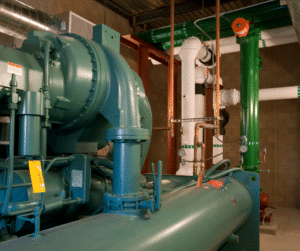

Selecting Suitable York Chiller Part: A reliable heating and cooling system requires York parts. All ll specific pieces of equipment can use the all-york part features. A more practical solution would be to incorporate these devices inside York machines.

York’s chiller parts can be engineered to work perfectly with all equipment brands. Since the components have been thoroughly vetted, you can rest assured that your system will work flawlessly with them as intended. You can rely on york chiller parts for all of your component needs.

Why Choose York Chiller Parts

York chiller part is suitable if you determine to extend your equipment’s lifespan by purchasing replacement parts. If you want to maintain your systems functioning properly, replacement components are a cost-effective option for businesses with several units. Buildings should maximize the performance and efficiency of their heating and air conditioning systems. Can improve the long-term performance of your  equipment by using replacement components for maintenance, repairs, and other servicing requirements.

equipment by using replacement components for maintenance, repairs, and other servicing requirements.

You can count on us when you need YORK chiller parts. Refrigeration systems in commercial and industrial buildings are dependent on chillers year-round for their cooling needs. When a chiller fails, your business could be in jeopardy. You can quickly repair your system.

The pieces of a YORK chiller differ according to the system it is used in. Some repairs are critical, while others are more routine. You should contact an expert if you feel that your chiller has a problem and need to be fixed.

Chillers and the parts that go into them are no doubt complicated. For the sake of saving money, you should never compromise on performance or quality. Even if you can fix problems with a chiller, relying on generic parts is a short-term solution.

Can I use YORK chillers in other chillers?

Yes! Elements matching the unit make sense for seamless integration of parts. If you buy generic components, you’ll never know for sure whether or not they’ll fit your vehicle. As a result, you’ve lost both time and money if the parts don’t work together correctly.

Yes! Elements matching the unit make sense for seamless integration of parts. If you buy generic components, you’ll never know for sure whether or not they’ll fit your vehicle. As a result, you’ve lost both time and money if the parts don’t work together correctly.

But we got you covered to depend on an authorized distributor like us to keep your business moving forward at top speed and avoid the potential drawbacks of dealing with third parties.

Don’t buy from them if you’re unsure about a company’s genuine york chiller part. Look for actual YORK-branded components and features alone.

Selection of YORK Chiller Parts

The YORK catalog can be complex for a newbie to navigate. Can decode the part numbers for your machine and any replacement parts you may need with the help of an experienced technician. You’ll save a great deal of time and money by placing your order for the correct part the first time.

Obtaining high-quality Chiller parts

It would be best if you were careful to get genuine York parts over imitations when shopping for York parts. You can rest assured that you’re getting high-quality equipment and details every time. We can count on you to supply parts for air systems, chillers, condensers, and maintenance kits for commercial and industrial systems.

York Climate Control Parts

Managing temperature control systems necessitates regular replacing parts, making it challenging. Access to spare details is essential when working with machinery in a commercial or industrial structure that will see a lot of use. When it comes to York parts, we are an excellent decision to offer the most acceptable value, service, and selection; you can rest assured that you’ll get the best.

Managing temperature control systems necessitates regular replacing parts, making it challenging. Access to spare details is essential when working with machinery in a commercial or industrial structure that will see a lot of use. When it comes to York parts, we are an excellent decision to offer the most acceptable value, service, and selection; you can rest assured that you’ll get the best.

Feel confident that you are dealing with an authorized York parts dealer. You can rely on us to provide you with a wide range of options, high-quality products, and dependable service.

Your chiller’s

Your chiller’s  Commercial and industrial settings are important markets for the chillers made by the York company in the US. The component used to boost the chiller’s performance is the York VSD coolant. Clean and purified air is in high demand.

Commercial and industrial settings are important markets for the chillers made by the York company in the US. The component used to boost the chiller’s performance is the York VSD coolant. Clean and purified air is in high demand. Coolers are also used in a wide range of locations, including hospitals and restaurants and hotels and schools, and manufacturing plants; they are used to maintain clean and comfortable air standards. Aside from that, coolers impact operating costs while also being extremely eco-friendly.

