Top 10 Benefits of Partnering with a Certified York Parts Distributor for Your HVAC Maintenance Needs

Maintaining an efficient and reliable HVAC system is crucial for both commercial and industrial facilities. One of the best strategies to ensure your HVAC system runs smoothly is by partnering with a certified York parts distributor. At Midwest Parts Center, we pride ourselves on being a trusted York parts distributor, providing top-quality parts and unmatched service to our clients. In this comprehensive guide, we will explore the top 10 benefits of partnering with a certified York parts distributor for your HVAC maintenance needs.

1. Access to Genuine York Parts

One of the most significant advantages of partnering with a certified York parts distributor is the assurance that you are getting genuine York parts. Genuine parts are specifically designed and manufactured to meet the high standards set by York, ensuring compatibility, performance, and longevity.

- Quality Assurance: Genuine parts undergo rigorous testing to meet York’s stringent quality standards.

- Perfect Fit: Authentic York parts are designed to fit seamlessly into your existing HVAC system, ensuring optimal performance.

- Longevity: Using genuine parts extends the lifespan of your HVAC system, reducing the frequency of repairs and replacements.

2. Expert Knowledge and Support

Certified York parts distributors possess extensive knowledge and expertise in HVAC systems and York products. This expertise translates into valuable support for your maintenance needs.

- Technical Expertise: Our team at Midwest Parts Center can provide detailed technical advice and troubleshooting support.

- Installation Guidance: We offer guidance on the correct installation of parts to ensure your system operates efficiently.

- Tailored Solutions: Our experts can recommend parts and solutions tailored to your specific HVAC system and operational requirements.

3. Comprehensive Inventory

Partnering with a certified York parts distributor ensures access to a comprehensive inventory of parts, covering all your HVAC maintenance needs.

- Wide Selection: We stock a wide range of parts, including filters, compressors, condensers, controls, and more.

- Availability: Our extensive inventory means we can quickly fulfill orders, minimizing downtime for your HVAC system.

- Special Orders: If a part is not in stock, we can quickly source it directly from York.

4. Warranty Protection

Using genuine York parts from a certified distributor ensures that you maintain the warranty protection on your HVAC system.

- Warranty Compliance: Using non-genuine parts can void your warranty. Genuine parts keep your warranty intact.

- Peace of Mind: Warranty protection provides peace of mind, knowing that any issues arising from defective parts will be covered.

- Cost Savings: Avoiding warranty voidance can save significant costs associated with repairs or replacements.

5. Improved System Performance

Genuine York parts are engineered to deliver optimal performance, ensuring your HVAC system runs efficiently and effectively.

- Enhanced Efficiency: High-quality parts contribute to the overall efficiency of your HVAC system, reducing energy consumption.

- Consistent Performance: Genuine parts ensure consistent performance, maintaining the desired temperature and air quality.

- Reduced Downtime: Reliable parts reduce the likelihood of unexpected breakdowns, ensuring uninterrupted operation.

6. Increased Longevity of Your HVAC System

Regular maintenance with genuine parts from a certified York parts distributor can significantly extend the lifespan of your HVAC system.

- Durable Components: Genuine parts are built to last, withstanding the demands of commercial and industrial environments.

- Preventive Maintenance: Regular replacement of worn-out parts with genuine ones prevents further damage to your system.

- Long-Term Savings: Extending the life of your HVAC system reduces the need for costly replacements, offering long-term savings.

7. Compliance with Industry Standards

Certified York parts distributors ensure that the parts you receive comply with all relevant industry standards and regulations.

- Safety Standards: Genuine York parts meet strict safety standards, ensuring safe operation of your HVAC system.

- Environmental Regulations: Compliance with environmental regulations helps your facility meet sustainability goals.

- Industry Certifications: Using certified parts ensures adherence to industry certifications, maintaining your facility’s credibility and reputation.

8. Streamlined Maintenance Processes

Partnering with a certified York parts distributor streamlines your maintenance processes, making it easier to keep your HVAC system in top condition.

