Every commercial or industrial facility depends on its chiller system to maintain consistent cooling performance. Whether supporting manufacturing operations, food processing plants, hospitals, or office complexes, these systems form the foundation of temperature regulation and efficiency. However, like any complex machine, chillers face wear, tear, and performance problems over time. The key to resolving these issues effectively lies in using authentic York chiller parts.

Common Chiller Issues Solved with Authentic York Chiller Parts

Midwest Parts Center recognizes how critical uninterrupted cooling is to business operations. Supplying genuine York chiller parts to commercial and industrial facilities nationwide, Midwest Parts Center ensures systems continue running efficiently, reliably, and safely. If you’re facing challenges with your chiller system or searching for exact replacement components, call +1 800 368 8385 to speak with a dedicated specialist.

Why Chiller Systems Demand Precision Parts

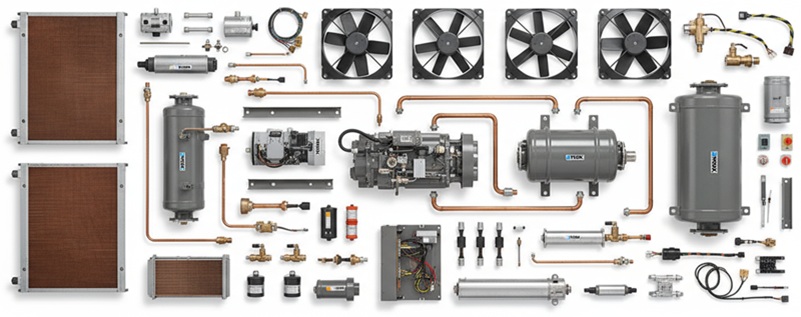

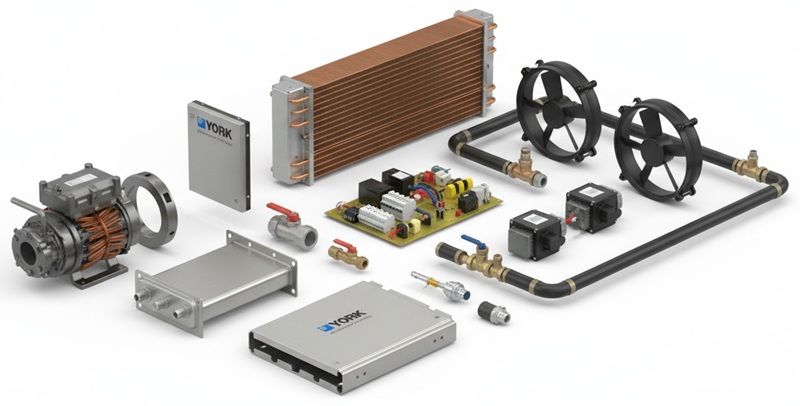

Chillers are not simple machines; they are intricate systems composed of compressors, condensers, evaporators, expansion valves, motors, and electronic controls. Each component must interact seamlessly with the next to produce cooling efficiently. When even one part underperforms or fails, the entire system’s efficiency can plummet.

Authentic York chiller parts are designed specifically for these systems, ensuring every component complements the original engineering. Using non-authentic parts may appear cost-effective at first but often leads to inefficiency, premature failure, and higher operational costs. Authentic York chiller parts, available through Midwest Parts Center, restore system balance and protect long-term performance in both commercial and industrial applications.

1. Declining Cooling Capacity

One of the earliest signs of trouble in a chiller system is a decrease in cooling capacity. Your system may struggle to meet temperature setpoints, or it could take far longer than usual to achieve them. This issue often stems from worn-out or dirty components that restrict heat transfer or refrigerant flow.

Common Causes:

-

Fouled condenser coils or evaporators

-

Faulty expansion valves

-

Weak or failing compressors

-

Clogged refrigerant filters

How Authentic York Chiller Parts Help:

Using factory-approved York chiller parts such as new compressor kits, expansion valves, and filters can restore original efficiency. Erie-based coils, heat exchangers, and valves manufactured by York are calibrated to meet specific system models, ensuring balanced capacity and flow. Midwest Parts Center provides these original replacements promptly so facilities can restore performance without downtime.

2. Rising Energy Consumption

When energy consumption increases without a change in operational load, it’s often a sign that the chiller system is working harder due to inefficiency. A few outdated parts can force the system to consume more electricity than necessary.