Coolers are also used in a wide range of locations, including hospitals and restaurants and hotels and schools, and manufacturing plants; they are used to maintain clean and comfortable air standards. Aside from that, coolers impact operating costs while also being extremely eco-friendly.

Even if you’re using a different model of the York HVAC system, we have access to the most current stock. Since we have access to many facilities, we may acquire parts. There is a high need for details for chillers, air conditioners, and VRF systems.

Even if you’re using a different model of the York HVAC system, we have access to the most current stock. Since we have access to many facilities, we may acquire parts. There is a high need for details for chillers, air conditioners, and VRF systems. We offer only the highest-quality parts to keep your air conditioning system in top working order and help it last as long as possible with minimal maintenance.

We offer only the highest-quality parts to keep your air conditioning system in top working order and help it last as long as possible with minimal maintenance. To ensure that commercial and industrial chillers run as efficiently as possible, we use only high-quality, original equipment manufacturer (OEM) parts.

To ensure that commercial and industrial chillers run as efficiently as possible, we use only high-quality, original equipment manufacturer (OEM) parts.

Existing York chilling machines can use York replacement parts are no substitutes for the parts that York uses in its chillers because of the company’s standards. When a component is replaced with a similar item, it may result in a decrease in performance.

Existing York chilling machines can use York replacement parts are no substitutes for the parts that York uses in its chillers because of the company’s standards. When a component is replaced with a similar item, it may result in a decrease in performance. It is critical to select the appropriate components. Every replacement part must meet its standards. Filling some spare details with identical items may appear possible, but this could lead to subpar performance. York’s catalog contains many products, from significant components to small accessories.

It is critical to select the appropriate components. Every replacement part must meet its standards. Filling some spare details with identical items may appear possible, but this could lead to subpar performance. York’s catalog contains many products, from significant components to small accessories. Whether it’s a school, hospital, skyscraper, or data center, each facility faces its own set of problems. Facilities must be able to deal with various weather conditions, including seasonal and even hourly fluctuations.

Whether it’s a school, hospital, skyscraper, or data center, each facility faces its own set of problems. Facilities must be able to deal with various weather conditions, including seasonal and even hourly fluctuations.

Before purchasing

Before purchasing  An adequate replacement strategy requires understanding the lead times for replacement parts. The lead time is an important consideration when deciding on which claims to hand.

An adequate replacement strategy requires understanding the lead times for replacement parts. The lead time is an important consideration when deciding on which claims to hand. York replacement parts have five inventory factors to consider. Even if your equipment does eventually break down, calculating how much time you’ll waste by not having sufficient replacement parts on hand will help you make an informed decision.

York replacement parts have five inventory factors to consider. Even if your equipment does eventually break down, calculating how much time you’ll waste by not having sufficient replacement parts on hand will help you make an informed decision.

York YVAA chiller parts are the most efficient air-cooled chillers; due to the new design, construction will be easier and more cost-effective while making better use of available building space.

York YVAA chiller parts are the most efficient air-cooled chillers; due to the new design, construction will be easier and more cost-effective while making better use of available building space. Carbon dioxide, which accounts for most of the world’s greenhouse gas emissions, is produced mainly by electric power plants. Commercial buildings’ HVAC systems are the biggest consumers of electricity. Using York YVAA chiller parts reduces the amount of electricity needed to cool the planet and reduce greenhouse gas emissions.

Carbon dioxide, which accounts for most of the world’s greenhouse gas emissions, is produced mainly by electric power plants. Commercial buildings’ HVAC systems are the biggest consumers of electricity. Using York YVAA chiller parts reduces the amount of electricity needed to cool the planet and reduce greenhouse gas emissions. Add Variable Speed Drives (VSD) to the condenser fans of your YVAA air-cooled chiller to reduce energy usage and fan noise. YVAA air-cooled chillers use innovative heat exchangers, variable speed compressors, and intelligent controls to give exceptional performance and value.

Add Variable Speed Drives (VSD) to the condenser fans of your YVAA air-cooled chiller to reduce energy usage and fan noise. YVAA air-cooled chillers use innovative heat exchangers, variable speed compressors, and intelligent controls to give exceptional performance and value.

