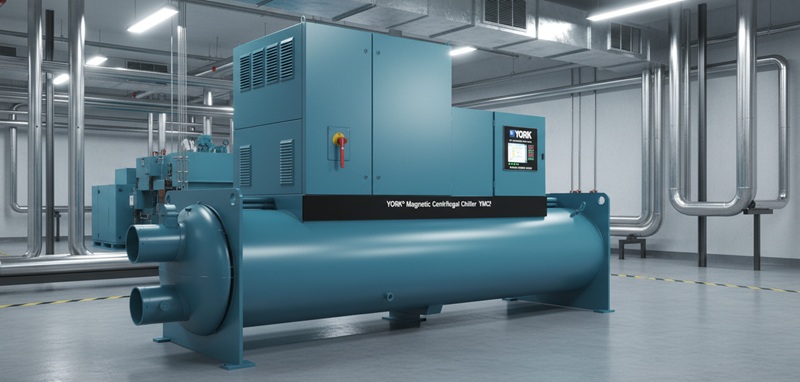

In today’s world, where energy efficiency and operational sustainability are essential, industrial and commercial facilities are increasingly turning to advanced HVAC solutions that offer superior performance and cost-effectiveness. Among the most trusted and innovative options in the market is the YT York chiller, a high-performance system designed to meet the demanding needs of large-scale operations.

High-Performance YT York Chiller | 800-368-8385

At Midwest Parts Center, we understand how critical it is for businesses to maintain a reliable and efficient cooling system. Whether you operate a manufacturing plant, data center, hospital, or large commercial complex, your HVAC system’s performance directly affects energy costs, comfort levels, and equipment longevity. That’s why we proudly provide authentic YT York chiller systems and replacement parts for our commercial and industrial clients.

To learn more about our products and services, or to order authentic York components, contact Midwest Parts Center at +1 800 368 8385 today.

🌟 Why the YT York Chiller is the Gold Standard in Cooling Technology

When it comes to HVAC systems, not all chillers are created equal. The YT York chiller stands out as a top performer, recognized for its exceptional energy efficiency, durability, and technological innovation. Designed for heavy-duty applications, the YT model provides stable and efficient cooling even under extreme conditions.

Industrial facilities require constant, large-scale cooling for processes and equipment. The YT York chiller is engineered with that exact purpose in mind. It utilizes advanced centrifugal technology to deliver optimal performance with minimal energy consumption. The system’s design minimizes mechanical losses and enhances heat transfer efficiency, leading to reduced operational costs.

Some key benefits of the YT York chiller include:

-

Exceptional Energy Efficiency: The system achieves superior performance with lower kilowatt-per-ton ratios, reducing utility expenses.

-

Quiet Operation: Despite its powerful capacity, the YT chiller runs with minimal noise levels, enhancing comfort in commercial spaces.

-

Long-Lasting Durability: Built with premium materials and advanced engineering, it withstands heavy usage and harsh environments.

-

Low Maintenance Requirements: Simplified design and durable components minimize maintenance downtime.

-

Eco-Friendly Design: Modern refrigerants and optimized compressors help reduce environmental impact.

At Midwest Parts Center, we provide authentic components and expert support to ensure that your YT York chiller operates at peak efficiency for years to come.

⚙️ How the YT York Chiller Improves Energy Efficiency

Energy efficiency is not just about saving money—it’s about optimizing performance. The YT York chiller is designed with advanced engineering principles that maximize cooling output while minimizing energy consumption.

Here’s how this innovative system achieves its outstanding efficiency:

1. Variable Speed Drive (VSD) Technology

The YT York chiller often includes VSD functionality, allowing the compressor motor to adjust speed based on cooling demand. This means the system only uses the energy it needs, significantly reducing power consumption during partial-load conditions.

2. Enhanced Heat Exchangers

Efficient heat transfer is the foundation of effective cooling. The YT chiller’s advanced heat exchanger design improves thermal performance, enabling quicker and more efficient temperature regulation.

3. Precision Controls

York’s control systems are engineered to deliver intelligent performance. With real-time monitoring and adaptive algorithms, the YT York chiller adjusts operations to maintain optimal energy use without compromising performance.