Possible Causes:

-

Aging compressors

-

Faulty control sensors

-

Coil fouling or fan imbalance

-

Incorrect refrigerant charge

York Chiller Parts Solution:

Replacing these components with authentic York chiller parts restores system calibration and performance. Precision fans, sensors, and coils from York ensure the chiller doesn’t overwork itself or consume unnecessary energy. Partnering with Midwest Parts Center allows maintenance teams to source verified components quickly and preserve the energy efficiency for which York chillers are famous.

3. Unusual Noise or Vibration

Loud clanging, constant hums, or vibration often indicate a mechanical issue inside the chiller. This is one of the most common complaints from facility managers, and acting quickly can prevent more expensive failures later.

Common Causes:

-

Imbalanced fans or bearings

-

Misaligned couplings

-

Worn motor mounts

-

Compressor damage

York Chiller Parts Solution:

Replacement vibration isolators, compressor assemblies, belts, and motor kits made by York are engineered to original tolerances. They operate quietly and reliably within design parameters, eliminating operational noise. Midwest Parts Center supplies these exact-fit parts to return the chiller to smooth, quiet performance.

4. Irregular Temperature Control

Inconsistent temperature regulation can disrupt production and reduce occupant comfort. This problem often traces back to malfunctioning sensors or control modules within the chiller system.

Possible Causes:

-

Faulty thermistors or temperature sensors

-

Aging control boards

-

Contaminated or blocked valves

-

Electrical communication faults

York Chiller Parts Solution:

Genuine electronic boards and control sensors ensure accurate temperature measurement and system response. When sourced from Midwest Parts Center, authentic York chiller parts like sensors, thermostatic controls, and actuators restore precise automation, allowing uninterrupted efficiency.

5. Frequent Cycling or System Shutdowns

If the chiller frequently turns on and off or experiences unexpected shutdowns, there’s likely an underlying equipment fault. Constant cycling wears down critical components and raises operational costs.

Common Causes:

-

Refrigerant pressure irregularities

-

Defective or dirty filters

-

Sensor malfunctions

-

Electrical relay faults

York Chiller Parts Solution:

Authentic York chiller parts such as pressure switches, control boards, and filters resolve the problem. They ensure consistent system communication and refrigerant flow. Midwest Parts Center stocks and supplies these essential parts so your maintenance teams can immediately address faulty cycling issues.

6. Refrigerant Leaks and Inefficient Cooling

Leaks are among the most serious problems industrial chillers face. They lead to reduced cooling, ice buildup, and compressor distress. Prompt identification and repair are vital.

Common Causes:

-

Cracked evaporator coils

-

Worn seals or gaskets

-

Damaged connection welds

York Chiller Parts Solution:

Using genuine York chiller parts such as factory-tested coils, O-rings, and seals prevents future leaks by ensuring perfect material compatibility with York’s refrigerant systems. Midwest Parts Center provides correctly matched leak-prevention components that restore system integrity and efficiency.

7. Control System Errors or Fault Codes

Modern York chillers use sophisticated microprocessor-based control systems. When digital faults appear, it often signals component mismatch or sensor failure. Diagnosing and replacing the incorrect part can quickly restore full automation.

Common Causes:

-

Faulty circuit boards

-

Outdated firmware

-

Inaccurate sensor readings

-

Communication failures in connected devices

York Chiller Parts Solution:

Midwest Parts Center supplies genuine York control boards, software updates, and sensor replacements to eliminate recurring error codes. Each part is specific to your model, ensuring compatibility with York’s controller logic and firmware.

8. Fouled or Dirty Condenser Coils

Built-up debris on condenser coils reduces heat transfer efficiency, forcing the chiller to work harder. If coils become too worn for effective cleaning, replacement is often the best option.

York Chiller Parts Solution:

York condenser coils, designed for exact performance specifications, ensure optimal heat exchange with minimal resistance. Midwest Parts Center provides original coils that meet York’s engineering criteria for durability and performance.

9. Compressor Failure and Hard Starts

Compressors are the central component of every chiller. If one fails, entire system operation halts. Even early signs like difficulty starting, overheating, or insufficient pressure warrant immediate attention.

Common Causes:

-

Electrical imbalances

-

Mechanical wear

-

Oil contamination

-

Over-cycling stress

York Chiller Parts Solution:

Only authentic York chiller parts—specifically compressor assemblies and replacement kits—match manufacturer torque, lubricant specifications, and load capacities. These factory-tested components deliver precise performance. Midwest Parts Center ensures quick access to full compressor assemblies and individual parts for all York models.

10. Water Flow Problems

If the chiller’s evaporator or condenser suffers from restricted water flow, system efficiency and reliability deteriorate rapidly. Proper flow rates are critical for balanced heat transfer.

