarms, repeated shutdowns, or unexplained performance drops should not be ignored. Prompt professional support minimizes the risk of extended downtime.

Midwest Parts Center serves commercial and industrial facilities with responsive service and reliable parts availability. If your York YT chiller requires assistance, calling +1 800 368 8385 connects you with professionals dedicated to supporting your operational needs.

Protecting Your Investment in Commercial Cooling

The York YT chiller represents a significant investment for any large facility. Protecting that investment requires consistent monitoring, accurate troubleshooting, and the use of genuine replacement components.

Addressing minor issues early prevents larger failures later. Maintaining accurate records of operating data and service history supports informed decision-making. When parts replacement becomes necessary, choosing components specifically engineered for the York YT chiller ensures continued reliability.

Midwest Parts Center remains committed to serving commercial and industrial environments with dependable support. Our focus is on helping facilities maintain peak HVAC performance through accurate part identification and responsive service.

Sustaining Long-Term Performance

Peak commercial HVAC performance is not achieved through reactive repairs alone. It requires a combination of preventive maintenance, careful monitoring, and access to reliable parts.

The York YT chiller is built for high-demand environments, but its performance depends on proper care. By following systematic troubleshooting practices and sourcing genuine components from Midwest Parts Center, facilities can maintain stability and efficiency.

If your commercial or industrial facility is experiencing York YT chiller performance issues, do not wait for minor concerns to escalate. Contact Midwest Parts Center at +1 800 368 8385 for reliable guidance and access to genuine parts designed to keep your system running at its best.

Maintaining peak performance is a continuous process. With expert troubleshooting and dependable support from Midwest Parts Center, your York YT chiller can continue delivering powerful, efficient cooling for years to come.