4. Reduced Compressor Workload

By improving refrigerant flow and minimizing pressure drops, the YT chiller reduces the strain on its compressor. Less mechanical work translates to less power consumption and extended component life.

5. Optimized System Integration

The YT York chiller integrates seamlessly with building management systems (BMS), allowing facility managers to monitor energy performance, adjust setpoints, and maintain system balance efficiently.

Each of these features contributes to lowering operational costs while maximizing cooling output—a win-win for any facility manager striving to meet energy efficiency goals.

🏭 Perfect Fit for Industrial and Commercial Applications

Industrial and commercial facilities operate in environments that demand continuous, reliable cooling. Whether it’s a factory floor filled with heat-generating machinery or a hospital that requires precise climate control, the YT York chiller delivers consistent, dependable performance.

Here’s how the YT chiller benefits different sectors:

🔹 Manufacturing Plants

Industrial manufacturing generates substantial heat during operations. The YT York chiller provides efficient process cooling, maintaining optimal equipment temperatures and preventing overheating that could lead to production downtime.

🔹 Data Centers

Servers and IT infrastructure require continuous cooling to prevent overheating and data loss. The YT York chiller ensures stable temperatures, safeguarding valuable digital assets.

🔹 Hospitals and Healthcare Facilities

Medical environments depend on reliable climate control for patient comfort and sensitive equipment. The YT chiller’s precision temperature management supports these critical applications.

🔹 Commercial Buildings and Offices

The YT chiller offers energy-efficient comfort cooling for office spaces, malls, and large buildings, reducing operating costs while maintaining ideal indoor conditions.

At Midwest Parts Center, we help each client choose the best YT York chiller configuration for their specific operational needs. Our experts ensure that your system performs at peak efficiency from day one.

🔧 Maintenance Made Easy with Midwest Parts Center

While the YT York chiller is engineered for reliability, regular maintenance is essential to sustain peak performance and prevent costly downtime. As a trusted York parts provider, Midwest Parts Center supplies all the authentic components needed for routine maintenance, including compressors, filters, sensors, coils, and controls.

Our technicians understand the intricate details of York chillers, allowing us to offer:

-

Accurate Part Identification: Ensuring you receive the correct part every time.

-

Fast Delivery: We minimize downtime by delivering parts quickly.

-

Expert Support: Our team can assist with installation guidance and troubleshooting.

Using genuine York parts is crucial for maintaining efficiency and extending system life. Aftermarket parts may seem cost-effective upfront but can compromise performance and reliability. Midwest Parts Center ensures your YT York chiller operates exactly as York intended—with precision, safety, and energy efficiency.

⚡ The Financial Benefits of Using a YT York Chiller

Investing in a YT York chiller may initially seem like a premium choice, but it delivers substantial financial returns over time. Energy efficiency, durability, and reduced maintenance costs make it one of the smartest long-term investments for commercial and industrial operators.

Here are the financial advantages:

-

Lower Energy Bills: Reduced power consumption leads to significant annual savings.

-

Reduced Downtime Costs: Reliable performance means fewer interruptions to business operations.

-

Extended Equipment Lifespan: Durable components and quality engineering minimize replacement costs.

-

Tax and Energy Incentives: Energy-efficient systems may qualify for rebates and sustainability incentives.

When combined with the professional support of Midwest Parts Center, your YT York chiller becomes a long-term asset rather than an expense.

🌍 Sustainability and Environmental Responsibility

Modern industries are focusing heavily on sustainability, and the YT York chiller aligns perfectly with these goals. The system is designed to reduce greenhouse gas emissions and energy waste while promoting eco-friendly operations.

By using advanced refrigerants and efficient compressors, the YT York chiller lowers the carbon footprint of your facility. Moreover, its long operating life means fewer replacements, which reduces environmental waste associated with manufacturing and disposal.

At Midwest Parts Center, we support businesses aiming to transition toward greener operations. By helping clients choose and maintain efficient YT York chiller systems, we contribute to a more sustainable industrial future.

🧩 Why Choose Midwest Parts Center for Your YT York Chiller Needs

When it comes to managing HVAC systems for commercial and industrial applications, experience and reliability matter. Midwest Parts Center has earned a solid reputation as a trusted provider of York equipment and components across the United States.