- Easy Ordering: Our efficient ordering system makes it simple to get the parts you need when you need them.

- Quick Delivery: Fast delivery times ensure minimal disruption to your operations.

- Maintenance Scheduling: We can assist in scheduling regular maintenance, ensuring timely replacement of parts and system checks.

9. Cost-Effective Solutions

While genuine parts may have a higher upfront cost, they offer cost-effective solutions in the long run by reducing the frequency of repairs and replacements.

- Lower Repair Costs: Reliable parts reduce the need for frequent repairs, saving you money on labor and part replacement.

- Energy Savings: Efficient parts lower energy consumption, reducing utility bills.

- Investment Protection: Using high-quality parts protects your investment in your HVAC system, ensuring it continues to operate efficiently for years to come.

10. Dedicated Customer Service

At Midwest Parts Center, we are committed to providing exceptional customer service. Partnering with us means having a dedicated team ready to support you with all your HVAC maintenance needs.

- Personalized Support: Our customer service team provides personalized support, addressing your specific needs and concerns.

- Responsive Service: We are quick to respond to inquiries, ensuring you get the help you need promptly.

- Ongoing Assistance: Our support doesn’t end with the sale. We are here to assist you with any issues or questions that arise during the life of your HVAC system.

Partnering with a certified York parts distributor like Midwest Parts Center offers numerous benefits for your HVAC maintenance needs. From access to genuine parts and expert support to improved system performance and cost savings, the advantages are clear. By choosing a trusted partner, you ensure that your HVAC system receives the best care possible, maximizing its efficiency, reliability, and longevity.

At Midwest Parts Center, we are dedicated to providing top-quality York parts and exceptional service to our clients. For more information on how we can support your HVAC maintenance needs, contact us today at +1 800 368 8385. Let us help you keep your HVAC system running smoothly and efficiently with our comprehensive range of York parts and expert support

Meeting Every Commercial Requirement with York Parts Distributor

In the fast-paced and demanding world of commercial and industrial operations, the need for reliable and efficient HVAC systems cannot be overstated. Ensuring these systems function optimally requires high-quality components and expert support. This is where a trusted York parts distributor like Midwest Parts Center comes into play. As a leading York parts distributor, we are dedicated to meeting every commercial requirement with superior products and exceptional service. Here, we will explore how partnering with a York parts distributor can address the diverse needs of commercial entities, ensuring optimal performance and longevity of HVAC systems.

Understanding the Role of a York Parts Distributor

A York parts distributor serves as a critical link between manufacturers and end-users, providing access to genuine York parts designed for peak performance and reliability. Midwest Parts Center, as an authorized York parts distributor, ensures that clients receive authentic components that meet York’s rigorous quality standards.

Key Responsibilities of a York Parts Distributor:

- Supplying Genuine Parts: Ensuring customers receive only authentic York parts.

- Providing Expert Support: Offering technical assistance and guidance for optimal system performance.

- Maintaining Inventory: Keeping a comprehensive stock of essential components to meet immediate needs.

- Facilitating Efficient Procurement: Streamlining the ordering and delivery process for quick and easy access to parts.

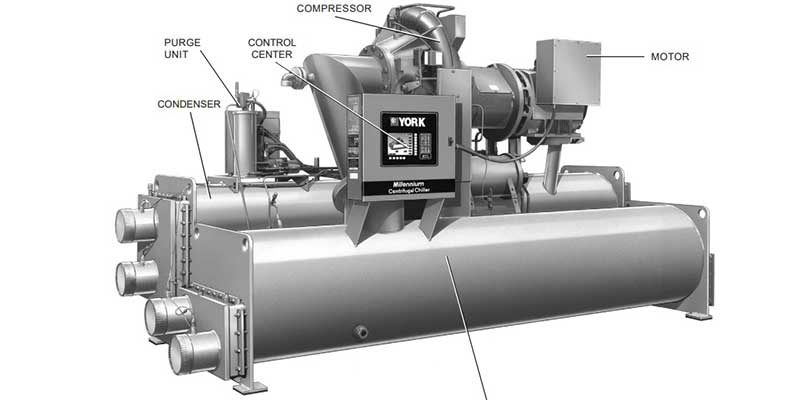

Comprehensive Range of York Parts

Commercial HVAC systems are complex and require various components to function correctly. As a York parts distributor, Midwest Parts Center offers a comprehensive range of parts to meet all your commercial HVAC needs.

