The Comprehensive Guide to York Genuine Parts for Commercial and Industrial Applications

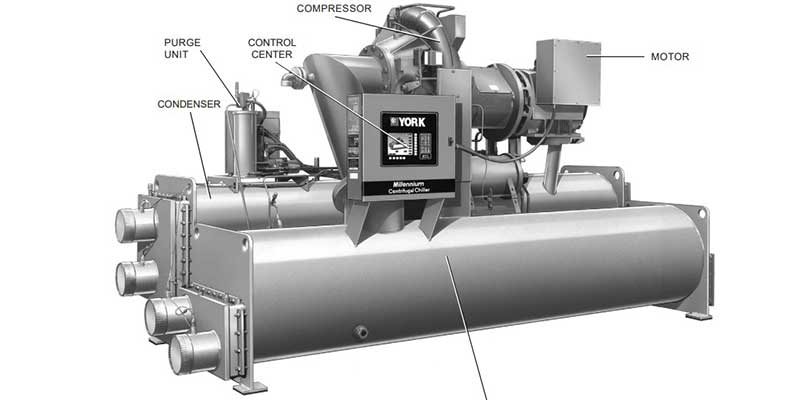

In the fast-paced world of commercial and industrial operations, the reliability and efficiency of equipment are essential for maintaining productivity and maximizing output. Every component, from the smallest valve to the largest motor, plays a critical role in the smooth functioning of machinery. When it comes to sourcing parts for renowned brands like York, authenticity and quality are non-negotiable. That’s where York genuine parts come into play, offering unmatched reliability and performance to meet the diverse needs of businesses operating in commercial and industrial sectors. At Midwest Parts Center, we serve as your comprehensive guide to York genuine parts, providing expertise, reliability, and support tailored to your specific requirements.

York genuine parts represent the epitome of quality and authenticity, engineered to exacting standards to ensure compatibility and performance with your equipment. As a trusted provider of York genuine parts, Midwest Parts Center is committed to delivering excellence and value to our customers by offering a comprehensive range of products and services tailored to commercial and industrial needs.

One of the key benefits of choosing York genuine parts for your commercial and industrial needs is the assurance of authenticity. Genuine York parts are manufactured using the highest quality materials and adhere to stringent quality control standards, ensuring compatibility and reliability with your equipment. By choosing genuine parts, businesses can avoid the risks associated with counterfeit or substandard components, safeguarding the integrity and longevity of their machinery.

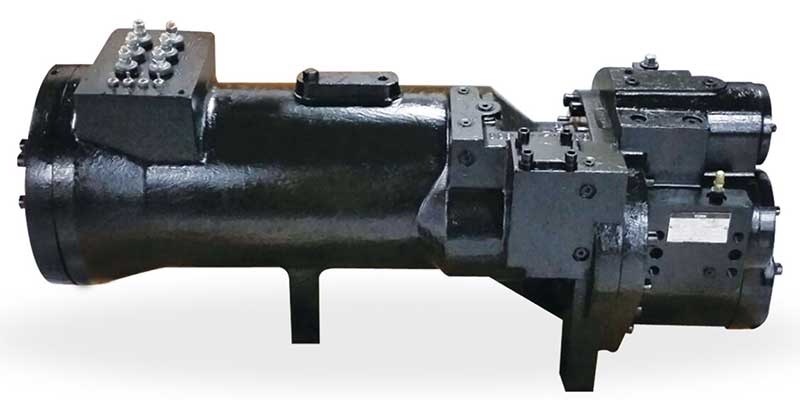

Another advantage of York genuine parts is their superior performance and durability. These parts are designed and tested to withstand the rigors of commercial and industrial operations, including high temperatures, heavy loads, and harsh operating conditions. With rugged construction and precise engineering, York genuine parts offer unmatched reliability and longevity, ensuring continuous operation and minimizing downtime in your facility.

York genuine parts also offer peace of mind and confidence in the reliability of your equipment. Whether it’s HVAC systems, industrial machinery, or refrigeration equipment, genuine parts provide the assurance that your equipment will operate at peak performance levels, delivering consistent results and maximizing productivity. With York genuine parts, businesses can minimize the risk of unexpected failures or malfunctions, reducing costly repairs and maintenance downtime.