Possible Causes:

-

Dirty strainers

-

Clogged heat exchangers

-

Pump failure

York Chiller Parts Solution:

Authentic inlet strainers, flow sensors, and heat exchangers from York maintain correct water velocity and system pressure. By sourcing genuine parts from Midwest Parts Center, facilities avoid cavitation damage and maintain appropriate flow.

The Risk of Aftermarket Imitations

The chiller parts market is full of substitutes claiming equivalence, yet even small differences in material composition or dimension can compromise system performance. Using imitation parts creates cascading issues: vibration, poor sealing, inaccurate temperature readings, and full equipment failures.

Authentic York chiller parts keep original balance, materials, and mechanical precision intact. Midwest Parts Center, serving industrial and commercial clients, offers the assurance of verified York authenticity. Facility managers can confidently maintain equipment knowing every replacement is backed by York’s rigorous engineering standards.

Extending Chiller Life with Proper Maintenance

Using genuine parts is one half of the equation; the other half is routine service. Industrial environments expose systems to fluctuating temperatures, contaminants, and operational stress. Establishing a consistent maintenance schedule using York chiller parts helps prevent issues before they occur.

Maintenance best practices include:

-

Monthly inspections for abnormal sound or vibration

-

Quarterly coil cleaning using proper agents

-

Regular filter and seal replacement

-

Verification of sensor calibration and system pressures

-

Annual performance audits with historical data logs

Midwest Parts Center supports ongoing maintenance programs by keeping critical York chiller parts in stock and ready for rapid dispatch.

Long-Term Advantages of Using Authentic York Chiller Parts

When your facility consistently uses original York components, several measurable benefits follow:

-

Reduced repair frequency

-

Stable energy costs

-

Longer intervals between major overhauls

-

Reliable temperature control for sensitive operations

-

Lower environmental impact through optimized efficiency

These outcomes make authentic York chiller parts a wise investment rather than a maintenance cost. Midwest Parts Center helps businesses maximize these results by providing a streamlined supply process and expert part-matching assistance. For help identifying correct components, call +1 800 368 8385.

How Midwest Parts Center Helps Industrial and Commercial Clients

Midwest Parts Center is more than a supplier—it is a full-service partner dedicated to the success of commercial and industrial cooling systems. The company offers detailed part identification support, quick turnaround times, and access to an extensive inventory of original York chiller parts.

Key customer benefits include:

-

Verified York authenticity for every order

-

Knowledgeable support staff familiar with chiller configurations

-

Fast quote and order processing

-

Industry-specific solutions for industrial facilities

-

Reliable nationwide shipping coverage

This combination of technical expertise and reliability has made Midwest Parts Center a trusted name in the commercial and industrial HVAC field.

Creating a Proactive Parts Strategy

Downtime prevention begins with preparation. By building an internal inventory of high-demand York chiller parts, your maintenance team can resolve minor issues before they escalate. Midwest Parts Center helps businesses establish proactive replacement schedules and parts tracking systems tailored to model type and operational conditions.

This proactive approach ensures consistent uptime, predictable maintenance budgeting, and extended system life—all without unexpected breakdowns.

The Path to Reliable Cooling Performance

Chiller systems represent one of the largest capital investments in a facility’s HVAC infrastructure. Protecting that investment means using genuine York chiller parts, not substitutes. Authentic components are produced with the same specifications, materials, and performance expectations as those originally installed in your system. They maintain efficiency, reduce breakdown risk, and extend equipment lifespan.

When operational stability matters, facilities choose trusted providers who uphold quality standards. Midwest Parts Center proudly delivers that reliability for businesses across commercial and industrial settings. From sensors and compressors to coils and gaskets, every product is authentic and built to last.

For expert assistance, or to order genuine York chiller parts today, contact Midwest Parts Center at +1 800 368 8385.

Boost System Performance with Factory-Approved York Chiller Parts | 800-368-8385

Commercial and industrial facilities rely on high-capacity cooling systems to keep operations efficient, productive, and stable. When these systems perform at their peak, they help reduce energy consumption, maintain precise environmental conditions, and keep critical processes running without interruption. But sustained performance depends heavily on the quality of the components inside the system. That’s why choosing factory-approved York chiller parts is the smartest investment in your HVAC infrastructure.

Midwest Parts Center, serving both industrial and commercial sectors, provides genuine York chiller parts designed to maintain equipment uptime, efficiency, and long-term system integrity. To order verified York components or seek expert part identification assistance, call +1 800 368 8385 today.

Why Your Facility Depends on York Chiller Parts

Industrial chillers are complex machines that operate continuously to handle large-scale cooling demands. Each part—from the compressor to the heat exchanger—is a precision-built component working in coordination. When any of these parts wears out or fails, cooling performance can drop rapidly.