Types of York Parts Available:

- Compressors: Essential for the cooling cycle, ensuring efficient temperature control.

- Condensers: Crucial for dissipating heat and maintaining system efficiency.

- Evaporators: Key to absorbing heat and enabling the cooling process.

- Controls: Advanced control systems for precise temperature and system management.

- Filters: Maintaining air quality and system cleanliness.

- Motors and Fans: Ensuring proper airflow and system performance.

Benefits of Partnering with a York Parts Distributor

Choosing to work with a York parts distributor like Midwest Parts Center offers numerous benefits, particularly for commercial and industrial clients who rely heavily on their HVAC systems for day-to-day operations.

Access to Genuine York Parts

One of the primary advantages is access to genuine York parts, which are designed and manufactured to meet the highest standards of quality and performance.

- Quality Assurance: Genuine parts ensure reliability and longevity, reducing the risk of system failures.

- Compatibility: Authentic parts are designed to fit perfectly within your existing York systems, ensuring seamless integration and optimal performance.

- Warranty Protection: Using genuine York parts helps maintain your system’s warranty, providing peace of mind and financial protection.

Expert Technical Support

Midwest Parts Center offers expert technical support, ensuring that you have the guidance needed to maintain and optimize your HVAC systems.

- Troubleshooting Assistance: Our team can help diagnose and resolve issues quickly, minimizing downtime.

- Installation Guidance: We provide detailed instructions and support for the correct installation of parts, ensuring proper functioning.

- Preventive Maintenance Advice: Regular maintenance is crucial, and our experts can help develop a maintenance schedule tailored to your system’s needs.

Extensive Inventory and Quick Delivery

Our extensive inventory ensures that we have the parts you need when you need them, reducing downtime and ensuring continuous operation of your HVAC systems.

- Wide Selection: We stock a broad range of parts to cover all potential needs.

- Availability: High inventory levels mean you can get the parts you need without long wait times.

- Efficient Delivery: Our streamlined ordering and delivery processes ensure quick turnaround times, minimizing disruption to your operations.

Meeting Commercial Requirements with Customized Solutions

Every commercial operation has unique needs and requirements when it comes to HVAC systems. As a York parts distributor, Midwest Parts Center is committed to providing customized solutions that meet these specific demands.

Tailored Recommendations

We understand that no two systems are the same. Our team works closely with clients to understand their specific needs and recommend parts and solutions that are best suited to their systems.

- System Assessments: We conduct thorough assessments to identify the parts and services that will optimize your system’s performance.

- Custom Solutions: Based on our assessments, we provide tailored recommendations that address your unique requirements.

Industry-Specific Solutions

Different industries have different HVAC needs. Whether you’re in manufacturing, healthcare, hospitality, or any other sector, we offer solutions that cater to your specific industry.

- Manufacturing: Ensuring robust and reliable HVAC systems that can handle the demands of production environments.

- Healthcare: Providing parts that ensure strict temperature and air quality control for patient safety and comfort.

- Hospitality: Ensuring guest comfort with reliable HVAC systems that maintain optimal temperatures and air quality.

Preventive Maintenance Programs

Preventive maintenance is key to the longevity and efficiency of your HVAC systems. We help develop and implement preventive maintenance programs that keep your systems running smoothly.

- Scheduled Inspections: Regular inspections to identify and address potential issues before they become major problems.

- Part Replacements: Timely replacement of worn or damaged parts to prevent system failures.

- System Optimization: Ongoing adjustments and optimizations to ensure your system is operating at peak efficiency.