At Midwest Parts Center, we understand the importance of providing comprehensive support and service to our customers. That’s why we offer a range of services, including parts identification, ordering assistance, and technical support, to ensure that you find the right York genuine parts for your specific needs. Our team of experienced professionals is dedicated to providing personalized assistance and support at every step of the process, helping you navigate the complexities of parts sourcing with ease.

Accessibility and convenience are essential considerations for businesses operating in today’s fast-paced environment. That’s why we offer multiple channels for accessing support and assistance. You can reach us via phone at our toll-free number, +1 800 368 8385, where our knowledgeable customer service representatives are available to assist you with any inquiries or orders. Additionally, our user-friendly online platform provides a convenient way to browse our catalog, place orders, and track shipments, all from the comfort of your own workspace.

As a company based in commercial and industrial areas, Midwest Parts Center understands the unique challenges and requirements of businesses in these sectors. That’s why we take a personalized approach to every interaction, striving to understand your specific needs and priorities. Whether you’re a small business owner or a large-scale industrial operation, you can trust us to provide tailored solutions that deliver maximum value and efficiency.

In conclusion, York genuine parts are the trusted choice for businesses in commercial and industrial sectors seeking reliability, performance, and authenticity. At Midwest Parts Center, we are committed to helping our customers unlock the full potential of their equipment by offering a comprehensive range of York genuine parts and support services. Contact us today at +1 800 368 8385 to learn more about how you can benefit from our expertise and experience in parts supply for commercial and industrial needs.

The Power of York Genuine Parts for Businesses

In the competitive landscape of commercial and industrial enterprises, the quest for reliability, efficiency, and longevity in equipment is paramount. Every component, every part, plays a crucial role in the seamless functioning of machinery, making the choice of parts supplier a critical decision for businesses seeking optimal performance. When it comes to renowned brands like York, authenticity and quality are non-negotiable. That’s where York genuine parts shine, offering unparalleled reliability, performance, and peace of mind to businesses across commercial and industrial sectors. At Midwest Parts Center, we serve as your trusted partner in unleashing the power of York genuine parts, providing expertise, reliability, and support tailored to your specific requirements.

York genuine parts represent the pinnacle of quality and authenticity, engineered to precise specifications to ensure compatibility and performance with your equipment. As a leading provider of York genuine parts, Midwest Parts Center is committed to delivering excellence and value to our customers by offering a comprehensive range of products and services tailored to commercial and industrial needs.

One of the key benefits of choosing York genuine parts for your business is the assurance of authenticity. Genuine York parts are manufactured using the highest quality materials and adhere to stringent quality control standards, ensuring reliability, compatibility, and durability with your equipment. By choosing genuine parts, businesses can mitigate the risks associated with counterfeit or substandard components, safeguarding the integrity and longevity of their machinery.

Another advantage of York genuine parts is their superior performance and longevity. These parts are engineered and tested to withstand the rigors of commercial and industrial operations, including high temperatures, heavy loads, and harsh operating conditions. With rugged construction and precise engineering, York genuine parts offer unmatched reliability and durability, ensuring continuous operation and minimizing downtime in your facility.

York genuine parts also offer peace of mind and confidence in the reliability of your equipment. Whether it’s HVAC systems, industrial machinery, or refrigeration equipment, genuine parts provide the assurance that your equipment will operate at peak performance levels, delivering consistent results and maximizing productivity. With York genuine parts, businesses can minimize the risk of unexpected failures or malfunctions, reducing costly repairs and maintenance downtime.

At Midwest Parts Center, we understand the importance of providing comprehensive support and service to our customers. That’s why we offer a range of services, including parts identification, ordering assistance, and technical support, to ensure that you find the right York genuine parts for your specific needs. Our team of experienced professionals is dedicated to providing personalized assistance and support at every step of the process, helping you navigate the complexities of parts sourcing with ease.

Accessibility and convenience are essential considerations for businesses operating in today’s fast-paced environment. That’s why we offer multiple channels for accessing support and assistance. You can reach us via phone at our toll-free number, +1 800 368 8385, where our knowledgeable customer service representatives are available to assist you with any inquiries or orders. Additionally, our user-friendly online platform provides a convenient way to browse our catalog, place orders, and track shipments, all from the comfort of your own workspace.

