Understanding the Technical Specifications of YT York Chillers

In the world of commercial and industrial cooling, choosing the right chiller system is crucial for maintaining optimal temperatures and ensuring energy efficiency. One of the most reputable names in the HVAC industry is York, known for its durable and highly efficient chiller systems. Among their popular models is the YT York chiller, a reliable workhorse designed to meet the demanding requirements of large-scale cooling applications.

At Midwest Parts Center, we specialize in providing high-quality HVAC solutions for commercial and industrial clients. This article delves into the technical specifications of the YT York chiller, offering insights that will help facility managers and HVAC professionals make informed decisions when selecting, operating, and maintaining this powerful cooling system. Understanding these specifications is vital for optimizing performance and ensuring a long service life.

For any inquiries or assistance, Midwest Parts Center is available at +1 800 368 8385.

Overview of the YT York Chiller

The YT York chiller is a centrifugal chiller, widely recognized for its superior energy efficiency, reliability, and performance in large-scale applications. Centrifugal chillers operate by compressing refrigerant using a rotating impeller, making them ideal for cooling large commercial buildings, industrial facilities, and other settings where robust cooling capacity is essential.

Key features of the YT York chiller include:

- High-efficiency operation for reduced energy consumption

- Advanced control systems for precise temperature regulation

- Robust design for long-term durability and minimal maintenance

- Flexibility to handle varying load conditions

The YT model is part of York’s broader line of centrifugal chillers, which are known for being versatile and capable of meeting a wide range of cooling needs. Whether you’re looking to improve energy efficiency or reduce maintenance costs, the YT York chiller is a solid choice for commercial and industrial applications.

Key Technical Specifications

Understanding the technical specifications of the YT York chiller is essential for ensuring that it meets the specific requirements of your facility. Below, we explore some of the most important specifications, including cooling capacity, energy efficiency, compressor technology, and more.

1. Cooling Capacity

The cooling capacity of a chiller is one of the most critical specifications, as it determines how much cooling the unit can provide. The YT York chiller offers a range of cooling capacities to suit different applications, typically measured in tons of refrigeration (TR). Depending on the model, the cooling capacity can range from approximately 200 TR to over 3,000 TR.

The wide range of available capacities makes the YT York chiller suitable for a variety of applications, from smaller commercial buildings to large industrial plants. When selecting a chiller, it’s important to choose a model with a cooling capacity that matches the load requirements of your facility to ensure optimal performance.

2. Energy Efficiency (COP and IPLV)

Energy efficiency is a top consideration for any HVAC system, as it directly impacts operating costs and environmental sustainability. The energy efficiency of a chiller is typically expressed in terms of Coefficient of Performance (COP) and Integrated Part Load Value (IPLV).

- COP: The Coefficient of Performance is a measure of how efficiently a chiller converts electrical energy into cooling energy. A higher COP indicates greater efficiency. The YT York chiller is designed to deliver a high COP, ensuring that your cooling system operates efficiently even under full-load conditions.

- IPLV: The Integrated Part Load Value measures efficiency under varying load conditions. It is particularly relevant for facilities where cooling demand fluctuates throughout the day or across different seasons. The YT York chiller is optimized for high IPLV performance, making it an energy-efficient choice even when operating at partial loads.

3. Compressor Technology

The compressor is the heart of any centrifugal chiller, and the YT York chiller features an advanced centrifugal compressor that is engineered for high performance and reliability. The centrifugal compressor uses a rotating impeller to compress refrigerant, creating a high-pressure environment that drives the cooling process.

Some of the benefits of the centrifugal compressor in the YT York chiller include:

- High Efficiency: Centrifugal compressors are known for their energy efficiency, especially in large-scale applications.

- Low Maintenance: The design of the centrifugal compressor minimizes wear and tear, reducing the need for frequent maintenance.

- Quiet Operation: Compared to other types of compressors, centrifugal compressors operate quietly, making them ideal for environments where noise control is important.

4. Refrigerant Type

The refrigerant used in a chiller plays a significant role in both its performance and environmental impact. The YT York chiller is designed to work with environmentally friendly refrigerants, such as R-134a or other low-global-warming-potential (GWP) refrigerants.