The Importance of Timely and Reliable Service

In commercial and industrial settings, HVAC systems are critical to maintaining comfortable and productive environments. Timely and reliable service is essential to ensure these systems operate without interruption.

Minimizing Downtime

Downtime can be costly for commercial operations. Our prompt and efficient service ensures that any issues are addressed quickly, minimizing disruption to your operations.

- Fast Response Times: Quick response to service requests to address issues promptly.

- Efficient Repairs: Expertise and efficiency in diagnosing and repairing system issues.

Enhancing System Reliability

Regular maintenance and high-quality parts enhance the reliability of your HVAC system, reducing the likelihood of unexpected breakdowns.

- Preventive Measures: Implementing preventive measures to address potential issues before they lead to system failures.

- Quality Parts: Using genuine York parts to ensure long-lasting and reliable performance.

Partnering with a certified York parts distributor like Midwest Parts Center provides numerous benefits for commercial and industrial clients. From access to genuine parts and expert support to customized solutions and timely service, we are dedicated to meeting every commercial requirement with excellence. Ensuring the optimal performance and longevity of your HVAC systems is our priority.

For more information on how Midwest Parts Center can support your HVAC maintenance needs, contact us today at +1 800 368 8385. Let us help you keep your HVAC systems running efficiently and reliably with our comprehensive range of York parts and expert support.

Why You Should Always Choose an Authorized York Parts Distributor

When it comes to maintaining and repairing HVAC systems, the quality of the parts you use is crucial. For those using York HVAC systems, choosing an authorized York parts distributor is essential to ensure reliability, performance, and longevity. Midwest Parts Center, an authorized York parts distributor, is committed to providing top-tier components and exceptional service to meet your commercial and industrial HVAC needs. In this article, we will delve into why you should always choose an authorized York parts distributor and the numerous benefits that come with this choice.

Understanding the Role of an Authorized York Parts Distributor

An authorized York parts distributor is a trusted partner who provides genuine York components specifically designed to fit and function seamlessly within York HVAC systems. These distributors have been vetted and approved by York to ensure they meet high standards of quality and service.

Key Functions of an Authorized York Parts Distributor:

- Supply Authentic Parts: Ensure customers receive genuine York parts.

- Technical Expertise: Provide expert advice and support for HVAC maintenance and repairs.

- Inventory Management: Maintain a comprehensive stock of essential parts.

- Efficient Procurement: Streamline the ordering and delivery process.

Advantages of Using Genuine York Parts

Using genuine York parts from an authorized distributor offers several significant advantages, ensuring your HVAC system operates efficiently and reliably.

Quality Assurance

One of the main benefits of sourcing parts from an authorized York parts distributor like Midwest Parts Center is the guarantee of quality. Genuine York parts are manufactured to meet stringent quality standards, ensuring they perform as expected.

- Durability: Authentic parts are designed to withstand the rigors of commercial and industrial use.

- Reliability: Genuine parts reduce the risk of breakdowns and failures, ensuring consistent performance.

- Compatibility: York parts are engineered to fit perfectly within your existing HVAC system, ensuring seamless operation.

Warranty Protection

Using genuine York parts helps maintain the warranty on your HVAC system. Many manufacturers require the use of authorized parts to keep the warranty valid, providing financial protection and peace of mind.

- Compliance: Ensures your system remains compliant with warranty terms.

- Coverage: Protects against costly repairs and replacements.

Optimal Performance

HVAC systems are complex, and using the right parts is essential for maintaining optimal performance. Authorized York parts distributors provide components that ensure your system runs efficiently.

- Energy Efficiency: Genuine parts help maintain your system’s energy efficiency, reducing operational costs.

- System Longevity: Proper parts extend the lifespan of your HVAC system, providing long-term savings.

- Performance: Ensure your system operates at peak performance, providing consistent comfort and air quality.

Expert Technical Support

Another critical advantage of working with an authorized York parts distributor is access to expert technical support. Midwest Parts Center offers extensive knowledge and expertise to assist with your HVAC needs.