As a company based in commercial and industrial areas, Midwest Parts Center understands the unique challenges and requirements of businesses in these sectors. That’s why we take a personalized approach to every interaction, striving to understand your specific needs and priorities. Whether you’re a small business owner or a large-scale industrial operation, you can trust us to provide tailored solutions that deliver maximum value and efficiency.

In conclusion, York genuine parts are the trusted choice for businesses seeking reliability, performance, and authenticity. At Midwest Parts Center, we are committed to helping our customers unlock the full potential of their equipment by offering a comprehensive range of York genuine parts and support services. Contact us today at +1 800 368 8385 to learn more about how you can benefit from our expertise and experience in parts supply for commercial and industrial needs.

Get trusted quality for York genuine parts

In the intricate machinery that powers commercial and industrial operations, every component plays a pivotal role in ensuring seamless functionality and optimal performance. For businesses reliant on renowned brands like York, the choice of parts supplier is critical. Authenticity and quality are non-negotiable when it comes to sourcing parts, and this is where York genuine parts stand out. Offering unparalleled reliability, durability, and peace of mind, York genuine parts are the cornerstone of efficient and effective equipment maintenance and repair. At Midwest Parts Center, we take pride in being your trusted provider of York genuine parts, offering expertise, reliability, and support tailored to your specific commercial and industrial needs.

York genuine parts represent the epitome of quality and authenticity, meticulously engineered to meet exacting standards and specifications. As a leading supplier of York genuine parts, Midwest Parts Center is dedicated to delivering excellence and value to our customers by providing a comprehensive range of products and services tailored to meet the demands of commercial and industrial sectors.

One of the paramount benefits of choosing York genuine parts for your equipment is the assurance of authenticity. Genuine York parts are manufactured using only the highest quality materials and adhere to stringent quality control measures, ensuring compatibility and reliability with your machinery. By selecting genuine parts, businesses can mitigate the risks associated with counterfeit or substandard components, thereby safeguarding the integrity and longevity of their equipment.

In addition to authenticity, York genuine parts offer superior performance and longevity. These parts are engineered and tested to withstand the rigorous demands of commercial and industrial operations, including high temperatures, heavy loads, and harsh environmental conditions. With their robust construction and precise engineering, York genuine parts deliver unmatched reliability and durability, ensuring continuous operation and minimizing downtime in your facility.

Moreover, York genuine parts provide peace of mind and confidence in the reliability of your equipment. Whether it’s HVAC systems, industrial machinery, or refrigeration equipment, genuine parts offer assurance that your equipment will operate at peak performance levels, delivering consistent results and maximizing productivity. By utilizing York genuine parts, businesses can minimize the risk of unexpected failures or malfunctions, thereby reducing costly repairs and maintenance downtime.

At Midwest Parts Center, we understand the importance of providing comprehensive support and service to our customers. That’s why we offer a range of services, including parts identification, ordering assistance, and technical support, to ensure that you find the right York genuine parts for your specific needs. Our team of experienced professionals is dedicated to providing personalized assistance and support at every step of the process, helping you navigate the complexities of parts sourcing with ease.

Accessibility and convenience are essential considerations for businesses operating in today’s fast-paced environment. That’s why we offer multiple channels for accessing support and assistance. You can reach us via phone at our toll-free number, +1 800 368 8385, where our knowledgeable customer service representatives are available to assist you with any inquiries or orders. Additionally, our user-friendly online platform provides a convenient way to browse our catalog, place orders, and track shipments, all from the comfort of your own workspace.

As a company based in commercial and industrial areas, Midwest Parts Center understands the unique challenges and requirements of businesses in these sectors. That’s why we take a personalized approach to every interaction, striving to understand your specific needs and priorities. Whether you’re a small business owner or a large-scale industrial operation, you can trust us to provide tailored solutions that deliver maximum value and efficiency.

In conclusion, York genuine parts are the trusted choice for businesses seeking reliability, performance, and authenticity. At Midwest Parts Center, we are committed to helping our customers unlock the full potential of their equipment by offering a comprehensive range of York genuine parts and support services. Contact us today at +1 800 368 8385 to learn more about how you can benefit from our expertise and experience in parts supply for commercial and industrial needs.