Here’s what makes us your ideal partner:

-

Extensive Industry Experience: Our team understands the unique challenges of large-scale facilities.

-

Authentic York Components: We supply only genuine parts to ensure system reliability.

-

Fast Turnaround: We prioritize quick order fulfillment to minimize downtime.

-

Technical Expertise: Our staff provides expert guidance to ensure your system operates at its best.

-

Customer Commitment: We build long-term partnerships through trust, quality, and service.

Whether you’re installing a new YT York chiller or maintaining an existing system, Midwest Parts Center provides the resources and expertise you need to keep your operation running efficiently.

For top-tier performance and energy savings, the YT York chiller is the ultimate solution for commercial and industrial facilities. Its cutting-edge technology, energy-efficient operation, and durability make it an investment that pays for itself over time.

When you need genuine York parts or professional support for your chiller system, contact Midwest Parts Center—your trusted partner in HVAC excellence.

📞 Call us now at +1 800 368 8385 to speak with one of our experts. We’ll help you select, maintain, or upgrade your YT York chiller to ensure maximum efficiency and reliability.

Energy efficiency is the cornerstone of modern industrial and commercial operations. With the YT York chiller, businesses can achieve superior cooling performance, lower energy consumption, and enhanced reliability—all while contributing to a more sustainable future.

At Midwest Parts Center, we take pride in being the go-to source for genuine York chillers and components. Our expertise, inventory, and dedication to customer satisfaction make us the preferred choice for facility managers across the nation.

If your facility demands consistent cooling and top-tier energy efficiency, it’s time to experience the power of a YT York chiller—backed by the trusted service of Midwest Parts Center.

📞 Call today at +1 800 368 8385 to discover how we can help your facility operate at peak efficiency with the performance and reliability of a high-quality YT York chiller.

The Complete Guide to Maintaining and Servicing Your YT York Chiller

In the world of industrial and commercial HVAC systems, few machines deliver the performance, reliability, and energy efficiency of a YT York chiller. Known for its powerful cooling capabilities and engineering excellence, this chiller is the backbone of many large-scale facilities—from manufacturing plants and hospitals to universities and data centers. But like any sophisticated system, it requires regular maintenance and professional servicing to continue operating at peak performance.

At Midwest Parts Center, we understand how crucial it is to keep your YT York chiller in top shape. With years of experience serving commercial and industrial clients, we provide everything you need—from genuine York parts to expert guidance—to ensure your chiller continues to deliver optimal performance, efficiency, and reliability.

In this complete guide, we’ll walk you through the importance of maintenance, the key steps in servicing, and practical tips to extend the life of your YT York chiller.

🌟 Why Proper Maintenance of Your YT York Chiller Matters

Your YT York chiller is a highly engineered piece of equipment that handles immense workloads. It’s responsible for maintaining precise temperature control across various processes and spaces. However, without routine care, even the most durable systems can experience reduced efficiency, mechanical wear, and unexpected failures.

Here’s why maintenance is so essential:

-

Improved Energy Efficiency:

Regular maintenance ensures all components—compressors, heat exchangers, and controls—operate efficiently, reducing energy consumption. -

Extended Equipment Lifespan:

Routine servicing prevents wear and tear, extending your chiller’s operational life and delaying the need for costly replacements. -

Minimized Downtime:

Preventive maintenance helps identify potential problems early, minimizing unexpected breakdowns that could disrupt operations. -

Optimal Cooling Performance:

A well-maintained YT York chiller maintains consistent temperature control, ensuring your facility’s comfort and productivity. -

Lower Operating Costs:

Efficient performance and fewer repairs translate directly to lower operating and energy costs. -

Environmental Responsibility:

A properly serviced chiller operates more cleanly, minimizing energy waste and reducing the facility’s carbon footprint.

By partnering with Midwest Parts Center, you ensure your YT York chiller continues to perform reliably and efficiently—no matter how demanding your operations may be.