York chiller parts are engineered to exact manufacturing standards that match the original design of York systems. They’re developed using advanced material technology and stringent quality control processes to ensure compatibility, efficiency, and durability. Using factory-approved parts from Midwest Parts Center guarantees your equipment performs as designed, meeting energy and operational standards set by your facility’s requirements.

Whether it’s a compressor replacement, control board upgrade, or simple filter change, genuine York chiller parts keep every aspect of your chiller functioning in balance.

Authenticity Makes the Difference

When it comes to HVAC equipment maintenance, not all parts are created equal. Non-genuine or counterfeit parts may look identical but can compromise system performance in critical ways. Small deviations in design or material can cause inefficiencies, noise, and premature failure.

Here’s how authentic York chiller parts deliver advantages for commercial and industrial users:

-

Ensure perfect fit and compatibility with existing system models

-

Maintain intended efficiency ratings and cooling capacity

-

Support energy-efficient operation year-round

-

Protect long-term service life and reduce breakdown frequency

-

Keep factory warranties and performance guarantees intact

Midwest Parts Center exclusively provides factory-approved York chiller parts, ensuring customers receive verified-quality replacements built to uphold York’s precise engineering standards.

Improving Energy Efficiency with Genuine York Chiller Parts

Energy efficiency is a major operational goal for facility managers, especially in large-scale industrial environments. Replacing worn or mismatched components with authentic York chiller parts ensures every subsystem runs at optimal energy levels.

Components like coils, fan motors, valves, and sensors play a vital role in maintaining balanced cooling cycles. Over time, minor inefficiencies accumulate, forcing machines to work harder. Genuine replacements designed for York systems restore that lost energy efficiency by aligning component performance with factory specifications.

Using genuine parts offers measurable savings in electricity costs, reduces the workload on compressors, and sustains smooth operation during demanding conditions. Midwest Parts Center supplies the authentic York chiller parts your facility needs to improve cooling output while minimizing power waste.

Common Areas Where Authentic York Chiller Parts Boost System Performance

York chillers are engineered for longevity, but some components wear out naturally due to extended use. Replacing these parts with genuine options is the key to bringing your equipment “back to new” performance levels.

Here are key system areas that benefit from factory-approved York chiller parts:

1. Compressors and Compressor Kits

The compressor is at the heart of the refrigeration process. A worn compressor results in inefficient refrigerant cycling, noise, and high energy draw. Replacing it with a factory-tested York compressor ensures cooling precision, stability, and mechanical reliability.

2. Heat Exchangers and Coils

These components handle the transfer of heat within the system. Genuine York heat exchangers and coils maintain proper thermal exchange and resist corrosion, providing consistent cooling output even in harsh environments.

3. Expansion Valves and Flow Controls

When flow regulation becomes inconsistent, the entire system loses balance. Authentic York expansion valves guarantee accurate refrigerant control, keeping temperature and pressure in sync.

4. Sensors and Electronic Boards

Intelligent controls are the brains of modern York chillers. Original sensors ensure data accuracy, while authentic control boards maintain harmonious communication across all subsystems. These parts sustain automation efficiency and avoid disruptive fault codes.

5. Filters, Gaskets, and Seals

Though small, these components play a huge role in protecting system cleanliness and pressure stability. Replacing them with authentic York chiller parts prevents leaks, ensures safety, and maintains refrigerant integrity.

Midwest Parts Center stocks these components and many more, allowing industrial and commercial clients to make confident replacement decisions with quick part verification and rapid fulfillment.

The Dangers of Aftermarket or Counterfeit Parts

Some operators attempt to save short-term costs by purchasing non-original parts. Unfortunately, that decision often leads to bigger expenses over time. Here’s what typically happens when imitation parts are used:

-

Increased wear on major components due to improper tolerances

-

Reduced operational efficiency leading to higher utility bills

-

System instability, resulting in frequent service emergencies

-

Risk of product contamination in sensitive environments

-

Voided manufacturer warranties and difficult repairs

Authentic York chiller parts safeguard against these risks. Midwest Parts Center sources genuine replacements directly through authorized channels, ensuring your investments uphold the highest operational standards. For assistance verifying your parts, call +1 800 368 8385.

How Genuine Parts Extend Equipment Lifespan

Industrial chillers represent significant capital assets. Extending their lifespan is a top priority for any facility. Using authentic York chiller parts achieves this goal by reducing operational stress and ensuring that all system components function within design parameters.