R-134a is a popular choice due to its excellent thermodynamic properties and lower environmental impact compared to older refrigerants like R-22. York continues to innovate by offering chillers that are compatible with next-generation refrigerants, ensuring compliance with evolving environmental regulations.

5. Variable Speed Drive (VSD) Technology

One of the standout features of the YT York chiller is its optional Variable Speed Drive (VSD) technology. VSD technology allows the chiller to adjust its operating speed based on real-time cooling demand. This capability significantly improves energy efficiency, especially during periods of reduced load.

With VSD, the chiller operates only at the speed necessary to meet the cooling load, reducing energy consumption and extending the lifespan of the equipment. This feature is particularly valuable in applications where cooling demand fluctuates, such as office buildings, manufacturing plants, and data centers.

6. Advanced Control Systems

The YT York chiller is equipped with state-of-the-art control systems that offer precise monitoring and management of the chiller’s operation. These controls provide real-time data on key performance metrics, allowing operators to fine-tune settings for maximum efficiency and reliability.

Some of the control features include:

- Touchscreen Interface: User-friendly interface for easy navigation and control adjustments.

- Remote Monitoring: Capability for remote access and monitoring via web or mobile applications.

- Diagnostic Tools: Built-in diagnostics for quick identification of issues and streamlined maintenance.

These advanced controls not only enhance the chiller’s performance but also contribute to proactive maintenance, reducing the risk of unexpected breakdowns.

7. Sustainability Features

As businesses increasingly prioritize sustainability, the YT York chiller stands out for its eco-friendly design and operation. Key sustainability features include:

- Low-GWP Refrigerants: Supports compliance with environmental regulations.

- High Efficiency: Reduces energy consumption and carbon emissions.

- Recyclable Materials: The chiller is constructed from materials that can be recycled at the end of its service life.

For businesses focused on reducing their environmental footprint, the YT York chiller aligns with green building standards and contributes to LEED certification points.

8. Durability and Reliability

The YT York chiller is built to withstand the rigors of demanding commercial and industrial environments. With heavy-duty construction and high-quality materials, the chiller offers long-term reliability and consistent performance.

York’s reputation for durability means that facility managers can count on their chillers to deliver dependable cooling year after year, even under challenging conditions. Regular maintenance and the use of genuine York parts, available through Midwest Parts Center, further enhance the longevity of the chiller.

Why Choose Midwest Parts Center as Your YT York Chiller Supplier?

As experts in commercial and industrial HVAC systems, Midwest Parts Center is your go-to source for all things related to the YT York chiller. We offer:

- Genuine York Parts: Ensure the highest performance and compatibility with your YT chiller.

- Expert Guidance: Our team has extensive knowledge of York chillers and can help you navigate technical specifications to select the right model for your needs.

- Responsive Support: Whether you need parts, service, or advice, our support team is ready to assist you with prompt and reliable service.

For more information or to get started with your chiller needs, contact us at +1 800 368 8385.

Understanding the technical specifications of the YT York chiller is crucial for optimizing its performance and ensuring it meets the specific demands of your facility. From cooling capacity and energy efficiency to compressor technology and control systems, every aspect of the YT chiller is designed to deliver reliable and efficient cooling.

At Midwest Parts Center, we are committed to providing the best HVAC solutions for commercial and industrial clients. As your trusted source for York products and services, we ensure that you get the right equipment, parts, and support to maintain a well-functioning and efficient HVAC system. Reach out to us today to learn more about how we can assist with your chiller needs.

Understanding and Maintaining Your YT York Chiller for Maximum Efficiency

The YT York chiller is a critical component in many commercial and industrial HVAC systems, offering efficient cooling solutions for large-scale facilities. Ensuring that your YT York chiller operates at peak efficiency is essential for minimizing energy costs, maximizing system longevity, and maintaining optimal performance. In this comprehensive guide, we’ll explore the key features of the YT York chiller, provide insights into how it functions, and share best practices for maintaining it to achieve maximum efficiency.

For expert assistance, Midwest Parts Center is here to support your commercial and industrial HVAC needs. Contact us at +1 800 368 8385 for more information.