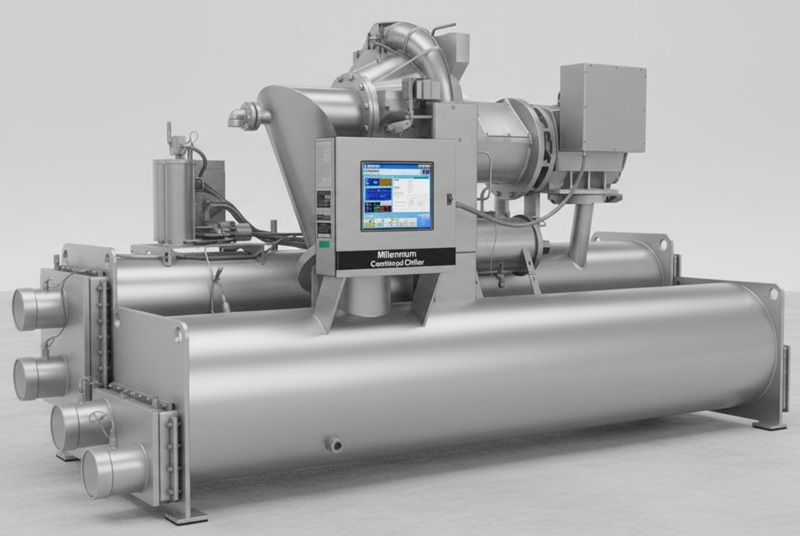

⚙️ Understanding the Key Components of a YT York Chiller

Before diving into maintenance procedures, it’s important to understand the major components that make your YT York chiller such a powerful and reliable machine:

-

Compressor:

The heart of the chiller that compresses refrigerant gas and drives the cooling cycle. -

Evaporator:

Absorbs heat from water or air, cooling it down before it circulates through your facility. -

Condenser:

Releases the absorbed heat into the environment via air or water. -

Expansion Valve:

Controls the flow of refrigerant and maintains system pressure balance. -

Refrigerant:

The working fluid that transfers heat within the chiller system. -

Control System:

Advanced electronic controls regulate temperature, pressure, and performance efficiency.

Each component must function flawlessly for the YT York chiller to achieve optimal energy efficiency and performance. That’s why regular inspections, cleaning, and part replacements are critical.

🔧 The Step-by-Step Maintenance Process

Maintaining a YT York chiller involves both preventive and corrective actions. Below is a detailed breakdown of the steps involved in ensuring your system stays in perfect condition.

1. Routine Inspection and Monitoring

Regular visual inspections are the foundation of good maintenance. These checks help detect early signs of leaks, corrosion, or wear.

- Check for oil and refrigerant leaks.

- Examine insulation for damage.

- Ensure all electrical connections are tight and corrosion-free.

- Inspect water lines for scale or blockage.

- Monitor system pressures and temperatures for unusual readings.

Tip: Always record inspection results to track performance trends over time.

2. Cleaning and Coil Maintenance

The efficiency of your YT York chiller depends heavily on clean heat exchange surfaces. Dirt, dust, and debris can accumulate on condenser and evaporator coils, reducing heat transfer.

- Clean condenser and evaporator tubes using appropriate brushes and chemical agents.

- Remove scale buildup and debris to restore thermal conductivity.

- Maintain clean filters to prevent airflow restriction.

Keeping coils and tubes clean can improve chiller efficiency by up to 15%, saving energy and costs.

3. Lubrication and Oil Analysis

Proper lubrication is critical for smooth compressor operation. Over time, oil can degrade or become contaminated with moisture or metal particles.

- Check oil levels and quality regularly.

- Perform oil analysis to identify contaminants or wear metals.

- Replace oil and filters as recommended by manufacturer guidelines.

Regular oil maintenance prevents friction and overheating, protecting the compressor—the most valuable component in your YT York chiller.

4. Refrigerant Charge Verification

The refrigerant is the lifeblood of your chiller. Too much or too little refrigerant can severely impact performance and efficiency.

- Measure refrigerant levels during operation.

- Check for leaks and repair them immediately.

- Use only the manufacturer-specified refrigerant type.

An optimized refrigerant charge ensures that your YT York chiller delivers maximum cooling with minimal energy consumption.

5. Control System Calibration

Modern YT York chillers feature advanced control systems that manage performance and energy use. Calibration ensures accurate readings and proper operation.

- Inspect control panels for error codes or alarms.

- Verify temperature sensors and pressure transducers.

- Update software or firmware as required.

- Test safety interlocks and control relays.