What are the advantages to use origonal York genuine parts

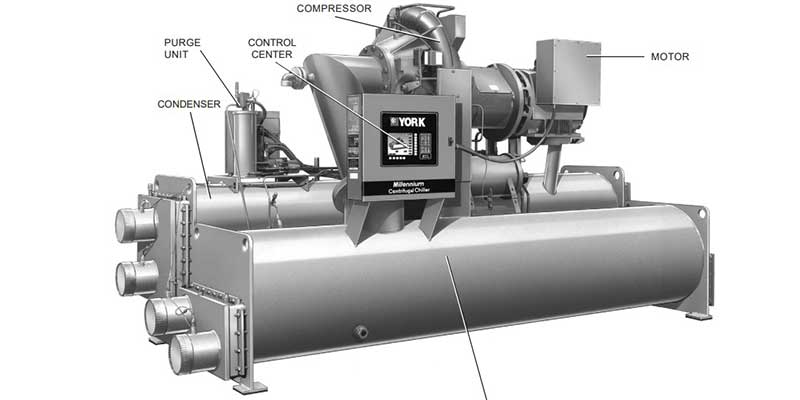

In the intricate machinery and systems powering commercial and industrial enterprises, every component holds significance, contributing to the overall efficiency, reliability, and longevity of the equipment. When it comes to maintaining and repairing equipment manufactured by renowned brands like York, the choice of parts is crucial. Authenticity, quality, and reliability are paramount considerations for businesses seeking to optimize their operations and minimize downtime. This is where original York genuine parts emerge as the preferred choice, offering unmatched quality, compatibility, and performance. At Midwest Parts Center, we specialize in providing original York genuine parts, offering a myriad of advantages tailored to the needs of businesses in commercial and industrial sectors.

One of the foremost advantages of utilizing original York genuine parts is the assurance of authenticity. Genuine York parts are manufactured to the highest standards of quality and precision, ensuring compatibility and seamless integration with your equipment. As a leading supplier of original York genuine parts, Midwest Parts Center is committed to delivering authenticity and reliability, thereby safeguarding the integrity and longevity of your equipment.

In addition to authenticity, original York genuine parts offer superior performance and reliability compared to aftermarket alternatives. These parts are engineered and tested to meet the stringent specifications and requirements of York equipment, ensuring optimal functionality and performance. By choosing original York genuine parts, businesses can minimize the risk of compatibility issues, malfunctions, and premature failures, thereby reducing downtime and maintenance costs.

Moreover, original York genuine parts are designed to withstand the rigors of commercial and industrial environments, including high temperatures, heavy loads, and harsh operating conditions. With their robust construction and durable materials, these parts offer unmatched durability and longevity, ensuring prolonged service life and minimal need for replacements or repairs.

Another advantage of using original York genuine parts is the peace of mind they provide. Whether it’s HVAC systems, industrial machinery, or refrigeration equipment, original York genuine parts offer reliability and consistency, ensuring that your equipment operates at peak performance levels. By utilizing genuine parts, businesses can minimize the risk of unexpected failures or malfunctions, thereby maximizing uptime and productivity.

At Midwest Parts Center, we understand the importance of providing comprehensive support and service to our customers. That’s why we offer a range of services, including parts identification, ordering assistance, and technical support, to ensure that you find the right original York genuine parts for your specific needs. Our team of experienced professionals is dedicated to providing personalized assistance and support at every step of the process, helping you maintain and optimize your equipment with confidence.

Accessibility and convenience are essential considerations for businesses operating in today’s fast-paced environment. That’s why we offer multiple channels for accessing support and assistance. You can reach us via phone at our toll-free number, +1 800 368 8385, where our knowledgeable customer service representatives are available to assist you with any inquiries or orders. Additionally, our user-friendly online platform provides a convenient way to browse our catalog, place orders, and track shipments, all from the comfort of your own workspace.

As a company based in commercial and industrial areas, Midwest Parts Center understands the unique challenges and requirements of businesses in these sectors. That’s why we take a personalized approach to every interaction, striving to understand your specific needs and priorities. Whether you’re a small business owner or a large-scale industrial operation, you can trust us to provide tailored solutions that deliver maximum value and efficiency.

In conclusion, original York genuine parts offer a multitude of advantages for businesses seeking reliability, performance, and authenticity. At Midwest Parts Center, we are committed to helping our customers unlock the full potential of their equipment by offering a comprehensive range of original York genuine parts and support services. Contact us today at +1 800 368 8385 to learn more about how you can benefit from our expertise and experience in parts supply for commercial and industrial needs.