The Importance of Efficient Chiller Operation

In large commercial and industrial facilities, cooling demands can be substantial, making chillers one of the most significant energy consumers. A well-maintained YT York chiller can provide reliable cooling with reduced energy consumption, leading to significant savings on operational costs. Additionally, consistent maintenance can extend the chiller’s lifespan, avoiding costly downtime and repairs.

Understanding how your YT York chiller works and how to maintain it effectively is key to optimizing its performance. Let’s start by examining the basic functionality and technical aspects of the YT York chiller.

How the YT York Chiller Works

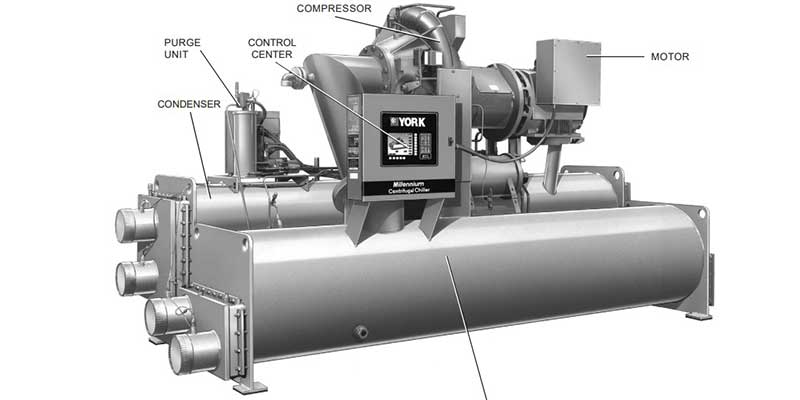

The YT York chiller is a centrifugal chiller designed for large-scale cooling applications. It operates by using a rotating impeller to compress refrigerant and drive the cooling process. The chiller works in a closed loop where it continuously circulates refrigerant through four primary components: the compressor, condenser, expansion valve, and evaporator.

- Compressor: The centrifugal compressor is the heart of the YT York chiller. It draws in low-pressure refrigerant vapor and compresses it into a high-pressure state, which increases the temperature of the refrigerant.

- Condenser: The high-pressure refrigerant then flows into the condenser, where it releases heat to the surrounding environment. This process causes the refrigerant to condense into a liquid state.

- Expansion Valve: The liquid refrigerant passes through the expansion valve, where it undergoes a pressure drop. This drop in pressure cools the refrigerant as it prepares to enter the evaporator.

- Evaporator: In the evaporator, the refrigerant absorbs heat from the chilled water circuit, causing the refrigerant to evaporate back into a vapor. The chilled water is then circulated throughout the building to provide cooling.

This cycle repeats continuously, ensuring that the chiller provides consistent cooling to meet the demands of the facility.

Key Features of the YT York Chiller

The YT York chiller is equipped with several advanced features that contribute to its efficiency and reliability. Some of the key features include:

- High-Efficiency Operation: The YT York chiller is engineered to deliver high efficiency, making it one of the most energy-efficient centrifugal chillers available. Its design allows for precise control of cooling output, ensuring minimal energy waste.

- Variable Speed Drive (VSD): Optional Variable Speed Drive technology allows the chiller to adjust its compressor speed based on real-time cooling demand. This capability results in significant energy savings, particularly during periods of reduced load.

- Advanced Controls: The chiller is equipped with state-of-the-art control systems that monitor and adjust performance in real-time. These controls offer features such as remote monitoring, diagnostics, and automated adjustments for optimal efficiency.

- Environmentally Friendly Refrigerants: The YT York chiller is designed to work with low-global-warming-potential (GWP) refrigerants, such as R-134a, which are environmentally friendly and comply with industry regulations.

- Robust Construction: Built with high-quality materials, the YT York chiller is designed for long-term durability and reliability, making it ideal for demanding commercial and industrial environments.

Best Practices for Maintaining Your YT York Chiller

Maintaining your YT York chiller is essential to keep it running efficiently and reliably. Regular maintenance not only helps prevent unexpected breakdowns but also ensures that the system operates at peak performance. Here are some key maintenance practices to follow:

1. Perform Regular Inspections

Routine inspections are crucial for identifying potential issues before they escalate. Regularly check key components such as the compressor, condenser, evaporator, and control systems for signs of wear, leaks, or unusual performance. Inspecting the chiller’s refrigerant levels, oil quality, and electrical connections is also important.