Authentic parts reduce friction, vibration, and mechanical misalignment—three of the primary causes of equipment degradation. Whether you’re managing a York air-cooled chiller, water-cooled chiller, or modular unit, factory-approved replacements maintain equipment longevity and stable performance over the years.

By partnering with Midwest Parts Center, facility managers gain peace of mind knowing their chillers will operate efficiently throughout their expected service life with fewer interruptions.

Performance You Can Measure

When your chiller system uses genuine York chiller parts, the benefits become visible across measurable performance metrics:

-

Reduced downtime due to faster part replacements

-

Stable cooling capacity under fluctuating environmental conditions

-

Consistent energy performance compliant with system ratings

-

Better overall indoor air quality and process cooling regulation

-

Fewer maintenance calls and lower annual service costs

Industrial teams that track system data before and after installing genuine parts often see immediate improvements in operational smoothness and energy stability.

Why Choose Midwest Parts Center

Midwest Parts Center specializes in supplying authentic York chiller parts to commercial and industrial facilities nationwide. The company’s focus is simple: deliver reliability, precision, and lasting value through genuine replacements.

Customers benefit from:

-

Direct access to verified York chiller parts

-

Support from knowledgeable professionals experienced in complex HVAC systems

-

Reliable identification and cross-referencing for existing York models

-

Fast order processing and delivery

-

Proactive support for preventive maintenance scheduling

Whether replacing a compressor or troubleshooting critical control board issues, Midwest Parts Center ensures your facility has the correct parts, delivered on time, to maintain uninterrupted cooling operations.

For personalized assistance, contact Midwest Parts Center at +1 800 368 8385.

Building a Proactive Maintenance Program with Genuine Parts

One of the most strategic ways to protect chiller system health is to develop a preventive maintenance plan using authentic parts. Preventive measures reduce the risk of emergency repairs and optimize equipment performance.

A well-structured program includes:

-

Regular inspections for vibrations, leaks, and refrigerant performance

-

Scheduled replacement of filters, seals, and valves

-

Coil cleaning and verification of condenser airflow

-

Temperature calibration checks for sensors and thermistors

-

Keeping an onsite reserve of regularly needed York chiller parts

Midwest Parts Center assists industrial clients in creating proactive inventory solutions that ensure essential components are always available when needed. This minimizes delays in maintenance scheduling and helps stabilize long-term operational budgets.

Keeping Downtime to a Minimum

Every minute of downtime in an industrial setting can translate to significant operational losses. Delays due to part shortages, poor-quality substitutes, or wrong replacements can cause costly interruptions. Midwest Parts Center’s trusted supply of authentic York chiller parts helps avert such risks.

With an extensive inventory and a knowledgeable support team, customers receive accurate recommendations and fast access to the components required for demanding operating conditions. Whether it’s an emergency repair or routine maintenance, having authorized York replacements on hand keeps your facility running efficiently.

Environmental and Sustainability Benefits

Besides energy performance, authentic York chiller parts also support eco-friendly operation. They are built to meet strict environmental standards, ensuring reduced emissions, minimal energy waste, and sustainable equipment use. Industrial and commercial sites striving to achieve green building certifications can benefit from the superior performance of authentic York replacements.

By optimizing the system to run within defined pressure and temperature limits, genuine parts also prevent refrigerant leaks—a critical factor in reducing ozone-depleting emissions. Midwest Parts Center ensures each part delivered supports environmental responsibility and system reliability together.

Protecting Your Investment with Proven Quality

York chiller systems represent both technological innovation and financial investment. Protecting that investment involves maintaining the integrity of every mechanical and electronic part. Choosing factory-approved York chiller parts from Midwest Parts Center ensures full compatibility with established engineering standards.

Each authentic part undergoes rigorous factory testing to confirm durability and conformity. Midwest Parts Center provides verified documentation for customers requiring assurance of authenticity. This commitment to quality helps facilities maintain system value while preventing the costly cycle of repair and replacement that comes with using non-genuine components.

The Path to Maximized Chiller Performance

Peak system performance isn’t just about having a chiller that runs—it’s about achieving continual reliability, low energy costs, and long-term functionality. Authentic York chiller parts form the backbone of consistent performance by maintaining the same efficiency benchmarks the system had when it was first installed.

Whether your facility needs to restore capacity, replace critical components, or implement an optimized maintenance routine, the solution is simple: rely on genuine York chiller parts supplied by Midwest Parts Center.

Midwest Parts Center supports commercial buildings, manufacturing plants, and industrial campuses with precision-engineered York parts built for excellence. Every replacement component helps reduce potential downtime and keeps cooling systems performing effortlessly.

For expert consultation or to order the parts your system needs, contact Midwest Parts Center at +1 800 368 8385.