A properly calibrated system maximizes automation and efficiency while minimizing operator intervention.

6. Water Treatment and Flow Management

For water-cooled chillers, proper water treatment is essential to prevent scaling, corrosion, and biological growth.

- Maintain appropriate water chemistry using inhibitors and biocides.

- Check water flow rates through condensers and evaporators.

- Clean strainers and cooling towers to ensure consistent circulation.

Poor water treatment can lead to fouled tubes, reduced efficiency, and costly repairs. Midwest Parts Center can help you source the right components and accessories to maintain proper water quality in your YT York chiller system.

7. Electrical System Checks

Electrical faults can cause severe damage if not detected early. Regular inspection ensures system safety and performance.

- Tighten loose connections and replace damaged wiring.

- Check motor starter contacts for pitting or wear.

- Verify voltage and current balance across phases.

- Inspect relays, sensors, and circuit boards.

These steps help prevent electrical inefficiencies and potential system failures.

8. Seasonal and Annual Maintenance

While some maintenance tasks are performed monthly, others should be scheduled seasonally or annually.

Seasonal Maintenance Includes:

- Checking start-up and shutdown procedures.

- Inspecting system insulation for leaks.

- Cleaning coils before peak season operation.

Annual Maintenance Includes:

- Comprehensive system performance testing.

- Full oil and refrigerant replacement (if necessary).

- Heat exchanger tube cleaning and descaling.

- Inspection of safety and control devices.

Midwest Parts Center offers scheduled maintenance plans to keep your YT York chiller running smoothly year-round.

🧠 Common Issues and Troubleshooting Tips

Even with proper maintenance, issues can arise. Here are some common problems with YT York chillers and how to address them:

-

Reduced Cooling Capacity: Check refrigerant levels, clean coils, and verify compressor performance.

-

Unusual Noise or Vibration: Inspect bearings, motor alignment, and fan assemblies.

-

High Energy Consumption: Ensure coils are clean, and verify control calibration.

-

Frequent Shutdowns: Look for faulty sensors, safety switches, or wiring issues.

-

Oil or Refrigerant Leaks: Identify leak sources and replace gaskets or seals immediately.

At Midwest Parts Center, our team can help you identify and resolve these issues quickly with genuine York replacement parts and expert support.

💡 Tips for Extending the Life of Your YT York Chiller

-

Schedule Preventive Maintenance Regularly. Don’t wait for problems to appear—schedule inspections at least twice a year.

-

Use Only Genuine York Parts. Counterfeit parts can damage your system and reduce performance.

-

Monitor Operating Conditions. Use digital tools and sensors to track efficiency and detect irregularities.

-

Train Your Maintenance Staff. Ensure your team understands proper chiller operation and maintenance procedures.

-

Partner with Experts. Work with Midwest Parts Center for professional service and authentic components.

By following these best practices, you can maximize the lifespan and performance of your YT York chiller, ensuring consistent comfort and efficiency in your facility.

🏢 Why Choose Midwest Parts Center

Midwest Parts Center has earned a reputation as the trusted source for genuine York parts and professional HVAC support in commercial and industrial markets. Our expertise, inventory, and commitment to customer satisfaction make us the ideal partner for maintaining your YT York chiller.

Here’s why facilities across the nation trust us:

-

Authentic York Components: We only provide original parts to ensure system reliability.

-

Comprehensive Inventory: From compressors to sensors, we stock all essential chiller components.

-

Technical Expertise: Our team understands York systems inside and out.

-

Fast Response Times: We deliver parts quickly to minimize downtime.

-

Unmatched Customer Support: Your success is our priority.

📞 Call Midwest Parts Center today at +1 800 368 8385 to discuss your chiller maintenance needs or order genuine York components.

The YT York chiller is an engineering marvel—powerful, efficient, and built to last. However, to get the most out of your investment, proper maintenance and servicing are essential. By following a structured maintenance schedule, using genuine parts, and partnering with experts like Midwest Parts Center, you ensure long-term performance, energy savings, and reliability.

Don’t wait for performance to drop—keep your YT York chiller running at its best with expert support from Midwest Parts Center.

📞 Contact us today at +1 800 368 8385 for expert advice, authentic parts, and top-quality service designed for commercial and industrial applications.