2. Monitor and Analyze Performance Data

The YT York chiller is equipped with advanced control systems that provide real-time performance data. Monitoring this data allows you to track important metrics such as energy consumption, cooling output, and system pressures. Analyzing trends can help you identify inefficiencies, enabling proactive adjustments before they impact performance.

3. Keep the Heat Exchangers Clean

Heat exchangers, including the evaporator and condenser, play a critical role in the chiller’s efficiency. Over time, dirt, debris, and mineral buildup can accumulate on the heat exchanger surfaces, reducing their ability to transfer heat effectively. Regular cleaning of the heat exchangers is essential to maintain optimal efficiency and prevent performance degradation.

4. Check and Replace Filters

Filters in the chiller system are responsible for removing contaminants from the refrigerant and oil circuits. Clogged or dirty filters can restrict flow and lead to reduced efficiency. Regularly inspect and replace filters as needed to ensure that the system runs smoothly.

5. Maintain Proper Refrigerant Levels

Refrigerant is the lifeblood of the chiller system. Maintaining the correct refrigerant levels is essential for efficient operation. Low refrigerant levels can lead to reduced cooling capacity, while overcharging can cause excessive pressure in the system. Periodically check refrigerant levels and adjust as necessary.

6. Lubricate Moving Parts

The compressor and other moving parts of the chiller require proper lubrication to reduce friction and wear. Regularly check the oil levels and quality, and replace the oil if it becomes contaminated or degraded. Proper lubrication helps extend the life of the compressor and other critical components.

7. Calibrate Controls and Sensors

The YT York chiller relies on accurate controls and sensors to maintain optimal performance. Over time, these components can drift out of calibration, leading to inefficiencies. Regularly calibrate the controls and sensors to ensure that they are providing accurate readings and making the correct adjustments.

8. Schedule Professional Maintenance

While many maintenance tasks can be handled by in-house teams, it’s important to schedule professional maintenance at regular intervals. Certified HVAC technicians have the expertise and specialized equipment needed to perform more complex maintenance tasks, such as leak detection, refrigerant charging, and in-depth diagnostics.

At Midwest Parts Center, we offer comprehensive maintenance services for the YT York chiller. Our team of experts is equipped to handle all aspects of chiller maintenance, ensuring that your system remains in peak condition.

9. Implement a Preventive Maintenance Plan

A preventive maintenance plan is the best way to ensure that your YT York chiller operates efficiently throughout its lifespan. This plan should include scheduled inspections, cleaning, part replacements, and performance checks. By addressing issues before they become major problems, you can avoid costly repairs and downtime.

10. Upgrade and Retrofit When Necessary

As technology advances, there may be opportunities to upgrade or retrofit your YT York chiller to improve efficiency and performance. For example, adding Variable Speed Drive (VSD) technology or upgrading the control system can result in significant energy savings. Consult with a professional to determine whether upgrades are feasible and beneficial for your system.

The Role of Genuine York Parts in Maintaining Efficiency

Using genuine York parts is essential for maintaining the efficiency and reliability of your YT York chiller. Aftermarket or generic parts may be cheaper upfront, but they often lack the precision engineering and quality standards required for optimal performance. Genuine York parts are designed to fit perfectly and work seamlessly with your chiller, ensuring that it operates as intended.

Midwest Parts Center is your trusted source for genuine York parts. We understand the importance of using high-quality components and offer a wide range of York parts specifically designed for the YT York chiller. Whether you need replacement parts, filters, or refrigerants, we have the expertise and inventory to meet your needs.

The YT York chiller is a powerful and efficient solution for commercial and industrial cooling applications. By understanding how the chiller works and following best practices for maintenance, you can ensure that your system operates at peak efficiency, reducing energy costs and extending the lifespan of your equipment.

At Midwest Parts Center, we are committed to helping you get the most out of your YT York chiller. Whether you need expert maintenance, genuine York parts, or guidance on optimizing your chiller’s performance, we are here to support your HVAC needs. Contact us at +1 800 368 8385 to learn more about how we can assist you in maintaining your chiller for maximum efficiency.