Planned maintenance and repair of deteriorating components should always be a priority. Also, if you want the required units to work correctly, you must repair them. You must have

Planned maintenance and repair of deteriorating components should always be a priority. Also, if you want the required units to work correctly, you must repair them. You must have  Preventive maintenance kits for York HVAC systems are available from us at a fair price. This amount has a considerable effect on the overall cooling system performance.

Preventive maintenance kits for York HVAC systems are available from us at a fair price. This amount has a considerable effect on the overall cooling system performance. York Preventative maintenance kits from York have five significant advantages. Additionally, York’s preventive maintenance kits for coolers boost efficiency and effectiveness. Experts in chiller maintenance and facilities management purchase spare parts in future breakdowns or repairs.

York Preventative maintenance kits from York have five significant advantages. Additionally, York’s preventive maintenance kits for coolers boost efficiency and effectiveness. Experts in chiller maintenance and facilities management purchase spare parts in future breakdowns or repairs.

York’s chiller models require parts that are perfectly compatible with the machinery.

York’s chiller models require parts that are perfectly compatible with the machinery.  It’s perfect for maintaining a constant temperature throughout a vast industrial complex.

It’s perfect for maintaining a constant temperature throughout a vast industrial complex. Many commercial building HVAC systems are subjected to a great deal of stress because of their nature. Because of their focus, these systems often require new or repaired components when they fail. Frequently, heating and air-conditioning components fail. If you want to improve your chiller’s performance, lifespan, and durability, you must use high-quality parts.

Many commercial building HVAC systems are subjected to a great deal of stress because of their nature. Because of their focus, these systems often require new or repaired components when they fail. Frequently, heating and air-conditioning components fail. If you want to improve your chiller’s performance, lifespan, and durability, you must use high-quality parts.

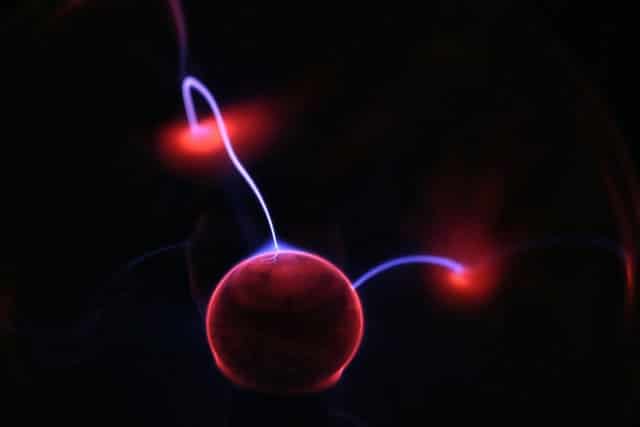

For the first time, an air purification business has successfully neutralized SARS-CoV-2,

For the first time, an air purification business has successfully neutralized SARS-CoV-2,  A simulation of the ionization conditions seen in the fuselage of a commercial airplane was carried out in the lab. It was established that within 10 minutes, 84.2 percent of the virus was inactivated, based on viral titrations. Only a fraction of the virus remained after 15 minutes, but at the end of the 30 minutes, it had been inactivated 92.6 percent of the time and 99.4 percent of it.

A simulation of the ionization conditions seen in the fuselage of a commercial airplane was carried out in the lab. It was established that within 10 minutes, 84.2 percent of the virus was inactivated, based on viral titrations. Only a fraction of the virus remained after 15 minutes, but at the end of the 30 minutes, it had been inactivated 92.6 percent of the time and 99.4 percent of it. Multiple data points are used by

Multiple data points are used by

setup, maintenance, and control. The ions emitted by the system can make the particles in the air larger, and they become easily removed from the air.

setup, maintenance, and control. The ions emitted by the system can make the particles in the air larger, and they become easily removed from the air. an excellent advantage as it charges the particles in the air to create a neutral environment. These particles in the air, such as coronavirus particles, are attracted to the ions. They then attract more particles such as smoke and dust and form larger particles. The large particle is removed from the air through the filtration system.

an excellent advantage as it charges the particles in the air to create a neutral environment. These particles in the air, such as coronavirus particles, are attracted to the ions. They then attract more particles such as smoke and dust and form larger particles. The large particle is removed from the air through the filtration system.