Troubleshooting and Diagnosis

When issues arise, having access to expert troubleshooting and diagnostic support can save time and money. Our team can quickly identify problems and recommend the appropriate solutions.

- Rapid Diagnosis: Quickly identify the root cause of issues.

- Effective Solutions: Provide recommendations for effective repairs or part replacements.

Installation and Maintenance Guidance

Proper installation and maintenance are vital to the performance and longevity of your HVAC system. Our experts provide detailed guidance to ensure parts are installed correctly and systems are maintained properly.

- Installation Support: Ensure parts are installed correctly to avoid future issues.

- Maintenance Tips: Provide advice on regular maintenance to keep your system running smoothly.

Preventive Maintenance Programs

Preventive maintenance is essential for avoiding costly repairs and ensuring your system operates efficiently. Midwest Parts Center can help develop and implement preventive maintenance programs tailored to your specific needs.

- Scheduled Inspections: Regular inspections to identify potential issues before they become major problems.

- Routine Maintenance: Perform routine maintenance tasks to keep your system in optimal condition.

- Part Replacements: Replace worn or damaged parts proactively to prevent system failures.

Extensive Inventory and Quick Delivery

Midwest Parts Center maintains a comprehensive inventory of York parts, ensuring that we have what you need when you need it. This extensive inventory allows us to meet the demands of commercial and industrial clients efficiently.

Wide Selection of Parts

We stock a broad range of parts to cover all potential HVAC needs, ensuring you can find the right components for your system.

- Variety: Offer a wide selection of parts to address various HVAC requirements.

- Availability: Maintain high inventory levels to ensure parts are readily available.

Efficient Procurement and Delivery

Our streamlined ordering and delivery processes ensure that you receive the parts you need quickly, minimizing downtime and disruption to your operations.

- Fast Processing: Quickly process orders to expedite delivery.

- Timely Delivery: Ensure parts are delivered on time to keep your systems running smoothly.

Meeting Diverse Commercial Requirements

Commercial and industrial operations have unique HVAC needs. Midwest Parts Center, as an authorized York parts distributor, is equipped to meet these diverse requirements with customized solutions.

Tailored Recommendations

We understand that no two HVAC systems are the same. Our team works closely with clients to understand their specific needs and provide tailored recommendations.

- System Assessments: Conduct thorough assessments to identify the best parts and solutions for your system.

- Custom Solutions: Provide customized solutions that address your unique requirements.

Industry-Specific Expertise

Different industries have different HVAC needs. Whether you’re in manufacturing, healthcare, hospitality, or any other sector, we offer solutions that cater to your specific industry.

- Manufacturing: Ensure robust HVAC systems that can handle the demands of production environments.

- Healthcare: Provide parts that ensure strict temperature and air quality control for patient safety and comfort.

- Hospitality: Ensure guest comfort with reliable HVAC systems that maintain optimal temperatures and air quality.

Comprehensive Support

Our support goes beyond providing parts. We offer comprehensive support to ensure your HVAC systems operate efficiently and reliably.

- Technical Assistance: Provide ongoing technical support for any HVAC issues.

- Maintenance Programs: Help develop and implement preventive maintenance programs.

- Emergency Support: Offer emergency support to address urgent HVAC needs.

Choosing an authorized York parts distributor like Midwest Parts Center offers numerous benefits for commercial and industrial clients. From access to genuine parts and expert support to customized solutions and timely service, we are dedicated to meeting every commercial requirement with excellence. Ensuring the optimal performance and longevity of your HVAC systems is our priority.

For more information on how Midwest Parts Center can support your HVAC maintenance needs, contact us today at +1 800 368 8385. Let us help you keep your HVAC systems running efficiently and reliably with our comprehensive range of York parts and expert support. By partnering with an authorized York parts distributor, you are investing in the reliability, efficiency, and longevity of your HVAC systems, ensuring they meet the demands of your commercial or industrial operations.